Research on Safe Service of Cable-Stayed System and Selection of

Cable Selection for Chishi River Special Bridge

Xinlin Shao

1,4

a

, Ben Ma

2,*

, Qiang Fan

1,4

, Shiyang Feng

1

, Yingzhi Zeng

1

, Yunjun Qiu

1,4

and Chengzhe Liu

3

1

China Construction Infrastructure Corp., Ltd., Beijing 100037, China

2

China State Construction Engineering Corporation Co., Ltd. (CSCEC), Beijing 100029, China

3

China Construction Sixth Engineering Bureau Co., Ltd., Tianjin 300451, China

4

China Construction South Investment Co., Ltd., Shenzhen 518101, China

*

Keywords: Service Environment, Diagonal Cable Function, Lasso Selection, Long Term Performance.

Abstract: Cable-stayed bridges have the advantages of sizeable spanning capacity and simple and beautiful modeling.

They have become one of the main bridge types for road crossing rivers, lakes, seas, and deep mountain

valleys. As one of the main load-bearing components of the bridge, the durability of the cable-stayed system

directly determines the operational safety of the bridge. The cable system is complicated in structure,

concentrated in force, difficult to seal, weak in protection, and prone to corrosion damage and fatigue

damage under the coupling effect of load and environment, resulting in the instability of the bridge

structure. In order to ensure the high-quality construction and long service life of bridges with cable-

carrying systems, this paper discusses the diseases that affect the safe service of cable-stayed bridges based

on the research project of Chishih River Special Bridge. By analyzing the risk factors affecting the safety of

the cable system, the primary causes of cable damage are obtained, which provides a reference for the safe

service of the cable system.

a

https://orcid.org/0009-0009-7482-8242

1 INTRODUCTION

Cable-stayed bridges mainly comprise main girders,

cable towers, and tension cables. Several cable-

stayed cables are fixed to the main girder, adding

elastic support within the girder span and reducing

the bending moment. The material characteristics are

fully utilized so that the cable-stayed towers are

mainly under pressure, and the cables are mainly

under tension. The world's first modern cable-stayed

bridge was built in Sweden in 1955 with a main span

of 182.6m Stromsant Bridge. With the gradual

maturation of modern mechanics theory, the strength

of new materials and other properties continue to

improve, and the number of cable-stayed bridges

worldwide has proliferated. In this process, China's

cable-stayed bridges have been developed for four

generations: the sparse cable system, dense cable

system, main girder soft thinning, and oversized

span. China's cable-stayed bridges nowadays mostly

use the dense cable structure, which significantly

reduces the height of the main girder, makes the

girder size smaller, reduces the deadweight,

improves the bridge headroom, increases the

spanning capacity of the bridge, and makes the

bridge deck system mainly under pressure, which

effectively improves the service life of the material.

In terms of wind vibration, due to the slight

difference in self-oscillation frequency between the

dense cables, they affect each other in mutual

vibration, offsetting part of the impact of wind

vibration and effectively improving the aerodynamic

stability (Rymsaz 2021).

2 RIPCORD ACCIDENT

With the increasing number of cable-stayed bridges

in China, many diseases and accidents related to

bridge structures and components have occurred in

recent years. The continuous accumulation of the

158

Shao, X., Ma, B., Fan, Q., Feng, S., Zeng, Y., Qiu, Y., Liu and C.

Research on Safe Service of Cable-Stayed System and Selection of Cable Selection for Chishi River Special Bridge.

DOI: 10.5220/0013590300004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 158-162

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

role of natural factors such as load and environment

on cable-stayed bridges, plus the surge in traffic,

Under the joint action of natural environmental

factors and human factors, will inevitably lead to the

accumulation of damage to the bridge structural

system components, so that its structural resistance

to attenuation, resistance to natural disasters, and

even in the regular use of the ability to decline, thus

making the safety and durability of the bridge

structure degradation. The safety and durability of

cable-stayed bridges should be emphasized.

The main path of force transmission of the cable-

stayed bridge is as follows: external load (vehicle

load) → central girder → tension cable anchorage

system → tension cable → cable tower. Cable-

stayed cable and cable anchorage systems are

collectively called cable systems. The tension cable

system is the central part of the load transfer,

effectively transferring the force on the main beam

to the cable tower. With the accumulation of time,

vehicle loads, environment cli, mate, and other

external factors such as non-linear superposition, the

performance of the tension cable system will

gradually decline. Diseases arising from the tie

system have led to the replacement of tie cables

within the design service life of several cable-stayed

bridges. A summary of the tension cable

replacements is shown in Table 1 (Xu et al., 2024).

3 DISEASE ANALYSIS OF LASSO

SYSTEM

From Table 2, a summary of tie system disorders, it

can be seen that for the 50 cable-stayed bridges, the

following four primary areas of disorders in the tie

system were identified, i.e., PE/HDPE sheath

cracking; tie disorders; corrosion of the tie

anchorage system; and ineffective filling of the

media (Gao et al., 2019).

Table 1: Tension cable replacement summary statistics.

Ordinal numbe

r

Bid

g

e name States Com

p

letion time Lasso's service time

1 Shanghai New Five Bridges China 1975 15

2 Shanghai Songjiang Port Bridge China 1982 12

3 Guangdong Haiyin Bridge China 1988 7

4 Guan

g

don

g

Jiu

j

ian

g

Brid

g

e China 1988 10

5 Guan

g

don

g

Zhuhai Qi'ao Brid

g

e China 2001 6

6 Guan

g

xi Baisha Brid

g

e China 1995 11

7 Ningbo Yongjiang Bridge China 1992 17

8 Sichuan Minjiang Bridge China 1990 10

9 Jinan Yellow River Hi

g

hwa

y

Brid

g

e China 1982 13

Table 2: Disease Information Summary for Lasso System.

Typical

Diseases

Sheath

cracking

Steel Wire Disease

Anchorage system

corrosion

Seal

material

failure

Amount 18 Corrode Break Turn Vibratory Anchorage

Connection

tube

2

35 7 2 2 5 2

4 PERFORMANCE EVALUATION

SYSTEM FOR TENSION

CABLES

The main characteristics to be met by the quality of

our construction projects are safety, practicality,

durability, stability, economy, and environmental

friendliness. Safety refers to the performance that

can ensure that the structure is in a safe condition

after the completion of the engineering structure and

guarantees the personal safety of the builders and

users. Practicality is the performance of the project

to meet the purpose of use. Durability is the

structure's life, the project in the specified

conditions, to meet the specified functional

requirements of using the years, that is, the project

after completing a reasonable service life cycle.

Stability refers to the ability of the engineering

structure to fulfill the necessary functions at the

specified time and conditions. Economy refers to the

ability of the structure to minimize cost after

satisfying safety, suitability, and durability during

the whole life cycle stage. Environmental

Research on Safe Service of Cable-Stayed System and Selection of Cable Selection for Chishi River Special Bridge

159

friendliness refers to the coordination of the project

with its surrounding ecological environment, the

economic environment of the region where it is

located, and the surrounding constructed projects to

adapt to sustainable development requirements. Tie

performance evaluation system consists of

mechanical properties, working performance,

durability performance, and protection performance

(Castillo et al., 1985).

4.1 Mechanical Property

The mechanical properties of the cable system

include steel wire tensile strength, steel wire

elongation, cable breaking force, stress relaxation

rate of the steel bar, steel wire torsional properties,

and corrosion fatigue performance. Suppose any of

the mechanical properties of the cable system do not

meet the standard. In that case, it will produce a

brittle steel wire fracture and lead to the cable's early

failure, resulting in safety accidents. Lasso fatigue

will reduce the load-carrying capacity of the cable,

so fatigue performance is a measure of the quality of

the cable, a comprehensive indicator.

4.2 Work Performance

The working performance of the diagonal cable

includes

• the performance of the cable against wind

and rain vibration,

• the performance of the cable against impact

and

• the anchorage performance of the

connection between the cable body and the

anchorage.

With the extended time, wind and rain vibration,

shock vibration will reduce the life of the sheath,

caused by the surface corrosion of the cable, the

cable body, and the anchorage connection between

the disturbance, reducing the anchorage performance

between the two.

4.3 Durability

Structural durability is defined as the ability of a

structure to maintain its safety, everyday use, and

acceptable appearance under normal conditions of

use, construction, and maintenance for a specified

number of years without additional costly

reinforcement. The following conditions affect the

durability of tie systems: stress cracking resistance

of sheathing, deterioration of sealing materials, and

fire resistance of ties.

4.4 Protective Properties

Protective properties: To prevent the direct contact

of steel and anchorage with external corrosive media

caused by the material's bearing capacity decline and

to take the components isolated from the external

environment performance. Mainly includes sheath

tensile rupture stress, watertight cable, cable end

drainage performance, and anchorage drainage

performance.

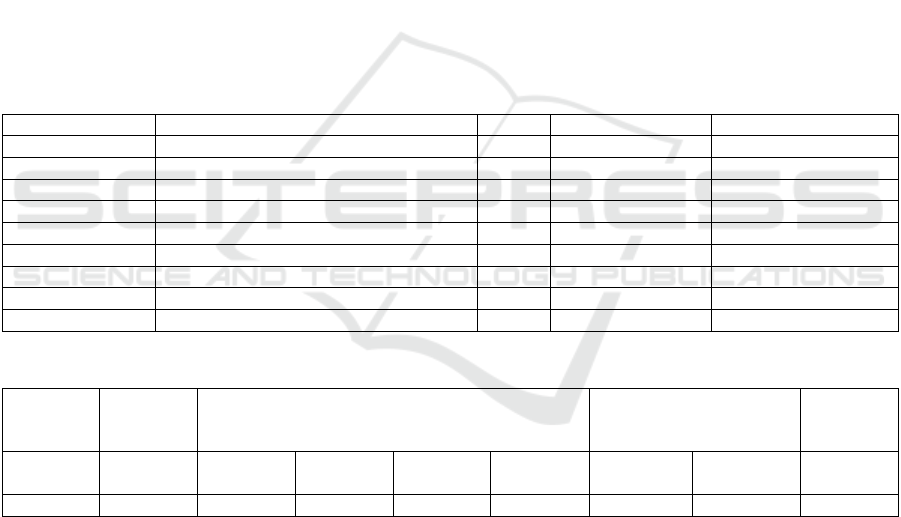

5 PROJECT OVERVIEW

Chishi River Bridge is located in Shenzhen

Shenzhen-Shantou Special Co-operation Zone, at the

mouth of Chishi River in Xiaomo Town. The main

bridge is a one-tower hybrid girder cable-stayed

bridge with a span arrangement of (256+50+40+40)

m. The total length of the main bridge is 386 m. The

width of the bridge deck is 44.0 m. The central

tower is a pike-shaped concrete tower with a height

of 111 m. The main span of the main girder is a steel

structure, and the side spans are prestressed concrete

structures with a center girder height of 3.5 m. The

structural system of the main bridge is the tower,

girder, and pier consolidation with the auxiliary

piers and the transition piers with vertical movable

bearings, and a specific range of compression

weights near the auxiliary piers on the concrete

girder side to prevent the operation phase from being

affected. Activity bearing on the concrete beam side

of the auxiliary pier near the set is a specific range of

pressure to prevent the auxiliary pier and transition

pier bearing in the operation phase of the adverse

reaction force. Cable space double face arrangement,

the central tower on each side of 19 pairs of cables, a

total of 76 bridges, cable material Ж15.2 type

prestressed galvanized steel strand. Slant cable

specifications total five kinds: 250-43, 250-55, 250-

61, 250-73, 250-85. As shown in Figure 1 (Stallings

et al., 1991).

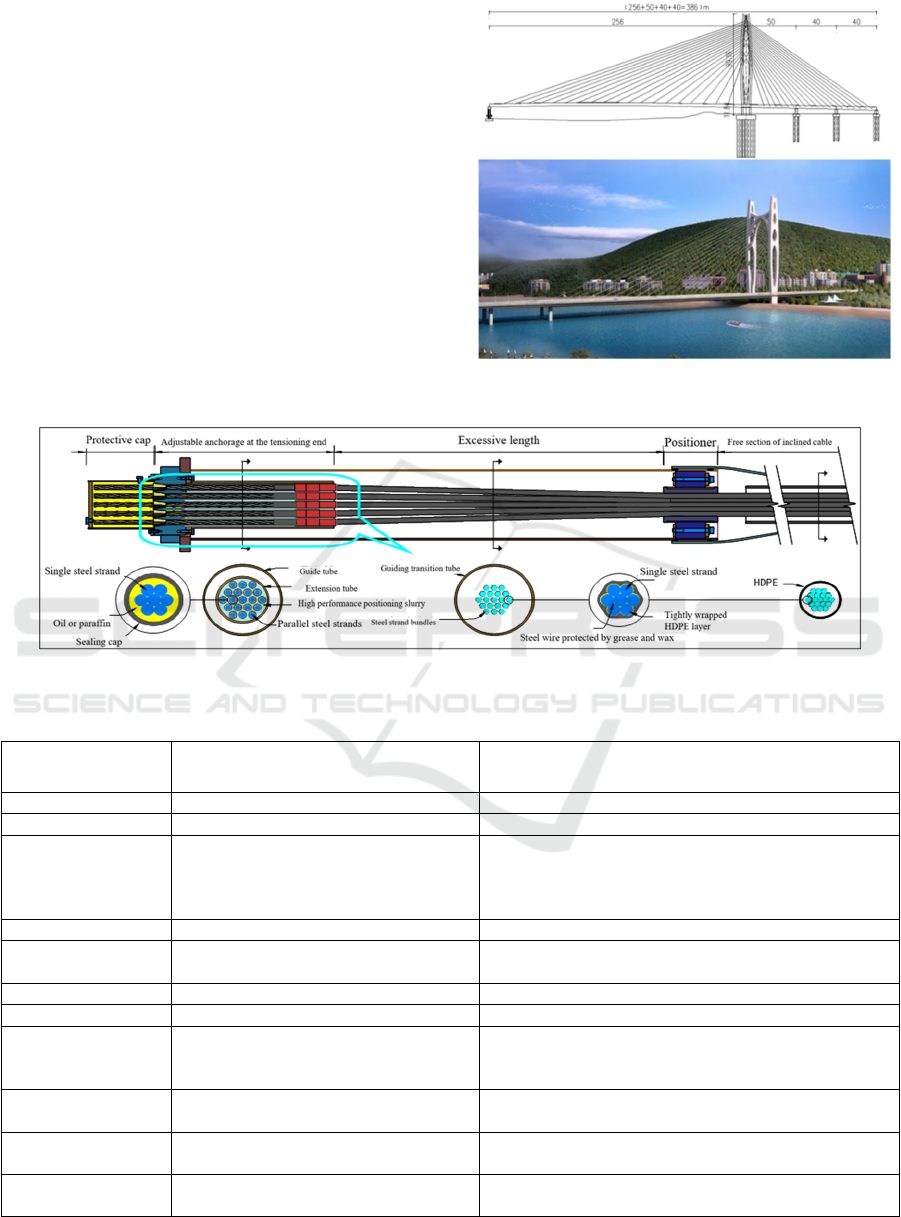

5.1 Lasso Selection Program

From Table 3, it can be seen that the cable selection

table.Through the disease analysis of the diagonal

cable system, the comparison of the cable

replacement project consumption, and the overall

evaluation of the cable performance evaluation

system, the galvanized steel strand diagonal cable

was finally selected. The stranded wire cable

consists of several strands of φsl5.2 high-strength,

low-relaxation galvanized steel strand. The cable

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

160

anchorage is a clip-type group anchor. The outer

layer is then wrapped with HDPE hot extrusion

molding; PE stranded wire strands outside the high-

density polyethylene outer sheath pipe. The stranded

steel strands and parts of the stranded wire cable are

made in the factory and then installed one by one

on-site to form the whole cable. The weight of the

whole cable does not control the installation of

stranded wire cable. As shown in Figure 2.

Figure 1: Engineering Design and Rendering.

Figure 2: Lasso Structure Diagram.

Table 3: Cable Selection Table.

Enterprise Twisted parallel wire cable Twisted parallel wire cable

Technical maturit

y

Mellow Mellow

Makin

g

s

φ

7 hi

g

h stren

g

th

g

alvanized steel wire Low relaxation

g

alvanized steel strand

φ

sl5.2

Cable anchors

Cold cast anchors for reliable

anchoring performance

Clip sheet type group anchors are used. Attention

should be paid to the fatigue

Strength, to prevent the clip sheet loosening under low

stress.

Fati

g

ue resistance Goo

d

Goo

d

Shield

Galvanized steel wire + hot-extruded

high-density PVC

Galvanized steel strand + HDPE + HDPE outer sheath

p

ipe

Lasso Diamete

r

Sli

g

htl

y

smalle

r

Sli

g

htl

y

lar

g

e

r

Tensionin

g

of ro

p

es Tense

g

rit

y

Distributed tensionin

g

, can be tensioned as a whole

Requirements for

transportation and

liftin

g

Large coil transportation is required,

and high lifting equipment

re

q

uirements are re

q

uire

d

Small coil transportation is required, and the lifting

equipment requirements are low,

Eas

y

to install

Speed of

construction

Fast Fast

Interchangeability

Large scale equipment required,

affecting transportation

Can be exchanged for single strand, only requiring

light equipment, without affecting traffic

Quality control Factory production quality guaranteed

On site formation of whole cables, easy control of steel

strand cuttin

g

len

g

th

Research on Safe Service of Cable-Stayed System and Selection of Cable Selection for Chishi River Special Bridge

161

To summarize, the key indicators of the tension

cable system that significantly impact the service

safety of cable-stayed bridges should be judged first.

The tie cable system produces a disease process for

sheath first cracking, resulting in bare steel wire and

corrosion media contact. Subsequently, the steel

wire surface in the electrochemical reaction under

the action of the etching pit weakened the original

steel wire's effective cross-section, resulting in

damage. With a further increase in the degree of

damage, steel wire pits produce stress concentration

and accelerate the development of cracks in the wire

until the wire stress is greater than or equal to the

tensile strength of the wire, causing wire breakage

out of work. In this process, the cable cross-section

damage increases, reaching the breaking force

threshold after the cable failure. By analyzing the

whole process of cable system disease, it can be seen

that the cable system of cable-stayed bridge service

safety of the critical indicators for wire tensile

strength, wire corrosion fatigue performance, cable

breaking force, and cable anchorage performance.

The final selection of tie ropes (Gero et al., 2009).

6 CONCLUSION

This chapter analyzes the long-term performance

indexes of tension cable systems by reviewing a

large number of literature and bridge inspection

reports and combining them with the corresponding

specifications. It summarizes and analyzes the

typical diseases and causes of the tension cable

system of 50 in-service cable-stayed bridges.

Diseases affecting the safe service of the cable-stay

system mainly include corrosion of steel wires in the

cable body, broken wires, and anchorage failure.

The main reason is that the HDPE sheath and sealing

device is aging and cracking, resulting in external

corrosion factors in the internal cable system,

coupled with the cable to withstand the fatigue load

coupling effect, causing the cable corrosion damage.

Based on the performance of the long-term

performance of the cable system is divided into

mechanical properties, work performance, durability,

and protection performance. After analyzing the

disease process of the cable system, the key

indicators to determine the long-term service safety

of the cable system are steel wire tensile strength,

steel wire corrosion fatigue performance, cable

breaking force, and cable anchoring performance.

The Chishih River Special Bridge cable selection

was carried out through a large number of analyses

and rigorous judgment. At the same time, it provides

a reference for the cable selection of other bridges.

ACKNOWLEDGMENTS

This work supported by the China Construction

Foundation Foundation Project Research on Key

Technologies for the Construction of Asymmetric

Single Tower Xielat Bridge over Chishi River

(CSCIC-2023-KT-(03))

REFERENCES

Rymsaz, J., 2021. Causes of the Collapse of the Polcevera

Viaduct in Genoa, Italy. MDPI Sinica1 7(11): 2076-

3417.

Xu, G. N., Xu, W. M., Wang, Z. H., Zhang, R. S., 2024.

Improved Deflection Prediction Model for PSC Box

Girder with Stay Cable System during Tensioning

Phase. Advances in Civil Engineering 1687-8086.

Gao, Y., Zhang, J. Q., 2019. A Sparse Model of Guided

Wave Tomography for Corrosion Mapping in

Structure Health Monitoring Applications. Applied

Sciences-Basel 15(9): 2076-3417.

Castillo, E., Fermandes-Canteli, A., Esslinger, V., et al.,

1985. Statistical model for fatigue analysis

ofwires,strands and cables. Int. Assoc.for Bridge and

Struc. Engrg. (IABSE). Proc., P.82/85.

Stallings, J. M., Frank, K. H., 1991. Stay-cable fatigue

behavior. Journal of Structural Engineering 117(3):

936-950.

Gero, A.M., Sven, S., 2009. Replacing Stay-Cables of the

Rhine River Bridge Rheinbrucke Flehewithout Traffic

Interruption. Proceeding of the 2009 Structures

Congress. Washington: ASCE, 518-526.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

162