Multi-Objective Optimization of Prefabricated Component

Transportation-Assembly Co-Scheduling Under Small Assembly Unit

Chunguang Chang

1a

, Shuqin Wang

1,* b

and Yan Dong

2c

1

School of Management, Shenyang Jianzhu University, Shenyang 110168, China

2

Finance Department, PetroChina Liaoning Marketing Company, Shenyang 110031, China

*

Keywords: Prefabricated Components, Collaborative Scheduling, Multi-Skill, Multi-Objective, Hybrid Algorithm.

Abstract: Addressing the schedule and cost problems of prefabricated component (PC) assembly processes due to

unreasonable distribution of PC, the transportation, assembly collaborative scheduling optimization model of

PC was studied. The minimum completion time problem and the waiting cost problem in both transportation

and assembly processes are analyzed, and the problem of large number of skilled workers in PC assembly

process is also studied. A multi-skilled team of workers is used to carry out the assembly process, and a multi-

objective optimization model of time-cost-workload equilibrium is set up in terms of the fairness of the multi-

skilled group's work. Then a hybrid NSGA-II simulated annealing algorithm is designed to solve above model,

and the PC transportation, assembly sequence and multi-skilled team allocation scheme are obtained, which

verifies the effectiveness and practicality of the model and algorithm.

1 INTRODUCTION

Green, environment-friendly assembly building is in

line with the national concept of sustainable

development, however, there is big difference in the

resource allocation of prefabricated component (PC)

transportation, construction and other aspects of

assembly building compared with traditional building

type. Scholars at home and abroad have studied

scheduling optimization model for PC transportation

and assembly, Wang et al. (2023) developed a

resource constrained scheduling model considering

uncertain activity time of assembled buildings. Xiong

et al. (2023) developed an optimization model for the

PC loading combination scheme. Luo et al.

(2023)

studied transportation scheduling problem for

assembly phase. Yin J et al.

(2024) considered

immediate lifting of PC on construction sites. Wang

et al., (2018) integrated worker competence into

prefabrication PC scheduling. Araz et al. (2019) also

consider the multi-skilled nature of workers in off-site

construction. Wang and Wu, (2021) consider the

a

https://orcid.org/0000-0001-8379-7569

b

https://orcid.org/0009-0007-8050-4637

c

https://orcid.org/0009-0000-5342-2889

impact of the skill level of the multi-competent

workers.

K

1

K

2

K

3

Component

loading

Transportation of

components

Component

unloading

J

3

J

2

J

1

Adjustment

reset

Lifting of

components

locate and

place lines

J

4

J

5

J

6

Support

Installation

node

connection

Sleeve

Grouting

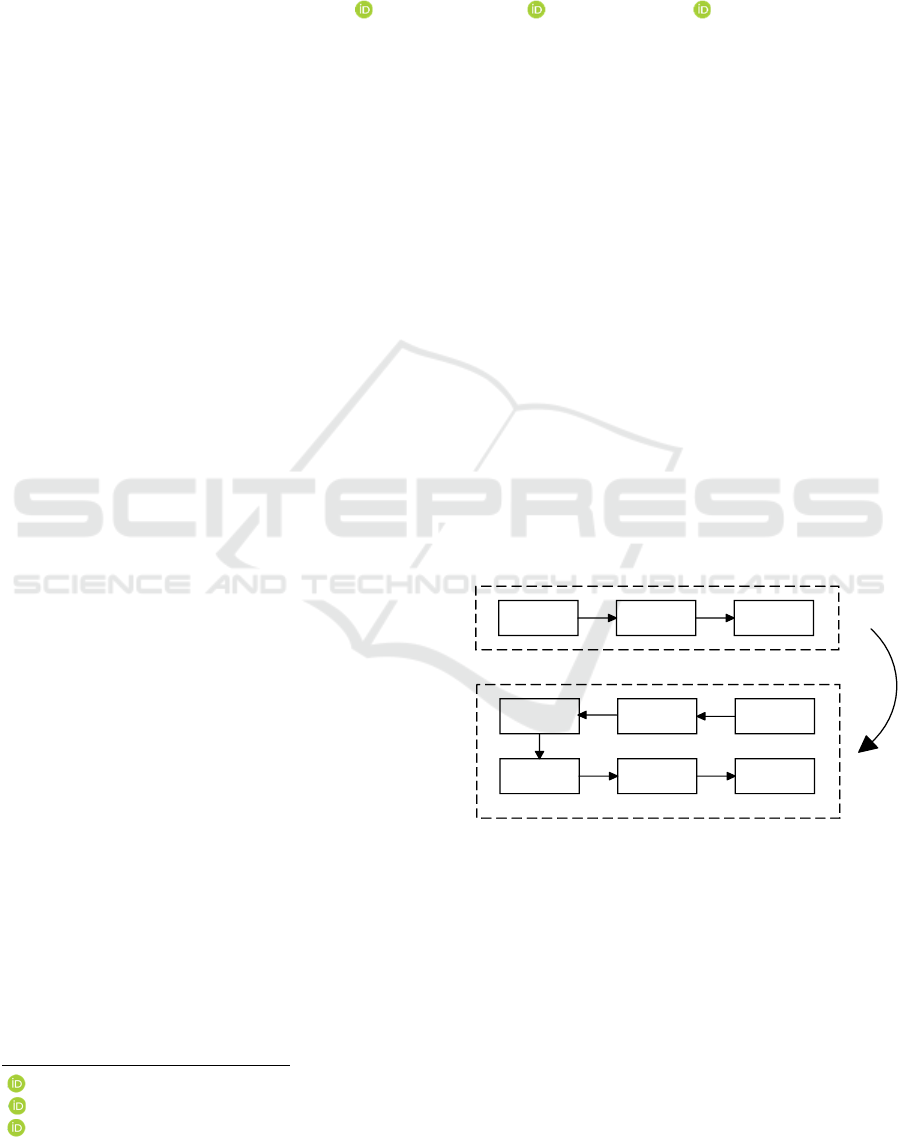

Figure 1: PC transportation-assembly scheduling flowchart.

130

Chang, C., Wang, S., Dong and Y.

Multi-Objective Optimization of Prefabricated Component Transportation-Assembly Co-Scheduling Under Small Assembly Unit.

DOI: 10.5220/0013578800004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 130-135

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

2 DESCRIPTION OF THE

PROBLEM

PC delivery will affect the duration and cost of the

entire construction process, so the focus is on the

overall transportation and assembly time and the

waiting cost of unloading and lifting the PC according

to the PC assembly process and lifting time

requirements. Meanwhile, multi-skilled teams

consisting of multi-skilled workers to fulfill the field

assembly tasks and consider the fairness of workers'

work. The PC transportation-assembly scheduling

procedures are shown in Figure 1.

3 MATHEMATICAL MODELS

3.1 Symbol Definition

To describe the model clearly, common

parameter and variable symbols and their

definitions are given and listed in Table 1.

Table 1: Common Parameter and Variable Symbols and Definitions.

Symbol Definitions Symbol Definitions

I

PC type number

1, 2,

I

M= ,

M

is the total number

of PC types

()

A

,,

I

ij

P

Actual operating time of procedure

j

for PC

()

,

I

i

during

assembly

i

Single PC number, 1, 2,iN= ,

N

is the total

number of PC

()

0

A

,,

I

ij

P

Initial operating time of procedure

j

for PC

()

,

I

i

during

assembly

k

Procedure number during transportation, 1, 2,kK=

,,ivI

WT

Waiting time for unloading vehicle

v

loaded with PC

i

of

type

I

j

Procedure number during assembly, 1, 2,jJ=

()

,,

I

ij

WL

Waiting time for lifting PC

()

,

I

i

at process

j

during

assembly

v

Transportation vehicle number,

1, 2, ,

I

vV=

,

I

V

is

total number of vehicles loaded with PC type

I

r

Multi-skilled shifts number, 1, 2, ,rR= ,

R

is team

total number

B

Maximum load capacity of transport vehicle

,

j

r

τ

Operating coefficient of a multi-skilled shifts

r

at process

j

during assembly

I

A

Weight of a single member of PC type

I

,,ivI

X

Binary variable for type

I

PC

i

is delivered by vehicle

v

TR

,,ivk

S

Start time of procedure

k

for PC

i

loaded by vehicle

v

during transportation

()

,,,

I

ijr

Y

Binary variable for procedure

j

for PC

()

,

I

i

is performed

by a multi-skilled teams

r

during assembly

()

A

,,

I

ij

S

Start time of procedure

j

for PC

()

,

I

i

during assembly

,

j

r

e

Binary variable for the multi-skilled team

r

has the

capability to complete the procedure

j

during assembly

TR

,,ivk

T

Completion time of procedure

k

for PC

i

loaded by

vehicle

v

during transportation

1

γ

Cost factor for waiting time for unloading

()

A

,,

I

ij

T

Completion time of procedure

j

for PC

()

,

I

i

during

assembly

2

γ

Cost factor for waiting time for lifting of PC

TR

,,ivk

P

Operating time of procedure

k

for PC

i

loaded by

vehicle

v

during transportation

3.2 Modeling

()

A

,,

min

M

NJ

FT= (1)

()

1,,,,2

,,

111 11 1

min

I

V

MN MNJ

ivI ivI

I

ij

Ivi ii j

C X WT WL

γγ

=== == =

=⋅ ⋅ +⋅

(2)

() ()

()

2

A

,,

11 1

2A

,

,, ,,,

1111

1

min

MN J

Ii j

RMNJ

Ii j

jr

Ii j Ii jr

rIij

P

PY e

RR

σ

== =

====

=⋅⋅−

(3)

Multi-Objective Optimization of Prefabricated Component Transportation-Assembly Co-Scheduling Under Small Assembly Unit

131

s.t.

TR TR TR

,, ,, ,,

1,2 , 1,2, , 1,2,

ivk ivk ivk I

TSPi Nv Vk K≥+ = = =

(4)

TR TR

,, ,, 1

max 2, 1,2, , 1,2,

ivk ivk I

STkiNvV

−

≥===

(5)

TR TR

,, ,, 1 ,,

3, 1,2, , 1,2,

ivk ivk ivI I

ST WTki Nv V

−

≥+ == =

(6)

{

}

TR TR

,, ,, 1 , 1,

max , 0 3, 1, 2, , 1, 2, , 1, 2,

ivI ivk iv k I

WT T T k i N v V I M

−−

=− ====

(7)

()

TR TR A

,, ,,

,,

min 3, 2, 1, 2 , 1, 2, , 1, 2,

ivk ivk I

Ii j

SP Skji Nv VI M+≤ === = = (8)

() () () ()

0

A

AA

,,

,, ,, ,, ,,,

1,2, , 1,2 , 1,2 , 1,2,

jr jr

Ii j Ii j Ii j Ii jr

TSP YeI Mi Nj Jr R

τ

≥+⋅⋅ ⋅ = = = =

(9)

() ( ) ()

{

}

AAA

,, , 1, ,, 1

max , 1, 2, , 1, 2 , 1, 2

Ii j Ii j Ii j

STTIMiNjJ

−−

≥===

(10)

() () ( )

{

}

AA

,, ,, , 1,

max ,0 2, 1,2, , 1,2

Ii j Ii j Ii j

WL S T j I M i N

−

=− ===

(11)

()

,

,,,

1, 2, , 1, 2 , 1, 2 , 1, 2,

jr

Ii jr

YeI Mi Nj Jr R≤= = = =

(12)

,,

0 or 1 1,2, , 1,2 , 1,2,

ivI I

XIMiNvV== = =

(13)

()

,,,

0 or 1 1,2, , 1,2 , 1,2

Ii jr

YIMiNjJ== = =

(14)

Equation (1) represents the minimum completion

time required from transportation to assembly. (2)

represents minimum waiting costs for unloading and

lifting of PC, where,

//

II

VNBA=

. (3)

represents the most balanced workload of the multi-

skilled team. (4) to (6) indicate the operating time

constraints for loading PC

i at procedure

k

by vehicle

v

during transportation. (7) and (11) indicate the

waiting time for unloading and lifting of PC,

respectively. (8) indicates PC unloading delivery time

constraints. (9) to (10) indicate the operating time

constraints of PC

()

,Ii

at procedure

j

. (12)

represents the multi-skilled teams assigned during

assembly has the capability to complete the task. (13)

to (14) represent ranges of the variables.

4 ALGORITHM DESIGN

Above problem belongs to NP-hard problem, so

NSGA-II algorithm by Deb et al. (2002) is chosen and

mixed with simulated annealing algorithm. Its flow is

as follows:

Step 1: Coding rules and creating initial

populations, a two-segment chromosome coding

structure is adopted, the first segment is the

transportation phase, including vehicle allocation and

PC scheduling coding based on the transportation

process, and the second segment is the assembly

phase, including multi-skilled shift assignment and

PC scheduling coding based on the assembly process.

Step 2: Calculation of fitness value, in this paper,

we solve for the fitness value based on the fitness

function:

2

fit F C

σ

=

.

Step 3: Genetic operation, sorting and grading the

individuals of the population according to the non-

dominated sorting method, calculating the congestion

distance between chromosomes of the same level,

selecting the parent population using the binary

tournament selection method, and then generating a

new set of chromosomes by transferring some of the

information of the parent to the next generation by

means of crossover and mutation.

Step 4: Simulate the annealing operator search,

accepting the optimal state in the region ensures a

comprehensive search by means of probabilistic

acceptance.

5 MODEL APPLICATION

5.1 Relevant Data Processing

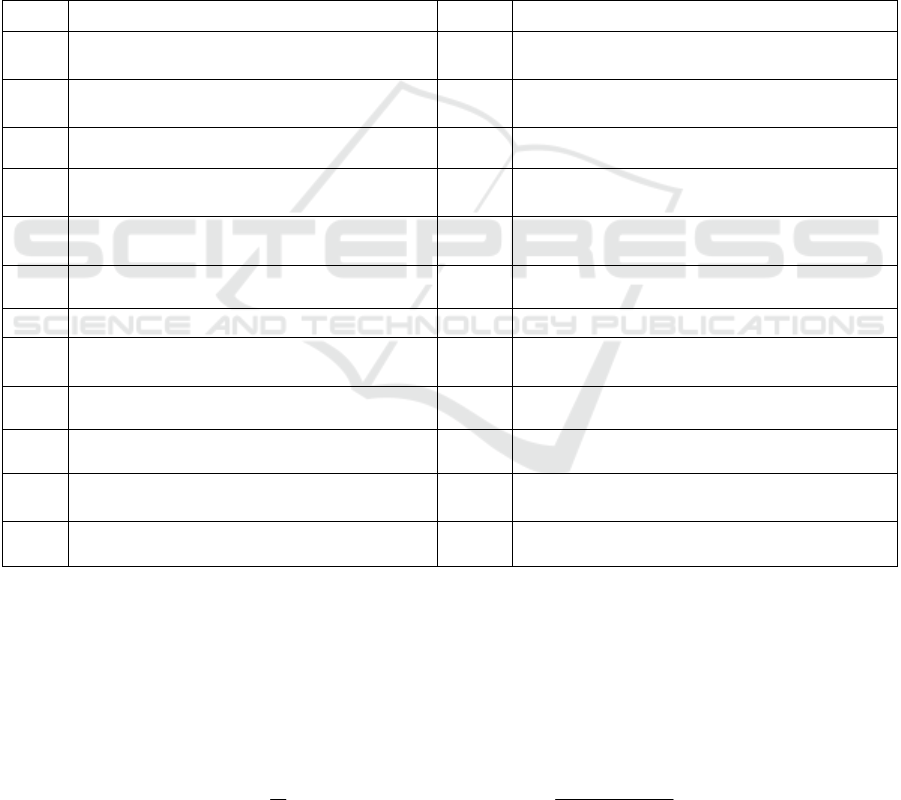

A total of 8 PC exterior walls, 5 interior walls and 11

floor slabs are required in the area. The maximum

load of the transportation trucks used is 16t, with a

total of 5 trucks, and the cost of unloading and lifting

waiting is 10 yuan/h and 60 yuan/h, respectively.

Other relevant data are shown in Table 2, and multi-

skilled team consisting of three multi-skilled workers,

whose operating coefficients are shown in Table 3.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

132

Table 2: Parameters related to PC.

Type of PC PC number

unit weight

(t)

unit of time /min Initial operating time /min

1

K

2

K

3

K

1

J

2

J

3

J

4

J

5

J

6

J

A

1

3.2

4 50 5 12 18 8 12 12 5

2 3 50 4 10 12 6 6 18 3

3 3 50 4 10 12 6 6 18 3

4 2 50 3 13 24 10 12 16 4

5 4 50 5 12 18 8 12 12 5

6 5 50 4 11 16 10 8 18 3

7 3 50 3 12 18 8 12 12 4

8 3 50 3 12 18 8 12 12 4

B

9

3

5 55 4 10 20 10 12 18 12

10 3 55 6 12 18 12 16 24 10

11 6 55 5 13 18 10 18 20 14

12 4 55 6 10 18 8 16 22 12

13 4 55 4 11 24 10 14 20 12

C

14

2.5

3 45 4 10 20 6 18 16 4

15 2 45 3 12 18 4 16 14 4

16 2 45 4 12 6 6 16 12 5

17 3 45 3 11 12 6 18 14 6

18 3 45 3 14 12 4 14 12 5

19 2 45 3 12 18 4 16 14 4

20 3 45 2 12 12 4 16 16 4

21 2 45 2 14 16 6 18 16 2

22 3 45 3 11 12 6 18 14 6

23 3 45 4 10 20 6 18 16 4

24 2 45 3 12 18 4 16 14 4

Table 3: Operational coefficients for multi-skilled teams.

Multi-skilled

teams

Operating coefficient

1

J

2

J

3

J

4

J

5

J

6

J

1 0.88

2 0.95 1.06 1.12 0.97

3 1.06 0.87 0.82

4 0.95 0.83 0.94 1.11

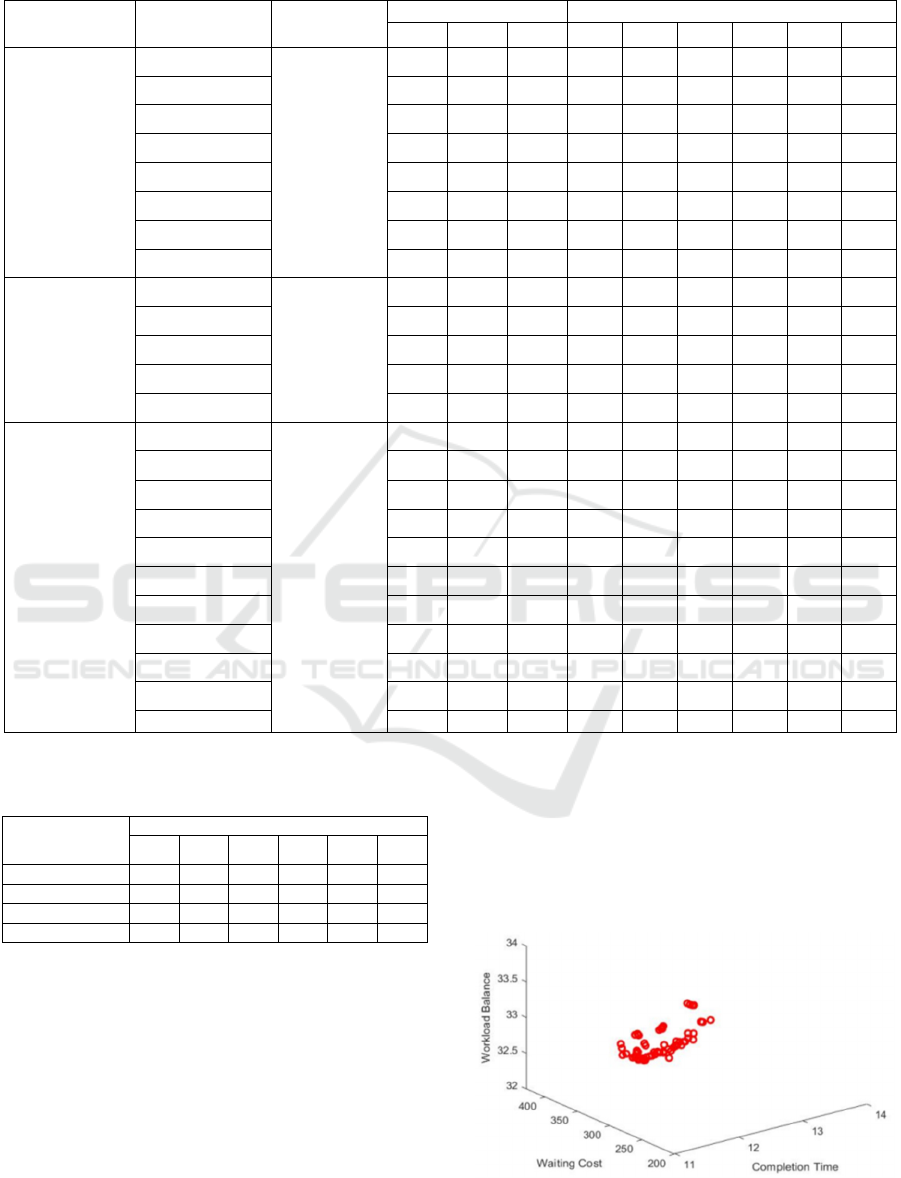

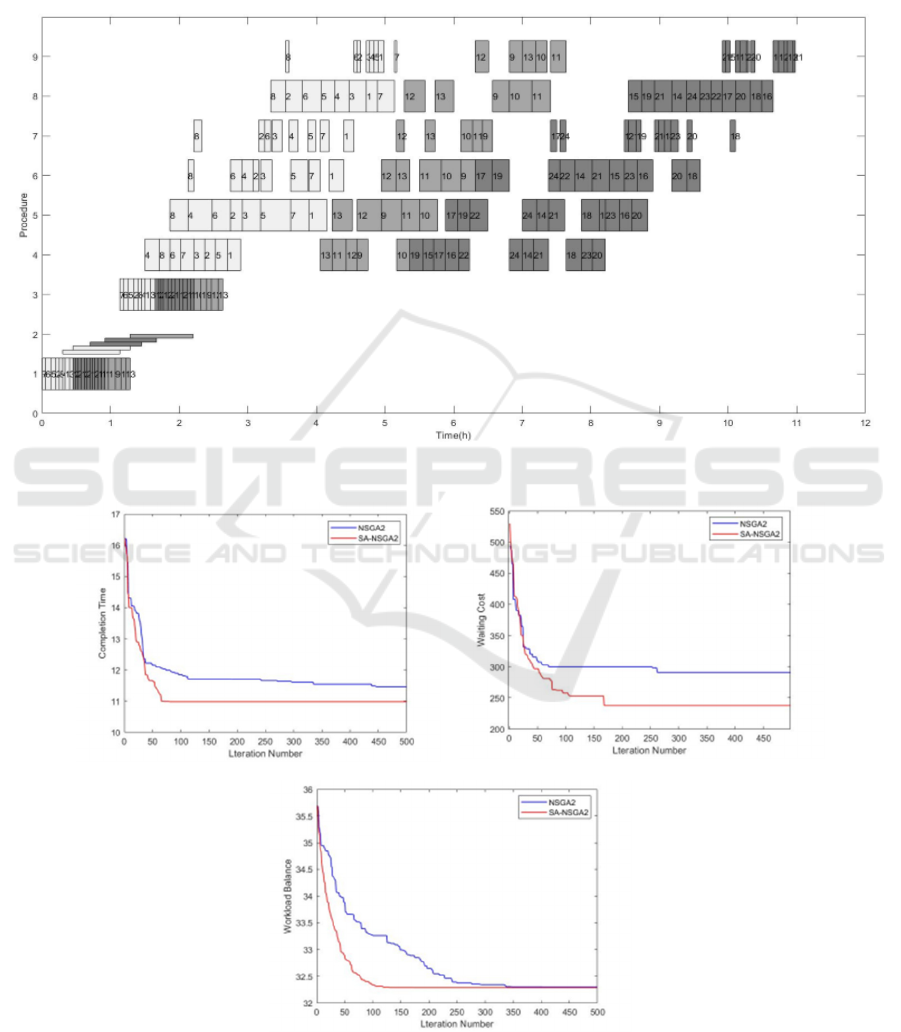

5.2 Analysis of Results

To express simply, above data unit is converted to

hour. The algorithm parameters are set as follows:

population size 80, iteration 500, crossover

probability 0.9, variance probability 0.1, annealing

temperature 100, annealing rate 0.96. The results of

the solution are shown in Figure 2. The Gantt chart

for PC is shown in Figure 3, and the corresponding

objective function values are: completion time 11.18

h, waiting cost 272.6 yuan, workload variance 33.18,

and multi-skilled teams in a set of processes

configured in the scheme 2-1-4-3-3-4. To verify the

effectiveness of the hybrid algorithm, the result is

compared with that by NSGA-II algorithm, and the

convergence of the two algorithms is shown in Figure

4.

Figure 2: Three-dimensional Pareto frontier.

Multi-Objective Optimization of Prefabricated Component Transportation-Assembly Co-Scheduling Under Small Assembly Unit

133

6 CONCLUSION

The PC co-scheduling model established in this paper

ensures the immediacy of PC assembly at the

construction site, provides methodological support

for PC co-scheduling and staffing, which is an

important direction for future construction enterprises

to develop into knowledge-based enterprises, and

verifies the effectiveness of the hybrid algorithm by

comparing it with the NSGA-II algorithm.

7-6-5-2-8

4-1-3 15-21-20-14-24-22

10-11-9-12-13

16-19-23-18-17

Figure 3: Gantt chart of the co-scheduling programme.

(

a

)

(

b

)

(c)

Figure 4: Comparison of the convergence of the two algorithms.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

134

ACKNOWLEDGEMENTS

This work is supported by Social Science Planning

Fund project of Liaoning Province (L22BGL041).

REFERENCES

Wang, H., Gong, X., Li, Y. 2023. A Construction

Scheduling Optimization of Prefabricated Buildings

Based on Improved NSGA-II Algorithm. Industrial

Engineering Journal, 26(2): 85

Xiong, F., Cao, J., Zhang, X. 2023. Integrated precast

production scheduling and loading combination with

considering time-varying characteristics of traffic

congestion. Computer Integrated Manufacturing

System, 29(8): 2761

Luo, Q, Deng, Q, Guo, X, et al. 2023. Modelling and

optimization of distributed assembly hybrid flow shop

scheduling problem with transportation resource

scheduling. Computers & Industrial Engineering, 186:

109717

Yin, J, Huang, R, Sun, H, et al. 2024. Multi-objective

optimization for coordinated production and

transportation in prefabricated construction with on-site

lifting requirements. Computers & Industrial

Engineering, 189: 110017

Wang, Z., Hao, H., Gong, J. 2018. Modeling Worker

Competence to Advance Precast Production Scheduling

Optimization. Journal of Construction Engineering and

Management, 144(11): 04018098.

Araz Nasirian, M., et al. 2019. Optimal Work Assignment

to Multiskilled Resources in Prefabricated

Construction. Journal of Construction Engineering and

Management, 145(4).

Wang, Y., Wu, L. 2021. A Research on Multi-project

Multi-skill Human Resource Scheduling Based on

Improved NSGA-II. Industrial Engineering Journal,

24(3): 130

Deb, K., Pratap, A., Agarwal, S., et al. 2002. A fast and

elitist multi objective genetic algorithm: NSGA-II.

Transactions on Evolutionary Computation, 6(2): 182-

197.

Multi-Objective Optimization of Prefabricated Component Transportation-Assembly Co-Scheduling Under Small Assembly Unit

135