Hydraulic Fracturing Test of Clay Core in Earth-Rock Fill Dam with

the Potential Weak Links

Qimeng Chen

a

, Jianming Xu

b

, Bin Huang

*c

, Boyang Chen

d

, Lei Ye

e

and Xi Zhao

f

School of Architecture and Civil Engineering, Huizhou University, China

*

Keywords: Hydraulic Fracturing, Triaxial Hydraulic Fracture Test, Clay Core.

Abstract: Hydraulic fracturing is of great concern in earth-rock dam engineering and is also one of the hot research

issues in earth core dams. Hydraulic fracturing can cause the destruction of the dam's anti-seepage body and

cause catastrophic consequences. This paper uses a triaxial hydraulic splitting test to quantitatively describe

the shape of hydraulic fractures in clay core, and further demonstrates the occurrence mechanism of hydraulic

fracturing from a microscopic perspective. Hydraulic fracturing is ultimately a deformation problem. Due to

the compressive deformation of the soil, the initial fracture takes an elliptical shape in the two-dimensional

space, thus producing a wedge splitting effect on the fracture tip.

1 INTRODUCTION

In earth-rock fill dam engineering, accidents caused

by hydraulic fracturing often lead to the destruction

of the dam's anti-seepage body, thus causing

catastrophic consequences. (Seed et al., 1976) and

(Wilson et al., 1984) both pointed out that hydraulic

fracturing is the occurrence and development of

cracks in soil.

There are many reasons for hydraulic fracturing

of the clay core in earth-rock fill dam. (Lowe et al.,

1970) classified cracks in dams into vertical cracks

caused by uneven settlement, horizontal cracks

caused by arching effects, shrinkage cracks caused by

water loss in the dam body, etc. (Sherard et al., 1973)

pointed out that cracks are a common problem in

earth-rock dams, which can occur during the

construction of the dam or after it is built. Based on

the assumption that there is a splitting failure zone in

the core wall, Lo and (Kaniaru et al., 1990)

analysed

the hydraulic fracturing characteristics of five earth-

rock dams including Balderhead, Hyttejuvet,

Viddalsuatu, Teton and Yard’s Creek. (Alfaro et al.,

a

https://orcid.org/0009-0005-9978-1453

b

https://orcid.org/0009-0006-5601-1616

c

https://orcid.org/0000-0002-1344-5733

d

https://orcid.org/0009-0001-7410-4318

e

https://orcid.org/0009-0003-7526-0798

f

https://orcid.org/0009-0003-1819-6638

2001; Wong et al., 2001) pointed out that hydraulic

fracturing pressure is not only related to the overlying

pressure at the location where hydraulic fracturing

cracks occur, but also related to the strength of the

soil and inherent cracks or defects. (Murdoch et al.,

2002) pointed out that the characteristics of shallow

hydraulic fractures obtained through excavation and

drilling cannot meet the needs of predicting the

development of hydraulic fractures. (Au et al.,

2003) used a modified consolidation instrument

to conduct hydraulic fracturing tests on kaolin

samples. Hydraulic fracturing tests were

conducted with liquids of different viscosities

under different consolidation states was analysed.

The influence of factors such as ratio and

boundary conditions on hydraulic fracturing.

These scholars have studied the quantitative

relationship between hydraulic pressure and

various influencing factors during hydraulic

fracture failure, but most of them focused on

drilled cylinders or square specimens.

In view of the potential weak links in the clay core

of earth-rock fill dam, this paper conducts

60

Chen, Q., Xu, J., Huang, B., Chen, B., Ye, L., Zhao and X.

Hydraulic Fracturing Test of Clay Core in Earth-Rock Fill Dam with the Potential Weak Links.

DOI: 10.5220/0013573400004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 60-65

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

experimental simulations through pre-existing cracks

to study the hydraulic fracture of the clay core, and

establishes the influence of various physical,

mechanical and other factors on the hydraulic

fracturing characteristics, including hydraulic

pressure, various factors and fracture dimensions.

2 TRIAXIAL HYDRAULIC

FRACTURING TEST

2.1 The Properties of Clay

The material used in this paper is low plastic clay,

with the liquid limit of 36% and the plastic index of

21%. The maximum dry density of light compaction

is 1.78 g/cm

3

and the optimum moisture content is

16.6%. The specimen was prepared with the

compaction degree of 98%, and the permeability

coefficient is 1.1×10

-6

cm/s. Particle-size distribution

and constitutive parameters are shown in Figure 1

and Table 1.

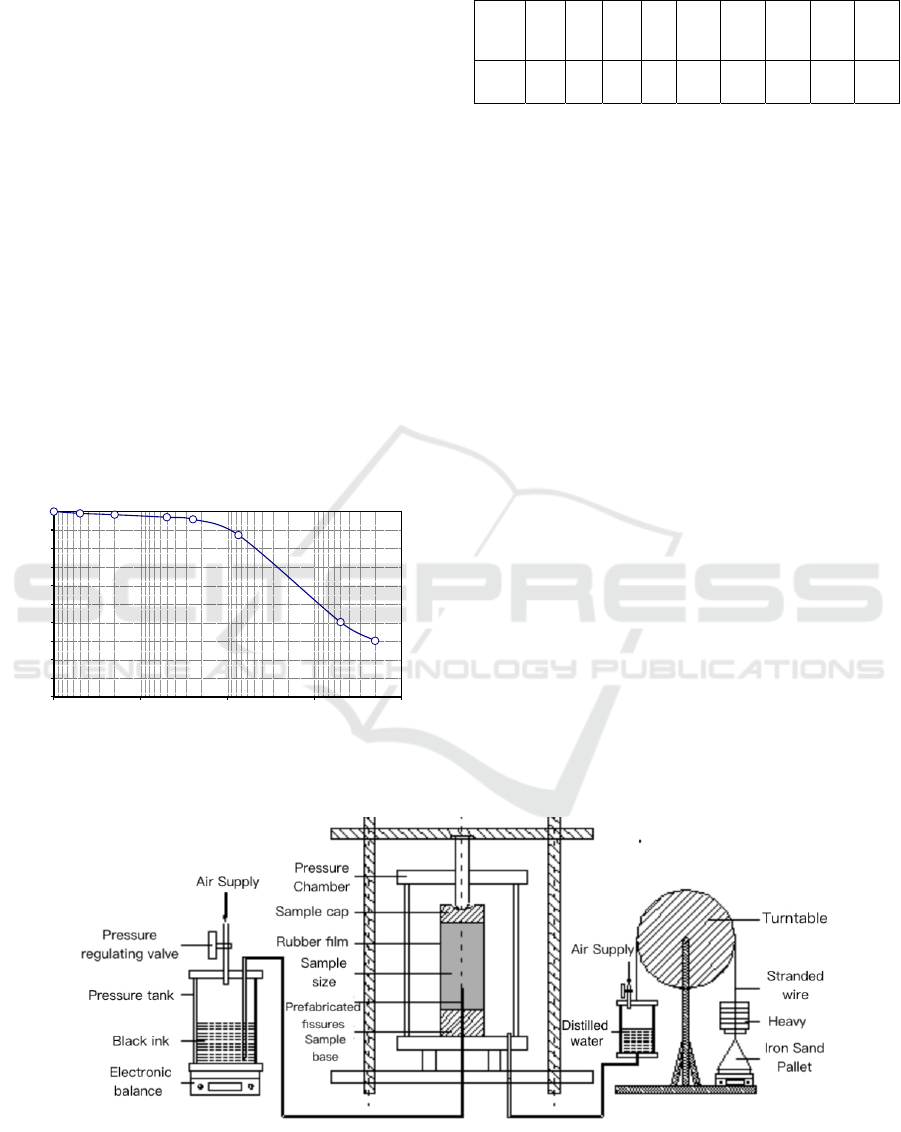

Figure 1: Particle-size distribution curve of clay.

Table 1: The parameters of Duncan-Chang model for clay.

c

CD

(kPa)

φ

CD

(

o

)

K n K

b

m F G R

f

D

60.7 19.6

139.

9

0.33

8

52.3 0.185 0.126 0.296 0.836 3.513

2.2 Triaxial Hydraulic Fracturing Test

The aim of triaxial hydraulic fracturing test is to study

the law of hydraulic fracturing of soil under confining

pressure and to obtain the failure mode of hydraulic

fracturing. The effects of saturation, compactness,

consolidation ratio, confining pressure, dimension of

pre-existing fracture and loading rate of hydraulic

pressure are studied.

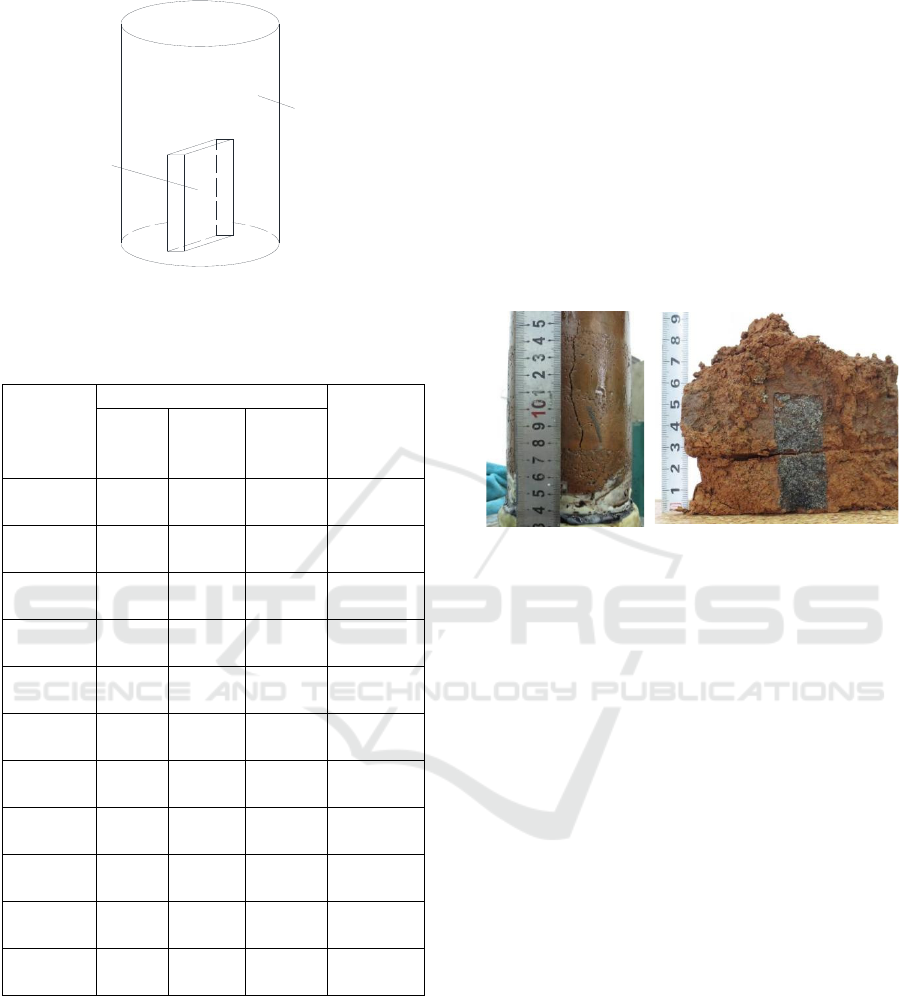

As shown in Figure 2, the test device consists of

three parts: a triaxial apparatus in the middle, a water

intake measuring device for fracturing pressure on

the left and an external variable measuring device for

confining pressure on the right. The specimen with

fracture is installed in the triaxial apparatus, the

specimen is wrapped in rubber membrane, the

pressure chamber is linked with the confining

pressure device, and the base of the specimen is

linked with the pressure water inlet device.

The triaxial hydraulic fracturing test can simulate the

stress state such as confining pressure and

consolidation ratio of the specimen, and it is an ideal

research method. The triaxial fracturing tests are

carried out in the aspects of saturation, compactness,

consolidation ratio, confining pressure, dimension of

pre-existing fracture and hydraulic pressure loading

rate. The test program is shown in Table 2, with a

compaction degree of 98%; the dimensions of pre-

existing fracture are shown in Figure 3.

Figure 2: Diagram of triaxial hydraulic fracturing test device.

0

10

20

30

40

50

60

70

80

90

100

0.0010.010.1110

Percent finer (%)

Particle size (mm)

Hydraulic Fracturing Test of Clay Core in Earth-Rock Fill Dam with the Potential Weak Links

61

Figure 3: Dimensions of pre-existing fracture in specimens.

Table 2: Testing program of triaxial hydraulic fracturing for

clay with pre-existing fracture.

No. of

sample

Dimension of fracture

Confinin

g

Pressure

(kPa)

Depth

(mm)

Lengt

h

(m

m

)

Openin

g (mm)

SLPL-

11

50 20 2 50

SLPL-

12

50 20 2 200

SLPL-

13

50 20 2 350

SLPL-

14

50 20 2 100

SLPL-

15

50 20 2 350

SLPL-

16

50 20 2 200

SLPL-

17

100 20 2 200

SLPL-

18

150 20 2 200

SLPL-

19

50 35 2 200

SLPL-

20

50 50 2 200

SLPL-

21

50 20 4 200

2.3 Results Analysis

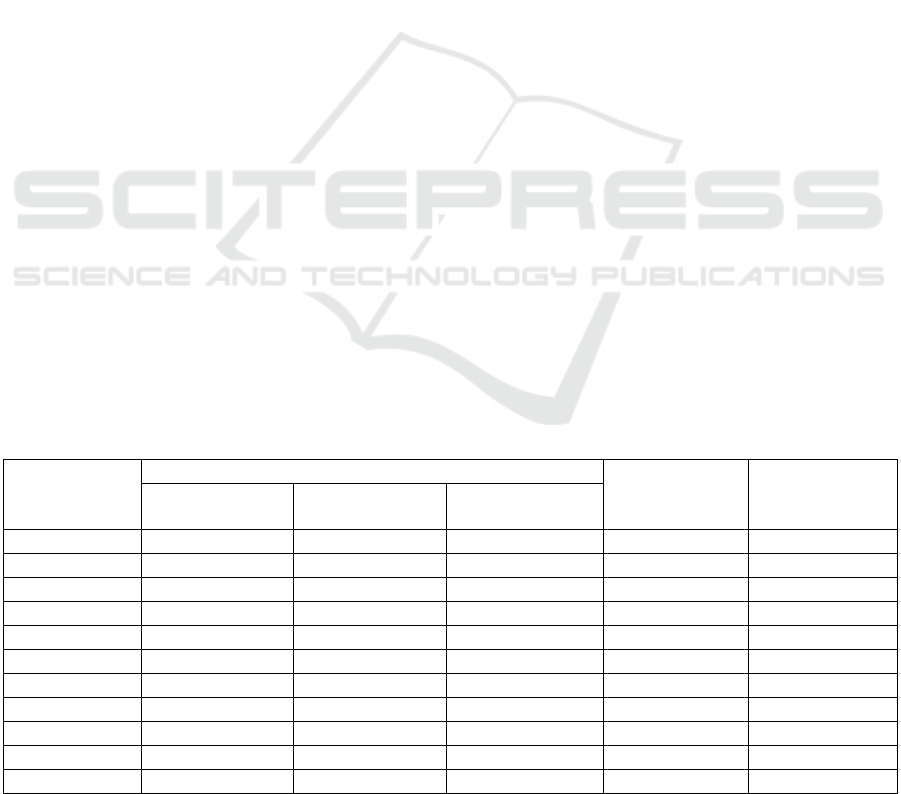

The development of hydraulic fracture in SLPL-15

specimen is shown in Figure 4. The sample size is

φ101 mm × H200 mm, and the pre-existing fracture

dimension is 50mm in depth × 20mm in length ×

20mm in opening. Consolidate for 48 hours under a

confining pressure of 350kPa. After starting the test,

the pore pressures are 50, 80, 120, 160, 200, 230, 270,

310, 350, and 390kPa. Each level of pressure lasts for

10 to 15 minutes until the change rate of the balance.

At 430 kPa pore pressure for 4 min, the specimen was

destroyed, ink gushed from the splitting crack, the

valve was closed, and the test was stopped. There are

three distinct long fractures and several small

fractures around the specimen. The apparent fracture

length of the sample is about 11 cm, which is larger

than the ink length inside the sample, and greater than

the depth of the pre-existing cracks by 5 cm. And the

depth of ink staining directly above the pre-existing

fracture is about 2 cm, which is shown that hydraulic

fracturing occurred to some extent along the fracture

depth.

(a) Sample surface

fracture

(b) Development of internal

fracture

Figure 4: Development of hydraulic fracture.

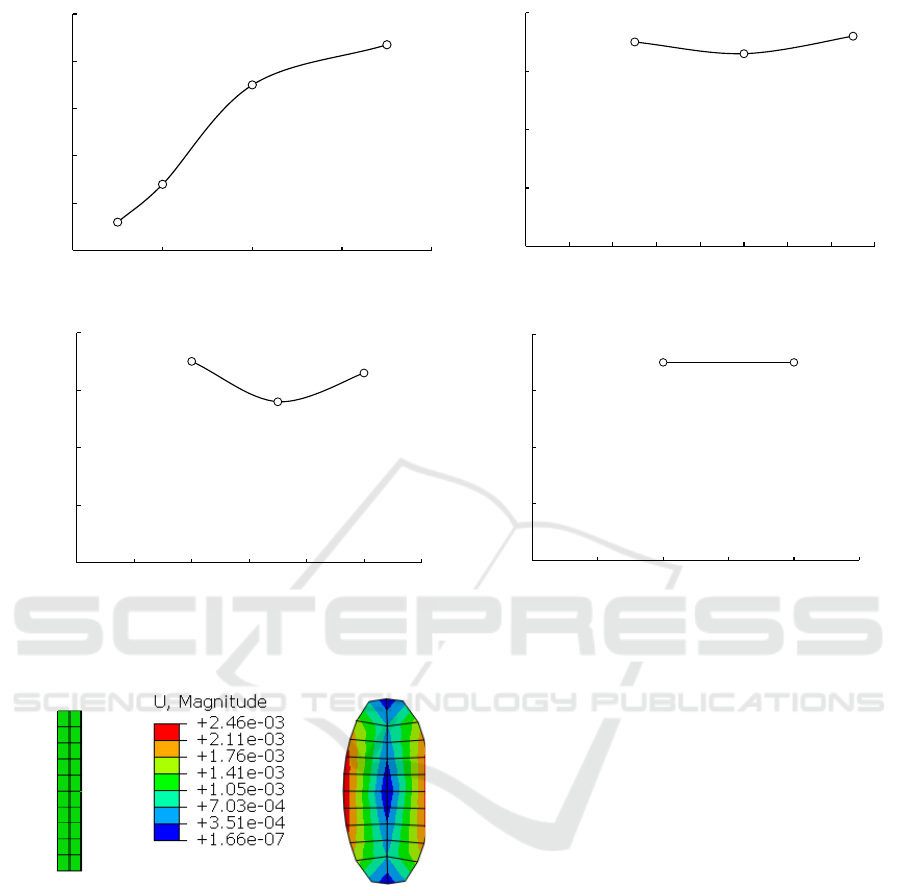

The results of hydraulic fracturing tests are shown

in Table 3, and the curves of fracturing pressure

versus confining pressure, fracture depth, fracture

length and fracture opening are shown in Figure 5. It

can be obtained as follows:

(1) the law of failure pressure and confining

pressure of hydraulic fracturing is the most

obvious. The bigger confining pressure is, the

bigger fracturing pressure is, but the increasing

trend of fracturing pressure is gradually slowing

down. When the confining pressure is below

200 kPa, the fracture pressure and confining

pressure increase linearly, and when the

confining pressure is over 400 kPa, the fracture

pressure shows an asymptotical trend and does

not increase linearly.

(2) the fracture pressure has little relation with

fracture depth, the fracture depth varies from

50mm to 150mm, and the fracture pressure

fluctuates very little, which is due to the fact that

the triaxial hydraulic fracturing test is basically

a failure mode of fracture propagation in the

direction of fracture length, although there is

fracture propagation along the depth of the

fracture, the fracture in the length direction

penetrates before the fracture in the depth

Opening

Depth

Length

Clay sample

Fracture

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

62

direction, so it shows that the fracture depth has

little effect on the fracture pressure.

(3) the relationship between fracture pressure and

fracture length is not significant. The

deformation characteristics of the pre-placed

fracture after fracturing pressure is elliptic (as

shown in Figure 6) , and the two ends are the tip

of the fracture, which are subjected to the tensile

force caused by the fracturing pressure, and the

two sides of the fracture are subjected to the

total splitting tensile force, this tension is borne

by a fracture-free soil.

(4) The longer the fracture, the lower the tension at

the tip of the fracture, but the greater the total

splitting tension on both sides of the fracture.

For this test, the longer the precast joint is, the

smaller the effective range of the soil which can

bear the total splitting tension is, but the test

result does not reflect the rule that the longer the

joint is, the smaller the splitting failure pressure

is, it should not belong to the simple tensile

failure mode of soil. Therefore, it is proposed

that the failure mode of the fracture tip is

gradually tensile fracturing. Although the stress

at the fracture tip is greater under the condition

of the shorter fracture, the stress at the fracture

tip decreases gradually with the extension of the

fracture length, when the fracture is extended to

a certain extent, it is close to the condition of the

fracture length, and the stress at the fracture tip

should be close to it.

(5) It is assumed that the equivalent fracture length

after fracture propagation is the sum of the

initial fracture length and the fracture length

after fracture propagation, according to the

Irwin equivalent fracture correction method in

fracture mechanics, the displacements in this

region will be released after the fracture appears,

and there may be relative displacements on the

upper and lower surfaces of the yield region,

resulting in displacements, free water is allowed

to transmit pressure inside, so the equivalent

fracture length is also assumed for hydraulic

fracturing of clay materials.

(6) the failure pressure of hydraulic fracturing has

little relation with the fracture opening,

provided that the pressure water can move

freely in the pre-existing fracture. This is

reflected in the clay core, no matter how big or

how small the opening of the fractures, as long

as the reservoir water can move freely and

transmit pressure in the weak links, there is a

possibility of hydraulic fracturing.

(7) when confining pressure is greater than 350 kPa,

hydraulic fracturing occurs to some extent along

the depth of the fracture, and the corresponding

fracturing pressure is 430 ~ 440 kPa, if the

deformation without restraint is large at the

middle and small at the two ends, thus causing

the tensile force at the fracture tip, the fracture

propagation will occur not only in the direction

of the precast fracture length under the larger

fracture pressure, but also in the direction of the

precast fracture length, in the depth direction of

the fracture also appears to expand, but the

length direction of the fracture first through,

resulting in hydraulic fracturing did not

continue to expand to the depth direction. In the

core-wall Dam project, the fracture depth

direction of the expansion of greater harm, more

attention should be paid.

Table 3: Results of triaxial hydraulic fracturing test on clay with potential fracture.

No. of sample

Dimensions of fracture Confining

pressure

(kPa)

Fracture

pressure (kPa)

Depth (mm) Length (mm) Opening (mm)

SLPL-11 50 20 2 50 60

SLPL-12 50 20 2 200 360

SLPL-13 50 20 2 350 440

SLPL-14 50 20 2 100 140

SLPL-15 50 20 2 350 430

SLPL-16 50 20 2 200 340

SLPL-17 100 20 2 200 330

SLPL-18 150 20 2 200 360

SLPL-19 50 35 2 200 280

SLPL-20 50 50 2 200 330

SLPL-21 50 20 4 200 350

Hydraulic Fracturing Test of Clay Core in Earth-Rock Fill Dam with the Potential Weak Links

63

(a) (b)

(c) (d)

Figure 5: The curves of hydraulic fracturing pressure vs. fracture size.

(a) Before

deformation

(b) After deformation

Figure 6: Deformation characteristics of fractures before

and after fracturing pressure is applied.

3 CONCLUSIONS

Hydraulic splitting is ultimately a deformation

problem. Due to the compressive deformation of the

soil, the initial fracture takes an elliptical shape in the

two-dimensional space, thus producing a wedge

splitting effect on the fracture tip. The damage

pressure of hydraulic fracturing has little relationship

with the fracture opening. In the core wall, no matter

how big or small the thickness of the fracture is, as

long as the reservoir water can move freely and

transmit pressure in the fracture, there is a possibility

of hydraulic splitting. Define the ratio of fracture

opening to equivalent fracture length as the

discriminant factor of hydraulic splitting. By

comparing the relationship between this factor and

the critical value, you can make a process judgment

on whether hydraulic splitting occurs.

ACKNOWLEDGMENTS

This study was supported by Guangdong Province

Undergraduate Innovation and Entrepreneurship

Project (Grant No. S202310577066 &

S202210577064), Undergraduate Online Courses

Committee of University in Guangdong Province

(Grant No. 2022ZXKC437), and Guangdong

Provincial Education and Scientific Research Project

-Higher Education Scientific Research Special Topic

(Grant No. 2023GXIK504).

0

100

200

300

400

500

0 100 200 300 400

Fracuring pressure(kPa)

Confining pressure(kPa)

0

100

200

300

400

0 20 40 60 80 100 120 140 160

Fracuring pressure(kPa)

Depth of fracture(mm)

0

100

200

300

400

0 102030405060

Fracuring pressure(kPa)

Length of fracture(mm)

0

100

200

300

400

012345

Fracuring pressure(kPa)

Opening of fracture(mm)

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

64

REFERENCES

Seed, H. B., 1976. Hydraulic fracturing and its possible role

in the Teton Dam failure[R]. Appendix D of Report to

U.S. Dept. of the Interior and State of Idaho on Failure

of Teton Dam by Independent Panel to Review Cause

of Teton Dam Failure, 1-39.

Wilson, C., 1984. Hydraulic fracturing in embankment

dams and available defensive measures[C]//

Proceedings of the eighth Regional Conference for

Africa on SMFE, Harare, 491-500.

Lowe, J., 1970. Recent development in the design and

construction of earth and rockfill dams[C]//

Proceedings of 10th International Congress on Large

Dams, Montreal, Canada, 11-23.

Sherard, J. L., 1973. Embankment dam cracking. In :

Embankment dam Engineering, Casagrande

Volume[M]. Edited by Hirschfeld R C and Poulos S J,

New York: John Wiley and Sons, 271-353.

Lo, K. Y., Kaniaru, K., 1990. Hydraulic fracture in earth

and rockfill dam[J]. Canadian Geotechnical Journal,

27(4): 496-506.

Alfaro, M. C.,Wong, R. C. K., 2001. Laboratory studies on

fracturing of low permeability soils[J]. Canadian

Geotechnical Journal, 38(2), 303-315.

Wong, R. C. K., Alfaro, M. C., 2001. Fracturing in low-

permeability soils for remediation of contaminated

ground[J]. Canadian Geotechnical Journal, 38(2),

316-327.

Murdoch, L. C., 2002. Mechanical analysis of idealized

shallow hydraulic fracture[J]. Journal of Geotechnical

and Geoenvironmental Engineering, ASCE, 128(6):

488-495.

Au, S. K. A., Soga, K., Jafari, M. R., Bolton, M. D. and

Komiya, K., 2003. Factors affecting long-term

efficiency of compensation grouting in clays[J].

Journal of Geotechnical and Geoenvironmental

Engineering, ASCE, 129(3): 254-262.

Hydraulic Fracturing Test of Clay Core in Earth-Rock Fill Dam with the Potential Weak Links

65