Design of Energy-Efficient Switched Reluctance Motor Using ANSYS

Software

S. Bhuvaneswari

a

, R. Ramya

b

and V. Srimathi

c

S. A. Engineering College, Anna University, Avadi Road, Tamil Nadu, India

Keywords: Switched Reluctance Motor (SRM), Energy-Efficient Motor Design Finite Element Analysis (FEA) ANSYS

Maxwell, Electromagnetics.

Abstract: This research presents the design of an energy-efficient Switched Reluctance Motor (SRM) using ANSYS

software, aiming to optimize performance and reduce energy consumption. The SRM is recognized for its

robust construction and high efficiency, making it suitable for various applications in electric vehicles and

industrial automation. Switched reluctance motor (SRM’s) are particularly gaining attention in the EV world

for their advantages over traditional motors, such as higher reliability, low material cost, high motor-drive

efficiency. Electric Vehicles (EVs) driven by electric motor reduces the usage of fossil fuel. The model shows

considerable improvement in efficiency and reduction in torque ripple.

1 INTRODUCTION

The Switched Reluctance Motor (SRM) has gained

significant attention in recent years due to its inherent

advantages, such as simplicity, robustness, and high

torque-to-weight ratio. With the growing demand for

energy-efficient solutions in various sectors,

including electric vehicles and renewable energy

systems, optimizing the design of SRMs has become

crucial. Traditional electric motors often face

challenges related to energy losses, inefficiencies,

and thermal management.

This study focuses on enhancing the performance

of SRMs through innovative design strategies using

ANSYS software, a powerful tool for finite element

analysis (FEA). By simulating electromagnetic fields

and analyzing thermal and mechanical stresses, we

aim to refine motor parameters such as rotor shape,

stator configuration, and winding techniques. The

goal is to minimize energy losses, improve efficiency,

and ensure reliable operation across a range of

applications.

In this paper, a phase radial force shaping method

is proposed by using harmonic content analysis. A

generic function for the radial force shape is

identified, whose parameters are calculated by an

a

https://orcid.org/0000-0003-2128-9459

b

https://orcid.org/0000-0008-4155-3310

c

https://orcid.org/0000-0002-5717-1946

optimization algorithm to minimize the torque ripple

for a given average torque. From the phase radial

force profile, a current reference is obtained. The

proposed methodology is experimentally validated

with a four-phase 8/6 SRM through acoustic noise

measurements at different speed and load conditions

(Emadi A, 2019).

A new method to detect the initial rotor position

of switched reluctance machine (SRM) is presented

in this article. Unlike most conventional position

estimation methods, the proposed method does not

need any extra premeasurement and only the data

with finite element method (FEM) are required. First,

a linear regression model (LRM) is presented to

describe the relationship between FEM and measured

inductance characteristics.

Then, to detect the position, the residual sum of

squares of the proposed LRM is considered as an

objective function, which is a convex function with

rotor position. The rotor position can be estimated by

minimizing the objective function with the golden-

section search method. Finally, the accuracy of the

proposed estimation algorithm is validated by the

experimental results on a three-phase 12/8 pole SRM

prototype (Bilgin, 2019).

40

Bhuvaneswari, S., Ramya, R. and Srimathi, V.

Design of Energy-Efficient Switched Reluctance Motor Using ANSYS Software.

DOI: 10.5220/0013575400004639

In Proceedings of the 2nd International Conference on Intelligent and Sustainable Power and Energy Systems (ISPES 2024), pages 40-45

ISBN: 978-989-758-756-6

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

2 DESIGN OF SWITCHED

RELUCTANCE MOTOR

This design approach outlines the steps necessary to

create a 4-phase, 8-pole switched reluctance motor

tailored to your specifications. Each aspect, from

geometry to control strategies, is critical to ensure

efficient operation and desired performance

characteristics.

Here's a detailed design outline for a 4-phase

switched reluctance motor (SRM) with the given

specifications.

2.1 Design Specifications

The following is the design specification of the SRM

motor.

• Phase Count: 4

• Stator Poles: 8

• Rotor Poles: 6 (common choice for 8 stator

poles)

• Phase Resistance (R): 0.96 Ω

• Aligned Inductance (L_aligned): 120 mH

• Unaligned Inductance (L_unaligned): 14

mH

• Phase Current (I_phase): 8 A

• Maximum Phase Voltage (V_max): 400 V

• Torque Inertia (J): 0.053 kg·m²

• Viscous Damping Coefficient (b): 0.008 N·

m·s

• Maximum Speed: 1500 RPM

• Power Output: 5.5 HP (approximately 4.1

kW).

2.2 Motor Geometry

Rotor Configuration is set to 6 poles so to maintain a

good balance with 8 stator poles. Stator and Rotor

Dimensions: The stator is designed with 8 evenly

spaced teeth. The rotor has 6 corresponding poles,

shaped to minimize air gap and enhance magnetic

interaction. The outer diameter, inner diameter, and

length of the stator and rotor based on the power

requirements and thermal considerations are

determined.

2.3 Magnetic Circuit Design

Core Material: Laminated silicon steel for both stator

and rotor to minimize eddy current losses is used.

Air Gap: Air gap is designed so as to optimize

torque production while minimizing losses.

Winding Configuration: Each stator pole will

have a winding. The number of turns can be

calculated based on the desired inductance and

phase current.

Turn Calculation:

Where L = inductance (H)

N = number of turns

μ = permeability of the core material

A = cross-sectional area of the core

(m²)

g = air gap (m)

2.4 Torque Calculation

The average torque can be calculated using the

following formula:

(2)

Where:

T = torque (N-m)

P = power (W) = 4.1 kW

ω = angular speed (rad/s)

For a maximum speed of 1500 RPM:

2.5 Control Strategy

Commutation: Use a microcontroller or FPGA to

manage the switching of phases based on rotor

position. This requires feedback mechanisms like

encoders or resolvers for precise rotor position

sensing.

Current Control: Implement a PWM strategy to

control the phase current, ensuring it stays at 8 A

while avoiding saturation.

2.6 Thermal Management

Ensure adequate cooling by either natural convection

or forced air cooling methods. Calculate the heat

dissipation based on power losses using:

(5)

Design of Energy-Efficient Switched Reluctance Motor Using ANSYS Software

41

2.7 Simulation and Prototyping

Finite element analysis (FEA) software to simulate

magnetic fields, torque production, and thermal

behaviour is used and the design is validated with a

prototype and refining the design can be done as

necessary.

2.8 Testing and Optimization

The efficiency is evaluated by performing the tests

and thermal performance, torque ripple is also

obtained. The design can be optimized based on the

test results.

2.9 Geometry Specifications

The SRM motor geometry specifications are given in

Table 1.

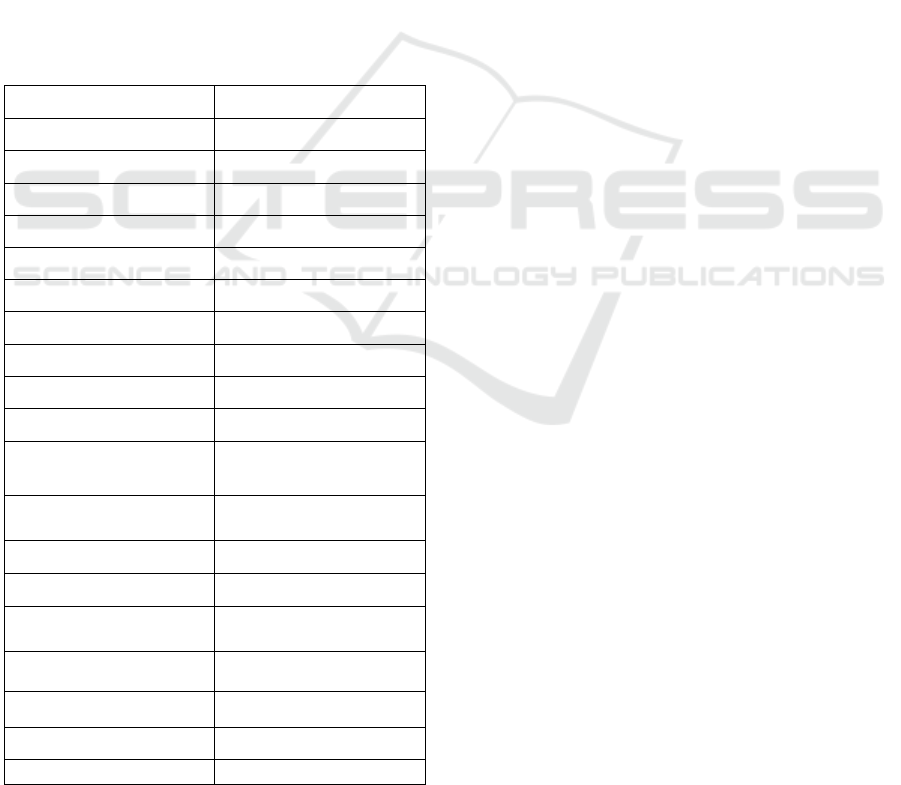

Table 1: Summary of Geometry Specifications.

PARAMETER

VALUE

Stator outer diameter

150mm

Stator inner diameter

100mm

Stator height

50mm

Rotor outer diameter

100mm

Rotor inner diameter

50mm

Rotor height

50mm

Air gap

1mm

Tooth Width

5mm

Tooth height

20mm

Slot depth

10mm

Phase resistance

0.96Ω

Aligned inductance

120 mH

Unaligned inductance

1204 mH

Phase current

8amps

Maximum phase

voltage

400V

Torque inertia

0.053 kg.m

2

Damping coefficient

0.008 nms

Maximum speed

1500 rpm

Power

5.5 Hp 4.1 kw

This geometric outline provides a solid foundation for

designing and building the switched reluctance motor,

ensuring optimal performance and efficiency based on

the specified operational parameters.

3 SIMULATION PROCEDURE

The proposed system aims to design an energy-

efficient Switched Reluctance Motor (SRM) utilizing

advanced simulation capabilities offered by ANSYS

software. The design process will encompass several

key stages, beginning with the selection of optimal

rotor and stator geometries to enhance torque density

and efficiency. By employing finite element analysis

(FEA), we will simulate the electromagnetic

performance, focusing on minimizing losses

associated with magnetic hysteresis and eddy

currents. The system includes the following features:

1. Geometric Optimization: Iterative design

adjustments to rotor and stator configurations to

achieve the best performance metrics.

2. Electromagnetic Analysis: Comprehensive

simulations to evaluate the motor’s magnetic

field distribution and torque characteristics

under various operating conditions.

3. Thermal Management: Assessment of thermal

behavior through heat dissipation analysis,

ensuring reliable operation and longevity of the

motor.

4. Performance Validation: Comparison of

simulation results with experimental data to

validate the design’s efficiency and

effectiveness.

By integrating these elements, the proposed

system aims to produce a high-performance SRM that

meets the growing demands for energy efficiency

while addressing the challenges faced by traditional

motor designs. This innovative approach is expected

to lead to significant advancements in motor

technology.

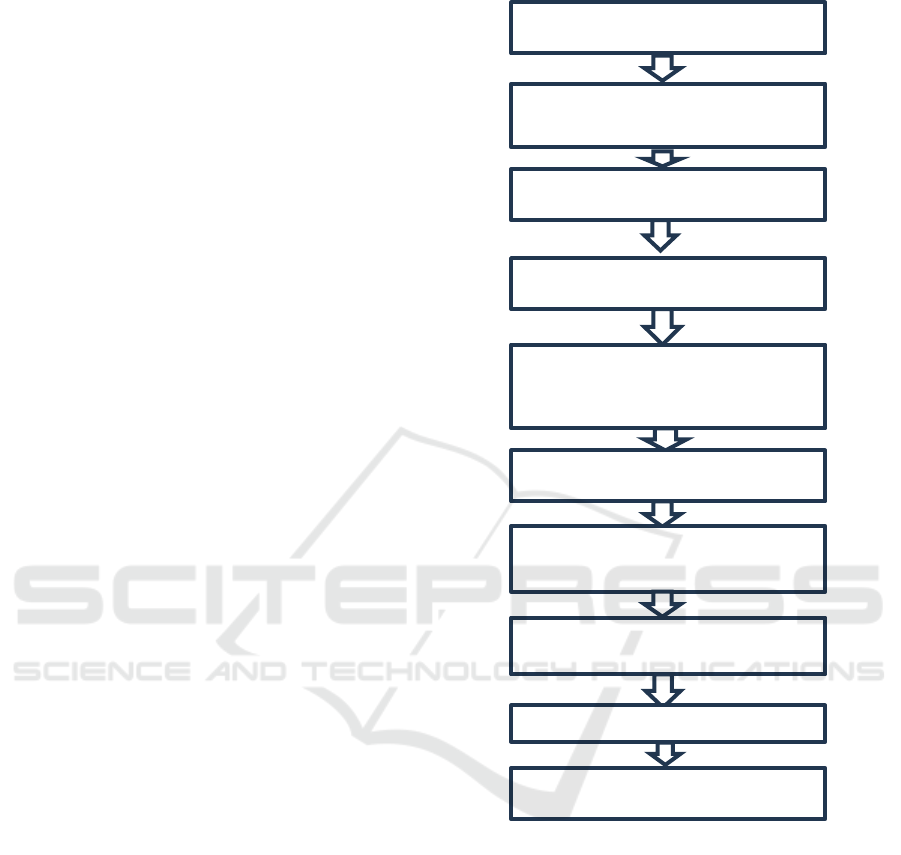

3.1 Motor Design Procedure

These steps can be used to design a motor in ANSYS.

It is explained using the following flowchart shown

in Figure 1.

This method makes use of ANSYS Maxwell,

which is especially well-suited for motor design and

electromagnetic field simulation.

Define the project in step 1.

Create a new project in ANSYS Maxwell.

Depending on your motor design requirements, select

between the 2D or 3D model. More complex

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

42

geometries require 3D design, while most motors are

often developed in 2D.

To set up the workspace for motor design, choose

the "Electromagnetic" or "Motor template”. Establish

the Design Environment

Step 2: Specify the unit of measurement is mm

cm, inches etc.

Select each motor component's material from the

ANSYS library, or import your own if necessary. Set

up any extra parameters, like temperature, if thermal

analysis

Create the motor geometry in Step 3.

Draw your motor's fundamental geometry using

the sketch tools, beginning with the stator, rotor, and

slots.

For simpler modifications, parameterize important

dimensions (such as the slot geometry, rotor diameter,

and stator inner and outer diameters).

Make sure the components are properly aligned

and spaced apart.

Assign Material Properties in Step 4.

Assign materials to each component of the motor,

such as copper for the windings and steel for the stator

and rotor.

Use characteristics such as conductivity and

magnetic permeability, which are essential for precise

electromagnetic analysis.

Step 5: Establish Boundary Conditions and

Excitations. Define the stator's coil windings and

configure voltage or current excitations as necessary.

Set boundary constraints such as "Periodic" or

"Symmetry" to streamline the model and cut down on

computation.

Configure the simulation setup in Step 6.

Figure 1: Motor design in Ansys.

Configure the type of solver. Because it takes

time-dependent magnetic fields into account, the

Transient Magnetic Solver is frequently used for

motor design.

Establish the rotor's motion parameters, such as its

starting position and rotating speed.

Mesh the model in step 7.

To guarantee fine meshing in crucial regions,

particularly close to the air gap between the stator and

rotor, use automatic or manual meshing.

Verify the mesh quality because a finer mesh

produces more accurate results but requires more

computing time.

Step 8: Execute the Simulation

Launch the simulation and track its development.

Design of SRM

Determination of initial

Geometry

Selection of material

Analysis of the

electromagnetic

Post processing to calculate

static characteristics of the

machine

Static requirement

Winding configuration and

control strategy

Dynamic performance of the

SRM

Dynamic requirement

End

Design of Energy-Efficient Switched Reluctance Motor Using ANSYS Software

43

After the simulation is finished, look for any faults or

warnings in the solution configuration.

Step 9: Examine the Outcomes

To comprehend the electromagnetic behaviour, go

over vector plots, flux lines, and magnetic field

distributions.

To assess motor performance and efficiency, measure

torque, back-EMF, core losses, and other

performance metrics.

Modify the design parameters and execute the

simulation again if the motor does not satisfy

performance requirements.

Step 10: Design Optimization (Optional)

Automate parameter sweeps with ANSYS's

optimization tools to increase torque or motor

efficiency.

Establish goals and limitations for the design, then

allow the software to suggest the best changes.

Step 11: Complete the Model

Complete the motor design if the results are

satisfactory.

Export the simulation results, mesh, and geometry for

use in physical prototyping or additional analysis.

This procedure ought to provide ANSYS motor

design a solid basis.

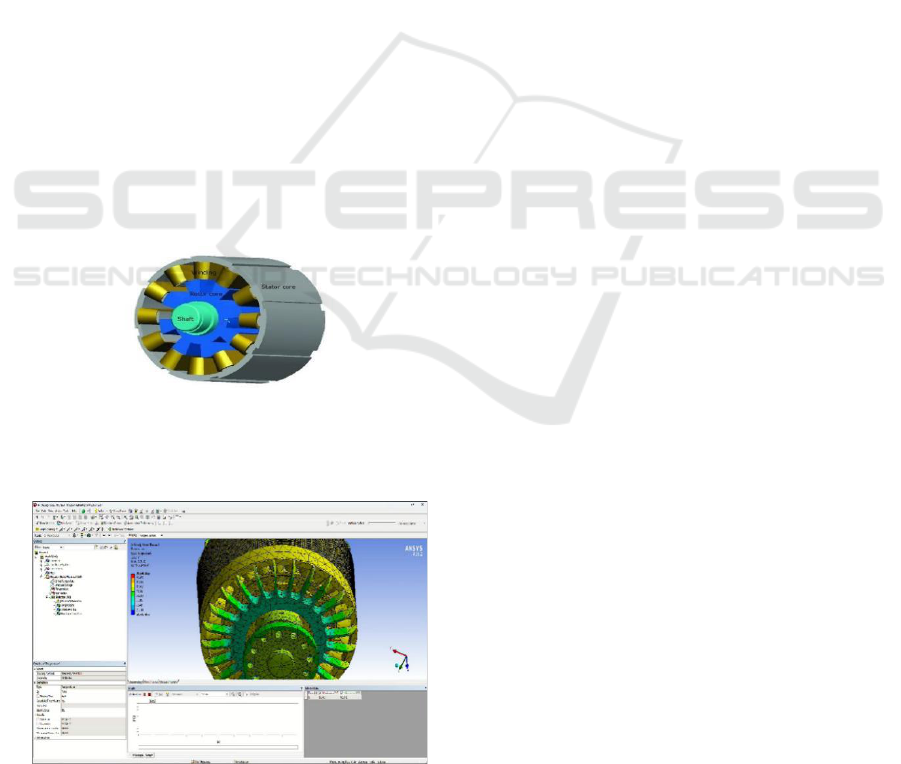

3.2 Motor Structure

The motor designed in Ansys is shown in Figure 2.

Figure 2: Motor structure.

3.3 Results and Discussion

Figure 3: Mesh distribution.

The finite element analysis and mesh

distribution is shown in Figure 3.

The simulation process typically involves

creating a detailed geometric model of the motor,

defining material properties, and setting up boundary

conditions. Using ANSYS Maxwell, engineers can

perform electromagnetic analysis to visualize flux

distributions and predict performance metrics such as

torque ripple and efficiency

By integrating these analyses, users can optimize

the design of SRMs for specific applications,

balancing factors like cost, performance, and

reliability. The ability to simulate various operating

conditions also aids in troubleshooting and improving

existing motor designs.

With an emphasis on crucial parameters including

magnetic flux density, torque output, back-EMF,

losses, and efficiency, the motor simulation in

ANSYS Maxwell offered a thorough examination of

the electromagnetic and thermal performance. The

main conclusions are summarized as follows:

Performance of Electromagnetics:

Magnetic Flux Density: To prevent saturation and

guarantee effective magnetic coupling, the flux

distribution in the stator and rotor stays within the

core material limits. On the other hand, minor

fluctuations close to the stator poles point to possible

regions for flux uniformity optimization.

Torque Output: The motor operates smoothly by

achieving a maximum torque within the design

parameters with little torque ripple. Any slight torque

ripple that is seen falls within the application's

permitted bounds.

Back-EMF: By matching the intended speed and

control parameters, the back-EMF profile verifies that

the motor will operate effectively under the intended

conditions.

Losses and Efficiency:

Core and Copper Losses: Core losses remain

moderate, attributed to optimized material selection

and design geometry. Copper losses are controlled,

though minor adjustments in winding resistance may

further reduce these losses.

Efficiency: The motor achieves a high efficiency

rate, indicating a well-balanced design with minimal

energy loss. This efficiency aligns with project

specifications and sustainable operation goals.

Temperature Distribution: The temperature

profile indicates a few hotspots near the windings, but

they are manageable within the designed cooling

system. Ensuring robust cooling or adjusting winding

material may further enhance thermal stability.

Structural Integrity: Force density analysis shows

the rotor and stator are structurally sound under

expected loads, confirming mechanical stability and

durability.

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

44

4 CONCLUSIONS

In this paper, the design and simulation of an energy-

efficient Switched Reluctance Motor using ANSYS

demonstrate significant improvements in

performance. ANSYS provided valuable insights into

the motor's magnetic characteristics and efficiency

through detailed FEA, while MATLAB allowed for

the validation of the motor’s dynamic behavior under

real-world conditions.

The findings indicate that with optimized design

parameters, the SRM can achieve high torque with

low energy losses. The control strategies developed

enhance the efficiency further, making SRMs a viable

option for various applications, including electric

vehicles and industrial drives. Future work could

involve refining the design based on experimental

data and exploring advanced control algorithms for

improved performance.

REFERENCES

Ramamurthy, S.S., Balda, J.C., (2020). Sizing a switched

reluctance motor for electric vehicles. IEEE

Transactions on Industrial Electronics, 37(1), pp. 45–

54.

Kjaer, P.C., Gribble, J., Miller, T.J.E., (2021). High-grade

control of switched reluctance machines. IEEE

Transactions on Industrial Electronics, 33(11), pp.

1585–1593.

Choi, C., Kim, S., Kim, Y., Park, K., (2022). A new torque

control method of a switched reluctance motor using a

torque-sharing function. IEEE Transactions on

Magnetics, 38(51), pp. 3288–3290.

Russa, K., Husain, I., Elbuluk, M.E., (2022). Torque ripple

minimization in switched reluctance machines over a

wide speed range. IEEE Transactions on Industry

Applications, 34(5), pp. 1105–1112.

Ding, W., Fu, H., Hu, Y., (2018). Characteristics

assessment and comparative study of a segmented-

stator permanent-magnet hybrid-excitation SRM drive

with high-torque capability. IEEE Transactions on

Industrial Electronics, 33(1), pp. 482–500.

Callegaro, A.D., Bilgin, B., Emadi, A., (2019). Radial force

shaping for acoustic noise reduction in switched

reluctance machines. IEEE Transactions on Power

Electronics, 34(10), pp. 9866–9878.

Li, H., Bilgin, B., Emadi, A., (2019). An improved torque

sharing function for torque ripple reduction in switched

reluctance machines. IEEE Transactions on Power

Electronics, 34(2), pp. 1635–1644.

Ge, L., Xu, H., Guo, Z., Song, S., De Doncker, R.W.,

(2021). An optimization-based initial position

estimation method for switched reluctance machines.

IEEE Transactions on Power Electronics, 36(11), pp.

13285–13292.

Design of Energy-Efficient Switched Reluctance Motor Using ANSYS Software

45