Application of Comprehensive Construction Technology for Steel

Sheet Piles in High Water Level Highway Foundation Pit Engineering

with Saline Soil in Confined Space

Xiyuan Liu and Shanzhi Fan

*,† a

Gansu Provincial Transportation Research Institute Group Co., Ltd., Lanzhou 730000, China

*

Keywords: Restricted Space, High Water Level Foundation Pit, Highway Engineering with Saline Soil, Steel Sheet Pile,

Comprehensive Construction Technology.

Abstract: This paper takes the foundation pit project of a highway reconstruction and expansion project in saline soil

areas in western China as an example. In the process of dealing with foundation pits in highway engineering

projects with high water levels and high salt content, the comprehensive construction technology of steel sheet

piles has been successfully applied to address the impact of uneven distribution of soil pressure and salt

expansion force on foundation pit excavation and support. Compared with the diaphragm wall and row - pile

support schemes, the steel sheet pile support scheme applied in this project has obvious advantages. Steel

sheet pile construction features high efficiency, good safety performance, and relatively low costs. Steel sheet

piles can better meet the requirements of noise reduction, green energy conservation in highway engineering

projects around urban areas. They are characterized by high utilization rate of urban space, good economy,

safety, and stability, as well as convenient operation. They are suitable for comprehensive operations in space

- restricted foundation pit construction around urban areas. At the same time, they can isolate salt migration

and counteract salt expansion force in highway engineering projects. They are particularly suitable for

foundation pit projects of highway projects around urban areas with high groundwater levels, high salt content,

high construction risks, and limited space, providing valuable experience for similar engineering construction

in the future.

1 INTRODUCTION

The term "large deformation" first originated from the

concept of mechanics and emerged in contrast to the

small deformation in the field of elasticity mechanics.

In the study of elasticity mechanics, (Xu, 2016)

assumed that after an object is subjected to force, the

displacements of all points in the entire object are far

smaller than the original dimensions of the object,

resulting in both the strain and the rotation angle

being much smaller than 1. This is the small-

deformation assumption, while large deformation

does not meet the above conditions. With the

development of geotechnical engineering, large

deformation has been introduced from the field of

mechanics into the engineering field to describe the

a

https://orcid.org/0009-0003-4904-7125

†

These authors contributed equally to this work and should

be considered co-first authors.

deformation with a large amount of deformation, a

long convergence time, and the potential to cause

damage to conventional support structures. In tunnel

engineering, there is still no unified description of

large deformation. Many scholars often have different

emphases on the definition of large deformation

according to the problems they study; (Jiang, 2004)

defined the large deformation of tunnel surrounding

rock as a progressive and time-effect-obvious plastic

deformation failure of the surrounding rock of tunnels

and underground engineering. It is different from the

brittle failure of rock burst movement and also

different from the collapse, sliding and other failures

restricted by certain structural planes in the loose

circle of the surrounding rock; (Yu, 1998) made the

following regulations on the large deformation of the

surrounding rock of squeezing tunnels based on the

Liu, X., Fan and S.

Application of Comprehensive Construction Technology for Steel Sheet Piles in High Water Level Highway Foundation Pit Engineering with Saline Soil in Confined Space.

DOI: 10.5220/0013574000004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 91-96

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

91

deformation of the early support of squeezing

surrounding rock: during tunnel construction, if the

displacement of the initial support exceeds 25 cm (for

single-track tunnels) and 50 cm (for double-track

tunnels), it is considered that large deformation has

occurred; (Zhang 2003) suggested taking the

displacement value of the initial support and the

damage phenomenon of the support as indicators and

defined large deformation as follows: when the initial

support of a tunnel with conventional support suffers

different degrees of damage due to high ground stress

and the ratio of the displacement value Ua to the

radius a of the tunnel wall is greater than 3%, it is

considered that large deformation has occurred.

China's current relevant highway code, the code

(Ding et al.,

2023) set this limit ratio as 0.013 and

divides large deformation into four grades according

to the magnitude: slight, moderate, severe, and

extremely severe. (Liu et al., 2008; Fei et al., 2012;

He et al., 1994; Kang et al., 2022; He, 2014), etc.

believed that the large deformation of the surrounding

rock is closely related to the actual engineering

phenomena, and thus proposed a definition of large

deformation based on the influence effect of rock

mass deformation and its engineering significance,

that is, the surrounding rock deformation that is

significantly greater than the normal level and may

cause adverse consequences. (He, 2014; The Second

Survey and Design Institute of the Ministry of

Railways, 1997; Wang, 2003; Wei et al., 2017; Wang,

2022; Liu et al., 2005; Chen et al., 2017; Li, 2014;

Wang et al., 2017; Fu and Ming, 2007; Yuan, 2016;

Yang and Kang, 2002), etc. the domestic and foreign

scholars have conducted a lot of research on the

excavation and support of foundation pits in restricted

spaces, but there is less research on foundation pit

excavations with a small space and high groundwater

levels in soft strata.

It is not difficult to see from the above numerous

elaborations that the definition of large deformation

is mainly expressed from two aspects. One is the

external manifestation of large deformation. Most

definitions of this type take the absolute or relative

value of the displacement of the surrounding rock and

the degree of damage to the support structure caused

by it as the criteria for judgment. They are intuitive,

quantitative, and easy to understand, but they fail to

reveal the essence of the large deformation of the

surrounding rock and have no guiding significance

for the further prevention and control of large -

deformation surrounding rock. The other is the

inducing mechanism of large deformation. Most

definitions of this type start from the mechanical

properties that cause large deformation and take the

internal causes and laws as the criteria for judgment.

They have reference value for the same type of

surrounding rock, but due to the complexity of the

geological environment, most of them are too one -

sided and cannot cover the many characteristics of

large - deformation surrounding.

2 PROJECT OVERVIEW

2.1 Engineering Background

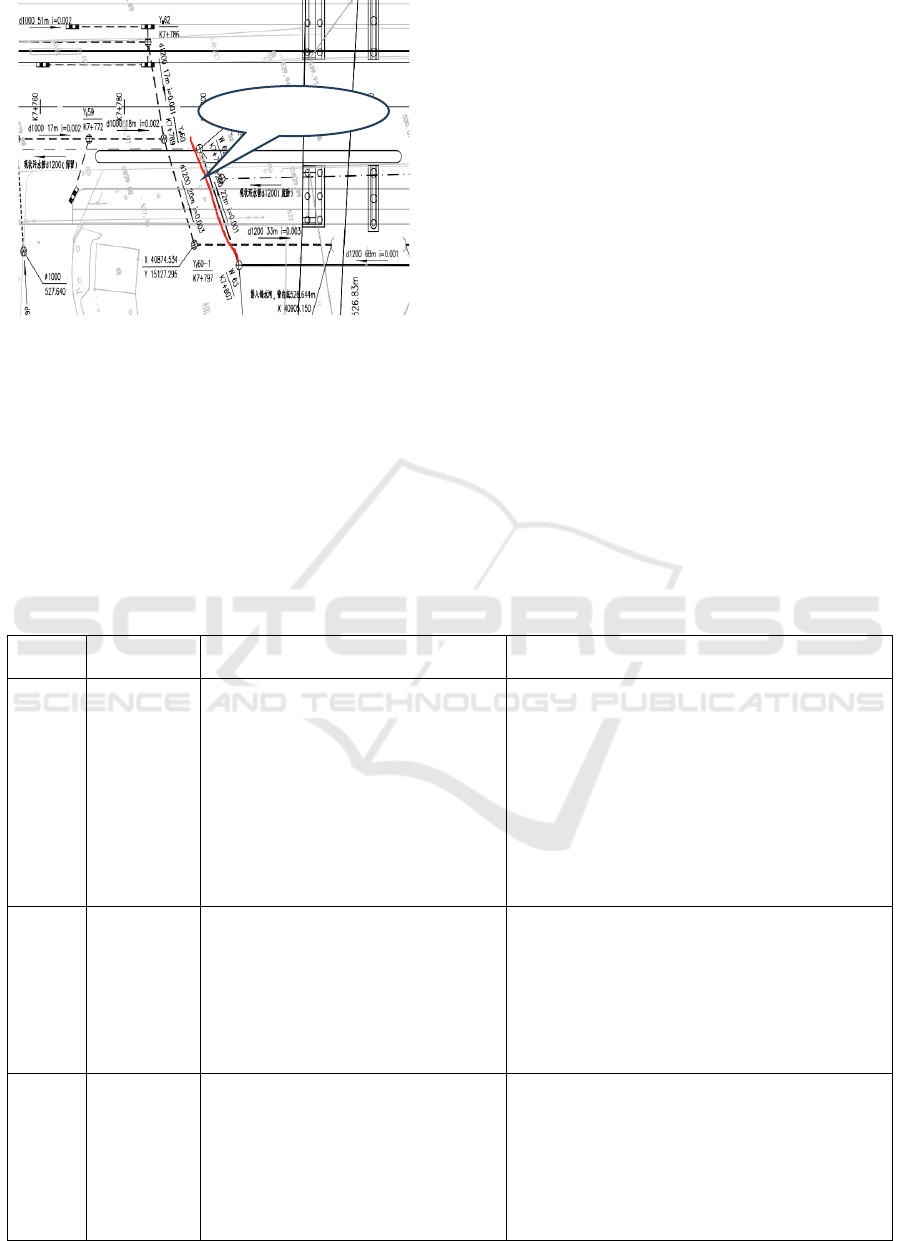

This reconstruction and expansion project is located

in a western city with saline soil, and it has a length

of 14.543 km. The highway is expanded to a two -

lane dual - carriageway, classified as an urban arterial

road. The project includes the Nanqiao Bridge, which

is 51.5 m long and 18.6 m wide and requires widening

and renovation. This bridge poses the greatest

construction difficulty and is a key control project.

Therefore, the construction of the Nanqiao section

needs to be strengthened. The auxiliary pipe gallery

beside the Nanqiao Bridge renovation on the main

road needs to have its pipelines widened to a position

close to the river on the original basis. During the

construction, the relocation of pipelines across the

river is involved. The green belts on both sides of the

river, the artificial slopes, and the original pipe

gallery foundation are built in the silt area of the

riverbed. The silt has a high water content and is in a

fluid - plastic state. The slope during construction is

an earth slope. Moreover, the excavation and

backfilling of saline soil need to be given due

attention during the construction process. To ensure

the smooth progress of the relocation project and the

safe and effective earthwork excavation, steel sheet

piles are used for temporary protection, with a design

life within the construction period. The construction

area is located in the northwest region, and attention

should be paid to winter construction., as shown in

Figure 1.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

92

Figure 1: Location of the project.

2.2 Scheme Comparison and Selection

We have compared three construction methods,

namely the diaphragm wall excavation scheme, the

row - pile support method, and the steel sheet pile

construction method. On the basis of considering

various factors such as the specific characteristics of

the project, construction period, and cost, the steel

sheet pile construction method has been selected. A

comparative analysis of the three construction

schemes has been carried out in terms of construction

difficulty, project cost, applicability, etc., as shown in

Table 1.

2.3 Overall Project Layout Deployment

T Nanqiao Bridge spans a local natural river. The

river flows from the northwest to the southeast. The

width of the river section at Nanqiao ranges from 10.0

to 30.0 meters, and the depth is approximately 4.5 to

5.0 meters. Both banks are protected by mortar - laid

strip - stone slopes. During the survey, there was a

small amount of flowing water in the river, with a

water depth of 0.5 to 1.5 meters. The excavation of

the pipe gallery is close to the river. Soft muddy soil,

as well as layers of eggs and gravel, are distributed on

the surface. Surface water is well - developed.

According to the comparison of the schemes in Table

1, it can be concluded that from the perspectives of

construction safety, investment, and dewatering, the

steel sheet pile method is preferentially selected for

foundation pit support.

Table 1: Comparison Table of Excavation Support Plans.

Serial

Numbe

r

plans applicability Feasibility analysis based on on-site conditions

1

Underground

continuous

wall

(1) For deep foundation pit engineering

projects, the excavation depth generally

exceeds 10m.

(2) There are safety - protected

buildings or structures in the vicinity.

(3) The space within the deep

foundation pit is relatively limited.

(4) The top - down construction method

is adopted.

The disposal of waste slurry is highly inconvenient.

As a temporary retaining structure, the diaphragm

wall incurs higher costs compared to other

methods. In case of an inappropriate construction

method or special construction geological

conditions, misalignment and seepage may occur at

the ends of adjacent wall segments. In this project,

there are soft muddy soils and alluvial layers

containing boulders. The soft muddy soils are fluid,

which increases the construction difficulty and

p

oses si

g

nificant construction risks.

2 Row pile

(1) Foundation pits are classified into

three safety levels: level - one, level -

two, and level - three foundation pits.

(2) It is mostly applied to the support of

basements with poor - quality soil for

excavation, complex surroundings

around the foundation pit, and relatively

dee

p

excavation.

In this project, the row - pile support generally

comes with a relatively high cost. Additionally, the

excavation site has limited space, the groundwater

level is high, and there are stringent requirements

for construction personnel and equipment.

3

Steel sheet

pile

(1) It is applicable to construction sites

where the amount of earthwork for

foundation pit excavation is small,

mechanized construction operations can

be carried out smoothly, and drainage is

unobstructed.

From the perspectives of cost - saving, construction

convenience and the characteristics of the

construction site itself in this project, steel sheet

piles can be reused. They can be easily driven into

soft muddy soil and clay. Steel sheet piles have

excellent water - retaining performance, high

adaptability, reliable quality, and can bring high

economic benefits.

the

p

ro

j

ect

Application of Comprehensive Construction Technology for Steel Sheet Piles in High Water Level Highway Foundation Pit Engineering

with Saline Soil in Confined Space

93

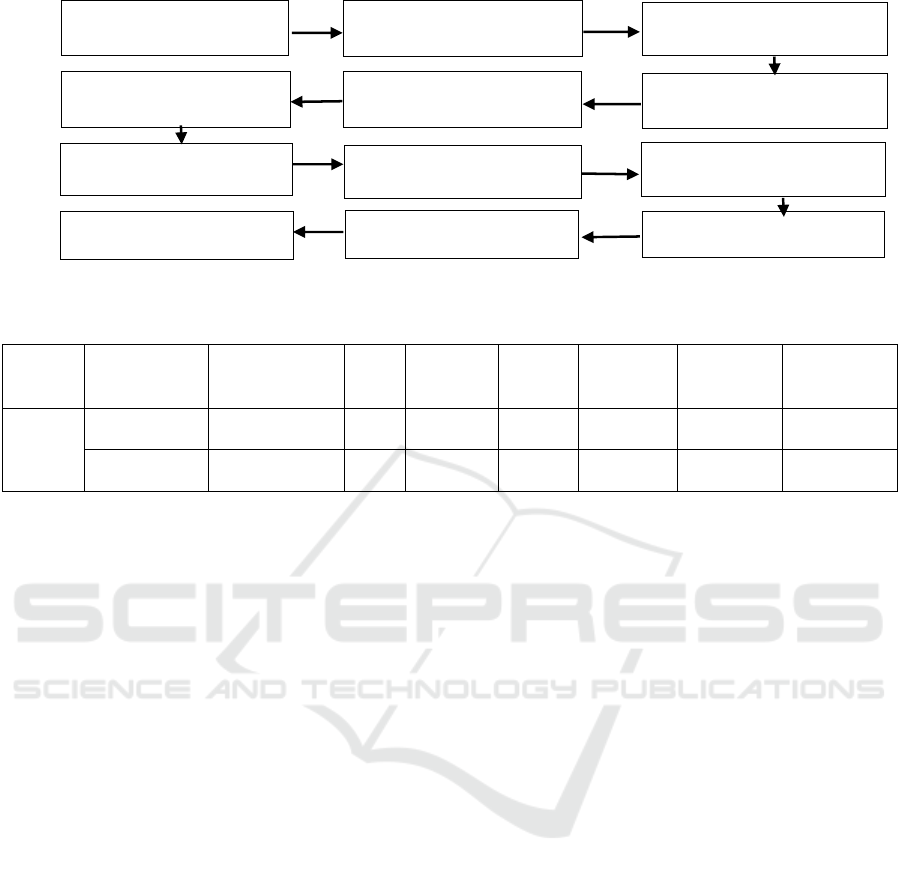

Figure 2: Schematic diagram of steel sheet pile process flow.

Table 2: Standardize slope ratio.

name slope height

Saline filled

soil

silt

Medium

sand

Loose

pebbles

Slightly

dense

p

ebbles

Medium

density

p

ebbles

Dense

pebbles

Slope

rate

H<5m 1:2 1:2.5 1:1.5 1:1.25 1:1 1:0.75 1:0.5

H=5~10m 1:2 1:3.0 1:1.5 1:1.5 1:1.25 1:1 1:0.75

H represents the height of slope or foundation pit excavation, measured in meters.

2.4 Construction Scheme

The depth of the foundation pit in this project is

approximately 4.7 - 7.7m. The backfill, silt, and sand

layers on the foundation trench walls have a loose

structure, classifying this as a "high - risk project".

Appropriate measures should be taken to ensure the

safe construction of the foundation trench. It is

recommended to adopt an excavation plan combining

slope-setting with temporary support. There are a

large number of underground pipelines distributed on

both sides of the original municipal roads near the

project site. These mainly include water supply,

sewage, rainwater, gas, power, and communication

pipelines, with a burial depth of around 0.7m-7.7m.

Therefore, it is proposed to conduct surveys and

marking of underground pipelines before

construction, formulate key protection plans, and

move or remove pipelines that may affect

construction when necessary to ensure construction

safety. In practice, protection measures should be

implemented according to the actual situation at the

construction site, such as using reinforcement

treatment. Based on the characteristics of this project

and the survey data, the technological process is

shown in Figure 2. The slope ratios of various soils

for the building slope are specified as shown in Table

2.

2.5 Construction Plan

Before connecting the new pipeline to the old sewage

pipeline, a confined - space operation plan should be

formulated. After it is approved, the operation must

be carried out strictly in accordance with the

requirements of the plan. Provide safety and technical

training to the operating personnel, distribute labor

protection supplies, and ensure an adequate supply of

emergency response items. Before the operation,

conduct gas detection and ventilation of the old

pipeline. The operation can only commence once the

conditions meet the requirements. During the

operation, assign dedicated personnel to monitor and

conduct continuous gas detection in the working area.

For the personnel involved in pipeline connection

work, arrange for two or more workers to carry out

the construction simultaneously.

3 SAFETY CALCULATION OF

STEEL SHEET PILE

ENCLOSURE STRUCTURE

According to the excavation specifications for steel

sheet piles, it is necessary to convert the uniformly

distributed load within a certain range on the outer

Measurement, laying out, and

positioning of steel sheet piles

Construction of surrounding

intercepting ditches

Dig trenches

Install guide beam

Construction of steel sheet piles

Dismantle the guide beam

earth excavation

Supporting construction

Pipeline construction

Backfilling construction

Remove the steel sheet pile

Gap treatment after steel sheet

p

ile removal

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

94

side of the steel sheet pile into a certain height of the

soil column,

ℎ

= 𝑞/𝛾 = 20𝑘𝑃a/20kN/m

=1.0𝑚, ℎ

—

𝑐𝑜𝑛𝑣𝑒𝑟𝑡 𝑡ℎ𝑒 ℎ𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑡ℎ𝑒 𝑠𝑜𝑖𝑙 𝑐𝑜𝑙𝑢𝑚𝑛 , q — the

load around the foundation pit,

𝛾— 𝑐𝑜𝑛𝑣𝑒𝑟𝑡 𝑡ℎ𝑒 𝑤𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑡ℎ𝑒 𝑠𝑜𝑖𝑙, the design

adopts 12 m Larson steel sheet piles, Minimum depth

of steel sheet pile into soil: H

min

=1.2 ×

(0.53+1.53)=2.5 m, Length of steel column:

L=2.5+5.0=7.5 m, Compliant with regulatory

requirements.

3.1 Construction Process of Steel Sheet

Piles

(1) Prepare the pile driving machine.

(2) During concrete pouring, first use machinery

to lift the sheet piles to the pile - insertion point for

pile insertion. Align them manually and precisely aim

at the pile - insertion port. Then, construct the steel

sheet piles one by one using the driving method. To

ensure the vertical angle, two levels are used for

control. Set up a fastening plate at the lock - mouth of

the steel sheet piles in the correct direction of the piles.

Once the piles are inserted in place, immediately weld

and fix them to the steel purlins with steel bars or steel

plates.

(3) When driving the steel sheet piles, if there are

gaps at the joints due to tilting, special - shaped sheets

with a wider upper part and a narrower lower part, or

with a width exceeding or less than the standard

distance are generally used for adjustment. If

processing is difficult, the center - line modification

method can also be adopted for correction.

(4) When vibrating and driving into the soil layer,

if there are crushed stones thrown into the foundation,

the vibrating pile - driving construction can be used

to pull out the piles first, and then drive them again.

Vibrate up and down and drive several times until the

piles are successfully driven in.

(5) Drive each pile into the soil layer in turn. At

the same time, pay attention to the accurate

positioning and alignment of the lock - mouths to

ensure the construction quality. Measure and

determine the position of the sheet piles according to

the construction drawings and install the guide frame

(the guide frame consists of guide beams and purlin

piles).

3.2 Common Issues in Steel Sheet Pile

Construction

Accurately measure and determine the position of the

sheet piles according to the construction drawings and

install the guide frame. The guide frame is composed

of guide beams and steel purlins.

(1) Use a level and a leveling instrument to control

and adjust the position of the guide light.

(2) The height of the beam should be appropriate,

reserving a certain height space for steel sheet pile

construction and improving work efficiency.

(3) As the steel sheet piles are poured, the guide

beam should not sink or deform.

(4) The position of the slide rail should be as

vertical as possible and should not collide with the

steel sheet piles.

4 CONCLUSION

This paper takes the high-water-level foundation pit

project of the pipe gallery in the Chengdu-Pengzhou

Road Reconstruction and Expansion Project as an

example to study the practical application effect of

the comprehensive construction technology of steel

sheet piles in dealing with high - water - level

foundation pits.

(1) Steel sheet piles can better meet the

requirements of urban noise reduction, green energy

conservation. They have advantages such as high

utilization rate of urban space, good economy, safety,

and stability, as well as convenient operation. They

are suitable for comprehensive operations in urban

foundation pit construction spaces with limitations (in

terms of height). They are particularly applicable to

urban foundation pit projects with high groundwater

levels, high construction risks, and limited space.

AUTHOR CONTRIBUTION

Xiyuan Liu: conceptualization, methodology, data

curation, writing-original draft preparation. Shanzhi

Fan: review & editing.

FUNDING INFORMATION

This paper is supported by Key R&D Program of

Gansu Provincial Department of Science and

Technology - Industrial Category (23YFGA0018).

DATA AVAILABILITY

The data used to support the findings of this study are

Application of Comprehensive Construction Technology for Steel Sheet Piles in High Water Level Highway Foundation Pit Engineering

with Saline Soil in Confined Space

95

available from the corresponding author upon request.

CONFLICTS OF INTEREST

We declare that we do not have any commercial or

associative interest that represents a conflict of

interest in connection with the work submitted.

REFERENCES

Xu, Z. L. 2016. Elasticity. Higher Education Press, Beijing.

Vol. 58, Issue 11, pages 76-80.

Jiang, Y. 2004. Research on Prediction, Forecasting and

Countermeasures of Large Deformation of Surrounding

Rock in Highway Tunnels. Chengdu University of

Technology, Chengdu.

Yu, Y. 1998. The mechanism and determination method of

large deformation in compressive rock support. World

Tunnel, (01): 46-51.

Zhang, Z. D. 2003. Exploration and Research on Large

Deformation of Squeezing Surrounding Rock Tunnels.

Modern Tunnel Technology, (02): 5-12+40.

Ding, X. L., Zhang, Y. T., Huang, S. L., et al. 2023,

Mechanism of Large Deformation of Tunnel

Surrounding Rock, Prediction and Application of

Squeezing Large Deformation. Journal of Rock

Mechanics and Engineering, 1-24.

Liu, Z. C., Zhu, Y. Q., Li, W. J., Liu, P. X., et al. 2008.

Research on the Mechanism and Grading Standards of

Large Deformation in Squeezing Surrounding Rock

Tunnels. Journal of Geotechnical Engineering, (05):

690-697.

Fei, W. P., Zhang, J. M., Cui, H. L., et al. 2012. Analysis of

Large Deformation Mechanism of Surrounding Rock

during Construction of Deep Underground Caverns.

Journal of Rock Mechanics and Engineering, 31 (S1):

2783-2787.

He, M. C., Peng, T., Chen, Y. J. 1994. Large deformation

problems and research methods in soft rock engineering.

Hydrogeology and Engineering Geology, (05): 5-8.

Kang, Y. S., Geng, Z., Liu, Q. S., et al. 2022. Research

progress on control technology and methods for large

deformation disasters in soft rock in China. Rock and

Soil Mechanics, 43 (08): 2035-2059.

He, M. C. 2014. Research progress and challenges in deep

soft rock engineering. Coal Journal, 39 (08): 1409-

1417.

The Second Survey and Design Institute of the Ministry of

Railways. 1997. Stability and Support Technology of

High Stress Ratio Coal bearing Strata Roadways

(Research Report). The Second Survey and Design

Institute of the Ministry of Railways, Chengdu.

Wang, R. 2003. Research on the Mechanism and Prevention

Measures of Large Deformation of Surrounding Rock in

Zhegushan Tunnel of National Highway 317. Chengdu

University of Technology, Chengdu.

Wei, L., Liu, Q., Huang, P. 2017. A review of research on

the mechanism and control measures of large

deformation in high stress soft rock tunnels. Highway,

62 (07): 297-306.

Wang, Y. 2022. Research on Large Deformation Control

Technology of Soft Surrounding Rock in Qingyunshan

Tunnel. Value Engineering, 41 (29): 106-108.

Liu, G., Zhang, F. Y., Li, X. Z., et al. 2005. Characteristics

and Mechanism Analysis of Large Deformation in

Muzhailing Tunnel. Journal of Rock Mechanics and

Engineering, (S2): 5521-5526.

Chen, S. H., Li, Z. P., Ma D. 2017. Xinguanjiao Tunnel on

Qinghai Tibet Railway. Tunnel Construction, 37 (07):

907-911.

Li, J. L. 2014. Rock Mechanics. Chongqing University

Press: A Series of Textbooks for Undergraduate

Guidance Professional Standards in Civil Engineering

for Higher Education Institutions, 318.

Wang, W. J., Dong, E. Y., Yuan, C., et al. 2017. Research

Progress on Anchor Rod Support Theory and

Technology for Deep and Large Deformation Tunnels.

Mining Engineering Research, 32 (02): 1-10.

Fu, Q., Ming, A. X. 2007. Mechanism of anchor rod (cable)

span reduction and its application in deep buried large-

span tunnels. China Mining, (05): 64-65+68.

Yuan, Y. 2016. Research on High Ground Stress Soft Rock

Large Deformation Control Technology for Lanxin

Second Line Daliang Tunnel. Southwest Jiaotong

University, Chengdu.

Yang, S. S., Kang, L. X. 2002. Summary and Prospect of

Research on Anchor Rod Support in Coal Mine

Roadways. Journal of Taiyuan University of

Technology, (04): 376-381.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

96