The Application Research of Post-Grouting Technology at the Pile

Base in Collapsible Loess Areas

Chuanzhong Feng

a

, Xue Liu and Shaowei Jiang

*

China First Highway Engineering Co., LTD., Beijing 100020, China

*

Keywords Bored Cast-in-Place Pile, Post-Grouting at Pile Base, Collapsible Loess, Pile Shaft Bearing Capacity,

Engineering Application.

Abstract During the construction of bored cast-in-place piles, issues such as grout loss, grout overflow at the pile top,

and the uplift of the reinforcement cage frequently occur, resulting in the pile's bearing capacity failing to

meet the design requirements even after post-grouting. This study investigates the application of post-grouting

technology for cast-in-place piles in collapsible loess formations and addresses its key technical challenges.

It focuses on controlling the grout fluidity at the pile base, preventing the uplift of the reinforcement cage by

installing a steel plate capsule at the pile base, and managing the bearing capacity of the pile after reducing

its length. The composite post-grouting technology was successfully implemented in the realignment project

of National Highway 108 (Xiangfen-Quwo-Houma section). This technology, utilizing three stages—open

grouting, closed grouting, and re-opened grouting—effectively enhanced the bearing capacity of the pile

foundation while controlling grout loss and reinforcement cage uplift. Experimental results indicate that the

vertical compressive ultimate bearing capacity of single piles fully meets design specifications, significantly

improving both the load-bearing performance and construction safety of the pile foundation. This technology

not only reduces pile construction costs but also enhances engineering quality and economic efficiency,

making it highly valuable and promising for broader engineering applications.

1 INTRODUCTION

With the rapid development of infrastructure

construction in China, the use of pile foundation

construction has increased significantly, and the post-

grouting technique at the pile base has been widely

adopted (Xu et al., 2017). However, issues such as

grout loss, grout overflow at the pile top, and the

uplift of the reinforcement cage still occur during

construction, causing the bearing capacity of the pile

to fall short of design requirements even after post-

grouting (Zhou et al., 2021; Tan et al., 2017). Liu

Zhonghua and colleagues, in their analysis of grout

overflow and treatment measures in the Hangzhou

Minghao Building project, pointed out that grout

overflow occurs when the grout rises beyond the

height of the pile (Gong et al., 2023).

During the construction of cast-in-place piles,

grout overflow and reinforcement cage uplift are two

critical issues with complex mechanisms influenced

by the geometric properties of the pile (e.g., pile

a

https://orcid.org/0009-0007-8199-5167

length, pile diameter), geological conditions, and

grouting parameters (Li et al., 2019). Short pile

designs tend to concentrate grouting pressure at the

pile base, leading to rapid upward grout flow and

increasing the risk of overflow. Enlarged pile

diameters expand the grout flow channel, raising the

upward grout height. Moreover, the thickness of the

mud layer around the pile significantly impacts grout

behavior; a thicker mud layer intensifies upward

grout flow, especially in short piles, leading to grout

rise beyond the pile length and resulting in overflow

(Vakili et al., 2021). Therefore, optimizing pile

design, conducting detailed geological investigations,

and carefully adjusting grouting parameters are

crucial to preventing grout overflow.

On the other hand, in the initial stage of cast-in-

place pile construction, the concrete has not yet come

into contact with the reinforcement cage, which

mainly relies on the balance between the buoyant

force of the slurry and its own weight. As concrete

filling progresses, the concrete level rises to the base

136

Feng, C., Liu, X., Jiang and S.

The Application Research of Post-Grouting Technology at the Pile Base in Collapsible Loess Areas.

DOI: 10.5220/0013580900004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 136-144

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

of the reinforcement cage, significantly increasing the

risk of uplift due to the added buoyant force (Zhou et

al., 2021). Eventually, as the conduit penetrates the

reinforcement cage, the anchoring force at the base of

the concrete increases, balancing the forces among

the concrete, the slurry buoyancy, and the weight of

the reinforcement cage, effectively preventing uplift.

To address these challenges, optimizing the grouting

process, enhancing construction monitoring, and

timely adjusting construction parameters are

necessary to ensure that the force states at each stage

remain under control, thereby ensuring the quality

and safety of the pile foundation construction.

Post-grouting technology for cast-in-place piles is

a technique in which grout is injected into the base

and sides of the pile through pre-installed ducts once

the pile has reached the required strength. In the loess

regions of Northwestern China, due to its unique

geological conditions, cast-in-place piles are widely

used because of their efficient utilization of soil

bearing capacity and well-established construction

techniques (Yu et al., 2017). Although post-grouting

is highly effective in enhancing side friction

resistance and strengthening the soil layer at the pile

base, the technique's application in loess regions faces

challenges due to the distinctive mechanical

properties of these soils. Some believe its

effectiveness in increasing side resistance in such

areas is limited, which has hindered the widespread

adoption of post-grouting technology at the pile base

(Wan et al., 2019). Despite existing knowledge and

practical achievements, there remain gaps in

understanding its mechanisms, subjective biases, and

deficiencies in analysis methods and precision in

construction techniques. These issues require further

in-depth analysis and study in conjunction with

practical engineering applications.

Based on this background, this paper presents the

developed post-grouting technology for pile bases

and its application in the realignment project of

National Highway 108 (Xiangfen-Quwo-Houma

section). The successful implementation of this

technology has significantly contributed to reducing

project construction costs, minimizing the total cost

over the full lifecycle, and saving overall investments.

Furthermore, this technology can be directly

promoted and applied in various pile foundation

projects, generating considerable economic and

social benefits, with broad application prospects and

significant engineering value.

2 PROJECT OVERVIEW AND

PROBLEMS

2.1 Project Overview

The project design begins near Zhujiageta in

Xiangfen County, Shanxi Province, with a dual four-

lane roadway and a design speed of 80 km/h. The

starting and ending points are designated as K0+000

to K48+723.5, covering a total route length of 48.723

km. The proposed route corridor passes through

Quwo County, an area located in the northern

temperate and warm temperate semi-arid continental

monsoon climate zone. This region experiences

distinct seasons, with cold and dry winters, dry and

windy springs, hot and rainy summers, and cool, clear

autumns.

At the Xiyang Interchange bridge site, the surface

layer consists of Q

3

silt and silty clay, with needle-

like pores and visible large voids. According to the

"Code for Building Construction in Collapsible Loess

Areas," the bridge site is classified as a self-weight

collapsible ground with a collapse grade of Level III

(severe). The thickness of the collapsible soil at this

location ranges from 14.5 to 15.0 meters.

2.2 Project Problem

Addressing the characteristics of collapsible loess, the

key challenges for shortening the length of pile

foundations in situ while ensuring the safety of

existing bridges and enhancing the bearing capacity

of the pile foundations include:

2.2.1 Control of Grout Fluidity in

Post-Grouting at the Pile Base

During the post-grouting process at the pile base

under high pressure, especially when using open split

grouting methods, accurately controlling the flow

direction of the grout poses challenges. The flow path

can easily change with the natural fissures in sandy

soil and gravel layers, increasing the risk of grout

overflow to the surface and causing the grouting

focus to be imprecisely concentrated in the pile base

area. Additionally, adjusting grouting parameters is

difficult, as precise control over pressure and volume

becomes challenging, making it hard to fully comply

with the predetermined design specifications. This

not only increases the fluctuations in the bearing

capacity of individual piles but also limits their

potential for enhancement.

The Application Research of Post-Grouting Technology at the Pile Base in Collapsible Loess Areas

137

2.2.2 Control of Reinforcement Cage Uplift

After Installing Steel Plate Capsules at

the Pile Base

In the construction of bored cast-in-place piles, the

slurry within the hole poses challenges for the

placement of the reinforcement cage equipped with

steel plate capsules, similar to a piston effect that

hinders slurry discharge and increases the difficulty

of lowering the cage (Zhang et al., 2011). Once the

reinforcement cage is in place, excess sediment tends

to accumulate at the bottom of the hole, making

secondary cleaning difficult. This requires precise

control of slurry properties and optimization of

reinforcement cage design in complex geological

conditions such as collapsible loess to ensure smooth

construction. Additionally, introducing efficient

cleaning techniques to minimize the impact of

sediment and ensure the quality and bearing capacity

of the pile foundation is key to enhancing

construction efficiency and engineering safety.

2.2.3 Impact of Shortened Pile Length on

Pile Shaft Bearing Capacity

In collapsible loess areas, once a pile foundation is

subjected to water infiltration, not only is the original

positive friction completely lost, but significant

settlement caused by soil collapse can also induce

negative friction, which results in additional loads

ultimately borne by the soil at the pile tip (Zhang et

al., 2006). If the length of the pile foundation is

shortened at this point, it will further weaken the

bearing capacity of the pile shaft, significantly

impacting the overall stability of the bridge structure

and increasing structural safety risks (Xi et al., 2022).

Therefore, when designing pile foundations in

collapsible loess regions, it is essential to fully

consider the risks of water infiltration and the

reasonableness of the pile length to ensure the

stability and safety of the bridge.

3 TECHNICAL CONTENTS

3.1 Composite Post-Grouting

Technology of Pile Bottom

Pile bottom composite post-grouting is divided into

three stages: open pile bottom grouting, closed pile

bottom grouting and open pile bottom re-grouting.

3.1.1 Pile Bottom Open Grouting

Open grouting technology involves injecting the

slurry directly into the soil through a non-blocking

grouting pipe to ensure that the slurry is fully

integrated with the soil, so as to achieve the desired

engineering effect. The slurry is injected into the

sediment and strata at the bottom of the pile, and the

root cement slurry veins are formed at the bottom of

the formation and the side wall of the pile. The

simulation effect diagram of open grouting at the

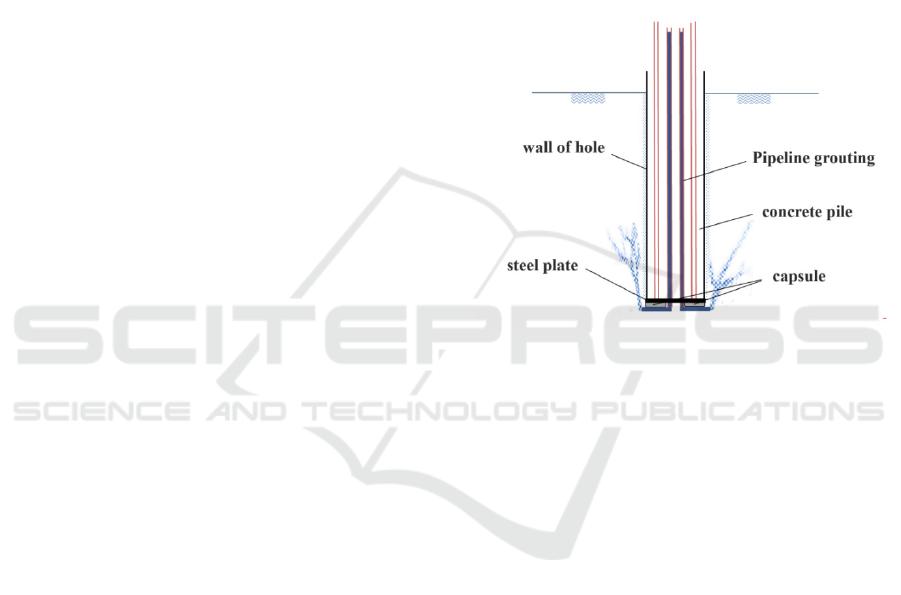

bottom of the pile is shown in Figure 1.

Figure 1: Simulated Effect of Open Grouting at Pile Bottom

in Soil Layers.

In view of the high pressure required for grouting

after pile bottom, split grouting is usually adopted for

open pile bottom grouting, but it is difficult to control

the grouting area under this method. Driven by high

pressure, the slurry is easy to diffuse disordered along

the natural cracks in sand, soil and gravel layer,

resulting in the grouting focus may not be precisely

concentrated in the pile bottom area. In addition, the

precise control of the pressure and the amount of

grouting becomes a big challenge in the process of

grouting, and it is difficult to strictly follow the design

standards, which affects the stability and consistency

of the grouting effect. Such uncertainty not only

intensifies the fluctuation range of the bearing

capacity of a single pile, but also weakens the stability

and reliability of its bearing capacity improvement

(Zhu, 1998).

3.1.2 Pile Bottom Closed Grouting

The remarkable feature of the closed post-compaction

grouting technology at the bottom of the pile is that

its process design cleverly ties the compression

grouting pipe to the steel cage to ensure the

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

138

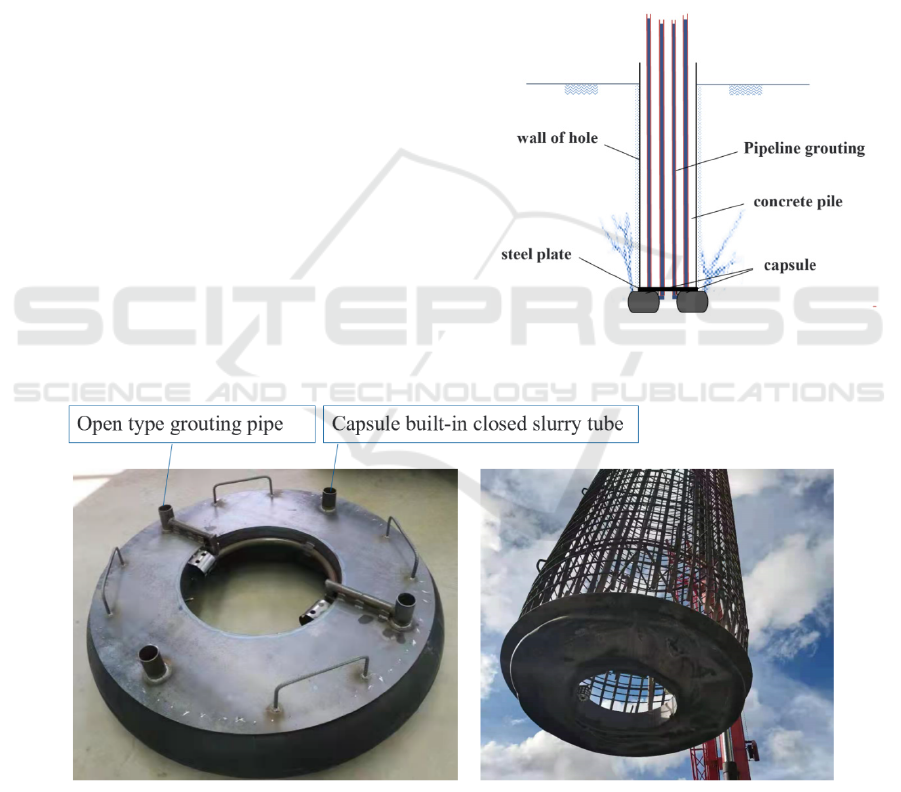

construction of the grouting channel. Especially

critical is the special steel plate capsule installed at

the bottom of the reinforcement cage, which is not

only structurally strong, but also carefully designed to

seamlessly connect with the grouting pipe, realising a

closed and efficient grouting process. This design

enables the grouting operation to be precisely

controlled, and the slurry enters the steel plate capsule

through the grouting pipe under pressure, and then

spreads effectively to the pile bottom and the

surrounding soil layer to achieve the expected effect

of foundation reinforcement, and the simulated effect

of "closed" grouting at the bottom of the pile and the

capsule are shown in Figure 2 and Figure 3.

During the construction process, slurry is injected

into the pre-set capsule at the bottom of the pile

through a precise slurry pipe system, which causes the

capsule to expand uniformly and gradually form a

solid stone enlarged head. This process not only

strengthens the pile base structure, but also cleverly

utilises the expansion force to extensively squeeze

and spread the previously injected cement slurry

around the pile base. This squeezing action prompts

the cement paste to mix with the pile bottom slag in

depth, and after the reaction, a denser cement soil

layer is formed, which effectively improves the

bearing capacity and overall stability of the pile

foundation. The closed post-pressure grouting

technique at the bottom of the pile can quickly and

effectively squeeze and eliminate the slag layer at the

bottom of the pile, and significantly improve the

cleanliness and tightness of the pile bottom area (Teh

et al., 2008; Orr, 2009; Wan et al., 2024). At the same

time, this technique ensures that the injected slurry is

accurately concentrated in the pile bottom, and the

pile bottom and its surrounding strata are compacted

and consolidated in depth by high-pressure action,

which further enhances the stability of the foundation.

In addition, the enlarged head formed during the

grouting process significantly enlarges the support

area of the pile bottom, and this structural

optimisation greatly improves the ultimate bearing

capacity of the pile foundation.

Figure 2: Simulation Diagram of Closed Pressure Grouting

Effect at the Pile Base in Soil Layers.

Figure 3: Plate capsule device picture.

3.1.3 Pile Bottom Open Grouting Again

The composite post-grouting technology at the pile

base integrates both open and closed grouting

techniques, retaining their respective advantages

while overcoming their limitations. Its most notable

feature is the combination of three grouting actions—

fracturing, permeation, and compaction—focused at

The Application Research of Post-Grouting Technology at the Pile Base in Collapsible Loess Areas

139

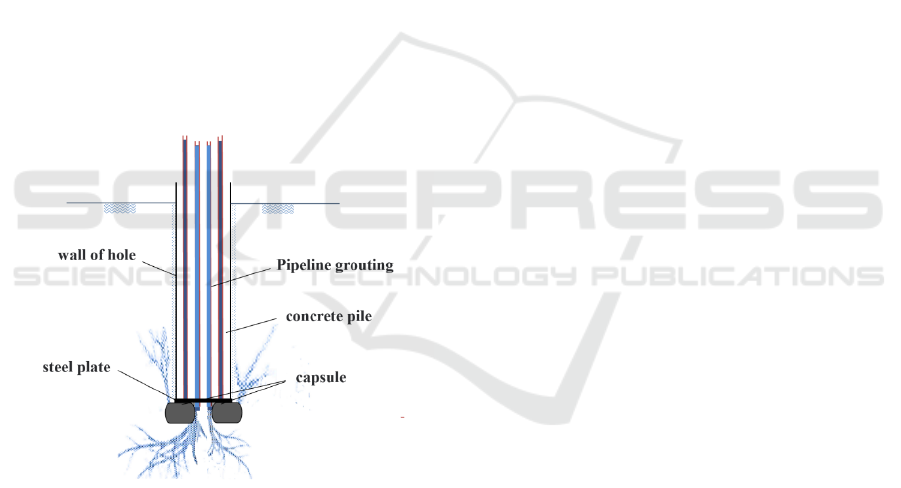

the pile base to work synergistically. The constraints

provided by the ring-shaped capsule at the pile base

effectively implement the "three-point" principle of

grouting, which includes precise control of the

grouting location, volume, and direction. The

simulated effect of this composite post-grouting at the

pile base is illustrated in Figure 4.

The design of the central-hole steel plate capsule

skillfully incorporates multiple functions. Its key

feature is the hole in the center, which plays a crucial

role during the descent of the reinforcement cage.

This design allows the slurry at the bottom of the pile

to pass smoothly through the holes, reducing

resistance to the descent of the reinforcement cage

and ensuring that it reaches the bottom of the hole

without obstruction. Furthermore, if excess sediment

accumulates at the bottom of the hole after the

reinforcement cage has reached its final position,

these holes serve as a secondary sediment removal

channel. Through the holes, the bottom of the pile can

be effectively cleaned, removing any excess sediment

and ensuring the quality and safety of the pile

foundation construction.

Figure 4: Simulation effect of open repressing grouting at

pile bottom in soil layer.

An open grouting pipe is installed in the central

holes to perform open grouting on the soil layers at

the pile base, which can eliminate possible issues at

the bottom of the pile, such as sediment, mud, voids,

and gaps, thereby solidifying the soil layer. Due to the

expansion of the closed grouting capsule, a large plug

is formed at the pile base, preventing the upward

return of the cement grout. The cement grout further

fractures and permeates downward around the pile

base, forming root-like grout veins that enhance the

consolidation effect of the soil layers around the pile

base, extending the reinforcement effect to greater

depths.

3.2 Floating Control Technology of

Steel Bar Cage

To prevent the uplift of the reinforcement cage after

installing a steel plate capsule at the pile base, it is

necessary to implement thorough preventive and

control measures in three areas: the design of the

reinforcement cage structure, the adjustment of

concrete and slurry, and the concrete pouring strategy.

3.2.1 Steel Cage Structure Optimization

Strengthen the straightness of the main reinforcement:

ensure that the main reinforcement of the steel cage is

straight without bending, reduce unnecessary joints,

so as to reduce the friction resistance and lateral

adsorption force generated when the concrete is

poured, and help the stability of the steel cage in the

hole.

Initial anchoring strategy: place the reinforcing

cage precisely on the bottom of the hole, and make

full use of one of the first instant concreting anchoring

effect, increase the reinforcing cage and initial

connection strength of hole wall.

Stirrup spacing adjustment and the orifice fixed:

appropriate increase the intensity of stirrup spacing in

order to optimize the structure of reinforcing cage, at

the same time in the orifice area add back pressure

device, further reinforcing cage position, prevent to

rise.

3.2.2 Concrete and Mud Performance

Management

Reduce the density of the mixed liquid: According to

the principle of buoyancy, the density of the mixed

liquid between the mud and the concrete in the hole

is reduced by precisely regulating the performance of

the mud, thus reducing the buoyancy effect on the

steel cage. Before perfusion, rock cuttings at the

bottom of the hole should be completely removed to

reduce the influence of impurities on the density of

the mixed liquid.

Concrete performance optimization: strictly

control the initial setting time of concrete, make sure

it's in the process of infusion to keep good workability

and liquidity, reduce the friction between the

reinforcing cage and, at the same time guarantee the

quality of concrete.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

140

3.2.3 Fine Perfusion Speed Control

Initial low speed perfusion: When the concrete liquid

surface first contacts the steel cage, the perfusion

speed should be slowed down to reduce the direct

impact force of concrete on the steel cage and avoid

the buoyancy surge resulting in floating.

Speed in stages: reinforced concrete initial setting at

the bottom of the cage, form a stable support, can be

gradually to speed up the infusion speed, to improve

construction efficiency, and ensure the safety of the

infusion process under control.

3.3 Pile Bearing Capacity Control

Technology

3.3.1 Selection of Grouting Mode

In the reinforcement of pile foundation, post-grouting

technology becomes the key because of the high

sensitivity of pile end to sediment (Guang-Yao et al.,

2012). The technology not only strengthens the pile

end sediment and produces bottom expanding effect,

but also the reinforcement effect of the pile end

sediment and soil is much stronger than that of the

pile side mud. Therefore, pile end reinforcement

should be taken as the primary consideration.

According to the Technical code for building pile

foundations (JGJ94-2008), when a single pile end is

grouting, the vertical reinforcement section is set to

be 12 meters above the pile end, which is essentially

focused pile end reinforcement. However, further

analysis shows that if this range is extended to the pile

side area 12 meters above the pile end, the overall

reinforcement effect will be more significant by using

the higher side friction resistance of deep soil.

Therefore, the optimal strategy is to adopt the

combination of pile end and pile side to maximize the

bearing capacity and stability of pile foundation.

3.3.2 Strengthening Mechanism of Post-

Grouting on Pile Side Resistance

In the construction technology of traditional bored

pile, mud wall protection, as a key measure in the

process of hole formation, effectively guarantees the

stability of hole wall and construction safety.

However, the mud crust formed by the gradual

solidification of mud around the hole wall is difficult

to be completely removed in the subsequent concrete

pouring process, thus building a "barrier" between the

pile and the soil. This layer of mud not only changes

the physical properties of pile soil interface, but also

profoundly affects the lateral resistance of pile. The

moisture rich in the mud skin softens the structure of

the adjacent soil under the action of infiltration,

resulting in a significant reduction in the strength of

the soil. At the same time, the mud skin itself has a

lower friction coefficient than the undisturbed soil,

which acts as a "lubricant" between the pile and the

soil virtually, reducing the direct friction contact area

between the pile and the soil, and thus weakening the

generation of pile side friction resistance. In addition,

with the gradual consolidation and hardening of pile

concrete, the mud layer tends to shrink in volume to

varying degrees, which further intensifies the

separation tendency between pile and soil, forming

new micro gaps, and further weakening pile side

resistance (Jia et al., 2011).

At the top of the pile under load, the effect of pile

side grouting can be analogy in around pile to form

an enhanced concentric cylindrical "reinforcing

tape". Through the infiltration and solidification of

the grouting material, the reinforcement belt realizes

the strengthening and integration of the soil on the

side of the pile, and its influence scope extends

roughly to 6 to 10 times the pile diameter. This

expanding effect not only enhances the interaction of

pile-soil interface, but also significantly changes the

stress distribution in soil body. With the formation of

the grouting reinforcement belt, the possible stress

concentration in the soil is relieved, and the shear

stress gradually dissipates and tends to be evenly

distributed within the reinforcement belt. At the outer

edge of the reinforced belt, the shear stress gradually

decreases until it reaches a level close to zero.

4 TECHNOLOGY APPLICATION

In order to test the technical effect, NK0+371.5

Beidong Interworking bridge and LK0+465.3 Xiyang

Interworking bridge of Xiangfen - Quwo - Houma

transit transformation project of National Highway

108 were applied and verified, Figure 5. shows the

installation and welding of the steel cage at the

application site.. The projects are located in Quwo

County, Linfen City, Shanxi Province. The pile body

adopts bored pile. The pile length of Beidong

Interconnecting bridge is 35m, the pile diameter is

1.5m, and the vertical compressive ultimate bearing

capacity of single pile is 16376.04kN. The pile length

of Xiyang interworking bridge is 35m, the pile

diameter is 1.8m, and the designed ultimate bearing

capacity is 13078.73kN.

The Application Research of Post-Grouting Technology at the Pile Base in Collapsible Loess Areas

141

(a) (b)

Figure 5: Installation (a) and welding (b) of steel cage.

Self balancing method to detect the pile bearing

capacity, its core idea is to use special loading

equipment on pile body in the load box, in the process

of pile is based on the test objectives and the

geological conditions of the default in reinforcing

cage in specific depth, then closed pile, at the same

time to ensure the loading box connecting line and

other monitoring equipment smooth extends to the

surface. After the pile body is fully cured, the device

applies pressure to the load box through a ground-

operated pressure system to simulate the stress

situation at both ends of the pile body. In this process,

the load box becomes a force transfer medium,

applying both an upward reaction force (Q

uu

) to the

upper pile and a downward positive force (Q

ud

) to the

lower pile. Since the side friction resistance of the pile

body and the surrounding rock and soil body balance

each other, a self-reaction system is formed, and no

external anchor pile or reaction device is required to

achieve the loading effect equivalent to the traditional

static load test (Cheng and Yu, X., 2013; Xing et al.,

2019).

With the loading force increases gradually, the

upper part of pile body in the reverse display its

bearing capacity under load characteristics, through

the monitoring equipment to record the

corresponding parameters such as displacement,

strain (Q

uu

series); At the same time, the lower pile

reflects its bearing capacity under forward loading,

and the corresponding response parameters are also

recorded (Q

ud

series). Finally, through detailed data

processing and analysis of the mechanical parameters

obtained during the loading process, the bearing

capacity of a single pile foundation can be calculated,

as shown in formula (1) (Murali et al., 2024).

1

uu

uud

QW

QQ

γ

−

=+

(1)

Where: Qu is the vertical compressive ultimate

bearing capacity of single pile /kN; Quu is the

measured ultimate bearing capacity of pile on the

upper section of load box /kN; Measured ultimate

bearing capacity of pile under Qud load box /kN; W

is the dead weight of the pile in the upper section of

the loading box; γ1 is the correction coefficient of pile

side resistance in the upper section of load box, with

a value of 0.9.

According to the results of self-balancing

experiment, the bearing capacity indexes of single

piles at two application points are statistically

calculated as shown in Table 1. The test and analysis

show that the vertical compressive ultimate bearing

capacity of single pile at the two application points

completely meet the design requirements.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

142

Table 1: Single pile bearing capacity statistics table.

sequence

number

pile foundation

pile

diameter

(m)

pile

length

(m)

Load box

buried

position

Limit value of

bearing

capacity of

p

ile (kN)

Design

bearing

capacity limit

(kN)

1

Beidong

Interconnecting

b

rid

g

e

1.5 35

Pile bottom

up 14.8

meters

Not less than

16515

16376.04

2

Xiyang

Interconnecting

b

rid

g

e

1.5 35

The bottom of

the pile is 7

meters up

Not less than

13316

13078.73

5 RESULT

This project has formed a complete set of technical

achievements in the post-grouting construction of pile

foundation in collapsible loess stratum, such as the

flow control of post-grouting slurry, the floating

control of steel cage after the pile bottom is installed

with steel plate capsule, and the bearing capacity

control of pile body after the length of pile foundation

is shortened. The research results have been

successfully applied in the support project of National

Highway 108 Xiangfen - Quwo - Houma transit line

change, and have played a demonstration role. As the

key basis for pile foundation optimization in loess

area, it is of great significance to improve the level of

bridge construction in our country, and enhance the

innovation ability and technical competitiveness of

bridge construction in our country. The results of the

project have a very positive role in reducing the

construction cost and the total cost of the whole life

cycle of the bridge, and saving the total investment.

The results can be directly applied in the construction

of various bridge projects, and can produce

remarkable economic and social benefits, and has

broad application prospects and important

engineering significance.

6 DISCUSSION

In this study, we successfully applied post-grouting

technology to address common issues in cast-in-place

piles, such as grout loss and reinforcement cage

uplift, in collapsible loess formations. By

implementing a composite grouting method in three

stages—open grouting, closed grouting, and re-

opened grouting—we significantly improved the

piles' bearing capacity and construction safety. The

use of a steel plate capsule at the pile base effectively

controlled grout fluidity and prevented reinforcement

cage uplift. This approach not only enhanced the

load-bearing performance but also reduced

construction costs, demonstrating its potential for

broader engineering applications.

REFERENCES

Xu, X., Yu, J., Xue, L., et al., 2017. Investigation of

Molecular Structure and Thermal Properties of

Thermo-Oxidative Aged SBS in Blends and Their

Relations. Materials, 10: 768.

Zhou, Z., Wang, K., Feng, H., et al., 2021. Centrifugal

model test of post-grouting pile group in loess area. Soil

Dynamics and Earthquake Engineering, 151: 106985.

Tan, Y., Lu, Y., Peng, F., et al., 2017. Post-Grouting of

Long Bored Piles in Clay. 338–347.

Gong, W., Zhang, Z., Lin, Y., et al., 2023. Full-scale field

test study of bearing characteristics of post-grouting

pile for offshore wind turbines. Ocean Engineering,

268: 113451.

Li, J., Shao, S., Shao, S., 2019. Collapsible characteristics

of loess tunnel site and their effects on tunnel structure.

Tunnelling and Underground Space Technology, 83:

509–519.

Vakili, A., Zomorodian, S. M. A., Totonchi, A., 2021.

Laboratory and Three-Dimensional Numerical

Modeling of Laterally Loaded Pile Groups in Sandy

Soils. Iran J Sci Technol Trans Civ Eng, 45: 2623-2636.

Zhou, Z., Xu, F., Lei, J., et al., 2021. Experimental study of

the influence of different hole-forming methods on the

bearing characteristics of post-grouting pile in Loess

Areas. Transportation Geotechnics, 27: 100423.

Yu, J., Huang, M., Li, S., et al., 2017. Load-displacement

and upper-bound solutions of a loaded laterally pile in

clay based on a total-displacement-loading EMSD

method. Computers and Geotechnics, 83: 64-76.

Wan, Z. H., Dai, G. L., Gong, W. M., 2019. Field study on

post-grouting effects of cast-in-place bored piles in

The Application Research of Post-Grouting Technology at the Pile Base in Collapsible Loess Areas

143

extra-thick fine sand layers. Acta Geotechnica, 14(5),

1357-1377.

Zhang, Z. M., He, J. Y., Fang, K., 2011. Experimental study

on size effect of large-diameter bored cast-in-situ piles

with post-grouting in soft soil. Chinese Journal of

Geotechnical Engineering, 33(sup2), 32-37.

Zhang, Z. M., Zhang, G. X., Wu, Q. Y., et al., 2006. Studies

on characteristics of mudcake and soil between bored

piles. Chinese Journal of Geotechnical Engineering.

Xi, P., Kan, M., Chen, L. Q., 2022. Model test and

numerical simulation study on the effect of mudcake

and length-diameter ratio on the bearing capacity of

bored cast-in-place piles. Advances in Civil

Engineering, 2022(Pt.13): 1.1-1.14.

Zhu, F., 1998. Centrifuge modelling and numerical analysis

of bearing capacity of ring foundations on sand.

Dissertation Abstracts International, 60-02: 0757.

Adviser: J. I. Clark..

Teh, K. L., White, D. J., Chow, Y. K., et al., 2008. A

comparison of the bearing capacity of flat and conical

circular foundations on sand. Géotechnique, 58(10):

781-792.

Orr, T., 2009. A comparison of the bearing capacity of flat

and conical circular foundations on sand d. j. white, k.

l. teh, c. f. leung and y. k. chow, géotechnique, 58(10),

781–792. 2008. Géotechnique, 60(2), 147-149.

Wan, Z. H., Duan, C., Hu, T., et al., 2024. Field study on

bearing capacity of large-diameter rock-socketed bored

piles with combined grouting in highly weathered rock

layers. Rock Mechanics and Rock Engineering, 57(10):

8701-8722.

Guang-Yao, L. I., Ke-Lie, Z., Zu-De, L. U., 2012.

Numerical simulation of size effect on bearing capacity

of large diameter rock-socketed piles under different

strengths of surrounding rocks. Rock and Soil

Mechanics, 33: 384-388.

Jia, J. L., Zhou, M., Zheng, J. H., 2011. Experimental study

on bearing behavior of large-diameter overlength cast-

in-place bored pile post-grouting. Advanced Materials

Research, 243-249:3251-3258.

Cheng, R. C., Yu, X., 2013. Experiment research on bored

pile with post-grouting technology. Advanced

Materials Research, 838-841, 854-857.

Xing, H., Liu, L., Luo, Y., 2019. Effects of construction

technology on bearing behaviors of rock-socketed

bored piles as bridge foundations. Journal of Bridge

Engineering, 24(4), 05019002.1-05019002.9.

Murali, A. K., Haque, A., Bui, H. H., 2024. Effect of smear

distribution on the load-bearing mechanisms of rock-

socketed piles in soft rocks. Journal of Geotechnical

And Geoenvironmental Engineering, 150(1),

4023127.1-4023127.14.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

144