Research on the Stress Analysis and Applicability of Flexible Support

Steel Strip in Soft Ground Highway Tunnels

Shiheng Yang

1,* a

, Tingwei Yang

1,2,3 b

, Chaobo Lu

1,2,3 c

and Chunfa Xiong

1,2,3 d

1

Guangxi Transportation Science and Technology Group Co., Ltd., Nanning 530007, Guangxi, China

2

Guangxi Highway Tunnel Safety Warning Engineering Research Center, Nanning 530007, Guangxi, China

3

Guangxi Key Lab of Road Structure and Materials, Nanning 530007, Guangxi, China

*

Keywords: Flexible Support Structure, Soft Ground, Highway Tunnel, Applicability Analysis.

Abstract: By using numerical experimental models, the support characteristics of steel arch bolt shotcrete initial

support structure and W-shape steel strip bolt shotcrete initial support system in grade IV surrounding rock

of soft ground highway tunnels were compared and analyzed. Experimental sections were carried out in

grade IV weak surrounding rock to compare the support effects of W-shape steel strip bolt shotcrete support

structure and steel arch bolt shotcrete support structure in soft ground highway tunnels. The results showed

that the use of W-shape steel strip bolt shotcrete support structure has the same good support effect as steel

arch bolt shotcrete support structure in soft ground highway tunnels. The implementation of W-shape steel

strip bolt shotcrete support structure can better exert the self-supporting capacity of surrounding rock, but its

restrained deformation amplitude is weaker than that of steel arch, which can provide reference for the

selection of support structure types for highway tunnels with similar geology.

a

https://orcid.org/0009-0009-9743-7885

b

https://orcid.org/0009-0004-4537-0205

c

https://orcid.org/0009-0003-8073-7714

d

https://orcid.org/0009-0005-7409-741X

1 INSTRUCTION

In the process of tunnel construction, the

surrounding rock and supporting structure interact

and deform together. During the deformation process,

the energy released by the surrounding rock, i.e. the

energy absorbed by the supporting structure, follows

the principle of energy conservation (Wang et al.,

2021). In the special environment of soft ground,

flexible support treatment should be carried out in

tunnel support, and the supporting structure can

undergo appropriate deformation, thereby enabling

the tunnel surrounding rock to fully exert its self

stabilization ability (Wei et al., 2017).

The flexible supporting system composed of

W-shape steel strip support, rockbolt, and anchor

cables combines the rockbolt and steel strips as the

main supporting structure under common force.

With flexible steel strips, the initial support structure

has better overall deformation coordination and

control ability, and is widely used in coal mine soft

rock roadway support (Sun, 2023; Sun, 2022; Zhang

and He, 2016).

The steel strip, due to its connection with the

anchor rod, can tightly adhere to the surface of the

surrounding rock, effectively preventing the collapse

of fragmented rock blocks when the tunnel arch or

side wall is relatively broken.Combining the radial

force provided by the rockbolt, a three-dimensional

control system is formed, which can fully utilize the

anchoring and suspension effects of the anchor cable

to reinforce the surrounding rock, enhance the

overall compressive strength of the surrounding rock,

increase the range of the surrounding rock

compressive stress zone, and prevent the overall

supporting structure of the rock from being damaged,

thereby controlling the displacement of the

surrounding rock and improving the overall stability

and bearing capacity of the tunnel (Lu et al., 2025;

Zhao et al., 2022; Zhang, 2014; Li et al., 2023).

Yang, S., Yang, T., Lu, C., Xiong and C.

Research on the Stress Analysis and Applicability of Flexible Support Steel Strip in Soft Ground Highway Tunnels.

DOI: 10.5220/0013574300004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 109-117

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

109

This paper conducts numerical simulation

calculations using the finite difference method to

compare and analyze the support effects of

traditional support structure and the flexible support

system in grade IV surrounding rock of weak rock

highway tunnels. The applicability of the flexible

support system composed of steel strip-rockbolt in

weak rock highway tunnels is explored. At the same

time, the support effect is compared through on-site

practical application.

2 NUMERICAL EXPERIMENTAL

MODEL

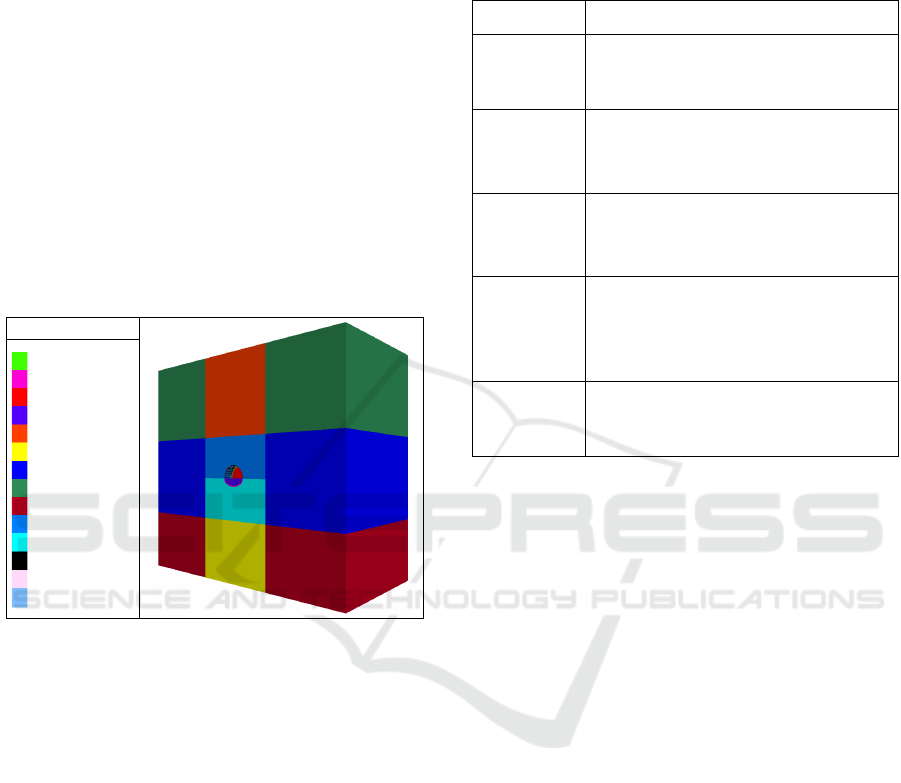

The numerical experimental model is shown in

Figure 1.

Legen

d

concretlinersy

concretlinerxy

insiderocksy

insiderockxy

outsiderock

outsiderock2

outsiderock3

outsiderock4

outsiderock5

outsiderocksy

outsiderockxy

beamSEL

cableSEL

shellSEL

Figure 1: Numerical simulation calculation model.

The width of the tunnel in the numerical

experimental model is 12.46 m and the height is 9.7

m. The X and Z directions of the model area are

taken as 120 m and 110 m, respectively. The tunnel

depth is 60 m in the Y direction, with a burial depth

of 100 m. The longitudinal spacing between steel

strips or steel arch is 0.8 m, the longitudinal spacing

between rockbolt is 0.8 meters, and the

circumferential spacing is 1.2 meters, arranged in a

plum blossom shape. rockbolt are arranged at

different locations in two types of support structures.

In the initial support structure of steel arch bolt

shotcrete, they are arranged between two steel arch.

In the initial support structure of W-shape steel strip

bolt shotcrete, they are arranged at the center of each

steel strip. In numerical calculations, steel arch and

steel strips are simulated using Beam elements,

rockbolt are simulated using Cable elements, and

shotcrete is simulated using Shell elements

(Liu,

2023). The material parameters of different models

are shown in Table 1.

Table 1: Material parameter table for numerical model.

material parameter

surrounding

rock

Unit weight: 23 kN/m

3

; Elastic modulus:

3 GPa; Cohesion force: 0.3 MPa;

Friction angle: 44°; Poisson's ratio: 0.27.

shotcrete

Bulk modulus: 13 GPa; Shear modulus :

10 Gpa; Unit weight: 22.45 kN/m

3

;

Thickness: 22mm; Elastic modulus:

23GPa; Poisson's ratio: 0.2.

steel arch

Section area of I-beam No.16: 2610mm

2

;

Moment of inertia: 11300000mm

4

;

Elastic modulus: 210GPa; Poisson's ratio:

0.3.

W-shape

steel strip

Width: 300mm; Thickness: 4mm;

Cross-sectional area :810mm

2

;

Moment of inertia:40824mm

4

; Elastic

modulus: 210GPa; Moment of inertia:

0.3.

rockbolt

Diameter: 20mm, Elastic modulus:

210GPa; Poisson's ratio: 0.2.

3 ROCK EXCAVATION

DEFORMATION

Extract the deformation and stress conditions of two

types of support structures after construction, as well

as the stress conditions of the support components

for analysis. Among them, the steel support

components of traditional support structures and

flexible support structures are steel arches and steel

strips, respectively.

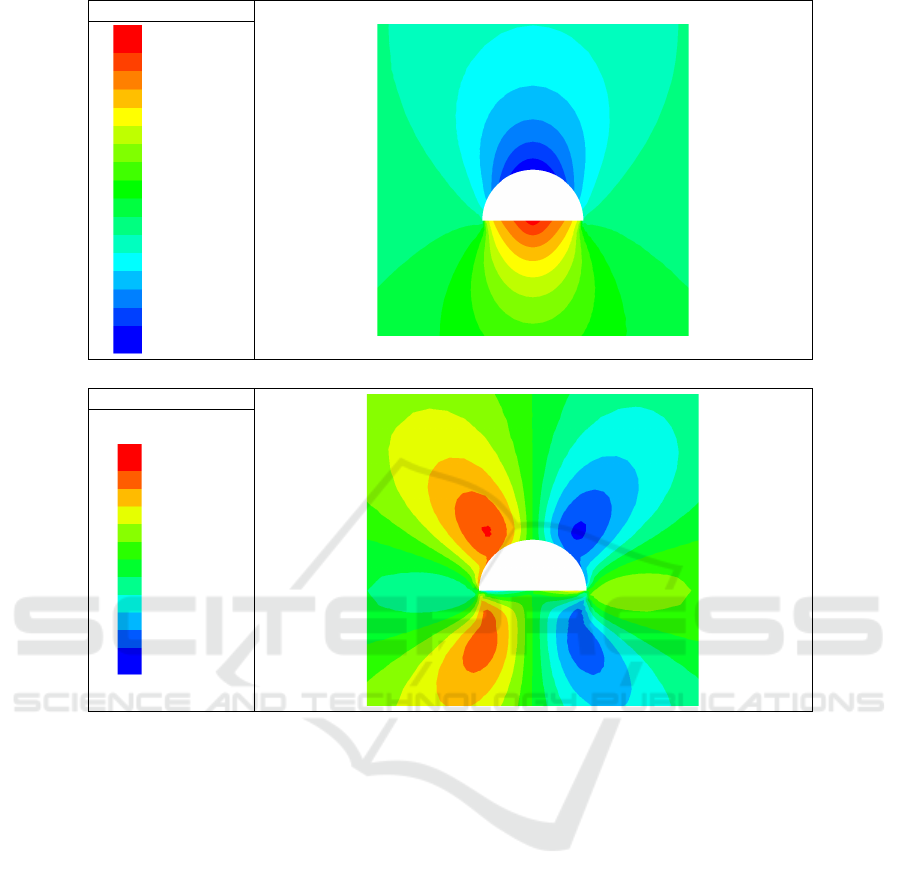

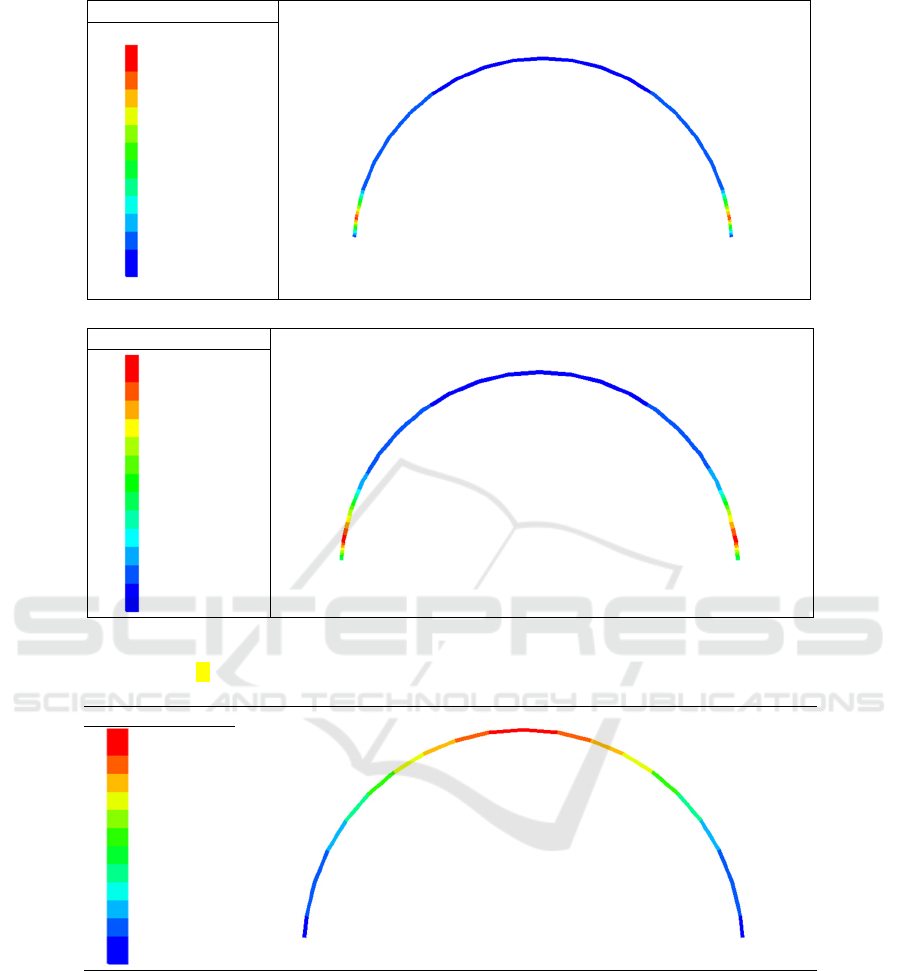

3.1 Rock Excavation Deformation

The displacement of the surrounding rock

deformation after tunnel excavation for the initial

support structure of steel arch bolt shotcrete and the

initial support structure of W-shape steel strip bolt

shotcrete is shown in Figure 2 and Figure 3.

Due to the lower overall stiffness of the W-shape

steel strip compared to the steel arch, the

deformation of the surrounding rock will be slightly

greater when using the W-shape steel strip bolt

shotcrete support structure. However, the flexible

support structure also has a good effect on

controlling the surrounding rock of the tunnel.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

110

Displacement/mm

9.583

9.000

8.000

7.000

6.000

5.000

4.000

3.000

2.000

1.000

0.000

-1.000

-2.000

-3.000

-4.000

-5.000

-6.000

-6.826

(a)

Vertical displacement

Displacement/mm

1.011

1.000

0.800

0.600

0.400

0.200

0.000

-0.200

-0.400

-0.600

-0.800

-1.000

-1.024

(b) Horizontal Convergence

Figure 2: Deformation diagram of the initial support structure of steel arch bolt shotcrete.

3.2 Results of Plastic Zone of

Surrounding Rock

The distribution of plastic zones in the surrounding

rock after tunnel excavation under two different

working conditions is shown in Figure 4.

Different support structures are applied after

tunnel excavation, and the distribution of plastic

zones in the surrounding rock is basically the same,

mainly in the shear plastic zone. In terms of the size

of the plastic zone, the plastic zone of the

surrounding rock after flexible support structure is

applied is smaller than that of traditional support

structure, indicating that flexible support structure

can better exert the self-supporting capacity of the

surrounding rock.

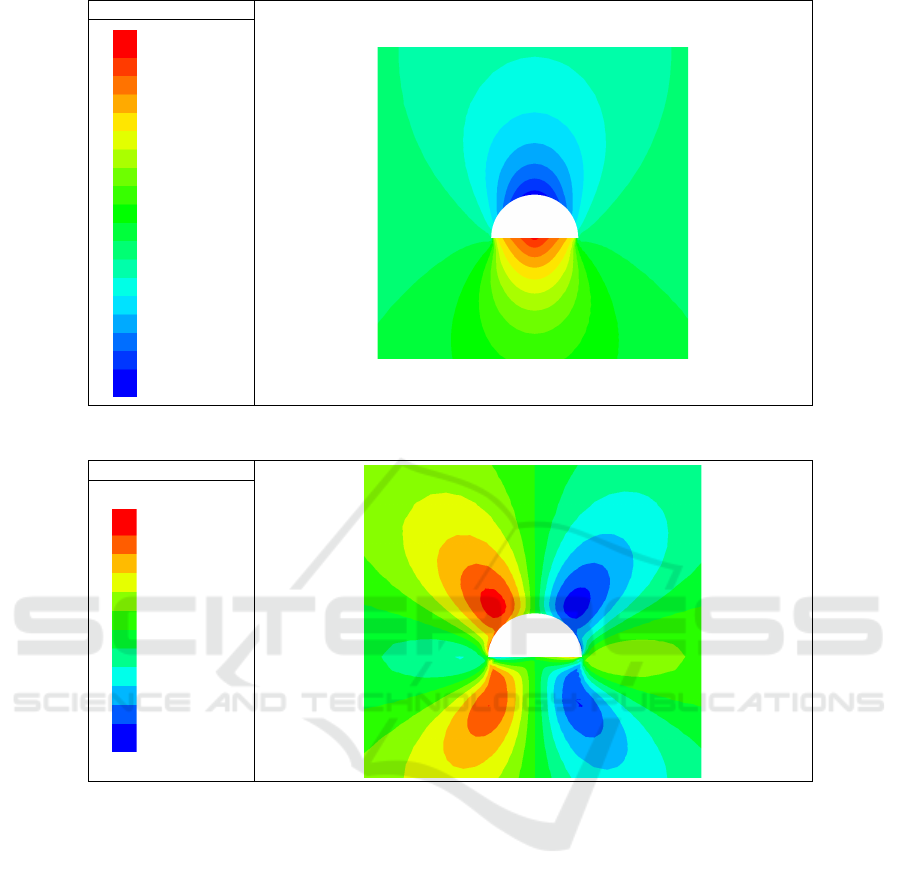

3.3 Stress Characteristics of Rockbolt

The stress distribution of the rockbolt under two

working conditions after tunnel excavation is shown

in Figure 5.

Due to the influence of the joint support system

formed with the steel strip, the stress distribution of

the rockbolt in the flexible support structure is

different from that in the traditional support structure.

The axial force of the rockbolt reaches its maximum

value at the end of the rockbolt and gradually

decreases along the direction of the rockbolt.In

terms of overall force distribution, the rockbolt of

the two support structures are basically consistent,

both reaching their maximum values near the arch

springing. Among them, the rockbolt of the flexible

support structure receive a maximum axial force of

20kN, which is 1.4 times that of the traditional

support structure. This indicates that in the flexible

support

structure, the surface W-shape steel strip

Research on the Stress Analysis and Applicability of Flexible Support Steel Strip in Soft Ground Highway Tunnels

111

Displacement/mm

10.501

10.000

9.000

8.000

7.000

6.000

5.000

4.000

3.000

2.000

1.000

0.000

-1.000

-2.000

-3.000

-4.000

-5.000

-6.000

-7.000

-7.457

(a)

Vertical displacement

Displacement/mm

1.090

1.000

0.800

0.600

0.400

0.200

0.000

-0.200

-0.400

-0.600

-0.800

-1.000

-1.097

(b)

Horizontal Convergence

Figure 3: Deformation diagram of the initial support structure of W-shape steel strip bolt shotcrete.

yields pressure and exerts the tensile function of the

rockbolt.

3.4 Stress Characteristics of Steel

Support

The bending moment distribution of the steel

support structure under two working conditions is

shown in Figure 6.

Compared with traditional support structures,

when constructing flexible support structures, the

bending moment experienced by steel strips is much

smaller than that of steel arches. The maximum

bending moment of the steel strip is 7.88 N·m, and

the maximum bending moment experienced by the

steel arch is 3.2 times that of the steel strip, with a

bending moment value of 25.26 N·m.

The stress distribution of the steel support

structure under two working conditions is shown in

Figure 7.

The stress distribution of the two support

structures is basically the same, with the arch crown

receiving the minimum stress and the arch lumbar

receiving the maximum stress. The maximum stress

value of the steel arch is 100.71 MPa, and the

maximum stress value of the steel strip is

126.78MPa. Compared with the steel arch, the joint

support structure formed by W-shape steel strip and

rockbolt is an active support structure, and the stress

distribution of the steel strip is more uniform.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

112

None shear-n shear-p shear-n shear-p tension-p

shear-p shear-p tension-p

(a)

support structure of steel arch (b)

support structure of W-shape steel strip

Figure 4: Distribution of plastic zone in surrounding rock of support structure.

Axial force/kN

14.65

14.00

13.00

12.00

11.00

1.00

9.00

8.00

7.00

6.00

5.00

4.00

3.00

2.00

(a)

support structure of steel arch

Axial force/kN

20.37

20.00

18.00

16.00

14.00

12.00

10.00

8.00

6.00

4.00

2.00

(b)

support structure of W-shape steel strip

Figure 5: Axial force diagram of anchor rods with different support structures.

Although the W-shape steel strip has a weaker

constraint on the excavation deformation of the

surrounding rock compared to the steel arch bolt

shotcrete support structure, and the stress amplitude

of the W-shape steel strip is also larger than that of

the steel arch, it is still within the yield strength.

Compared with the steel arch bolt shotcrete support

structure, through deformation, it can fully exert the

deep migration of the surrounding rock stress and

the self bearing capacity of the surrounding rock.

The steel strip is closely attached to the surface of

the surrounding rock and works together with

rockbolt to provide "active support" for the

surrounding rock, which could make the

effectiveness of the steel strip is higher than that of

the steel arch.

Research on the Stress Analysis and Applicability of Flexible Support Steel Strip in Soft Ground Highway Tunnels

113

Bending moment/(N·m)

25.26

25.00

22.50

20.00

17.50

15.00

12.50

10.00

7.50

5.00

2.50

0.00

-2.39

(a)

support structure of steel arch

Bending moment/(N·m)

7.88

7.00

6.00

5.00

4.00

3.00

2.00

1.00

0.00

-1.00

-2.00

-3.00

-4.00

-4.29

(b)

support structure of W-shape steel strip

Figure 6: Bending moment diagram of steel support for different support structures.

Axial stress/MPa

48.86

50.00

55.00

60.00

65.00

70.00

75.00

80.00

85.00

90.00

95.00

100.00

100.71

(a)

support structure of steel arch

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

114

Axial stress/MPa

87.37

87.50

90.00

92.50

95.00

97.50

100.00

102.50

105.00

107.50

110.00

112.50

115.00

117.50

120.00

122.50

125.00

126.78

(b)

support structure of W-shape steel strip

Figure 7: Stress diagram of steel support for different support structures.

4 ENGINEERING APPLICATION

TESTS

4.1 Experimental Design

Based on a certain highway tunnel, a field test

section was conducted. The

ZK101+500-ZK101+650 tunnel is designed with

grade Ⅳ surrounding rock, with a tunnel burial

depth of 110m~133m. The formation is composed of

moderately weathered thin sandstone interbedded

with mudstone, with well-developed joints and

fissures, and the surrounding rock is relatively

fragmented. The original design adopted the grade

Ⅳa support method, with initial support parameters

of HRB400 grade 3 threaded steel; the diameter of

the rockbolt is 20mm, the type of it is mortar

rockbolt, the length of it is 3.0m; the diameter of the

steel mesh is 6.5mm, and the arrangement is

25×25cm; the steel arch adopts I16 I-beam with a

longitudinal spacing of 80cm; the shotcrete adopts

C20 strength and is applied with a thickness of 22cm;

the design requirement is to reserve a thickness of

8cm after excavation. The construction of this

section adopts the two-step method for excavation,

with a height of 4.5 meters for the excavation of the

upper center bench . After excavation, 13 steel strips

are continuously used instead of the original design

I16 I-beam steel arch at ZK101+560-ZK101+570.4.

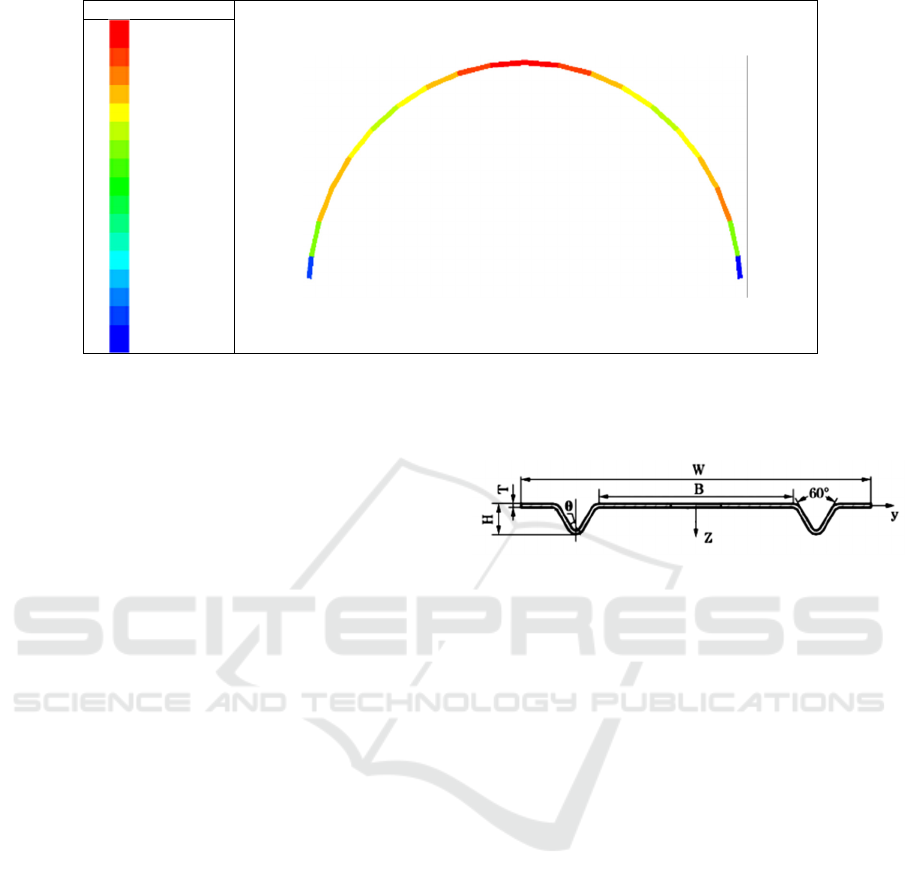

The steel strip structure is shown in Figure 8.

W-steel strip width, 300mm; B-Steel strip support width,

155.6mm; H-steel strip height, 23.5mm; T-steel strip thickness,

4mm, Sectional area, 810mm

2

Figure 8: Structural diagram of experimental steel strip.

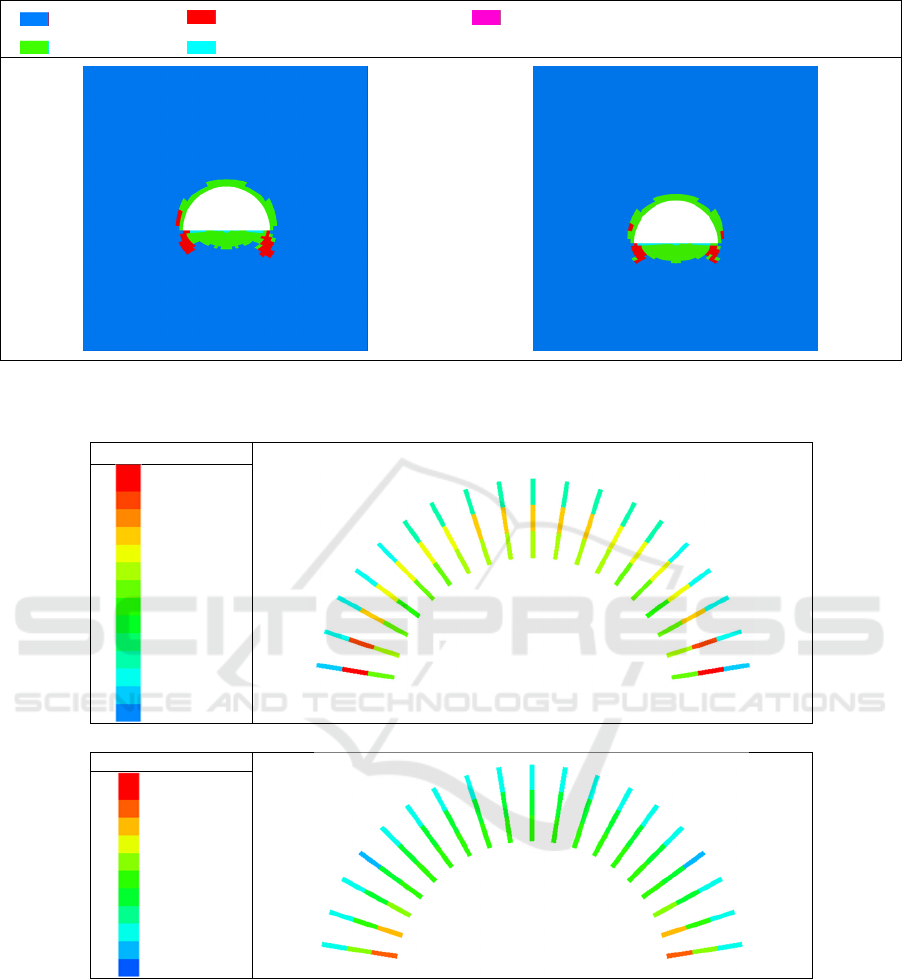

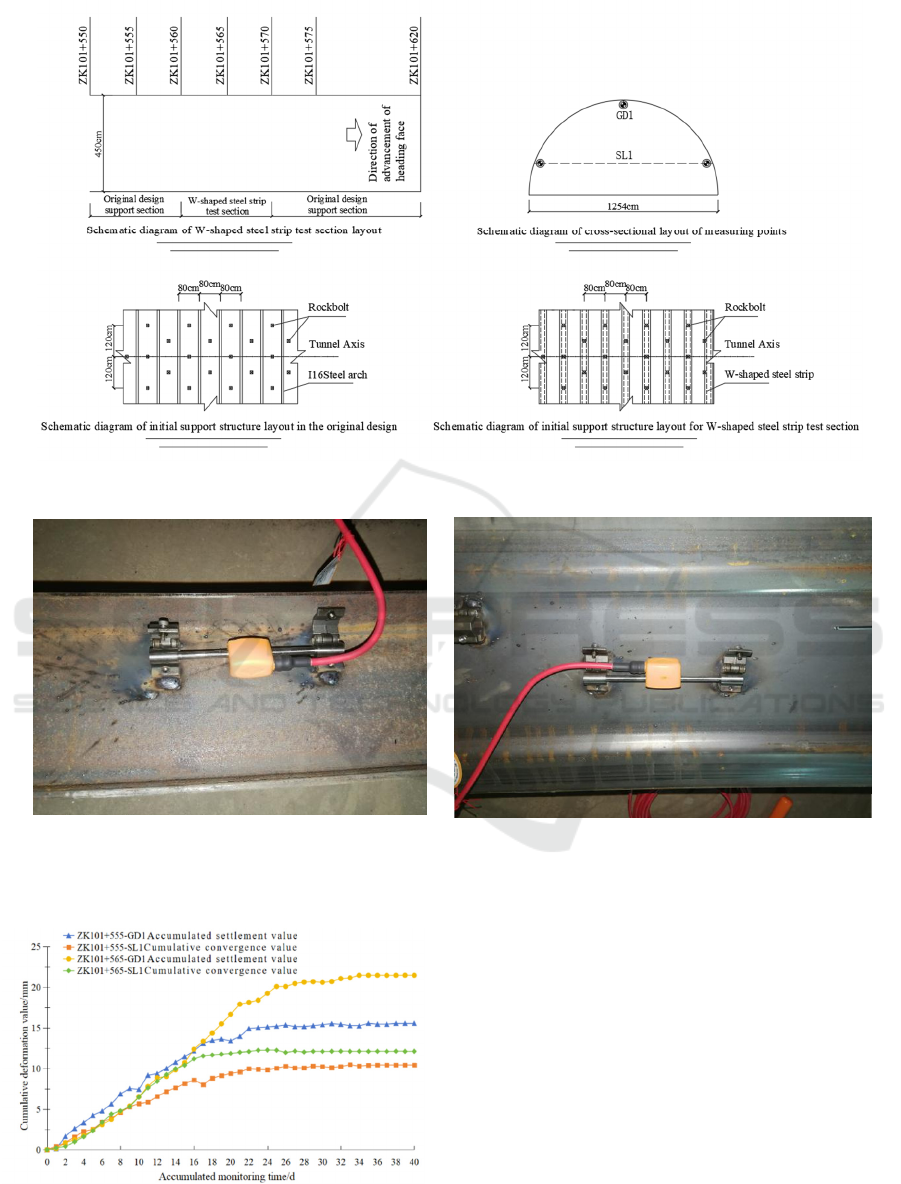

The middle position of the section ZK101+565 is

selected as the monitoring section, and compared

with the adjacent section ZK101+555 steel arch

support structure section. The experimental section

setting is shown in Figure 9.The actual installation

of steel support components on site is shown in

Figure 10.

4.2 Test Results

The deformation monitoring data of two sections for

40 days of support deformation monitoring are

shown in Figure 11.

By comparing the deformation of two

cross-sectional support structures, it was found that

under the same surrounding rock conditions, their

deformation patterns were basically the same. The

deformation increased rapidly in the first 7 days and

eventually stabilized over time.

In addition, no cracking or block shedding was

found in the on-site support structure. The initial

support structure composed of W-steel strips

replacing steel archs can also maintain the stability

of weak surrounding rock for the support of

excavated highway tunnels.

Research on the Stress Analysis and Applicability of Flexible Support Steel Strip in Soft Ground Highway Tunnels

115

Figure 9: Schematic diagram of engineering test layout.

(a)

Rigid connection of sensors in steel arch (b)

Rigid connection of sensors in W-shape steel strip

Figure 10: Layout of engineering test site.

Figure 11: Monitoring section deformation curve.

5 CONCLUSION

By establishing a numerical model, a stress analysis

was conducted on the flexible support structure

constructed in soft ground highway tunnels. The

feasibility of using steel strips instead of traditional

steel arches was compared and verified through field

experiments, and the following conclusions were

drawn.

(1) In soft ground, the initial support structure

composed of W-steel strips replacing steel arch has

basically the same support effect on the excavated

highway tunnel, but the constraint amplitude for

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

116

tunnel excavation deformation control of steel strip

is smaller than that of steel archs.

(2) Compared with the initial support structure

composed of steel arch, the range of damage or yield

in the plastic zone of the surrounding rock caused by

the initial support structure of W-steel strip is

basically the same. The initial support structure of

W-steel strip can better exert the self-supporting

capacity of the surrounding rock.

(3) Within the safe strength range, the initial

support structure of W-steel strip can better utilize

the strength advantages of steel materials and

rockbolt, and fully exert its support effect.

(4) Through on-site testing, it has been verified

that the initial support structure composed of

W-steel strips replacing steel arch can also maintain

the stability of weak surrounding rock for the

support of excavated highway tunnels.

DECLARATION OF COMPETING

INTEREST

The authors declare that they have no known

competing financial interests or personal

relationships that could have appeared to influence

the work reported in this paper.

ACKNOWLEDGEMENTS

The research of this article is supported by

Guangxi's key research and development plan

(Guike AB24010276).

REFERENCES

Wang, W., et al. 2021. Mechanical Analysis of

Non-circular Tunnel Lining Considering

Ground-support Interaction. Chinese Journal of

Underground Space and Engineering, 17(S2):

631-636+649.

Wei, Z., He, F., Zhang, G., et al. 2017. Failure

mechanism and cable truss control of large-scale

section gob-side entry roof with fully mechanized

caving. Journal of Mining & Safety Engineering,

34(1): 1-8.

Sun, H. 2023. Interaction and Stability Analysis of

Surrounding Rock and Lining Structure of High

Temperature Hydraulic Tunnel. Shihezi University,

Shihezi.

Sun, H. 2022. Research on the large deformation

mechanism of soft rock and support

countermeasures of NPR anchor cable-truss in Tayi

tunnel. China University of Mining &

Technology-Beijing, Beijing.

Zhang, G., He, F. 2016. Asymmetric failure and control

measures of large cross-section entry roof with

strong mining disturbance and fully-mechanized

caving mining. Chinese Journal of Rock Mechanics

and Engineering, 35(4): 806-818.

Lu, W., et al. 2025. Study on the mechanism of roof

collapse and anchoring-grouting support parametric

sensitivity in deep goaf based on upper limit

method. Journal of Mining & Safety Engineering,

1-16.

Zhao, Z., Yang, P., Zhang, M., et al. 2022. Stability of

weakly cemented soft surrounding rock under

combined effect of water environment and

inhomogeneous ground stress. Journal of Mining &

Safety Engineering, 39(1): 126-135.

Zhang, J. 2014. Engineering Geological Properties of

Soft Surrounding R ocks of Mountain-crossing

Tunnels and Construction Countermeasures. Tunnel

Construction, 34(08): 749-753.

Li, J., et al. 2023. Study on Structural Effect of Steel

Belt of Prestressed Anchorage System for Soft Rock

Tunnel. Journal of Disaster Prevention and

Mitigation Engineering, 43(01): 41-49.

Liu, F. 2023. Treatment of Highway Tunnel Disease and

Finite Element Analysis of Steel Belt

Reinforcement Technology. Construction& Design

For Project, (01): 96-98.

Research on the Stress Analysis and Applicability of Flexible Support Steel Strip in Soft Ground Highway Tunnels

117