Reflections on the High-Quality Development of Geosynthetic

Materials Engineering Testing

Fei Fei

1,2,3* a

and Weile Xiang

1,2,3 b

1

Guangzhou Harbour Engineering Quality Examination Co., Ltd., Guangzhou 510230, China

2

CCCC Fourth Harbour Engineering Institute Co., Ltd., Guangzhou 510230, China

3

Key Laboratory of Environment and Safety Technology of Transportation Infrastructure Engineering, CCCC,

Guangzhou 510230, China

*

Keywords: Soil Composite Materials, Inspection Work, High-Quality Development, Status Quo, Suggestions.

Abstract: At present, Chinese inspection and testing market is undergoing a process of gradual opening up, and the

penetration and competition among testing institutions is extremely fierce. In this fierce market competition,

testing agencies can improve market competitiveness only by achieving high-quality development. Through

studying the current situation and problems of geosynthetic materials testing, this paper puts forward

suggestions from the aspects of people, equipment, quality system and information construction, in order to

provide reference for the new management and operation mode of testing institutions.

1 INTRODUCTION

Material testing is an important link to provide quality

assurance for engineering, and plays an important

role in engineering quality control. As an entity

serving the society, testing institutions are technical

organizations that provide testing services for the

trade (Zhao, 2013), and the accuracy and scientificity

of testing data and results are the ultimate

embodiment of service quality. In the testing work,

the service quality of testing institutions is often

affected by factors such as the level of testing

personnel, the accuracy of instruments and

equipment, and the perfection of the laboratory

quality management system

(Mo, 2023). Nowadays,

traditional testing institutions have problems such as

low personnel quality, backward equipment,

inadequate supervision, and difficult quality control,

which have a certain impact on the quality of project

construction.

In order to solve the problems faced by traditional

testing institutions, improving service quality,

enhancing competitiveness, promoting industrial

upgrading, and promoting high-quality development

of testing institutions have become the only way.In

a

https://orcid.org/0009-0006-1119-9504

b

https://orcid.org/0009-0005-2517-9339

accordance with the requirements of CMA and CNAS

quality certification and accreditation management,

starting from the aspects of testing personnel,

equipment, supporting software, site and

environment, the information technology is combined

with laboratory management to establish a digital and

intelligent test and inspection platform. A new

information management model featuring business

process optimization, scientific resource allocation,

reliable quality control, accurate risk management

and control, and scientific and accurate data has been

formed

(Wang et al., 2023).

2 SIGNIFICANCE OF HIGH-

QUALITY DEVELOPMENT

The testing industry is a high-tech service industry,

productive service industry and scientific and

technological service industry supported by the state

(Jiang et al., 2012). At present, China has formed the

world's fastest growing, largest and most potential

testing market

(Jiang et al., 2015). With the

continuous development of Chinese foreign trade and

Fei, F., Xiang and W.

Reflections on the High-Quality Development of Geosynthetic Materials Engineering Testing.

DOI: 10.5220/0013574100004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 97-101

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

97

the relaxation of testing market access restrictions by

governments at all levels, the development

momentum of testing institutions has become more

and more strong, and the competition among various

institutions has become more intense. In this fierce

market competition, only by achieving high-quality

development can testing institutions have stronger

innovation ability and market adaptability, seize

market opportunities, obtain more benefits, and

promote the sustained and healthy development of the

testing market. At the same time, the high-quality

development of testing institutions also plays a

leading role in maintaining quality and safety,

accelerating technological innovation, and promoting

industrial progress.

The report to the 20th National Congress of the

Communist Party of China pointed out that high-

quality development is the primary task of

comprehensively building a modern socialist country.

In the future, continuing to promote high-quality

development will always be the main melody of

China's economic construction. As an important part

of the national quality infrastructure (You et al.,

2019), the realization of high-quality development is

the embodiment of a positive response to national

policies, which not only can obtain a better

development environment and policy support to

enhance the development space and potential of

enterprises, but also the key to ensuring the safety of

people's lives and property and social stability and

unity.At the same time, in the context of the complex

and severe global economic situation, the high-

quality development of testing institutions plays an

important role in promoting the high-quality

development of the economy and society, and also

provides for the recovery of the global economy.

3 TESTING WORK STATUS AND

PROBLEMS

Geosynthetic materials are the general term for all

synthetic materials used in civil engineering (Huo,

2022). The production and application of domestic

geosynthetic materials started in the 1980s

(Liu,

2016), and after more than 30 years of development,

the product types have been continuously enriched,

and are widely used in road, railway, water

conservancy, electric power construction, seaport,

airport, military industry, environmental protection

and other engineering fields (Liu et al., 2019).

Although geosynthetic materials have a lot of

applications in engineering construction, and have

solved many technical problems for engineering

construction, there are still some problems to be

solved.

(1) Backward equipment

Instruments and equipment are the basic

components of testing work, and the performance and

reliability of testing instruments directly affect the

accuracy of testing results and the quality of the entire

construction project (Zhang, 2021). At present, the

national government continues to support the

application of geosynthetic materials in various

industries and the research and development and

manufacturing of new products. With the

breakthrough of new technologies and the continuous

construction of domestic and foreign infrastructure

(Zhou et al., 2020), the geosynthetic materials testing

industry will usher in more market space.However,

the traditional test equipment does not have the

intelligent function, has the characteristics of time

consuming, labor consuming and low efficiency. For

example, the traditional cutting work of geotextile is

completed by manual use of templates and scissors,

which has large cutting errors, low fabric utilization,

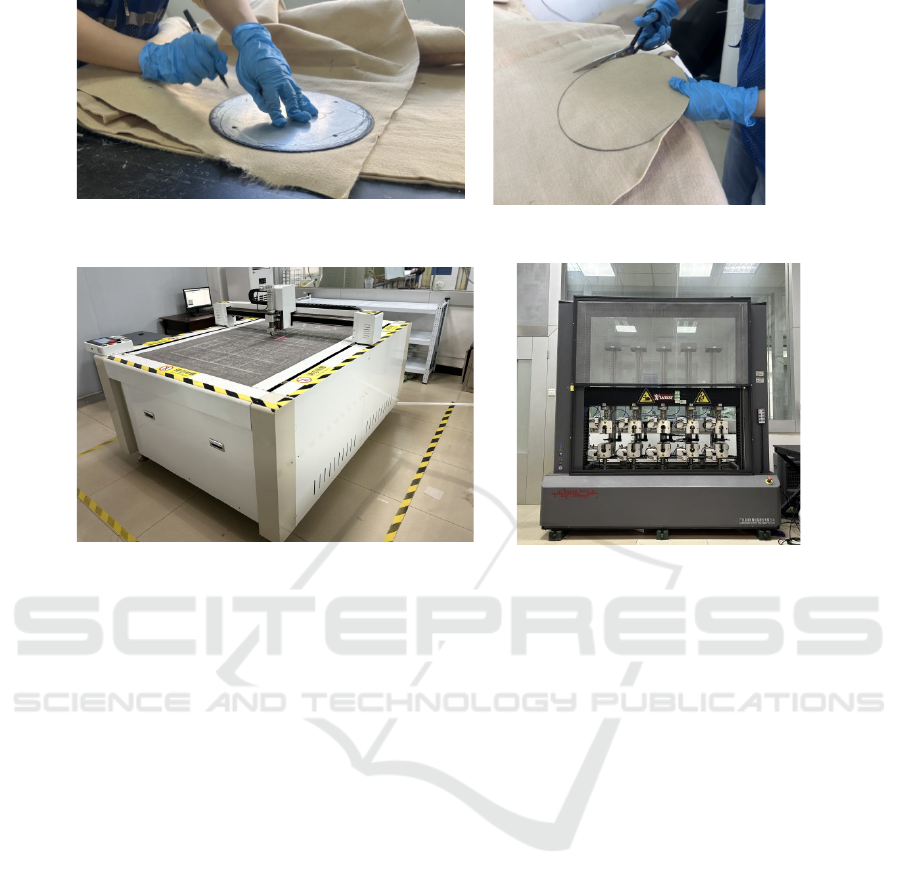

high labor intensity and low efficiency (Figure 1).

The equipment of geotextile tensile test is mostly

simplex, which can only complete the detection of

one sample at a time, and the efficiency is extremely

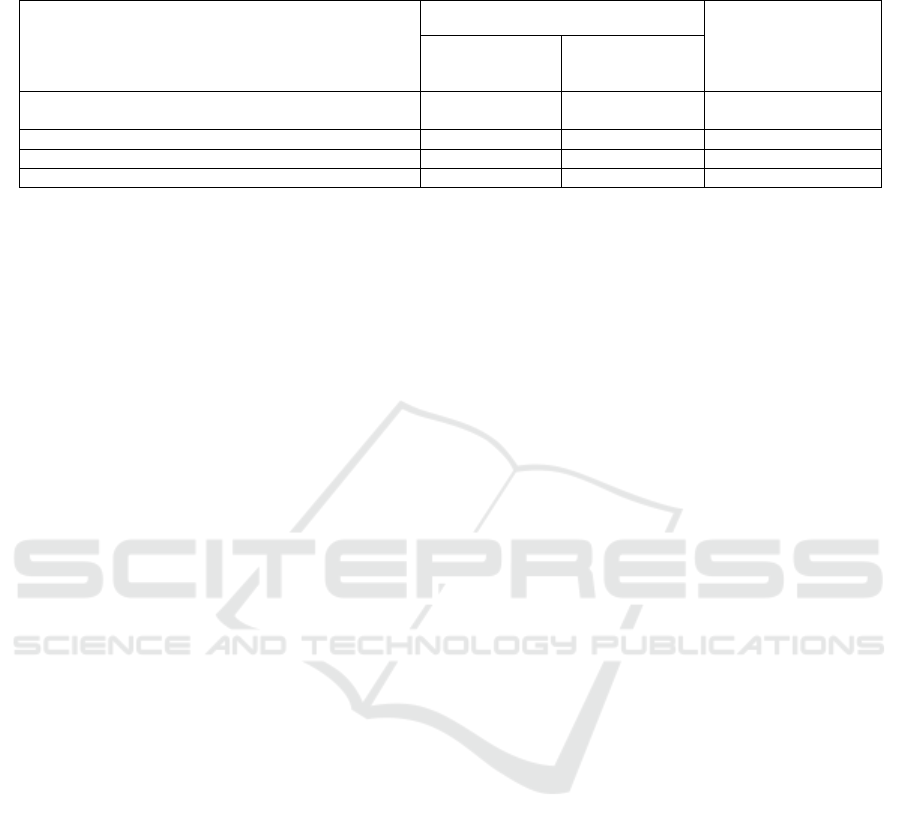

low. At present, there are already devices on the

market that can speed up the cutting rate and detection

rate of geotextiles (Figure 2), but these devices are

mostly for geotextiles, and other categories of soil

composite materials are difficult to use。It can be

seen that the update speed of instruments lags behind

the development of geosynthetic new materials,

which seriously affects the effective development of

testing work and is not conducive to the expansion of

the domestic market, and causes the market

competitiveness of testing institutions to weaken.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

98

Figure 1: Traditional cutting work.

(a) Automatic cutting machine

(b) Microcomputer controlled electronic

universal testing machine (five stations)

Figure 2: Geotextile equipment. (Note 1: Automatic cutting machine has the characteristics of simple operation, fast cutting

speed, low labor intensity, mass production, high efficiency, high precision and fabric saving; The problem of property damage

of geosynthetic materials is avoided by cold processing. Note 2: The Microcomputer controlled electronic universal testing

machine can not only carry out the detection of five samples at the same time, but also reduce the labor intensity of the

detection personnel, so as to achieve the goal of high efficiency and high output.)

(2) Technical personnel shortage

In the testing work, the inspection personnel is the

most important component, which determines the

quality of the inspection work.With the development

of geosynthetic materials industry, new materials and

testing equipment continue to emerge, and the

continuous construction of intelligent and

information platforms, testing institutions need

professional and highly qualified testing technical

personnel. At present, testing personnel lack excellent

professional knowledge and rich work experience,

weak sense of responsibility, which seriously hinders

the high-quality development of testing institutions,

and will lead to quality problems in testing work and

cause hidden dangers.

(3) Non-uniform test standard

The test specification of geosynthetic materials in

China includes two categories: national standard and

industry standard. National standards are equivalent

to or modified according to international

standards.Industry standards involve the Ministry of

Water Resources, the Ministry of Transport, the

Ministry of Ecology and Environment, the Ministry

of Housing and Urban-Rural Development and other

sectors, and have formulated corresponding industry

product standards and application technical

specifications based on international standards,

national standards and some national standards (Xie

et al., 2012). It can be seen that there are many norms

in our country and there are differences among them.

In the testing work, customers will formulate test

specifications according to the nature of engineering

and design requirements. Some customers choose

national standards while others choose industry

standards. The selected testing specifications are

inconsistent and the test conditions are different,

which will have different degrees of impact on the test

results, as shown in Table 1. At the same time, the

industry standard update is relatively slow, can not

keep up with the development of new materials,

which also has a non-negligible impact on the

development of testing work.

Reflections on the High-Quality Development of Geosynthetic Materials Engineering Testing

99

Table 1: Test results under different test standard (Xie et al., 2012).

Item

Standard

Difference ratio

(②-①)/①

National standard

Ministry of

transportation

standard

Test ambient temperature and humidity

20℃±2℃

65%±4%

20℃±2℃

65%±5%

/

Adjustment time of sample status/h 24 24

/

Tear strength of woven geotextile/N 707 785 +11.0

Tear strength f geotextile/N 338 345 +2.0

(4) Underexploited international markets

Infrastructure construction plays an important role

in driving economic growth and is also a hot spot in

international cooperation (Liu et al., 2019). At present,

the global infrastructure development needs are

strong, and the gap is still huge. With the continuous

update and development of geosynthetic materials, its

role in infrastructure construction will continue to

improve. The operation mode of traditional testing

institutions in China is faced with such problems as

backward equipment, low working efficiency and

difficult quality control. For example, the maximum

gripping force of the mainstream pneumatic fixture is

only 20kN, while the strength of the geotextile

applied in engineering is basically between 50 and

100kN, and some special ones even reach 1000kN,

obviously the detection conditions do not match the

detection needs. In the face of the opportunities

brought by domestic and foreign civil engineering

construction, the strength of domestic testing

institutions is weak and the facilities are backward,

and the allocation of resources cannot be in line with

international demand, which will lead to the failure to

open up the international market and the loss of

market opportunities.

4 RECOMMENDATIONS FOR

HIGH-QUALITY

DEVELOPMENT

(1) Attach importance to the construction of talents

The high-quality development of enterprises

needs to form innovative development momentum,

and the essence of innovation-driven is talent-driven,

so the key to high-quality development lies in people.

Only people with high-quality development ability

can promote the high-quality development of

enterprises. Testing personnel are an important part

of testing institutions, and training versatile versatile

talents has become the key to solve the shortage of

personnel and weak technical strength (Hou et al.,

2023). First, strengthen the construction of high-level

and high-level first-class talents, introduce highly

educated talents, and drive the overall development of

the test group. The second is to strengthen the training

of employees, formulate and improve the training

plan of employees, and establish the training

mechanism of employees. The third is to hold skills

competition regularly to stimulate the potential of

employees and encourage employees to improve their

skills.

(2) Construction of quality control system

The construction of quality control system can

ensure the scientific and rational work of testing

institutions, reduce the operational errors of testing

personnel, and then obtain accurate and true

inspection reports to provide support for the quality

of construction projects (Yang and Liang, 2023). The

establishment and improvement of the quality system

can control equipment, personnel, management and

other factors that affect the test quality, which is

conducive to forming an organic whole with clear

division of labor, coordinated responsibilities and

mutual promotion (Zhu, 2014). The first is to

establish a systematic and comprehensive quality

control system to achieve full coverage of elements

according to the Measures for the Management of the

Qualification of Inspection and Testing Institutions,

the Criteria for the Evaluation of the Qualification of

Inspection and Testing Institutions, the Criteria for

the Accreditation of Testing and Calibration

experimental capabilities and other documents. The

second is to establish a suitable quality control system

according to the work scope, work type and workload

to provide support for the accuracy of the test report.

The third is to document the organizational structure,

procedures and process elements of the quality

control system to form a management system

document.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

100

(3) Improve quality supervision and control

Establishing an effective quality supervision and

control system can further reduce the risk and

improve the quality of testing. Through improving the

internal supervision system, to restrict the behavior of

inspection personnel, to ensure that the whole process

of inspection work is real and effective. For example,

the inspection institution installs a camera in the test

operation room to retain the image data of the

detection process to ensure the authenticity,

effectiveness and traceability of the detection process,

which greatly improves the quality of supervision and

reduces the labor intensity of manual supervision. At

the same time, a corresponding reward and

punishment system should be set up to reward

employees with outstanding work, remind employees

with average performance, and change employees

with poor performance through post transfer or

conversation, so as to stimulate employees' sense of

responsibility.

(4) Construction of laboratory informatization

Introducing modern information technology into

quality inspection is of great significance, on the one

hand, it can speed up the development process of

enterprises, on the other hand, it can comprehensively

improve the quality and overall efficiency of

inspection work. First, the application of information

technology in testing work, quality management

system and internal supervision and control can not

only speed up the efficiency of testing work, but also

improve the overall level of testing institutions. At the

same time, testing institutions need to invest a lot of

funds to introduce, update and upgrade testing

equipment, build intelligent and information-based

test platforms, and continue to improve testing

capabilities and market competitiveness.

5 CONCLUSION

With the progress of The Times, new materials

continue to emerge, and people's quality concepts are

gradually improved, which has higher requirements

for geosynthetic materials detection work, we must

pay attention to the development of geosynthetic

materials detection work. In view of the current status

and existing problems of geosynthetic materials

testing in China, this paper closely follows the

national pace and conforms to the policy, reflects on

how to practice high-quality development, and puts

forward relevant suggestions, which has reference

significance for improving the comprehensive

strength of testing institutions.

REFERENCES

Zhao, G. 2013. Discussion on Improving the Operation

Effectiveness of Laboratory Quality Management

System. Mechanical and Electrical Components,

33(02): 52-55.

Mo, L. 2023. Problems existing in the management of

construction engineering quality inspection institutions

and their solutions. Chinese Architectural Decoration,

(14): 140-142..

Wang, B., Yang, J., He, Y., et al. 2023. Understanding and

practice of digital transformation in oilfield enterprise

laboratories. Petroleum Science and Technology

Forum, 42(03): 79-85..

Jiang, E., Cao, Y., Li, J. 2012. Reservoir sediment resource

utilization and River health. In Technical Progress in

Reservoir Dam Construction and Management:

Proceedings of the 2012 Annual Conference of China

Dam Association. Yellow River Water Conservancy

Press, Zhengzhou. Pages 47-53.

Jiang, E., Cao, Y., Dong, Q., et al. 2015. Long-term effects

of sediment resources utilization in the Yellow River.

Yellow River, 37(2): 1-5, 12.

You, L., Li, H., Li, K., et al. 2019. Analysis of sediment

deposition characteristics of Zipingpu Reservoir since

its operation. Yellow River, 43(11).

Huo, J. 2022. Practical application of geosynthetic

materials in civil engineering. Aging and Application of

Synthetic Materials, 51(01): 110-112+138.

Liu, X. 2016, Application of geosynthetic materials in highway

engineering. Transportation World, (19): 54-55.

Liu, K., Zhao, Y., Zhang, N. 2019. Development status and

trend outlook of geosynthetic materials. Textile Review,

(S1): 6-28.

Zhang, Z. 2021. Study on Influencing Factors of

construction inspection quality. Urban Housing,

28(S1): 225-226.

Zhou, D., Zhang, P., Xie, S. 2020. Current situation analysis

and development countermeasures of geosynthetic

materials industry in China (2020). Plastic Additives,

(03): 6-9.

Xie, R., Dong, Z., Guo, W., et al. 2012. Common problems and

their influence in geosynthetic materials inspection

technology. China Harbor Construction, (06): 17-20.

Hou, X., Zhang, K., Zhao, Q. 2023. Exploration and

practice of standardization management in grass-roots

inspection and testing institutions. Standardization in

China, (14): 133-135.

Yang, Z., Liang, B. 2023. Discussion on the Quality

Management System of Construction Engineering Test

and Inspection Institutions. Urban Construction Theory

Research (Electronic Edition), (25): 49-51.

Zhu, M. 2014. Research on quality improvement method of

indoor soil test. Science and Technology Information,

12(22): 64-65.

Reflections on the High-Quality Development of Geosynthetic Materials Engineering Testing

101