Analysis of Cell Balancing Algorithms in Battery Management

System

Rohan Balesh Dodamani

a

, Rakhee Kallimani

b

and Anupama R Itagi

c

Electrical and Electronics Engineering, KLE Technological University, Dr. M S Sheshgiri Campus, Belagavi, India

Keywords: Electric Vehicles, Battery Management System, Cell Balancing, Control Algorithms.

Abstract: Environmental support for eco-friendly transportation systems have positioned electrical vehicles (EVs) as

vital tools in the fight against global warming and as effective means to reduce reliance on fossil fuels. To

achieve this, EVs depend on long life batteries supported by an advanced battery management system (BMS).

A primary task of the BMS is cell balancing, which regulates both the state of charge (SoC) and voltage of each

cell to improve the system’s efficiency, durability, safety, and lifespan. Imbalances among cells in a battery pack

often due to random connections or usage variations can lead to issues such as overcharging, undercharging,

accelerated degradation, or even pack failure. This paper explores advanced cell balancing algorithms, focusing

on SoC and voltage control methods, and smart BMS control strategies to enhance cell balancing efficiency,

contributing to the development of longer lasting EV technology.

1

INTRODUCTION

A robust BMS is crucial for the efficient operation of

electric vehicles, emphasizing monitoring, reliability

and continuous advancements to address current

challenges (Prakasha et al., 2022). In Electrical

vehicles maintaining cell balance is vital for

maximizing usable capacity, efficiency, and battery

lifespan. Typical methods include voltage and SoC

balancing, with innovations targeting imbalances in

individual cells. These advancements refine real time

detection of unbalanced cells, improving the safety,

lifespan, and overall efficiency of battery systems (Piao

et al., 2015). Cell balancing methods are crucial for

managing battery packs with multiple series cells,

especially in EVs. These techniques focus on

aligning the SoC across cells to maximize overall

functionality, enhance safety, and prolong battery life.

Various algorithms address voltage mismatches that

stem from production differences, temperature shifts,

and discharge profiles. Yet, many traditional

approaches emphasize voltage balancing without

accounting for deeper causes of imbalance, which can

reduce balancing effectiveness. A comprehensive

a

https://orcid.org/0009-0008-4504-6527

b

https://orcid.org/0000-0003-0790-024X

c

https://orcid.org/0000-0003-1105-1244

understanding of these algorithms is key to boosting

battery systems reliability and efficiency, aiding in

the broader adoption of EVs and advanced battery

technologies (Barsukov et al., 2009). lithium ion

batteries, favored for their substantial energy density,

are commonly used in EVs. Ensuring safe operating

conditions is critical, as exceeding these limits may

reduce lifespan or lead to risks like thermal runaway

(Pro¨ bstl et al., 2018).Various DC DC converter

topologies, like bidirectional Cuk and flyback

converters are essential in active cell equalization,

often achieving over high efficiency. The selection

depends on the specific design needs, with ongoing

research aimed at improving energy efficiency and

performance for reliable electric vehicle battery packs

(Miranda et al., 2023). Analyzing the algorithms

employed in DC-DC converters is essential for

enhancing efficiency, performance, and stability in a

wide range of applications. These algorithms are

generally divided into two main categories:

conventional methods and artificial intelligence-based

methods. Recent advancements have enabled the

integration of enhanced techniques that significantly

improve the performance of DC-DC converters,

Dodamani, R. B., Kallimani, R. and R Itagi, A.

Analysis of Cell Balancing Algorithms in Battery Management System.

DOI: 10.5220/0013577400004639

In Proceedings of the 2nd International Conference on Intelligent and Sustainable Power and Energy Systems (ISPES 2024), pages 97-102

ISBN: 978-989-758-756-6

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

97

especially in conductance modes and microgrid

systems (Li et al., 2017).

2

LITERATURE SURVEY

Balancing of cells is critical in BMS to preserve

SoC and voltage of the battery cells. Vibrations and

other deviations during manufacturing together with

chemical degradations can lead to cell overcharge

or deep discharges hence compromising on its

performance and its life expectancy. Depending on

its nature, balancing methods are passive or active.

Active balancing techniques like switched capacitor

and DC-DC converters (Lee et al., 2016) try to

redistribute charge for balance. On the other hand,

passive balancing techniques ensures that overcharged

cells expel energy through fixed or switchable shunt

resistors. It seeks to clearly elucidate the various

differences between active and passive strategies

(Babu and Ilango, 2022). While passive battery

balancing has its key advantages, it can be seen

disadvantageous because efficiency drops with the

surplus energy that is converted to heat in resistors.

In other words, depending on the charge level of the

cell with the lowest capacity, the capacity of the whole

system of batteries also changes and some adaptations

must be made accordingly (Deja, 2019).

Shunting resistor techniques(Daowd et al.,

2011) in passive balancing release excess energy

as heat, making them inefficient for low-power

systems. Fixed shunt resistors continuously divert

current, while switched shunt resistors enable

controlled discharge, both causing energy loss.

Active balancing (Rovianto et al., 2024) ensures

equalized currents and voltages, enhancing energy

density, reducing thermal stress, and increasing

battery life. Methods like capacitor, inductor, and

transformer based balancing (Khoshkbar-Sadigh

et al., 2021) redistribute energy using DC-DC

converters improving performance. Equalization

structures (Marcin et al., 2023)include cell-to-cell,

cell-to-battery, battery-to-cell, and bidirectional setups,

optimizing energy transfer. DC-DC converters (Verma

et al., 2013)in BMS manage voltage and current

effectively, employing advanced control techniques to

enhance reliability and system efficiency.

Figure 1: Flyback Converter

Figure 1 shows a flyback Converter with a DC

source and controller. The converter regulates power

to the load using a transformer for isolation and

voltage control. It has low conduction loss and is

cost-effective, making it an efficient solution for

energy transfer (Selvaraj and Vairavasundaram, 2023).

The control algorithm operates in conjunction with

bidirectional flyback DC-DC converter (Simcak and

Danko, 2021) to achieve efficient energy transfer and

the SoC balance among various battery cells. The

algorithm initially establishes the SoC of the battery

cells and uses the forgetting factor recursive least

square–extended Kalman filter (FFRLS-EKF)

algorithm to monitor and to estimate these SoC levels

continuously. First it determines what is the lowest

and highest SoC batteries to build an equalization

group for energy transfer. If the cell with the highest

SoC discharges directly into the cell with the lowest

SoC, the SoC of the weaker cell will increase in

the first mode of operation. To enable more efficient

energy sharing, subsequent equalization modes employ

multiple higher SoC cells discharging their energy

to lower SoC cells in order. The converter operates

according to the algorithm’s control and constantly

adjusts the energy transfer value according to the SoC

states of the cells in real time. The equalization

process is continuous, guaranteed to continue until

the SoC values are balanced within the specified

range, through continuous monitoring and dynamic

adjustment. In this work, the integration of both the

Active Cell Equalization Algorithm and bidirectional

flyback converter improves overall efficiency and

performance, while also addressing the issue of SoC

inconsistencies across the battery cells(Qin et al.,

2022).

Figure 2: Buck Boost Converter.

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

98

Figure 2 shows a buck-boost converter with a DC

source and controller that adjusts voltage based on

load requirements. These converters are compact,

efficient and ideal for applications with fluctuating

input voltages, like battery management and energy

storage (Yi and Wang, 2023). The cell balancing

algorithm uses buck-boost converters to balance the

SoC of series connected lithium ion battery cells.

Through closed loop control with PI controllers (Yeoh

et al., 2022), the algorithm switches between Buck

and Boost modes to optimize energy transfer. PWM

signals regulate switches for efficient energy transfer,

ensuring equal SoC and improving battery cycle life

and power delivery (González-Castaño et al., 2021). A

reconfigurable converter, operating as a boost

converter, is utilized in the balancing system to

manage a battery voltages. Controlled by PI

controllers (Wan et al., 2023), the boost converter

facilitates voltage synchronization across the battery

cells. In no load conditions, small signal modeling

is used to derive the control equations. Under load

conditions, a dual loop control strategy is employed,

consisting of a high bandwidth inner current loop and

a slower outer voltage loop. This strategy efficiently

balances the SoC across the cells, as demonstrated in

simulations with lithium ion batteries.

The algorithm explains the use of modified

bidirectional Cuk converters in DICM for battery cell

balancing in lithium ion battery packs. A serially

connected battery pack model with equalizers is

designed and an optimal control method based on the

conjugate gradient method (Ouyang et al., 2016) is

implemented to minimize energy loss and rapidly

reduce the differences in SoC. The algorithm controls

currents by modifying the PWM duty cycles of the

MOSFETs, ensuring optimal safety and performance.

Simulations highlight the effectiveness of this method

in achieving the quick SoC convergence with minimal

effort.

A SoC based centralized control approach for an

active balancing algorithm using a centralized DC-DC

converter system, which is a non isolated power

converter, is employed in Constant Current (CC).

Since it monitors the SoC of every battery cell

continuously in a battery pack to balance its SoC

levels, hence battery job performance and life is

improved. Our algorithm keeps the current constant

during the balancing process using SoC data, so that

energy can be redistributed efficiently among the cells.

For uniform charge distribution, cells with higher

SoC transfer excess energy to cells with lesser SoC.

A SoC based centralized control facilitates achieving

maximum energy transfer rates and minimizing energy

losses as well as protecting against over charging

or over discharging. CC mode integration provides

stable current flow, which makes the balancing

process robust, at the cost of sophisticated control

strategies and accurate SoC estimation to execute

properly(ELVIRA et al., 2019).

The proposed voltage balancing scheme

combines zero sequence signal injection (ZSI) and

Redundant Level Modulation (RLM) for a four-level

Neutral Point Clamped (NPC) converter(Wang et al.,

2020). The reference voltages of all phases are first

subjected to ZSI, then the duty ratios of the top and

bottom capacitors are adjusted based on neutral point

currents to minimize voltage deviation. RLM is

used next to control the middle capacitor voltage by

adjusting the duty cycle of the dominant phase. This

dual mechanism results in the cancellation of

capacitor voltages and reduces switching transitions,

enhancing converter efficiency and performance.

The algorithm used here is the Amortized Q-

learning (AQL) algorithm (Karnehm et al., 2024), an

enhancement of the traditional Q-learning model,

specifically designed to balance the SoC in

reconfigurable batteries. Unlike traditional Q-learning,

which faced memory limitations when controlling

more than seven modules, AQL addresses this issue,

enabling control of up to 12 modules. The approach

combines machine learning with algorithmic control,

allowing it to manage complex scenarios such as

idle

cells or safety concerns like thermal runaway.

Experimental results, tested on both a hybrid cascaded

multilevel converter and BM3 converter simulation,

validate the algorithm’s effectiveness, though it is

20.3% slower in balancing compared to previous

methods. Despite its higher computational complexity,

the AQL algorithm offers advantages, such as reduced

switching times, making it suitable for reconfigurable

battery applications in DC sources.

The battery pack utilizes a half-bridge

configuration with two complementary switches for

each cell (Sorouri et al., 2024), enabling selective

bypassing to balance the SoC and prevent rapid

discharge of low SoC cells. The architecture

integrates an Artificial Neural Network (ANN) that

actively manages the SoC by generating PWM signals.

These signals are based on the variance of each cell’s

SoC in relation to the average SoC, allowing for

efficient balancing of the battery cells. This system

models each cell as a circuit with resistor capacitor

pairs, and the ANN processes input data, adjusting the

duty cycle signals for precise control of half-bridge

switches. The objective is to minimize SoC variations

while maintaining cells within a safe operating range,

thus improving overall battery performance and

longevity.

Analysis of Cell Balancing Algorithms in Battery Management System

99

The cell balancing system uses modular low

voltage bypass DC-DC converters connected in a

series input, parallel output configuration to equalize

the SoC of battery cells and supply an auxiliary low

voltage load (Rehman et al., 2015). Each bypass

converter operates autonomously, using a PI

controller to regulate the low voltage bus voltage and

droop control to balance the SoC of the cells. The

droop control ensures stable load current sharing

without a communication links by introducing a virtual

droop resistance, which damps oscillations and

maintains system stability. The results confirm

effective SoC balancing and stable operation for a

three cell lithium ion Nickel Manganese Cobalt Oxide

battery pack.

An Adaptive Model Predictive Control balancing

algorithm (Salamati et al., 2017) is proposed to

balance cell voltages across a series connected lithium

ion battery stack and uses a multi winding flyback

converter to achieve voltage balance efficiently. First,

the voltages of each cell are measured by the central

controller, sorted from highest to lowest and the

future voltage behavior of each cell is predicted with

Recursive Least Squares identification. If the cell

voltage difference between two terminals exceeds

some defined threshold then the balancing process is

initiated. Then the controller strategically discharges

the cell with the highest voltage by turning on its

corresponding switch and calculates when the current

would reach a predefine peak. The controller divides

this discharge process into two equal stages, selecting

optimal combinations of switches for the second

and third highest voltage cells to minimize voltage

standard deviation within the stack. The method uses

the predictive models to adjust the switch states to

balance current flow and uniform SoC distribution

which results in reducing voltage differences as well

as increasing the battery performance.

This

decentralized

structure

enables

the

hybrid droop control algorithm to be effectively used

in BMS (Chowdhury and Sozer, 2020), where each

battery cell is paired with its own DC-DC converter,

enhancing reliability by removing communication

links. The algorithm employs dual droop control,

where virtual resistance is used to regulate voltage

and virtual admittance is applied to control current,

allowing for the adjustment of reference values. It

ensures SoC based power sharing, dynamically

regulates direct current bus voltage and corrects

voltage errors through closed loop control. A

controller processes current discrepancies to generate

the MOSFET gate signals, demonstrating effective

SoC equalization and suitability for distributed energy

storage systems.

The balancing algorithm works by checking the

SoC of each cell in the battery pack(Zhou et al.,

2023). A two layer controlling strategy is

implemented, whereby the first layer selects the

balancing action based on the current SoC values, and

the second layer fine tunes the control signals with

fuzzy logic to achieve the optimum path of energy

transfer between cells. The algorithm activates

corresponding switches in the converter circuits to

allow energy flow from higher SoC cells to lower

SoC ones, to maintain uniform voltage levels over all

cells. Dynamic resizing enhances battery health and

efficiency.

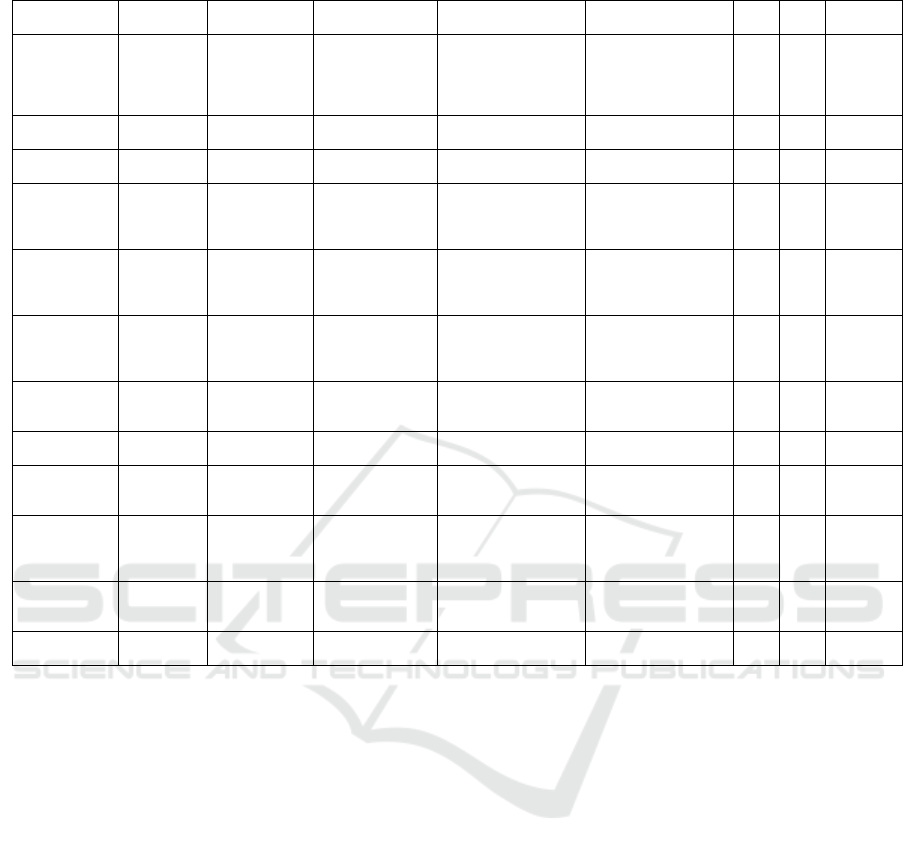

Table 1: Acronyms.

Acronym Description

EVs Electric Vehicles

BMS Battery Management System

SoC State of Charge

DC Direct Current

PI Proportional-Integral

PWM Pulse Width Modulation

MOSFET Metal Oxide Semiconductor Fiel

d

Effect Transisto

r

FFRLS-EKF Forgetting Factor Recursive Leas

t

Squares

–

Extended Kalman Filte

r

ZSI Zero-Sequence Signal Injection

AQL Amortized Q-learning

CC Constant Current

RLM Redundant Level Modulation

BM3 Battery Modular Multilevel

Managemen

t

ANN Artificial Neural Network

AMPC Adaptive Model Predictive Control

RLS Recursive Least Squares

Table 1 provides a summary of key acronyms used

in the research. Table 2 provides an analysis of various

balancing topologies and algorithms used in BMS,

focusing on both voltage and SoC balancing. The

table outlines the equalization structure, converter

types (isolated and non-isolated), algorithms and the

merits and demerits of each topology. It highlights

key factors such as efficiency, energy utilization

and control complexity. This analysis offers a

comprehensive comparison that helps in understanding

the relative strengths and weaknesses of different

methods in practical applications. By presenting this

information in a well structured manner, it provides

valuable guidance on selecting the most appropriate

technique based on factors such as cost, scalability

and compatibility with existing systems. This

overview proves to be indispensable for researchers

and engineers, aiding in the development of optimized

and robust BMS for various applications.

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

100

Table 2: Analysis of Different Balancing Structures and Algorithms in Battery Systems Based on Converters.

Balancing

Topology

Equalization

Structure

Converter Type

Algorithm

Merits

Demerits

Voltag

e

SoC

References

Flyback Converter

Cell to Cell

Isolated

FFRLS method for

model parameter

identification

EKF method for

SOC estimation

Efficient energy utilization

Advanced SOC estimation

Algorithm complexity

Dependence on accuracy

✓

(Qin et al.,

2022)

Buck-Boost

Converter

Cell to Cell

Non-Isolated

PI Controllers

PWM Control

Efficient energy transfer

Quick balancing

Complex design

High cost

✓

(Yeoh et al.,

2022)

Boost Converter

Cell to Cell

Non-Isolated

PI Control

Stable operation

Flexible operation

Energy losses in converter

Controller dependency

✓

(Wan et al.,

2023)

Cuk Converter

Cell to Cell

Non-Isolated

Optimal Control using

Conjugate Gradient

Method

Adaptive

duty

cycle

control

Optimal control

Energy loss during mode

transitions

PWM

frequency

limitations

✓

✓

(Ouyang

et al., 2016)

Power Converter

Cell to Cell

Non-Isolated

Constant Current

(CC) Mode

SOC-Based

Centralized Control

High speed Efficien

t

transfer

Control complexity

Requires precise SOC

estimation

✓

(ELVIRA

et al., 2019)

Four-Level NPC

Converter

Cell to Cell

Non-Isolated

Closed-loop balancing

with RLM Level-

shifted carrier

PWM

Wide modulation range

Simple implementation

Increased switching losses

More transitions

✓

(Wang

et al., 2020)

Half-Bridge and

BM3

Cell to Cell

Non-Isolated

Amortized

Q-learning for SOC

balancing

Combines control with

ML

Balances SOC

Slower than conventional

Memory limitations

✓

(Karnehm et

al., 2024)

Half-Bridge

Converters

Cell to Cell

Non-Isolated

Artificial Neural

Network (ANN)

ANN for SOC balancing

Optimal bypassing

Computational overhead

Reliability issues

✓

(Sorouri

et al., 2024)

Bypass Converter

(Dual

Active

Bridge)

Cell to Cell

Isolated

Combined droop

control

PI controller

Efficient

autonomous

balancing

Improved stability

Prolonged balancing

Unidirectional limit

✓

(Rehman

et al., 2015)

Flyback Converter

Cell to Cell

Isolated

AMPC for cell

equalization RLS for

voltage

prediction

Efficient

p

rediction

Improved performance

Computational complexity

Prediction reliance

✓

(Salamati et

al., 2017)

DC/DC Converter

Cell to Cell

Isolated

Non-Isolated

Hybrid Droop

Increased reliability

Effective

SOC

equalization

Complex design Paramete

r

sensitivity

✓

(Chowdhury

and Sozer,

2020)

Inductor

Converter

Cell to Cell

Non-Isolated

Fuzzy Logic

Improved efficiency

Extends lifespan

Complex strategy

Higher costs

✓

(Zhou et al.,

2023)

3

CONCLUSIONS

This paper evaluates the algorithms used in balancing

methods for BMS in electric vehicles . These

algorithms are designed to improve the energy and

optimize the dynamics of energy transfer within

battery cells. As a result, battery packs become more

reliable, durable and capable of performing

efficiently in high energy demand applications.

Balancing is enhanced through the use of advanced

DC-DC converters that regulate voltage and energy

requirements assisted by the various algorithms to

ensure efficient regulation. Choosing the right

control algorithm remains a complex task, factoring

in computational load, real time adaptability, power

consumption and application relevance. The future

advancement of battery management systems will

depend on a deeper understanding of these algorithmic

solutions, which must be further refined to achieve

optimal performance and prolong battery life.

REFERENCES

Babu, P. S. and Ilango, K. (2022). Comparative analysis

of passive and active cell balancing of li ion batteries.

In 2022 Third International Conference on Intelligent

Computing Instrumentation and Control Technologies

(ICICICT), pages 711–716. IEEE.

Barsukov, Y. et al. (2009). Battery cell balancing: What to

balance and how. Texas Instruments, pages 2–1.

Chowdhury, S. and Sozer, Y. (2020). Adaptive cell balancing

of series connected batteries using hybrid droop

controller. In 2020 IEEE Applied Power Electronics

Conference and Exposition (APEC), pages 1668–1672.

IEEE.

Daowd, M., Omar, N., Van Den Bossche, P., and Van Mierlo,

J. (2011). Passive and active battery balancing

comparison based on matlab simulation. In 2011 IEEE

Vehicle Power and Propulsion Conference, pages 1–7.

IEEE.

Deja, P. (2019). Tests of bms battery management system

with active and passive system of balancing the battery

capacity. In IOP Conference Series: Materials Science

Analysis of Cell Balancing Algorithms in Battery Management System

101

and Engineering, volume 679, page 012009. IOP

Publishing.

ELVIRA, D. G., BLAV

´

I, H. V., MONCUS

´

I, J. M. B.,

PASTOR,

A

`

.

C., CASTILLO,

J.

A.

G., and

SALAMERO, L. M. (2019). Active battery balancing

via a switched dc/dc converter: Description and

performance analysis. In 2019 16th Conference on

Electrical Machines, Drives and Power Systems

(ELMA), pages 1–6. IEEE.

Gonza´lez-Castan˜o, C., Restrepo, C., Kouro, S., Vidal-Idiarte,

E., and Calvente, J. (2021). A bidirectional versatile

buck–boost converter driver for electric vehicle

applications. Sensors, 21(17):5712.

Karnehm, D., Bliemetsrieder, W., Pohlmann, S., and Neve,

A. (2024). Controlling algorithm of reconfigurable

battery for state of charge balancing using amortized q-

learning. Batteries, 10(4):131.

Khoshkbar-Sadigh, A., Dargahi, V., Khorasani, R. R.,

Corzine, K. A., and Babaei, E. (2021). Simple active

capacitor voltage balancing method without cost

function optimization for seven-level full-bridge flying-

capacitor-multicell inverters. IEEE Transactions on

Industry Applications, 57(2):1629–1643.

Lee, Y., Jeon, S., Lee, H., and Bae, S. (2016).

Comparison on cell balancing methods for energy

storage applications. Indian Journal of Science and

Technology, 9(17):92316.

Li, B., Xu, C., Lib, C., and

Guan, Z.

(2017). Working

principle analysis and control algorithm for

bidirectional dc/dc converter. Journal of Power

Technologies, 97(4).

Marcin, D., Lacko, M., Bodna´r, D., Pancura´k, L., and Stach,

L. (2023). Overview of active balancing methods and

simulation of capacitor based active cell balancing for

battery pack in ev. In 2023 International Conference on

Electrical Drives and Power Electronics (EDPE),

pages 1–8. IEEE.

Miranda, J. P., Barros, L. A., and Pinto, J. G. (2023). A

review on power electronic converters for modular bms

with active balancing. Energies, 16(7):3255.

Ouyang, Q., Chen, J., Xu, C., and Su, H. (2016). Cell

balancing control for serially connected lithium-ion

batteries. In 2016 American control conference (ACC),

pages 3095–3100. IEEE.

Piao, C., Wang, Z., Cao, J., Zhang, W., and Lu, S. (2015).

Lithium-ion battery cell-balancing algorithm for battery

management system based on real-time outlier

detection. Mathematical problems in engineering,

2015(1):168529.

Prakasha, G., Kumar, S. S., Kumar, K. S., Darshan, A., and

Venkatesha, G. (2022). Electric vehicle battery power

management system analysis. In 2022 International

Interdisciplinary Humanitarian Conference for

Sustainability (IIHC), pages 1179–1183. IEEE.

Pro¨ bstl, A., Park, S., Narayanaswamy, S., Steinhorst, S.,

and Chakraborty, S. (2018). Soh-aware active cell

balancing strategy for high power battery packs. In

2018 design, automation & test in europe conference &

exhibition (DATE), pages 431–436. IEEE.

Qin, D., Qin, S., Wang, T., Wu, H., and Chen, J. (2022).

Balanced control system based on bidirectional flyback

dc converter. Energies, 15(19):7226.

Rehman, M. M. U., Zhang, F., Evzelman, M., Zane, R.,

and Maksimovic, D. (2015). Control of a series-

input, parallel-output cell balancing system for

electric vehicle battery packs. In 2015 IEEE 16th

Workshop on Control and Modeling for Power

Electronics (COMPEL), pages 1–7. IEEE.

Rovianto, E., Khairunnisa, B. W. L., Fardan, M. F., Harsito,

C., and Prasetyo, A. (2024). Balancing the charge: the

evolution of battery active equalizers in shaping a

sustainable energy storage future. International

Journal of Power Electronics and Drive Systems

(IJPEDS), 15(3):1687–1710.

Salamati, S. M., Salamati, S. A., Mahoor, M., and

Salmasi,F. R. (2017). 31. leveraging adaptive model

predictive controller for active cell balancing in li-ion

battery.

Selvaraj,

V. and Vairavasundaram,

I. (2023). Flyback

converter employed non-dissipative cell equalization

in electric vehicle lithium-ion batteries. e-Prime-

Advances in Electrical Engineering, Electronics and

Energy, 5:100278.

Simcak, M. and Danko, M. (2021). 11. simulation

verification of balancing system based on number of

cells. Communications.

Sorouri, H., Oshnoei, A., and Teodorescu, R. (2024).

Intelligent cell balancing control for lithium-ion battery

packs. In IPEMC 2024-ECCE Asia-10th International

Power Electronics and Motion Control Conference-

ECCE Asia.

Verma, S., Singh, S., and Rao, A. (2013). Overview of

control techniques for dc-dc converters. Research

Journal of Engineering Sciences ISSN, 2278:9472.

Wan, G., Zhang, Q., Li, M., Li, S., Fu, Z., and Liu, J. (2023).

Balancing strategy for battery systems based on

reconfigurable converters.

Wang, J., Yuan, X., and Jin, B. (2020). Carrier-based

closed-loop dc-link voltage balancing algorithm for

four level npc converters based on redundant level

modulation. IEEE Transactions on Industrial

Electronics, 68(12):11707–11718.

Yeoh, S. H., Pok, C. Y., Lum, K. Y., and Yiauw, K. H. (2022).

Active cell balancing with dc/dc converter for electric

vehicle. In 2022 10th International Conference on

Smart Grid and Clean Energy Technologies (ICSGCE),

pages 39–45. IEEE.

Yi, F.

and

Wang, F.

(2023). Review of

voltage-bucking/boosting techniques, topologies, and

applications. Energies, 16(2):842.

Zhou, L., Li, J., Jiang, L., Xu, X., Zhao, W., Cheng, B., Liu,

Y., Su, X., and Zou, G. (2023). Battery state of charge

and temperature equalization algorithm based on fuzzy

control. In 2023 3rd International Conference on New

Energy and Power Engineering (ICNEPE), pages 925–

929. IEEE.

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

102