Research on Vibration Characteristics of Powerhouse Structure of

Variable Speed Unit Section in Fengning Pumped Storage Power

Station

Guoqing Liu

1,* a

, Lianghua Xu

1

, Xin Jia

2

and Chunlei Wei

3

1

State Key Laboratory of Simulation and Regulation of Water Cycle in River Basin, China Institute of Water Resources and

Hydropower Research, Beijing 100048, China

2

Hebei Fengning Pumped Storage Co., Ltd., Chengde 068350, China

3

State Grid Xinyuan Group Co., Ltd., Beijing 100032, China

Keywords: Pumped Storage Power Station, Powerhouse Structure, Vibration Characteristics, Natural Frequency,

Vibration Control Standard.

Abstract: Taking the powerhouse of 12# variable speed unit section in Fengning pumped storage power station as a

research object, a three-dimensional finite element model of the powerhouse structure was established.

Firstly, the modal analysis method was used to calculate and research the natural vibration characteristics of

whole and local structures of the powerhouse. Then, based on the field measured pressure pulsation data, the

vibration responses of the powerhouse structure were simulated under the action of hydraulic vibration

source. And referring to the relevant vibration control standard of powerhouse, the vibration responses of

the powerhouse were analyzed and evaluated. The results show that the top 20 natural frequencies of the

whole structure of the powerhouse range from 13.71 to 34.00 Hz, and the top 3 vibration modes are mainly

the whole vibration of the structure above the volute layer. The calculation values of natural frequencies of

the busbar floor and pillars are not significantly different from the measured values, indicating that the

establishment of the calculation model and the setting of the boundary conditions are reasonable and

effective. The maximum vibration responses of local structures of the powerhouse meet the vibration

control standard of powerhouse under pumping and generating conditions.

a

https://orcid.org/0009-0005-8512-4049

1 INTRODUCTION

Pumped storage power station is a green, low-

carbon, clean and flexible regulated power supply

with the most mature technology, the best economy

and the greatest potential for large-scale

development (Zhou et al., 2023). With the

development and needs of pumped storage power

station construction, pump turbine unit is developing

towards the direction of ultra-high head, large

capacity, high speed and variable speed. As the

supporting structure of unit, the powerhouse of

hydropower station may experience whole or local

vibration when subjected to exciting forces such as

mechanical force, electromagnetic force and

hydraulic force generated during the operation of

unit (Gao et al., 2023). At present, vibration

problems have been occurred on powerhouse

structures of many pumped storage power stations in

China when they are operating (Wang et al., 2023).

Therefore, in-depth research on vibration

characteristics of powerhouse is of great significance

to effectively avoid the harmful vibration that may

occur on the structure.

This paper took the powerhouse structure of 12#

variable speed unit section in Fengning pumped

storage power station as a research object. After

completing the analysis of natural vibration

characteristics of whole and local structures of the

powerhouse, the vibration responses of the

powerhouse structure under pressure pulsation were

calculated, and the vibration safety of the

powerhouse was analyzed and evaluated according

to the vibration control standard of powerhouse. It is

Liu, G., Xu, L., Jia, X., Wei and C.

Research on Vibration Characteristics of Powerhouse Structure of Variable Speed Unit Section in Fengning Pumped Storage Power Station.

DOI: 10.5220/0013573000004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 31-36

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

31

expected that the research results can provide a

scientific basis for the design and safe operation of

pumped storage power station.

2 CALCULATION MODEL AND

PARAMETERS

2.1 Project Overview

Fengning pumped storage power station is located in

the west of Chengde, Hebei Province, China. A total

of 12 units with a capacity of 300 MW are installed

in the main powerhouse, of which 11# and 12# units

are variable speed units. Below the generator layer is

an integral cast concrete structure, which is divided

into six layers, including draft tube layer, volute

layer, volute interlayer, turbine layer, busbar layer

and generator layer from bottom to top. The power

station adopts a structural type of one unit and one

joint, and structural joints are set between the

installation site and main powerhouse, and between

the auxiliary powerhouse and main powerhouse.

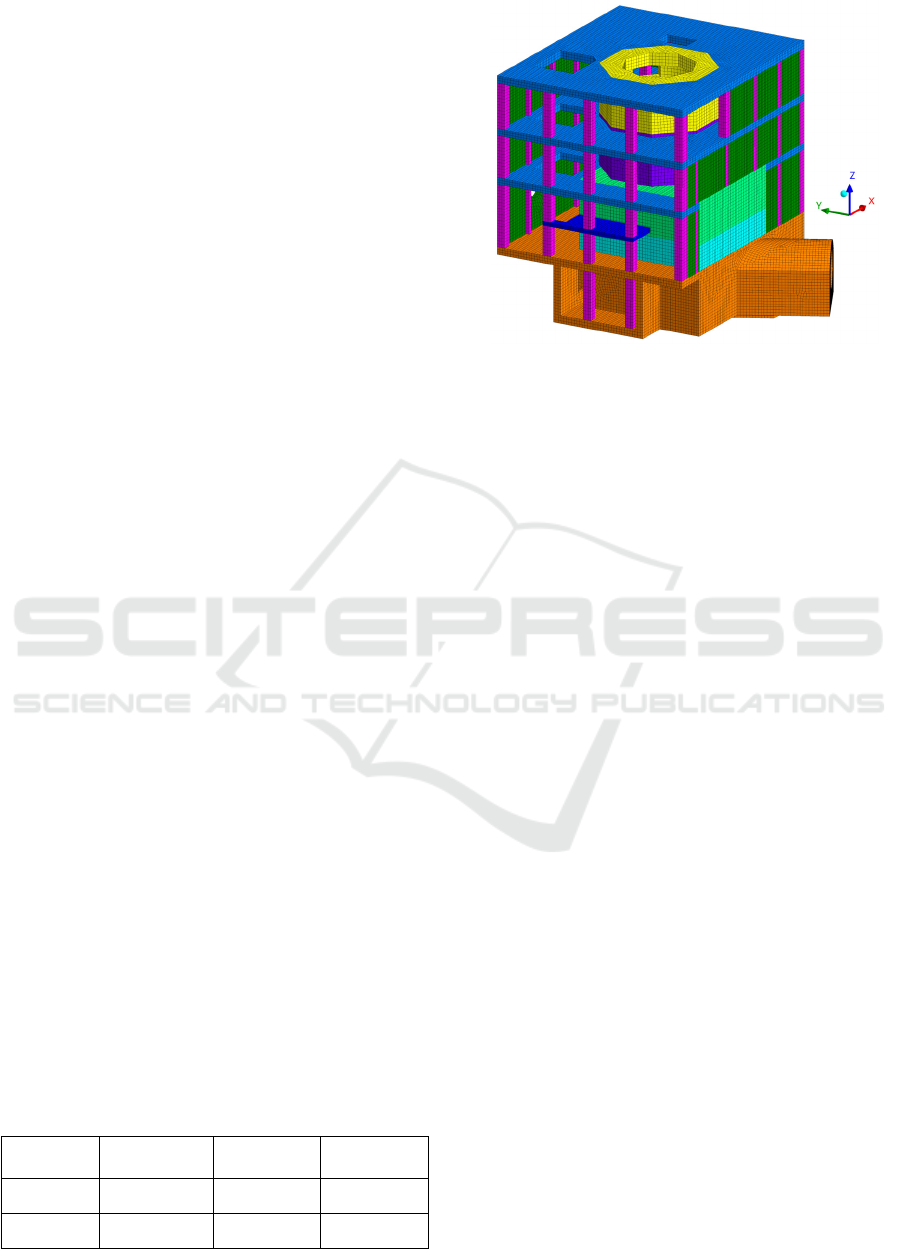

2.2 Finite Element Model

The powerhouse structure of 12# variable speed unit

section is taken as a research object. X direction is

bounded by the left and right structural joints, Y

direction is taken to the upstream and downstream

side walls connected with the surrounding rock, and

Z direction is taken from the bottom of concrete

around the draft tube to the generator floor. Concrete

structures such as floors, side walls, pillars, wind

hood, turbine pier, concrete around volute and draft

tube, as well as flow channel metal structures such

as volute and draft tube are simulated in a finite

element model. All concrete structures are

segmented by three-dimensional solid elements, and

all flow channel structures are simulated by shell

elements. The finite element model of the

powerhouse structure is divided into 231100

elements and 249727 nodes, as shown in Figure 1.

The powerhouse structure is simulated by elastic

constitutive relationship, and the concrete grade is

C30. The material parameters are shown in Table 1.

Table 1: Material parameters.

Material

Elastic

modulus (GPa)

Poisson ratio

Density

(kg/m

3

)

C30 30 0.167 2500

Steel 200 0.300 7850

Figure 1: Three-dimensional finite element model of

powerhouse structure.

2.3 Boundary Conditions

The left, right and top sides of the finite element

model are set as free surfaces, and the other

boundaries (the connection parts between the

powerhouse and surrounding rock) are set as

viscoelastic artificial boundaries.

3 ANALYSIS OF NATURAL

VIBRATION

CHARACTERISTICS OF

POWERHOUSE STRUCTURE

3.1 Natural Vibration Characteristics

of Whole Structure

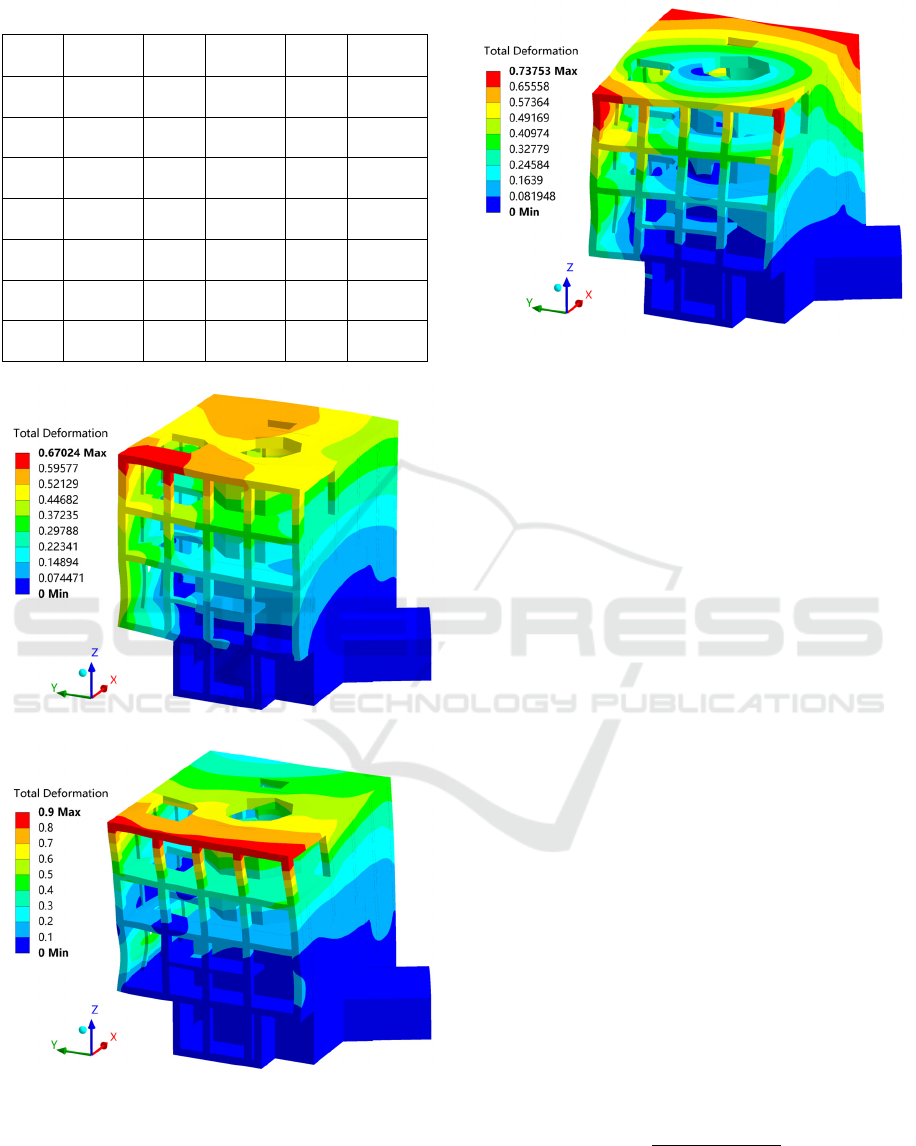

The calculation results of the top 20 natural

frequencies of the whole structure of the powerhouse

are shown in Table 2, and the top 3 vibration modes

are shown in Figure 2. The top 20 natural

frequencies of the whole structure of the powerhouse

range from 13.71 to 34.00 Hz. The first vibration

mode of the powerhouse is mainly X-direction

vibration of the whole structure above the volute

layer. The second vibration mode is mainly Y-

direction vibration of the whole structure above the

volute layer. The third vibration mode is mainly

torsional vibration of the whole structure above the

volute layer around Z axis. The other vibration

modes are mainly the vertical vibration in local areas

of the floors and the normal vibration in local areas

of the side walls.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

32

Table 2: Natural frequencies of whole structure

No.

Frequency

(Hz)

No.

Frequency

(Hz)

No.

Frequency

(Hz)

1 13.71 8 27.40 15 31.38

2 15.06 9 27.84 16 32.14

3 18.73 10 28.34 17 32.54

4 21.79 11 29.06 18 32.93

5 22.46 12 29.61 19 33.42

6 25.30 13 30.16 20 34.00

7 26.30 14 30.78

(a) First vibration mode

(b) Second vibration mode

(c) Third vibration mode

Figure 2: Top 3 vibration modes of whole structure.

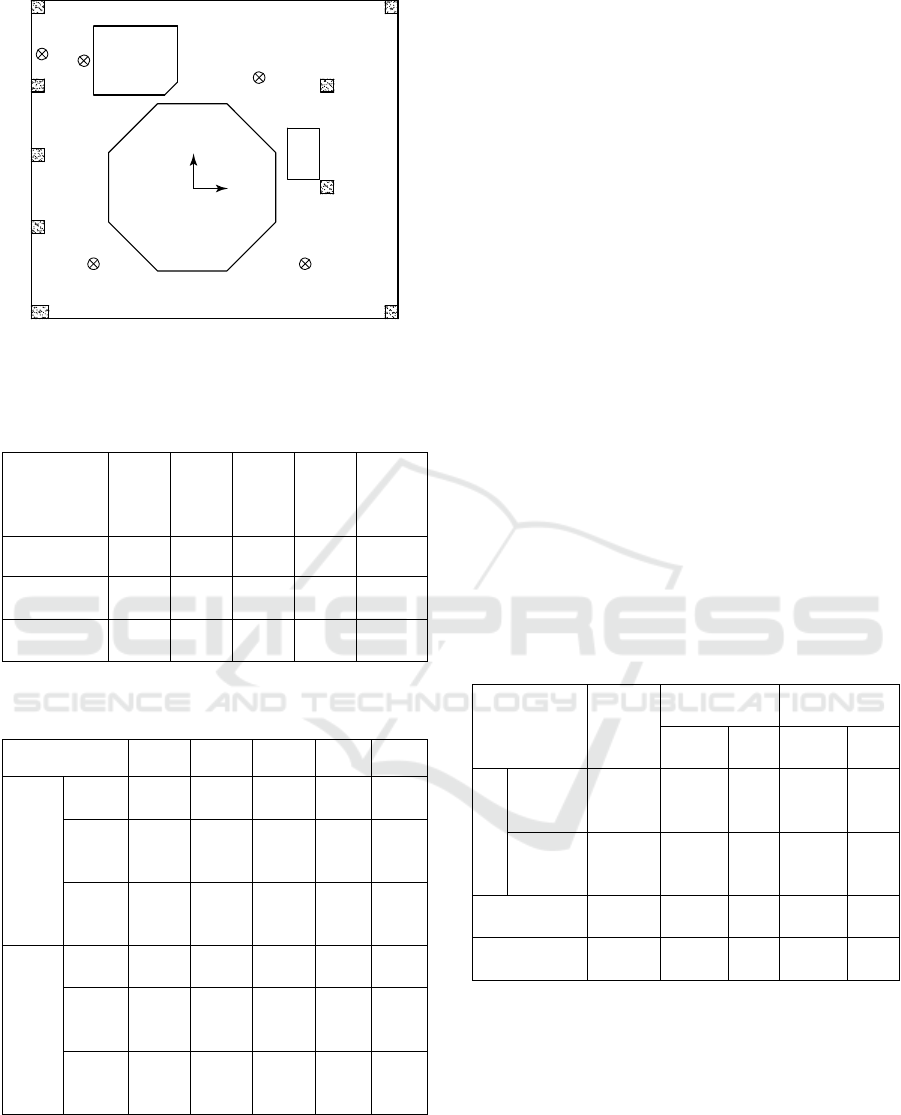

3.2 Natural Vibration Characteristics

of Local Structures

Due to the complex space structure of the

powerhouse, the same vibration mode often shows

simultaneous vibration of different parts. Therefore,

it is very difficult to accurately calculate the natural

frequencies of local structures we are concerned

about by using the calculation method of natural

frequencies of whole structure. Here, the massless

foundation method is adopted, that is, the density of

all the other structures except the local structure

calculated is assigned as 0, and only their constraints

on the local structure studied are considered.

Limited by the paper length, this paper mainly

analyzes the natural vibration characteristics of the

busbar floor and pillars. For the floor, because its

horizontal vibration is relatively small, its vertical

vibration should be the focus of attention. Similarly,

for the pillars, their horizontal vibration should be

emphatically analyzed. The number of peak points

of the vertical first vibration mode of each area on

the busbar floor and the number of pillars are shown

in Figure 3, and the corresponding calculation

results of natural frequencies are shown in Tables 3

and 4. As a comparison, the field test results of

natural frequencies of the floor and pillars are also

listed in Tables 3 and 4, in which the relative error

expression between the calculation and test values of

natural frequency is

𝑅𝑒𝑙𝑎𝑡𝑖𝑣𝑒 𝑒𝑟𝑟𝑜𝑟

|

|

100% (1)

Research on Vibration Characteristics of Powerhouse Structure of Variable Speed Unit Section in Fengning Pumped Storage Power Station

33

Figure 3: Numbers of peak points of vibration mode of

busbar floor and pillars.

Table 3: Vertical first natural frequency of each area on

busbar floor.

Peak point

of

vibration

mode

FB_1 FB_2 FB_3 FB_4 FB_5

Test (Hz) 46.88 32.32 43.07 76.60 111.90

Calculation

(Hz)

45.33 32.28 41.13 72.72 119.27

Relative

error

(

%

)

3.31 0.12 4.50 5.07 6.59

Table 4: Horizontal first natural frequency of each pillar

on busbar layer.

Pillar PB_1 PB_2 PB_3 PB_4 PB_5

X

directi

on

Test

(

Hz

)

— — 77.98 79.98 71.48

Calcul

ation

(Hz)

68.66 68.01 72.89 76.88 74.34

Relativ

e error

(%)

— — 6.53 3.88 4.00

Y

directi

on

Test

(Hz)

— — 71.09 79.10 81.93

Calcul

ation

(Hz)

68.27 69.30 69.66 76.20 76.71

Relativ

e error

(%)

— — 2.01 3.67 6.37

The maximum relative error between the

calculation and test values of the vertical first natural

frequencies of local areas of the busbar floor is

6.59%, and the maximum relative error between the

calculation and test values of the horizontal first

natural frequencies of the busbar pillars is 6.53%. In

general, the difference between the calculation and

test values of natural frequency of each structure is

small, indicating that the calculation model

established and the boundary conditions set in this

paper are reasonable, and the calculation method is

feasible.

4 ANALYSIS OF VIBRATION

RESPONSES OF

POWERHOUSE STRUCTURE

4.1 Vibration Control Standard of

Powerhouse

As the support system of unit, the powerhouse is

also a daily office space for the staff, so its structural

design is very important to ensure the safety and

comfort of the staff. At present, there is no unified

evaluation standard for the vibration control of

pumped storage power station powerhouse. In this

paper, the vibration control standard of powerhouse

is listed in Table 5 according to reference (Ma et al.,

2013), which can be used as a quantitative basis for

the prediction and control of powerhouse vibration.

Table 5: Vibration control standard of powerhouse.

Structure

Displace

ment

(mm)

Velocity

(mm/s)

Acceleration

(m/s

2

)

Horizont

al

Vertic

al

Horizont

al

Vertic

al

Floo

r

As

building

structure

0.2 5.0 5.0 1.0 1.0

Human

health

evaluation

0.2 5.0 3.2 1.0 0.4

Wind hood,

Turbine pie

r

0.2 5.0 5.0 1.0 1.0

Other building

structures

0.2 10.0 10.0 1.0 1.0

4.2 Analysis and Evaluation of

Vibration Responses of Powerhouse

Because the hydraulic vibration source occupies a

dominant position, this paper mainly analyzes the

vibration responses of the powerhouse structure

under the action of hydraulic vibration source. In

order to make the simulation results more accurate

and reliable, the dynamic load comes from the

measured pressure pulsation data in the flow channel,

X

Y

Z

Hanging ball

valve hole

Hanging

hole

FB_4

FB_5

FB_3

FB_2

PB_1

PB_2

PB_3 PB_4

PB_5

FB_1

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

34

Table 6: Maximum vibration responses of local structures under pumping condition.

Structure

Displacement (μm) RMS velocity (mm/s) RMS acceleration (m/s

2

)

X Y Z X Y Z X Y Z

Generator floor 1.884 3.180 3.755 0.082 0.131 0.215 0.031 0.029 0.099

Busbar floor 1.413 2.664 3.838 0.077 0.107 0.215 0.035 0.039 0.086

Turbine floor 2.031 2.406 3.078 0.193 0.199 0.281 0.129 0.166 0.213

Wind hood 1.570 2.337 2.962 0.133 0.108 0.230 0.071 0.057 0.103

Turbine pier 1.874 2.184 2.479 0.163 0.146 0.417 0.124 0.097 0.363

Busbar pillar 1.755 3.177 1.896 0.139 0.125 0.120 0.060 0.049 0.038

Turbine pillar 1.984 2.945 1.695 0.272 0.168 0.118 0.132 0.074 0.066

Table 7: Maximum vibration responses of local structures under generating condition.

Structure

Displacement (μm) RMS velocity (mm/s) RMS acceleration (m/s

2

)

X Y Z X Y Z X Y Z

Generator floor 1.722 2.379 4.148 0.105 0.125 0.308 0.035 0.037 0.153

Busbar floor 1.075 2.031 3.977 0.113 0.140 0.229 0.057 0.056 0.098

Turbine floor 1.839 2.425 3.327 0.206 0.225 0.417 0.134 0.183 0.261

Wind hood 1.379 1.749 2.367 0.131 0.118 0.259 0.069 0.058 0.111

Turbine pier 1.629 1.719 1.987 0.182 0.148 0.445 0.133 0.101 0.388

Busbar pillar 2.181 2.051 1.735 0.178 0.148 0.159 0.077 0.058 0.052

Turbine pillar 2.126 2.673 1.991 0.312 0.221 0.138 0.147 0.102 0.069

and the calculation method adopts the time history

method. The time history calculation is divided into

two working conditions: pumping and generating

(full load). The selected representative load duration

is 2 s, and the structural damping ratio is 0.02. The

maximum vibration responses of typical local

structures of the powerhouse under pumping and

generating conditions are shown in Tables 6 and 7,

respectively.

Compared with Table 5, the maximum

displacement, root mean square (RMS) velocity and

root mean square (RMS) acceleration of local

structures of the powerhouse such as floors, wind

hood, turbine pier and pillars are small under the

two working conditions, which meet the vibration

control standard of powerhouse, indicating that the

risk of vibration damage of the powerhouse

structure is very low under steady-state operating

conditions.

5 CONCLUSIONS

The following conclusions are obtained:

(1) The top 20 natural frequencies of the whole

structure of the powerhouse range from 13.71

to 34.00 Hz. The top 3 vibration modes are

mainly the whole vibration of the structure

above the volute layer, and the other vibration

modes are mainly the vertical vibration in local

areas of the floors and the normal vibration in

local areas of the side walls.

(2) By comparing the calculation and test values

of the vertical first natural frequencies of local

Research on Vibration Characteristics of Powerhouse Structure of Variable Speed Unit Section in Fengning Pumped Storage Power Station

35

areas of the busbar floor and the horizontal

first natural frequencies of the busbar pillars, it

can be seen that there is little difference

between the two values, indicating that the

calculation model established and the boundary

conditions set in this paper are reasonable end

effective.

(3) The maximum vibration responses of local

structures of the powerhouse such as floors,

wind hood, turbine pier and pillars are small

under pumping and generating conditions,

which meet the vibration control standard of

powerhouse, indicating that the risk of

vibration damage of the powerhouse structure

is very low under steady-state operating

conditions.

ACKNOWLEDGMENTS

The authors are grateful for the financial support

from the Headquarters Management Technology

Project of State Grid Corporation of China (No.

5419-202243054A-1-1-ZN).

REFERENCES

Zhou, X.B., Zhou, J.P., Du, X.H., 2023. Thoughts on the

high-quality development of pumped storage industry

in the new era[J]. Hydropower and Pumped Storage,

9(3): 20-24, 36.

Gao, M.W., Fang, C.Y., 2017. Vibration responses

analysis of hydro-plant powerhouse structure due to

endogenic vibration[J]. Water Power, 43(2): 44-46,

103.

Wang, L.P., Ma, Y.F., Kong, Z.Y., et al., 2022. Analysis

of static and dynamic characteristics of underground

powerhouse in Fengning pumped storage power

station[J]. Engineering and Technological Research,

7(18): 7-10.

Ma, Z.Y., Zhang, Y.L., CHEN, J., et al., 2013.

Powerhouse and units coupling dynamics theory of

hydropower station and its application[M]. Beijing:

China Water and Power Press.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

36