Indication of Solution Temperature and Conductivity During

Electrochemical Oxidation of Hydrazine Wastewater

Zhen Zhou, Shouzhong Wang, Xiaojun Fang, Wen Ma, Ningran Hou and Yuan Cheng

*a

State Key Laboratory of Technologies in Space Cryogenic Propellants, Beijing 100028, China

*

Keywords: Electrochemical Oxidation, Unsymmetrical Dimethylhydrazine, Conductivity, Temperature.

Abstract: The electrochemically activated persulfate process has been demonstrated to enhance the efficacy of the

degradation of unsymmetrical dimethylhydrazine (UDMH) in wastewater. The concentration of UDMH was

typically determined through amino sodium ferrocyanide spectrophotometry. Nevertheless, the lengthy

chromogenic reaction time and intricate operational procedure impede the efficiency of the analysis. The

utilization of solution conductivity and temperature as indicators to ascertain the extent of UDMH degradation

can enhance the efficiency of the analytical process. The impact of varying voltage, initial pH, ionic strength,

Na₂S₂O₈ dosage, circular flow, and UDMH concentration on the observed patterns of UDMH concentration,

pH, solution temperature, and conductivity were investigated. A correlation was identified between the

transition points for the rapid and gradual changes in conductivity and temperature, which occurred five

minutes earlier than those observed in the UDMH concentration and pH. During the sampling process, the

degree of UDMH removal can be predicted online by monitoring the solution temperature and conductivity,

thereby reducing the duration of the test and enhancing the efficiency of the analysis.

1 INTRODUCTION

The generation of propellant wastewater from rocket

launches is a significant environmental concern. Each

launch produces over 300 tons of wastewater (Li et

al., 2017), with high-density launches generating

even greater quantities. This wastewater has the

potential to overwhelm wastewater treatment systems

and negatively impact the surrounding ecological

environment at satellite launch centers. While the

advent of novel green propellants, such as liquid

hydrogen and liquid oxygen, has mitigated the

environmental impact, conventional propellants,

particularly unsymmetrical dimethylhydrazine

(UDMH), retain a pivotal role in thruster attitude

adjustment (Zheng et al., 2006). UDMH is classified

as a Class II highly toxic substance, and it has the

potential to cause a deficiency of vitamin B6, which

can lead to disease. Furthermore, it has been

identified as a teratogenic, carcinogenic, and

mutagenic hazard to humans (Zeng et al., 2019a;

Deng et al., 2015).

a

https://orcid.org/

0000-0002-3191-3270

The current treatment methods for UDMH can be

broadly classified into the following categories:

adsorption, ion exchange, biological treatment,

advanced oxidation processes, and so forth. In a study

conducted by (Gu et al., 2019), UDMH was adsorbed

using oxalic acid-modified attapulgite, resulting in an

adsorption efficiency of 95%. Nevertheless, the

adsorption method is primarily applicable to the

treatment of propellant wastewater with low

concentration and significant fluctuations in water

quality (Gu et al., 2019). Li et al. (2006) synthesized

a strong acid cation exchange fiber, which

demonstrated a treatment capacity that was 3.86 times

greater than that of 732 strong acid cation exchange

resin. Nevertheless, the ion exchange capacity is

susceptible to interference from background hardness

ions, and the regeneration rate is relatively slow

(Deng et al., 2015). Wang (2005) achieved 98%

removal of UDMH and 89% removal of COD

Cr

through the domestication of activated sludge.

However, this method has a complex microbial

cultivation process and a lengthy degradation reaction

time, which restricts its promotion and application.

Zeng's team prepared nitric acid-modified g-C

3

N

4

Zhou, Z., Wang, S., Fang, X., Ma, W., Hou, N., Cheng and Y.

Indication of Solution Temperature and Conductivity During Electrochemical Oxidation of Hydrazine Wastewater.

DOI: 10.5220/0013573700004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 71-77

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

71

(Zeng et al., 2019b), TiO

2

/g-C

3

N

4

(Zeng et al., 2018),

and modified TiO

2

/g-C

3

N

4

(Zeng et al., 2019a), which

demonstrated a notable degradation effect on UDMH.

Hou et al. (2019) employed a near-critical water

oxidation process to facilitate the harmless treatment

of high-concentration UDMH waste liquid.

Plasma is the fourth state of matter, occurring

when gases are ionized to a sufficient extent. It can be

produced either completely or partially, and only

under specific conditions. The process of high-

pressure discharge results in the formation of a

considerable number of free electrons, which are

subsequently accelerated to attain a high level of

energy. Ultraviolet light irradiation, shockwaves and

other physicochemical effects are produced by high-

energy electrons and non-elastic collisions between

atoms or molecules. The prevailing hypotheses

regarding the mechanisms by which plasma removes

water pollutants are as follows: high-energy electron

action, ozone oxidation, and ultraviolet light

radiation. The utilization of plasma in wastewater

treatment offers a number of advantages, including a

compact structure, a small footprint, convenient

operation, wide adaptability to raw water, the absence

of the need to add chemicals during the reaction

process, and the absence of risk of secondary

pollution.

Qiu et al. (2020) employed nanosecond pulse

power to achieve the degradation of 83.2% of acid red

73 dyes. Rong et al. (2020) applied low-temperature

plasma to treat polyacrylamide, achieving a

degradation rate of 85.74%. Liu et al. (2020)

exploited the strong reductive ·H and oxidative ·OH

generated during low-temperature plasma discharge

to achieve the simultaneous reduction of Cr(VI) and

oxidation of phenol. Yi et al (2019) utilized dielectric

barrier discharge low-temperature plasma to achieve

the degradation of 82.1% of UDMH. Nevertheless,

the fundamental theory and empirical findings

pertaining to the utilization of plasma for the

remediation of hydrazine propellants are

comparatively scarce within both domestic and

international academic circles. Furthermore, the

direct application of plasma in industrial wastewater

treatment is characterized by high energy

consumption and a low energy throughput, which

constrains the practical deployment of this

technology (Wu et al., 2019).

The Fenton-like advanced oxidation technology

based on sulfate radicals has recently attracted

attention due to several favorable characteristics. Its

oxidation-reduction potential (2.5-3.1 V) is higher

than that of ·OH (1.8-2.7 V), the half-life of ·SO

4

-

is

long and difficult to affect by pH, and it has strong

oxidation selectivity. At room temperature, the

oxidizing power of persulfate is limited and requires

activation by an activator to produce ·SO

4

-

. The

activation of persulfates can be achieved through the

application of ultraviolet visible light, heat, alkali,

microwave radiation, carbon materials, and transition

metals. Of these, ultraviolet light radiation and heat

produced under plasma action have been

demonstrated to be particularly effective in this

regard.

Based on this, the combination of plasma and

persulfate to remove UDMH can be used to activate

persulfate, producing ·OH and ·SO

4

-

, in two ways.

Firstly, ultraviolet light and heat produced by plasma

can be used to activate persulfate. Secondly, ozone

and high-energy electrons formed by plasma

discharge enable direct attack on pollutants. This

approach allows the complementary advantages of

both methods to be achieved.

In the preceding stage, the parameters, including

voltage, initial pH, background ion concentration,

persulfate dosage, circulation flow rate, and pollutant

concentration, were optimized to identify the optimal

operating conditions for the process (Zhou et al.,

2023). These conditions were found to result in a

93.8% removal efficiency for 100 mg/L UDMH.

However, the measurement of UDMH concentration

in the effluent was obtained by the GB/T 14376-1993

amino ferrocyanide sodium spectrophotometry

method, which has a lengthy coloration reaction and

complex operational steps. Accordingly, we explored

the potential of utilizing convenient test indicators as

proxies for the degree of reaction, with a view to

employing them as alternative indicators for UDMH

concentration. In this regard, we examined the

fluctuations in solution temperature and conductivity

throughout the UDMH treatment process.

2 METHOD

2.1 Reagents

Na

2

S

2

O

8

, NaCl, NaOH, HgSO

4

, Ag

2

SO

4

,

(NH

4

)

2

Fe(SO

4

)

2

·6H

2

O, Na

2

HPO

4

·12H

2

O, Na

2

[Fe

(CN)

5

NO]·2H

2

O, 1,10-phenanthroline, acetic acid,

acetylacetone, ammonium acetate were all purchased

from the National Pharmaceutical Group, analytical

pure. K

2

Cr

2

O

7

was provided by the National

Pharmaceutical Group as a guarantee reagent.

Anhydrous ethanol, citric acid, 95-98% H

2

SO

4

were

provided by the Beijing Chemical Factory. UDMH

was provided by the Beijing Aerospace Test

Technology Research Institute (98.7%), and all steps

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

72

involving the dilution, degradation, and analysis of

UDMH were carried out in a fume hood. All reagents

were dissolved and diluted with ultrapure water

prepared by Milli-Q (18.2 MΩ, USA) and stored in a

refrigerator set at 4°C after preparation.

2.2 Experimental Apparatus

The entire experimental system consists of the

following components: a tubular reactor, a blower, a

power supply, an oscilloscope (MSO7104B, Agilent

Technologies), a peristaltic pump (LongerPump), a

water tank, and so forth. The UDMH solution in the

water tank is forced into the inlet by the peristaltic

pump (LLS PLUS-B163, Kachuaner Fluid

Technology Co., Ltd.), enters the quartz inner tube

from the bottom, overflows from the top of the inner

tube, and enters the gap between the inner and outer

tubes. Upon traversing the 110 mm-long discharge

zone, the wire mesh assumes the role of the high-

voltage pole, while the UDMH wastewater serves as

the ground pole. The treated solution is then conveyed

to the lower water tank, where it is subjected to a

further treatment cycle via the peristaltic pump.

During the sampling process, it is essential to ensure

that the power supply is deactivated and that the

reaction is terminated with the addition of 0.1ml of

anhydrous ethanol. The pH, conductivity, and

solution temperature of the samples should be

measured. Once the experiment has concluded, the

liquid in the central tube should be emptied, rinsed

with ultrapure water on several occasions and the

remaining water should be drained away. The

concentration of UDMH in the solution is determined

by the GB/T 14376-1993 amino ferrocyanide sodium

spectrophotometry method, with the measurement

instrument being the SHIMADZU UV-2550

spectrophotometer. Meanwhile, the temperature and

conductivity are recorded with the HACH HQ14d

apparatus.

3 RESULTS AND DISCUSSION

3.1 Influence of Initial pH

Changing the pH of the solution will change the form

of existence of UDMH, and it is necessary to study

the changes in solution temperature and conductivity

under different pH conditions. Degradation of 100

mg/L UDMH waste water under the environment of

maintaining a NaCl background ionic strength of 50

mmol/L, a discharge voltage of 12.5 kV, a

Na

2

S

2

O

8

/UDMH (mol/mol) ratio of 1.0 and a

circulation flow rate of 140 mL/min.

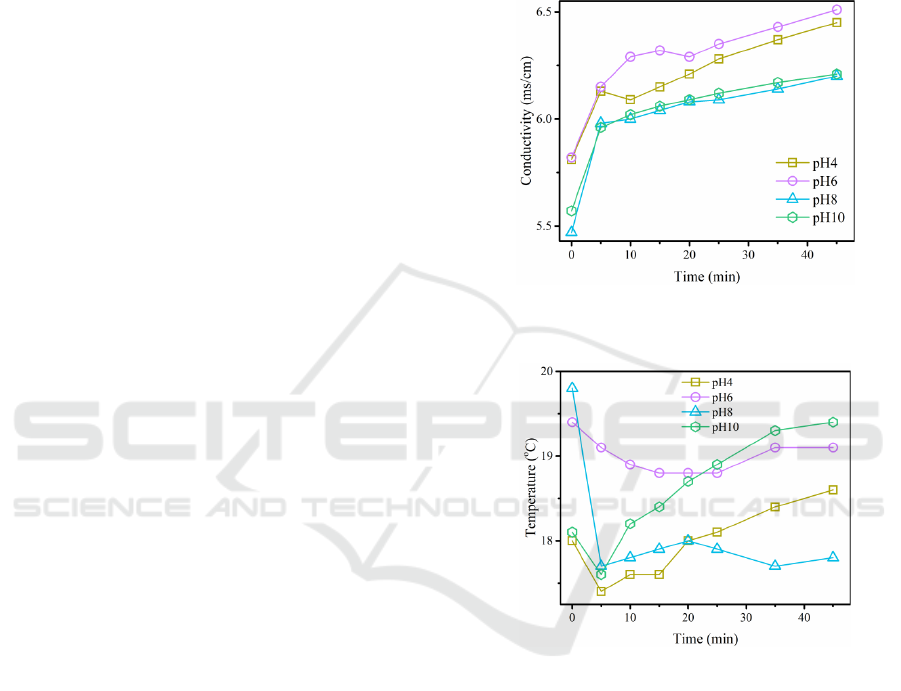

The change in conductivity of the solution is

shown in Figure 1. As can be seen from the figure, the

solution conductivity corresponding to the initial pH

of 4-10 increases as the reaction time is increased,

rising rapidly within the first 5 minutes and then

slowing down.

Figure 1: Conductivity variation with time as initial pH

fluctuation.

Figure 2: Temperature variation with time as initial pH

fluctuation.

The change in solution temperature is shown in

Figure 2. Except for the solution corresponding to the

initial pH of 6, the solution temperature decreases

rapidly within the first 5 minutes and then increases.

When the initial pH is 6, the solution temperature

decreases slowly and starts to increase after 25

minutes.

Compared with previously reported patterns of

change in UDMH concentration and pH (Zhou et al.,

2023), the rapid response phase of solution

temperature and conductivity also appeared to

precede the initial pH change by 5 min, i.e. the cut-

off point between rapid and slow responses for

solution temperature and conductivity was 5 min, and

Indication of Solution Temperature and Conductivity During Electrochemical Oxidation of Hydrazine Wastewater

73

10 min was used as the cut-off point between rapid

and slow responses for UDMH concentration and pH.

3.2 Influence of Background Ion

Concentration

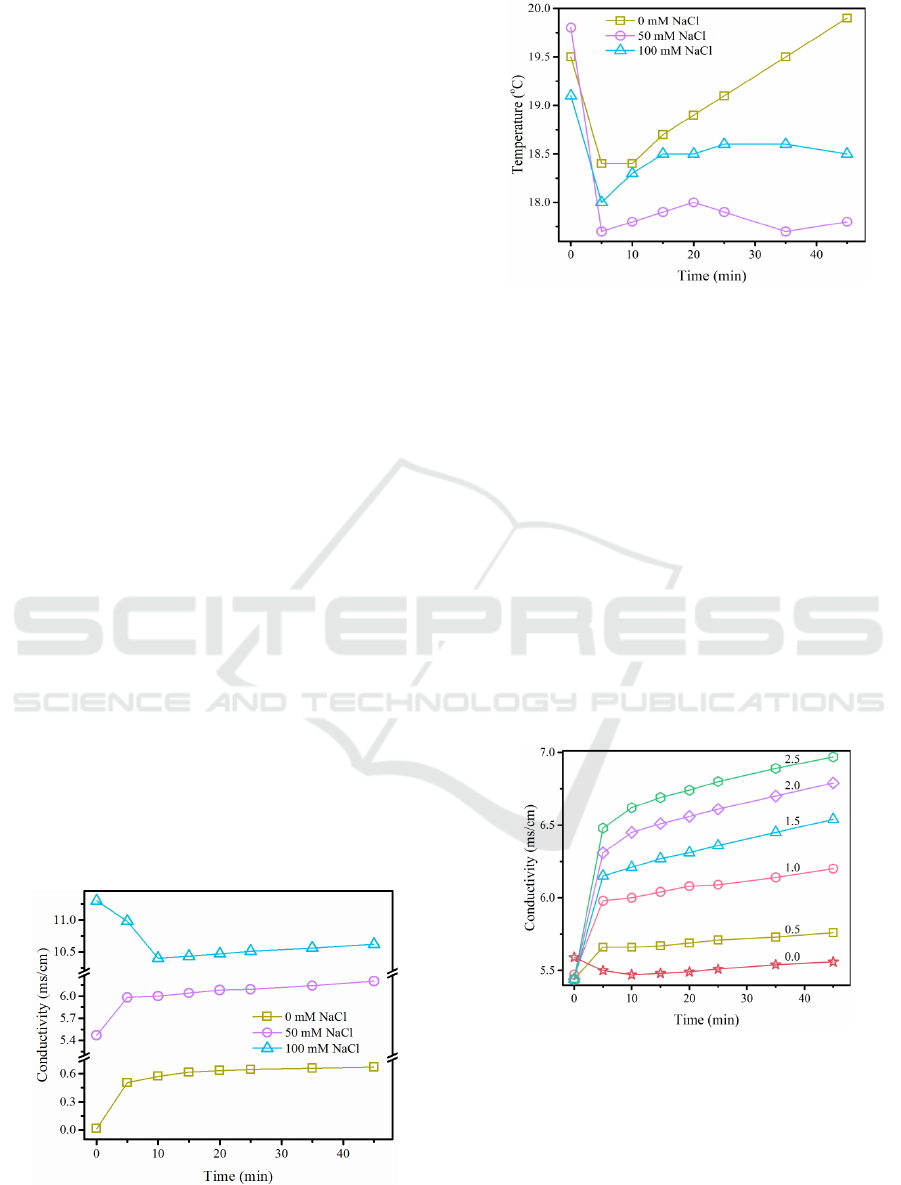

The changes in solution temperature and conductivity

were investigated as the background ionic strength of

NaCl was varied at a molar ratio of Na

2

S

2

O

8

to

hydrazine hydrate of 1.0, an initial pH = 8, a discharge

voltage of 12.5 kV, a recirculation flow rate of 140

mL/min and an initial concentration of meta-

dihydrazine of 100 mg/L.

The change in conductivity of the solution is

shown in Figure 3. As can be seen from the figure, the

solution conductivity corresponding to 0 mM and 50

mM NaCl increases as the reaction time is increased,

rising rapidly within the first 5 minutes and then

slowing down. In contrast, the conductivity of the

solution corresponding to 100 mM NaCl decreases

rapidly during the first 10 minutes and then increases

slowly. The rapid decrease in conductivity is due to

the high concentration of Cl

-

which is rapidly

oxidized and gasified in the electrochemical reaction.

The variation in solution temperature is shown in

Figure 4. The solution temperature decreased rapidly

for the first 5 min, then the solution temperature

increased. The solution temperature increased

linearly with the fastest growth at 0 mM NaCl

background ionic strength. The increase in

temperature may be due to the low conductivity and

high resistivity of the solution resulting in high heat

generation.

Similarly, the cut-off points for fast and slow

solution temperature, conductivity were 5 min earlier

than the cut-off points for fast and slow UDMH

concentration, acidity and alkalinity as the

background ionic strength was varied.

Figure 3: Conductivity changing with time as NaCl

concentration fluctuates.

Figure 4: Temperature changing with time as NaCl

concentration fluctuates.

3.3 Influence of Na

2

S

2

O

8

Dosage

Optimization of Na

2

S

2

O

8

as a key factor in the

degradation of UDMH wastewater is necessary.

UDMH effluent of 100 mg/L was degraded by

maintaining the initial pH = 8, a recirculation flow

rate of 140 mL/min, a background NaCl ionic

strength of 50 mmol/L and a loaded voltage

environment of 12.5 kV.

The variation in solution conductivity is shown in

Figure 5. As can be seen from the figure, without

Na

2

S

2

O

8

the solution conductivity decreased slightly

in the first 10 minutes and then slowly increased.

After the addition of Na

2

S

2

O

8

, the solution

conductivity increased rapidly in the first 5 minutes

and then the growth rate slowed down.

Figure 5: Conductivity changing with time as Na

2

S

2

O

8

fluctuates.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

74

Figure 6: Temperature changing with time as Na

2

S

2

O

8

fluctuates.

The variation of the solution temperature is shown

in Figure 6. After the addition of Na

2

S

2

O

8

, the

solution temperature decreased for the first 5 minutes,

after which the solution temperature increased. In

contrast, when Na

2

S

2

O

8

was not added, the solution

temperature continued to decrease slowly and then

reached a steady state.

The cut-off point for fast and slow solution

temperature and conductivity was 5 min when

Na

2

S

2

O

8

dosage was varied.

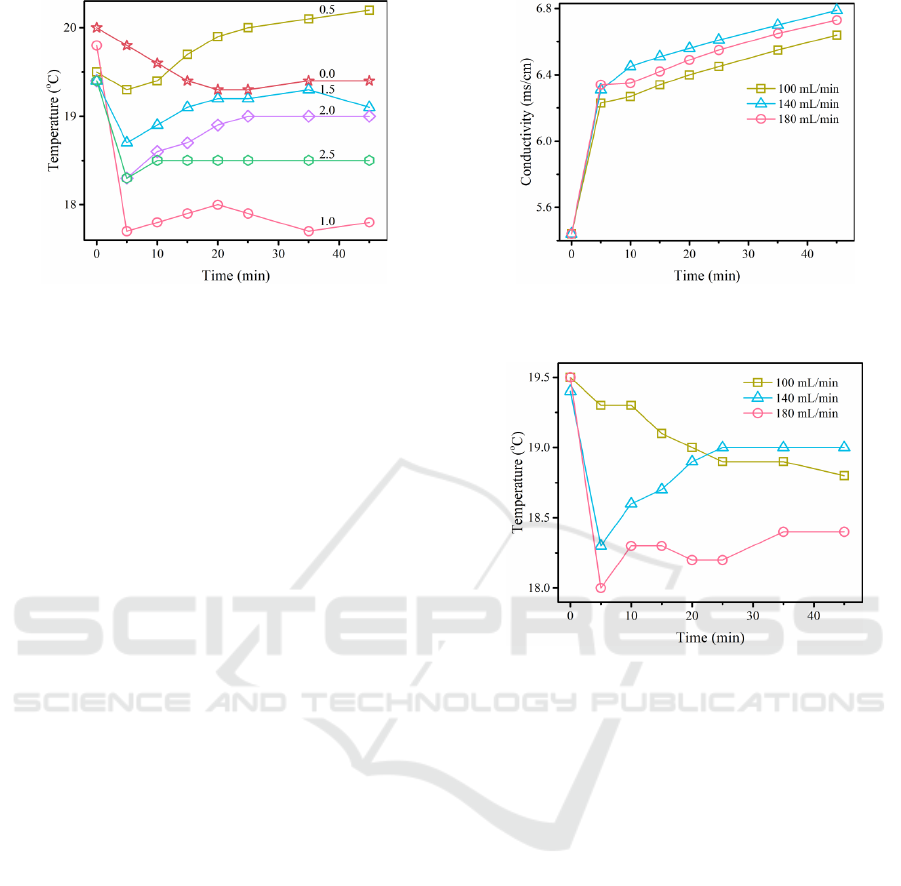

3.4 Influence of Circulation Flow Rate

The influence of the circulation flow rate on the

solution temperature and conductivity was

investigated under the conditions of maintaining an

initial pH of 8, a NaCl background ionic strength of

50 mmol/L, a Na

2

S

2

O

8

/UDMH (mol/mol) ratio of 2.0

and a voltage of 12.5 kV.

The variation of the solution conductivity is

shown in Figure 7. As can be seen from the figure, the

solution conductivity corresponding to the three

different recirculation flow rates all increased with

reaction time. The conductivity increased rapidly in

the first 5 min and then the growth rate slowed down

and the final conductivity followed the pattern of the

UDMH removal rate, reaching a maximum value at

140 mL/min.

The variation in solution temperature is shown in

Figure 8. 140 mL/min and 180 mL/min correspond to

solutions with a rapid decrease in temperature during

the first 5 min, after which the solution temperature

increases. In contrast, the temperature of the solution

corresponding to 100 mL/min decreased

continuously.

The cut-off point for the fast and slow changes in

solution temperature and conductivity is 5 minutes

when the cyclic flow rate is varied.

Figure 7: Conductivity changing with time as circular flow

fluctuates.

Figure 8: Temperature changing with time as circular flow

fluctuates.

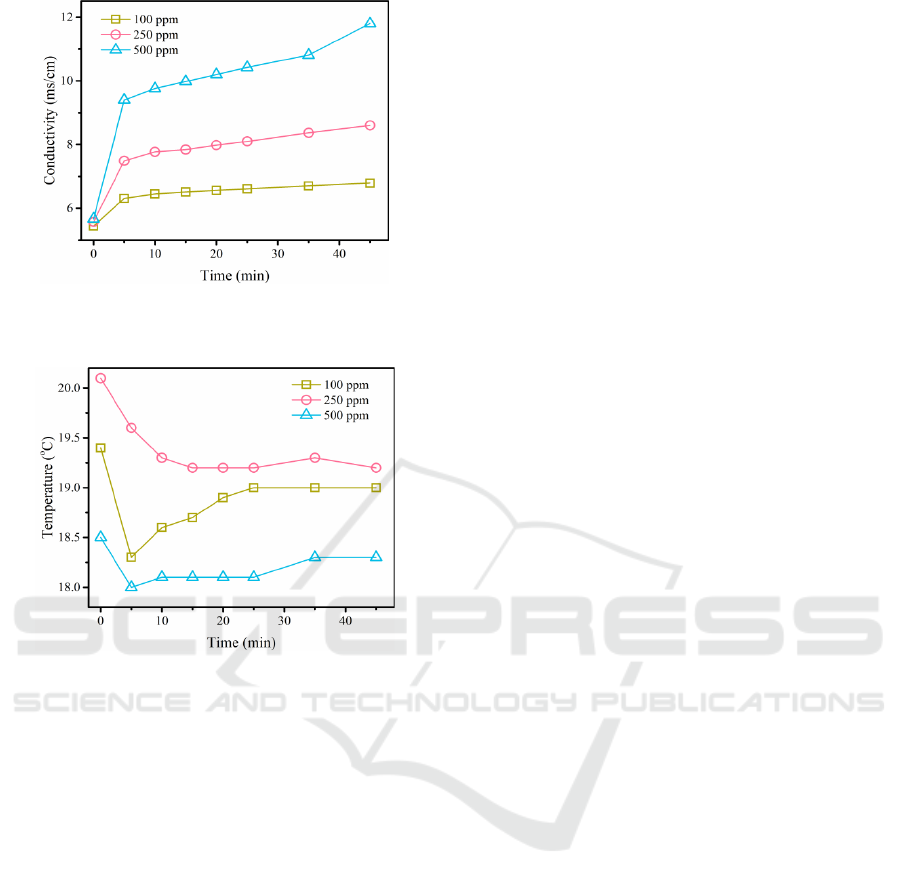

3.5 Influence of UDMH Concentration

The effects of fluctuations in the initial concentration

of UDMH on the temperature and conductivity of the

solution were investigated under the environment of

maintaining the initial pH = 8, circulating flow rate of

140 mL/min, NaCl background ionic strength of 50

mmol/L, Na

2

S

2

O

8

/UDMH (mol/mol)=2.0 and

loading voltage of 12.5 kV, and the results are shown

in Figures 9-10.

The variation of the solution conductivity is

shown in Figure 9. As can be seen from the figure, the

solution conductivities corresponding to the three

different initial UDMH concentrations all increased

with reaction time, with a rapid increase in

conductivity in the first 5 minutes and a slower rate

of increase thereafter.

Indication of Solution Temperature and Conductivity During Electrochemical Oxidation of Hydrazine Wastewater

75

Figure 9: Conductivity variation with time as UDMH

concentration fluctuates.

Figure 10: Temperature variation with time as

UDMH concentration fluctuates.

The changes in solution temperature are shown in

Figure 10. 100 ppm and 500 ppm correspond to

solutions with a rapid decrease in temperature during

the first 5 minutes, after which the solution

temperature increases. In contrast, the temperature of

the solution corresponding to 250 ppm continued to

decrease.

The cut-off point for the fast and slow changes in

solution temperature and conductivity is 5 min when

the initial concentration of UDMH is changed.

4 SUMMARY

In order to solve the problems of long colour

development reaction time and complicated operation

steps of spectrophotometric measurement of UDMH

concentration, the conductivity and temperature of

the solution, which are convenient for testing, were

used as the indicators to judge the degree of

electrochemical degradation of UDMH. During the

degradation of UDMH wastewater by Na

2

S

2

O

8

synergistic plasma, when the variables such as

voltage, initial pH of solution, background ion

concentration, Na

2

S

2

O

8

dosage, recycle flow rate, and

initial concentration of UDMH were changed, the

change rules of the UDMH concentration, acidity and

alkalinity with the temperature of the solution, and the

electrical conductivity were checked in turn, and the

results showed that: under different reaction

conditions, the change of the UDMH concentration

and the acidity and alkalinity were fast and slow. The

results showed that under different reaction

conditions, the cut-off point of UDMH concentration,

acidity and alkalinity appeared at 10 min, and the

corresponding transition point of solution

temperature and conductivity was 5 min. Based on

this, the transition point of UDMH rapid degradation

to slow degradation can be predicted online by

collecting the solution temperature and conductivity

during the sampling process, so as to shorten the

duration of the test and improve the efficiency of the

test.

REFERENCES

Li, Y., Li, B., Huang, H., Gong, C., Wan, X. 2017. Research

Progress on Propellant Wastewater Treatment. In The

8th National Conference on Chemical Propellants.

China Chemical Society, vol. 4.

Zheng, M., Chen, X., Cheng, R., Li, N., Sun, J., Wang, X.,

Zhang, T. 2006. Catalytic decomposition of hydrazine

on iron nitride catalysts. Catal. Commun., 7(3): 187-

191.

Zeng, B.P., Jia, Y., Xu, G., Li, M., Feng, R. 2019a.

Preparation of TiO

2

/g-C

3

N

4

under the action of CTAB

and its photocatalytic degradation of unsymmetrical

dimethylhydrazine wastewater. Material Engineering,

47(09): 139-144.

Deng, X., Liu, X., Liu, Y., Cao, L. 2015. Progress in the

treatment technology of unsymmetrical

dimethylhydrazine wastewater. Chemical Propellants

and Polymer Materials, 13(3): 21-25,34.

Bu, X., Liu, X. 2013. Experimental study on the adsorption

of unsymmetrical dimethylhydrazine by oxalic acid-

modified attapulgite. Chemical Propellants and

Polymer Materials, 11(01): 55-58.

Gu, D. 2019. Study on the degradation mechanism of

typical psychoactive substances by advanced oxidation

technology. China University of Mining and

Technology, Xuzhou.

Li, X., Zeng, Q., Feng, C., Zhou, S. 2006. Adsorption

performance of ion exchange fiber on unsymmetrical

dimethylhydrazine. Chemical Engineering, 6(1): 23-

27.

Wang, L. 2005. Aerobic biodegradation and kinetics of

unsymmetrical dimethylhydrazine wastewater.

Chongqing University, Chongqing.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

76

Zeng, B. P., Xu, G., Jia, Y., Feng, R. 2019b. Nitric acid-

modified graphite phase carbon nitride photocatalytic

degradation of unsymmetrical dimethylhydrazine

wastewater. Environmental Pollution and Control,

41(02): 160-163,169.

Zeng, B. P., Xu, G., Jia, Y., Li, M., Ma, J. 2018. Preparation

of TiO

2

/g-C

3

N

4

and its photocatalytic degradation of

unsymmetrical dimethylhydrazine wastewater. Applied

Chemical Industry, 47(04): 771-774,779.

Hou, R., Liu, Z., Ma, W., Fang, X. 2019. Experimental

study on the near-critical water oxidation treatment of

high-concentration unsymmetrical dimethylhydrazine

waste liquid. Water Supply and Drainage, 45(4): 82-87.

Qiu, C., Gu, X., Liu, Z., Zhu, A., Yan, K. 2020.

Experimental study on the treatment of organic dye

wastewater by nanosecond pulse discharge. High

Power Laser and Particle Beams, 32(2): 025010.

Rong, J., Li, L., He, Y., Zhang, Y., Li, F., Shi, T. 2020.

Study on the low-temperature plasma process for

efficient purification of PAM-containing wastewater.

Chemical New Materials, 48(3): 269-273.

Liu, H., Song, Z., Song, C., Wang, S. 2020. Study on the

simultaneous removal of Cr(VI) and phenol from water

by low-temperature plasma technology. Industrial

Water Treatment, 40(4): 35-43.

Yi, Z., Qing, Z., Wang, D., Jiang, M., Wang, Y., Huang, Y.

2019. Study on the degradation of unsymmetrical

dimethylhydrazine wastewater by low-temperature

plasma. Integrated Technology, 8(6): 65-74.

Wu, H., Chen, W., Fang, Z., Liu, F., Fan, J., Yin, B. 2019.

Optimization of dielectric barrier discharge for

activating persulfate to treat tetracycline wastewater.

High Voltage Technology, 45(5): 1387-1395.

Zhou, Z., Zheng, Z., Li, H., He, R., Hou, R., Yu, Y., Yang,

Y. 2023. Activated persulfate by dielectric barrier

discharge plasma for the degradation of unsymmetrical

dimethyl hydrazine as wastewater pollutants. Pol. J.

Environ. Stud., 32(4): 3447-3454.

Indication of Solution Temperature and Conductivity During Electrochemical Oxidation of Hydrazine Wastewater

77