Ecobot: Autonomous Trash Collection and Segregation System

Harshitha M

a

, Madhurithu T

b

, Mohamed Yousuf

c

, Nikhilesh Singh

d

and Deekshitha Arasa

e

Department of Electrical and Electronics, Dayananda Sagar College of Engineering, Kumaraswamy Layout,

Bengaluru, Karnataka, India

Keywords: Autonomous Garbage Collector, Trash Collector, Trash Segregator, Machine Learning, Sustainable Waste

Management.

Abstract: The rapid growth of urbanization, economic development and population has led to a significant global

garbage crisis, causing severe environmental and health issues. Traditional waste management systems

struggle to manage the increasing volume of waste effectively. This paper presents an innovative solution; an

autonomous trash collection and segregation system designed to operate within defined areas. Utilizing

robotics and machine learning, the system is built around a Raspberry Pi to navigate autonomously, collect

garbage and segregate waste efficiently. This system aims to enhance the sustainability and efficiency of

waste management practices, aligning with global efforts towards smart cities and technology-driven

improvement in quality of life.

1 INTRODUCTION

The exponential increase in waste generation due to

technological advancements and changing lifestyles

has created a pressing need for efficient waste

management systems. Ineffective waste disposal

contributes to environmental pollution and health

hazards. Existing solutions, such as trash segregators

and collectors with predefined navigation, address the

problem partially but often lack the ability to integrate

collection and segregation seamlessly. To bridge

these gaps, we propose an autonomous garbage

collection and segregation system designed to operate

in predefined areas such as indoor floors, pathways,

and other controlled environments. This system

leverages modern technology to collect and segregate

trash efficiently, providing a sustainable solution to

an age-old problem and supporting smart waste

management initiatives.

a

https://orcid.org/0009-0001-8719-1094

b

https://orcid.org/0009-0005-4741-1258

c

https://orcid.org/0009-0008-2828-1728

d

https://orcid.org/0009-0009-0759-1345

e

https://orcid.org/0009-0009-9197-396X

2 LITERATURE SURVEY

The paper (Sengupta et al., 2019) proposes an

autonomous system whose navigation can be

controlled by the regional corporate office through a

website or an application. The robot identifies the

filled trash bins, lifts it, empties the bin and replaces

a new bin in the spot.

The paper (Bharathi et al., 2018) explains how the

authors build a trash collecting robot. The robot first

detects for an object during its run using sonar. The

picture of object is then captured for detection as a

trash or not with DNN algorithm. The object detected

as trash is picked up and dropped into bin.

The paper (Jinquiang et al., 2018) presents

another method of trash collecting set-up. The object

detection is done using ultrasonic sensor. The image

captured by pi-cam is sent to server via TCP/IP

protocol, being a client. The server uses Fast ANN

algorithm to classify the object as a garbage or not,

and according the robot picks it, else follows the path.

M, H., T, M., Yousuf, M., Singh, N. and Arasa, D.

Ecobot: Autonomous Trash Collection and Segregation System.

DOI: 10.5220/0013575200004639

In Proceedings of the 2nd International Conference on Intelligent and Sustainable Power and Energy Systems (ISPES 2024), pages 29-34

ISBN: 978-989-758-756-6

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

29

The paper (Parashar and Tomar, 2018) has a

moving bin that takes a pre- defined path and stops at

every house bin. They use RFID technology for

communication. If house bin is detected full through

ultrasonic sensor, its opening mechanism puts out the

trash into moving bin, else moving bin moves

forward. The paper (R and V, 2018) uses a GPS,

vehicle odometer and IMU sensor for robot location

status. The path-planning, image-processing and

obstacle detection are all performed by CPU. Trash

classification is done by GPU. CPU controlled

manipulator picks the trash and driver controls

motors. The paper (D et al., 2018) has a moving bin

that collects the garbage from the house bins notified

by IR sensor in the house bin. Both bins communicate

through RF signal, controlled by Arduino. The

moving bin moves on pre- defined path; it collects the

trash and dumps it to the dumping station. In the paper

(Varuneshreddy and Nikhil, 2018), the robot is a trash

can-collecting system that takes a designated path.

The robot differentiates a can when its breadth is

found less than specified breadth using IR sensor. The

2-DOF arm picks the trash and dumps it in the bed.

The paper (Ulu and Radha, 2017) gives the

information about a trash collector designed for

beaches. It uses an IP camera for object detection with

PIC.

3 PROPOSED FORMULATIONS

The existing situation of waste management is

lagging behind in consideration to the amount of

waste generated. Moreover, the involvement of

workers in the garbage collection, transportation and

other operations increase the rate of risking their

health. There also exists another drawback that, the

waste at places with untidy environment cannot be

cleaned by creating threat to human health. The post

operations in garbage management, segregation is

also a tough task without proper co-ordination and

response from individuals. Therefore, it is now

important to include and expand the technological

factors in the matter of waste management in all

aspects, along with addressing the issues.

3.1 Garbage Detection

The system is structured in such a way that the camera

locates the trash on its way of navigation. This task is

performed with the help of ML algorithm and image

processing, by classifying objects and trash on the

path.

3.2 Garbage Collection

The system on identifying trash on path, it moves

towards the trash and picks it up using a robotic arm.

3.3 Garbage Segregation

The same system while capturing the frame of trash,

uses the algorithm and image processing technique to

decide whether the trash detected is biodegradable or

non-biodegradable. The arm accordingly makes its

movement and drops the trash into the respective

trash bin.

3.4 Autonomous Navigation

The robot is capable of making self - navigation

movement with the help of GPS (Global Positioning

System) and magnetometer on most of the hard land

regions with single initial positioning definition and

no human intervention.

4 METHODOLOGY

The Raspberry Pi (Raspberry Pi 4 Model B)

microcontroller is the main task controller for the

whole system. The system first starts its movement

from the initial position set with help of GPS. The

robot then continues its motion in the forward

direction with help of GPS and magnetometer. The

system ensures to avoid obstacles using ultrasonic

sensors placed in front. The model continues its

motion otherwise. All the movements of the robot are

assisted by the Steering and DC motors. The model

on its way of motion, examines for any kind of object

nearby using the Pi- Camera. If an object is detected,

the Pi-Camera sends the image to the Raspberry-Pi.

The ML algorithm of trash identification available on

the microcontroller checks for whether the object

detected is a trash or not. If the object is found to be a

trash. The algorithm further performs classification to

recognize whether the trash is a biodegradable or non-

biodegradable one. These inputs from Pi-Camera can

be sorted as trash identification data and trash

categorization data. The Raspberry Pi uses the data of

trash identification data to decide the motion of the

robot towards trash.

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

30

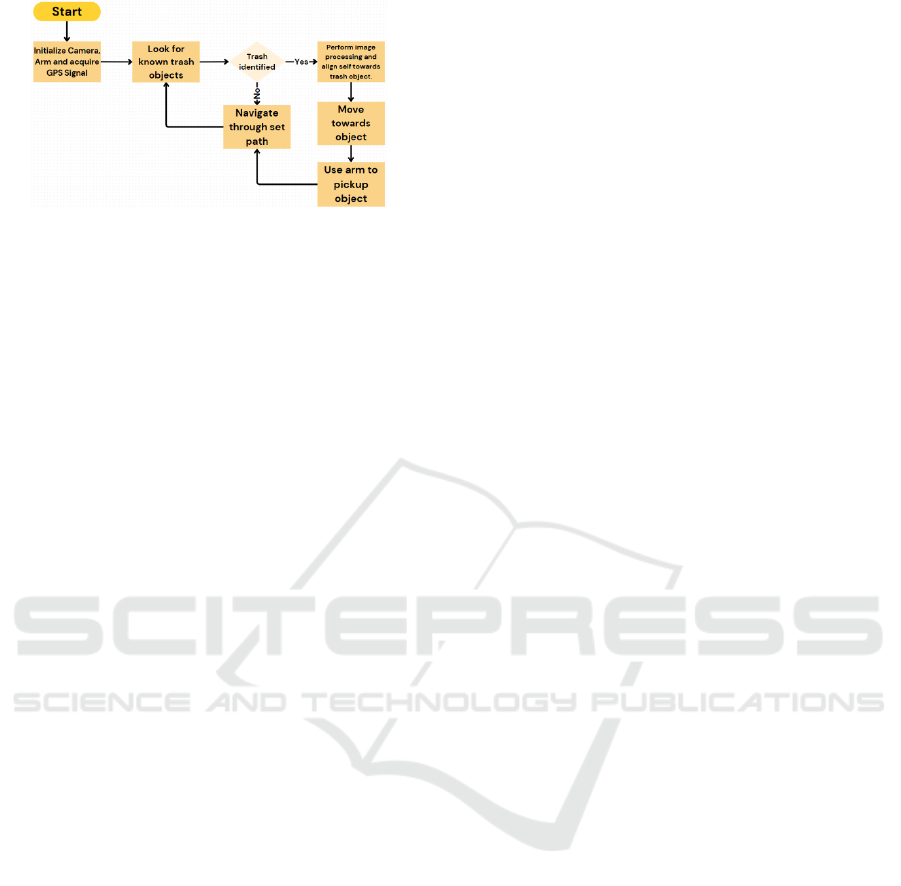

Figure 1: Flowchart of working.

The model makes turn in order to place the trash

image to the center of the frame of the Camera and

then moves towards trash and stops at a certain

distance from the trash.

The trash categorization data determines the arm

movement. The arm picks the trash and makes a left

or right turn in the backward direction to drop the

garbage into respective bin. The robot then comes

back to its position from where the trash was detected

and makes its forward movement. If the object

detected is not found to be garbage, the model moves

on the region for frontward motion.

The robot makes turns with the data input from

GPS and magnetometer. So, to sum it up the 12v

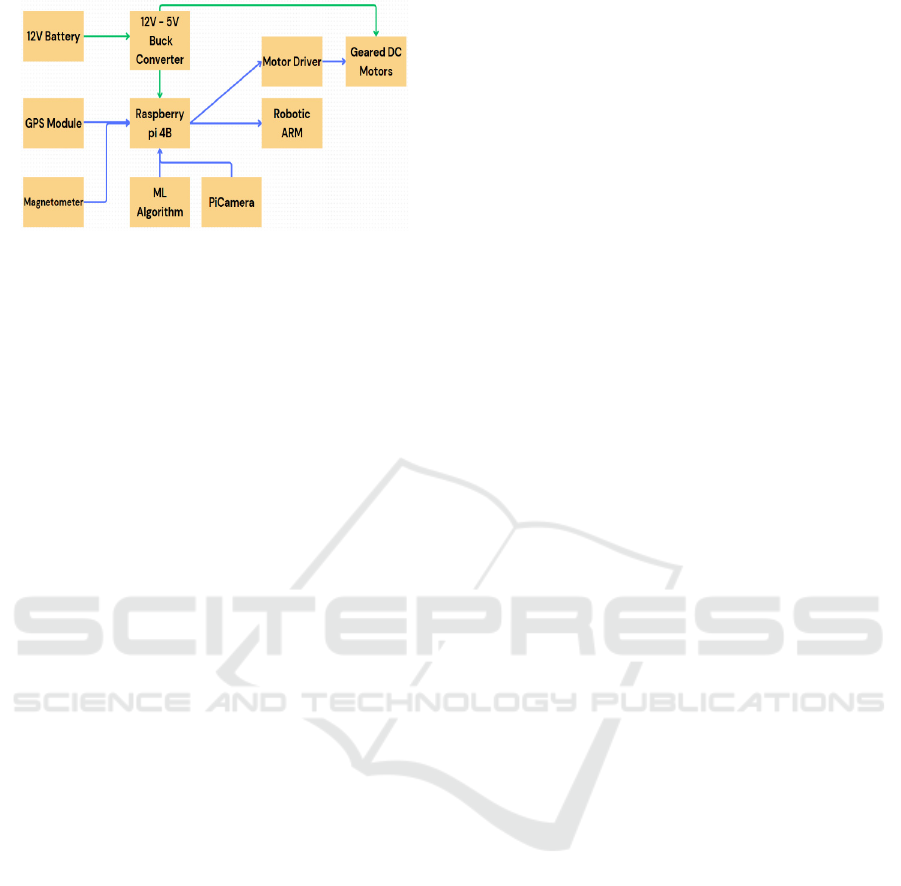

battery is the main powering unit for all the

components in the system. The 12v is stepped down

to 5v to power the raspberry pi and servo motors used

for various applications. The GPS module and

magnetometer supplied navigation of the system.

They provide the input data to the raspberry pi

directly based on which decisions for movement are

taken.

The pi camera provides the images of the

surrounding objects for trash identification. This task

is done with the help of the ML model developed.

Based on all these inputs the raspberry pi provides the

instructions to the motor driver and the arm serves

according to which DC motors and arm performs

their operation of motion and object picking.

4.1 Circuit Description

The complete system is programmed using the python

programming language. The Raspberry Pi (Raspberry

Pi) is powered from the battery via a buck converter

(XL4015) with 5V. The antenna affixed GPS module

is connected to the microcontroller through Vcc-5V,

Gnd-Gnd, Tx - Digital pin, Rx - Digital pin (GPS-

Raspberry Pi). The module uses UART

communication to feed the data into PC; that it

received via RF signals. The magnetometer uses I2C

protocol for communication with the Raspberry Pi

4B.

The obstacle detection component ultrasonic

sensor uses the Trig and Echo pin to share data

accordingly with Raspberry Pi. The Pi- Camera

shares the data using CSI (Camera Serial Interface)

with Raspberry Pi. The connection includes the plug

in of the 15- pin ribbon cable to the CSI port of

Raspberry Pi.

Ultrasonic sensor is also used for object detection.

The picking mechanism of the system includes

robotic arm which is directly controlled by Raspberry

Pi data signals. The rotation of the servos in the arm

decides the arm motion. The decision of the rotations

is made concurrently by the Raspberry.

The servos are powered with 5V via buck

converter (XL4015). The movement managing

system includes 12V DC motors which are driven

through L298N DC motor driver. The driver is

powered directly. The model movement is controlled

by the Ackermann steering as well. The MG995 servo

motor of the steering receives the signal from

Raspberry Pi. The ML algorithm provides the

assistance for trash detection and segregation.

5 WORKING OF MODEL

The above image gives the flow chart for the

algorithm based on which the ML model used in the

system is developed. This flow chart explains the

method of navigation and trash collection performed

by the system. The robot is powered up for its start.

This enables the arm, camera and the navigation

system. The initial position of the system is noted

with the help of the GPS module (via RF signal). The

robot makes its movement for detection of trash.

If the trash is identified the robot aligns itself to

bring the trash to its center frame and moves towards

the trash. The robotic arm then picks up the trash and

drops it into the respective bin. The system comes

back to its position and moves along the set path

continuing the trash detection task. If the trash is not

detected by the robot, it would continue its motion on

the set path for performing the trash detection task.

The whole system working can be divided into

different parts:

(i) Control Unit

The whole system is controlled with the

Raspberry Pi 4B model. The microcontroller

performs all the tasks of data collection, data

analyzation decision making and motion control of

Ecobot: Autonomous Trash Collection and Segregation System

31

Figure 2: Block Diagram of Circuit.

the robot. It also controls the movement of the arm

picking mechanism.

(ii) Powering Unit

The system is powered by a 12V 4.5Ah Sealed-

Lead Acid rechargeable battery. The step down of the

voltage is done from 12 – 5V for powering the

Raspberry Pi and robotic arm using XL4015 5A DC-

DC Step Down Adjustable buck converter. The

motors driver of wheel motors is powered with 12V

directly from the battery.

(iii) Navigation Module

This arrangement includes Neo 6M GPS module,

HMC5883l magnetometer along with Raspberry Pi.

Predetermined path set up using waypoints. The robot

starts at its initial location, acquires its current

location using GPS module and calculates the angle

it needs to travel for the next waypoint. Then turns

itself in the required direction and moves forward.

The HMC5883L magnetometer module is used for

the accurate directions with respect to earth’s

magnetic field.

(iv) Steering mechanism and motion control

The movement of the system is aided by two 12V

DC motors and the Ackermann steering technique.

The motors are of rating with 100 rpm which are

driven by L298N DC motor driver. The turns made

by the model is controlled through the steering. An

MG995 servo motor is used for steering movement.

(v) Obstacle Detection

The obstacle detection is done using two

ultrasonic sensors placed at the front ends of the robot

on either of its sides. A signal indicating the obstacle

detection commands the steering turns through

Raspberry Pi.

(vi) Trash detection

This process is encountered by Pi-Camera along

with ultrasonic sensor and Raspberry Pi. The camera

reads images 640x480 pixels. This image is first pre-

processed to bring out tinier details of the image and

then given to a customer thrash detection model. The

model returns category name and a bounding box

around the trash object the trash is identified.

(vii) Picking mechanism

The trash picking function is performed by the

robotic arm and directed by the Raspberry Pi. The

arm has four joints with 5-DOF motion. It consists of

three MG995 and three SG90 servo motors.

(viii) Trash segregation technique.

The hardware required for this task is Pi- Camera

and Raspberry Pi Supervised by the ML algorithm.

The ML model can make segregations between

biodegradable and non-biodegradable garbage. Once

the model returns the category name, the result if

more than a threshold then it is classified into

respective category.

(ix) Model Training

The model used for detecting and segregating

trash was trained by retraining a pre-trained model.

Retraining machine learning models is the process of

updating a pre-trained model with new data or

adapting it to new conditions. This process ensures

that the model stays accurate, relevant, and performs

well in changing environments. Around 500 images

of each class were clicked in different backgrounds

and lighting conditions. The images were labelled and

arranged in the COCO dataset format.

The model architecture chosen for retraining was

MobileNet-V2 which is a Convolutional Neural

Network by Google designed to run on low-end

devices. It is commonly used for tasks like image

classification and object detection on mobile and

other edge devices.

The hyperparameters set for the training process

were input size of 256x256 pixels, a learning rate of

0.3, batch size of 8 and a total of 30 epochs. The

training was done on Google collab server using a

Nvidia T4 GPU runtime. The post training evaluation

results were obtained as validation loss of 0.23. The

model was then exported in tflite format file.

5.1 Robot Movement and Function

Robot acquires its current location and it's heading

direction. Camera looks for known trash objects, if

any are found then using open cv library the robot

locates the object in the frame and tries to center the

object in the frame by steering itself. As the robot is

approaching the object its size in the frame starts to

increase.

The size on reaching a preset threshold the

ultrasonic sensor come into action and precisely

measure the distance to the object. When this distance

becomes equal to the reach of the arm, the motors

stop. Now the arm reaches for the object and picks it

up and puts it in the appropriate bin.

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

32

5.1.1 Trash Detection

Resize the frame and convert it to RGB. Use

MediaPipe’s object detection to identify trash objects.

Draw bounding boxes and label detected trash items.

Display or save the annotated frame with detected

trash. Implemented logic to classify the detected trash

into categories like biodegradable or non-

biodegradable.

5.2 Comparative Analysis

The system in (R and V, 2018) performs the trash

collection task only on grass whereas the proposed

system can perform the trash collection on various

types of hard lands.

The robot in (Bharathi et al., 2018) follows a pre-

defined path and picks up the trash present only the

path of movement. The developed system detects the

trash away from the set path and also collects those

trash objects.

The presented robots make its movement based on

the path following technique or wall following

technique, while this robot makes the path decision

using GPS mode without the requirement of laying

the path on the floor for every region or availability

of bounded area. The existing projects only ensure the

garbage collection neglecting its segregation. The

present system collects and trash and also segregates

them spontaneously. The presented robot does not

require any human intervention between its start and

stop operation.

6 RESULTS

Figure 3: Final Working Robot.

(i) Trash detection

The trash is detected using ML algorithm with an

accuracy of 98 to 100 percent.

The task of trash detection is completely handled

by the Machine learning model that is been build up.

The task is supported by Pi- camera operation.

Figure 4: Trash detection and movement towards trash.

(ii) Trash classification

Trash that is completely non- biodegradable like

plastic material are detected as non-biodegradable.

The trash that is capable of getting decomposed like

fruit peels and paper are identified as biodegradable

material.

Figure 5: Biodegradable garbage identification.

(iii) Trash picking task

The arm is capable of picking up the detected

garbage material with the instructions provided from

the

microcontroller based on the data given by Pi-

Camera and ultrasonic sensor with ML training.

Figure 6: Picking of trash by the robot.

(iv) Model Training

The model is able to provide an output with the

accuracy of 75.5%. The time gap between the

command and the action of the system is recorded as

201ms.

Table 1: Benchmark results for model.

Average

precision

Latency on

Raspberry Pi

4B

Model Size

75.5% 201ms 12MB

Ecobot: Autonomous Trash Collection and Segregation System

33

7 CONCLUSIONS

The robot results as a system that is capable enough

to address the issue of waste management efficiently

from detection to segregation autonomously on

numerous hard land types. The task of waste

identification and classification is performed with use

of camera only with the technology of ML and image

processing without much hardware. This stands as

one of the advantages in the system. The autonomous

nature is another major plus factor for the model. The

robot can be made robust for all find of lands and

trash. The proposed system can be made versatile by

incorporating other techniques few in number only.

The use of IoT can make the robot a wirelessly

accessible, locatable and manageable device.

Bluetooth insertion could make it capable for manual

handling and motion. This feature can be initiated

with the use of radio frequency signal as well. Some

structural changes of increased height can make allow

for trash detection even on grassy areas. Some minor

changes in tyre type, size and thickness can make the

robot usable in rocky and sandy regions as well.

ACKNOWLEDGEMENT

We would like to sincerely thank everyone who

helped us finish this research paper on, "Ecobot;

Autonomous Trash Collection and Segregation

System". We would especially like to thank Mrs.

Deekshitha Arasa, Assistant professor, for her

invaluable advice, steady support, and insightful

observations during the project. We also want to

thank Dayananda Sagar College of Engineering in

Bangalore's Department of Electrical and Electronics

Engineering for their unwavering encouragement and

support.

REFERENCES

Sengupta, V. Varma, M. Sai Kiran, A. Johari, Marimuthu R

(2019). "Cost-Effective Autonomous Garbage

Collecting Robot System Using IoT and Sensor

Fusion", International Journal of Innovative

Technology and Exploring Engineering. Vol-9, Issue -

1, November, DOI: 10.35940.

Bharathi V Asst prof, Gayathri K, Jayashree S, Kiruthika

D, Maheswari P (2018). "Automatic Bin-Bot - Garbage

Collecting System using iot", International Journal of

Engineering Research & Technology (IJERT). ISSN:

2278-0181.

Jinqiang Bai, Shiguo Lian, Zhaoxiang Liu, Kai Wang,

Dijun Liu (2018). "Deep Learning Based Robot for

Automatically Picking up Garbage on the Grass", IEEE

Transactions on Consumer Electronics.

DOI:10.1109/TCE.2018.2859629, CITATIONS 156.

Shikha Parashar1, Pankaj Tomar (2018). "Waste

Management by a Robot- A Smart and Autonomous

Technique", IOSR Journal of Electronics and

Communication Engineering (IOSR-JECE). Volume

13, Issue 3, Ver. II, May- June, PP 31-36.

Purushothaman.R, Bharathi.V (2018). "Automatic Bin Bot-

Garbage Collecting System in Residential Areas and

Enlightening Disposal Mechanism", International

Research Journal of Engineering and Technology

(IRJET). e-ISSN: 2395-0056 Volume: 05 Issue: 08,

August, p-ISSN: 2395-0072.

Rama Prabha D, Sagar Mahindru, Akshat Srivastava and

Nilalohita P (2018). "Autonomous Garbage Collector–

Robo Dumpster", International Journal of Civil

Engineering and Technology. Vol-9, Issue–12,

December, pp. 545–552.

N.Varuneshreddy, K. Nikhil (2018). "Garbage Collection

Robot on the Beach Using Wireless Communications",

International Journal of Research in Engineering,

Science and Management. Vol-1, Issue-10, October,

ISSN: 2581-5782.

Kunda Sreenivas Ulu, K.Kalyani Radha (2017). "Iot Based

Solar Integrated Garbage Monitoring Using Robot on

Raspberry Pi", International Journal of Mechanical

and production Engineering. Vol 5, Issue-10, October,

ISSN: 2320-2092.

Osiany Nurlansa, Dewi Anisa Istiqomah, and Mahendraa

stusangghapawitra (2014). "AGATOR (Automatic

Garbage Collector) as Automatic Garbage Collector

Robot Model", International Journal of Future

Computer and Communication. Vol-3, Issue -5,

October, DOI: 10.7763/IJFCC.2014.V3.329.

S. Reddy, (2020). "Autonomous garbage collection robot",

International Journal of Advanced Research in

Engineering and Technology. Vol.5, no.3, pp. 120–128.

K. Singh and P. Das (2021), "Trash Segregation System

Using Machine Learning", Journal of Environmental

Engineering and Science, vol. 14, no. 2, pp. 89–97.

J. Patel and A. Kumar (2022), "Iot-enabled waste

management systems: Current trends and future

prospects," Smart Cities Journal, vol. 10, pp. 245–260.

P. Sharma, et al (2020)., "Design and implementation of

robotic arm for garbage collection," Robotics and

Systems Engineering Review, vol. 6, no. 1, pp. 50–60,

2020.

T. Shimizu and K. Nakamura (2021), "Machine learning-

based garbage classification and collection robot",

Journal of Robotics Research, vol. 35, no. 4, pp. 285–

298.

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

34