Agrotechnical and Agrochemical Studies of Gas-Dynamic Effects on

Soil and Plants

Rasulion Toljev, Ikromali Karimov, Xamidullo Sadulaev, Kamaljon Muhamadsodikov,

Azizjon Isomidonov, Nargiza Rajaboya, Abdusamad Muydinov, Gulnora Khasanova

and Islomjon Kakhkh

orov

Technical Sciences, Fergana Polytechnic Institute, Republic of Uzbekistan, Fergana.

Keywords: Agrotchnical, Agrochemical, Soil, Plants, Gas

Abstract: In this article, the issues discussed in the basis of the developed method for loosening the arable soil surface

by micro-explosions are based on the principle of impact on the soil by a shock wave formed as a result of the

detonation of fuel-air mixtures in the pipes of a gas-dynamic generator. In this case, the shock wave creates

pulse pressure on the soil surface with a high gradient of increase. In this case, the plants are not damaged,

since mechanical contact of the tool with the soil is completely eliminated. It has been established that soil

treatment with shock waves leads to an increase in the total microbial number in the soil layer (D-30cm).

After a day, continuous growth of small colonies of microorganisms is observed. Further observations of the

development of the plant showed that at each phase (appearance of sympodial branches, beginning of

flowering, etc.) cotton treated with shock waves is ahead of cotton in control plots in terms of phase timing.

By the time of ripening, this lead reaches 10÷12 days. As is known, when the soil is sufficiently enriched with

carbonic acid (H

2

CO

3

), soil stratification occurs, and at the same time the plants absorb the necessary elements

well and develop better. The soil will contain a concentration of calcium, which displaces hydrogen, and in

the final state, the nitric acid formed during the nitrification process will be neutralized. This is confirmed by

the results of experimental studies, which showed the rapid sprouting development of cotton. Earlier ripening

provides significant advantages in cotton growing - there is more time left for harvesting, the quality of the

delivered fiber increases, and the risk of crop loss is reduced. Experts consider this property of the developed

soil crust loosener GDRP (gas-dynamic soil loosener) to be very important.

1 INTRODUCTION

Currently, mechanical tillage throughout the world is

carried out using mechanical tools. The force on the

soil is transmitted through any tool - a harrow tooth, a

plow share, a rotary sprocket needle, a disk, etc. and

so on. It is obvious that science and technology do not

have any serious alternatives to such a solution.

However, there are some types of soil cultivation

in which the operation of mechanical tools is not

perfect. For example, the task of loosening the soil

crust in regions with a hot climate is solved by such

methods as harrowing, “calcining” the crust with the

tooth of a rotary hoe, manually with grape hoe and

various prickly devices.

Mechanized methods of dealing with crust are not

effective enough, because the tool, in contact with the

crust, creates, in addition to forces directed normally

to the surface of the crust, lateral shear forces. As a

result, a shift in the crust elements occurs, “evering”

and damage to the seeds. Because of this, it is

problematic to increase the processing speed, and

already sprouted fields cannot be processed at all,

because Young plants are damaged (Tojiyev, 2019).

Nevertheless, at present there are no effective

solutions that replace mechanical tools. This once

again demonstrates the difficulty of such a task.

However, it is fair to say that the search must continue.

2 METHODS

This article outlines some of the results of such a

search. The central idea of the research is to propose

a detonation (explosive) wave as a “tool” of force.

Toljev, R., Karimov, I., Sadulaev, X., Muhamadsodikov, K., Isomidonov, A., Rajaboya, N., Muydinov, A., Khasanova, G. and Kakhkhorov, I.

Agrotechnical and Agrochemical Studies of Gas-Dynamic Effects on Soil and Plants.

DOI: 10.5220/0013451400004654

In Proceedings of the 4th International Conference on Humanities Education, Law, and Social Science (ICHELS 2024), pages 799-808

ISBN: 978-989-758-752-8

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

799

Detonation of gas mixtures of conventional

combustibles (gasoline, gas) with air produces a force

impulse with the following parameters:

a. pressure in the shock wave 35 atm;

b. flow rate of detonation products 800

m/sec;

c. movement of the detonation wave along

the channel at a speed of about 1600 1800

m/sec.

Such a gas-dynamic impulse, hitting any surface,

acts on it as a sharp, short blow. The impact force and

direction can be adjusted and the impact can be

directed, for example, strictly perpendicular to the

surface without lateral (shear) force components. The

“tool” is gas, as opposed to a harrow tooth, needle,

etc. In this sense, the “explosive” effect promises

certain advantages. But an explosion (even a micro-

explosion) in agricultural technology is a completely

new matter, unexplored by anyone, without printed

information, raising many questions. Actually, the

answers to these questions form the content of this

article.

3 RESULTS AND DISCUSSION

The authors of the article are aware that within the

framework of one study it is impossible to answer all

the questions in such an unconventional matter, and

therefore the main goal was not only to substantiate

the proposed principle theoretically, in laboratory and

bench conditions, but also to create prototypes of

equipment and test them in natural conditions.

Note that the development of the GDR is not the

scientific goal of this article, and the GDR scheme is

used here; it is described to preserve the logic of

presentation of all the material in the article and at the

same time, details are omitted for the presentation of

which would require a lot of space.

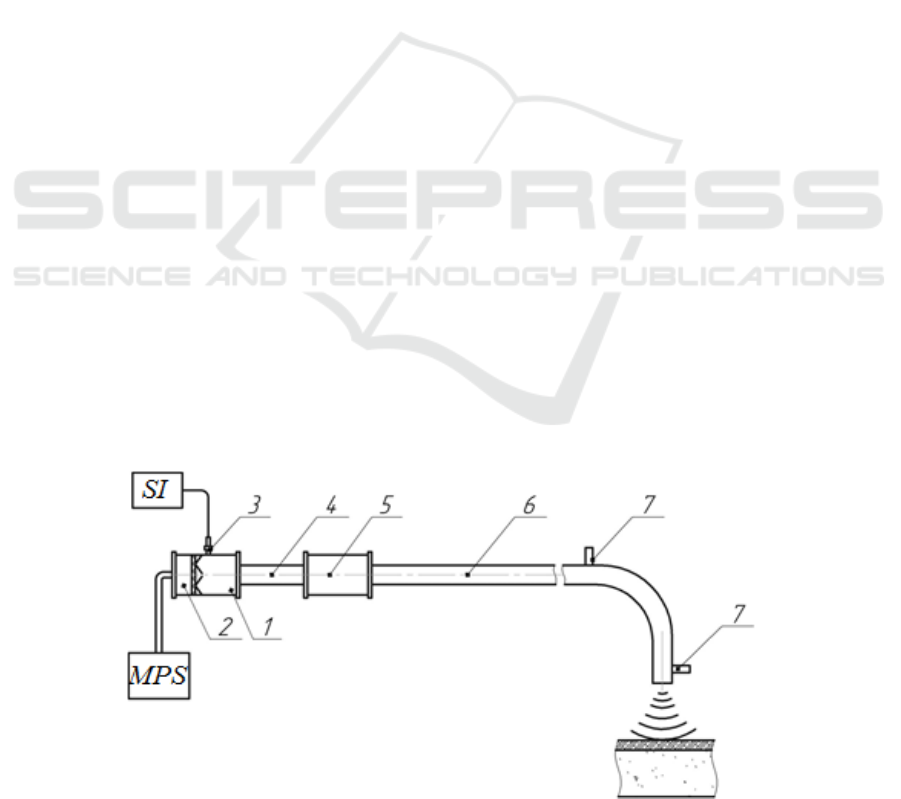

In general, the concept of a gas-dynamic soil

ripper (GSD) is constructed as follows: an air source

(compressor) is connected to the power take-off shaft

(PTO) of the base tractor. The rotating compressor

supplies air to the mixing chamber with fuel. The fuel

is also supplied to the mixing chamber in strict

accordance with the pressure H (air pressure in the

fuel supply tank and the selected area f of the fuel

nozzle. After the mixing chamber, the mixture enters

the detonation wave generator, where it is

periodically burned in detonation mode with a given

frequency (Tojiyev, Erkaboyev, Rajabova, and

Odilov, 2021). In Fig. 1. a schematic diagram of the

gas flow control unit is given.

1-ignition chamber; 2-chamber check valve; 3-

spark plug; 4-section; 5-turbulator; 6-acceleration

pipe; 7-sensors; SI - system instigation; MPS –

mixture preparation system.

In this regard, in 2020, we immediately conducted

laboratory (without sowing in the field) experiments

on the treatment of corn, cotton and dzhugar seeds

with shock waves generated by the HDRP unit

(Tojiyev and Rajabova, 2021).

Experiment scheme: 1) The seeds were placed in

fabric bags, which were located on the ground

between the output ends of the working bodies of the

HDRP; 2) “irradiation” with shock waves from a

working HDRP lasted from 1 to 3 minutes; 3) The

development of sprouts was monitored and

quantitative indicators were measured.

Observations were carried out on the dynamic

growth of sprouts in Petri dishes and some parameters

were measured. As follows from the information

presented here, the development of sprouts of all three

crops, the seeds of which were treated with shock

waves, was accelerated. The size of the leaves and

roots of these sprouts is significantly increased.

Figure 1: Schematic diagram of the gas flow control unit.

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

800

When a shock wave passes through the plant

seeds, the latter experience short-term compression.

The time of such compression is estimated at

approximately 1/150000 sec (Tojiyev, 1993). Thus,

the observed trend of accelerated development of

seeds treated with shock waves served as an argument

for launching a field experiment in 2020 in sowing

seeds in the field.

For this purpose, the experimental plot was allocated

with plots sown with cotton seeds pre-treated with

shock waves.

Thus, laboratory and field experiments show that

pre-sowing treatment of seeds with shock waves has

a significant effect on their further development.

Annual recording of the emergence of seedlings in

experimental and control plots showed a stable trend

in the emergence of cotton seedlings treated with

HDRP during the period: after sowing and before

emergence.

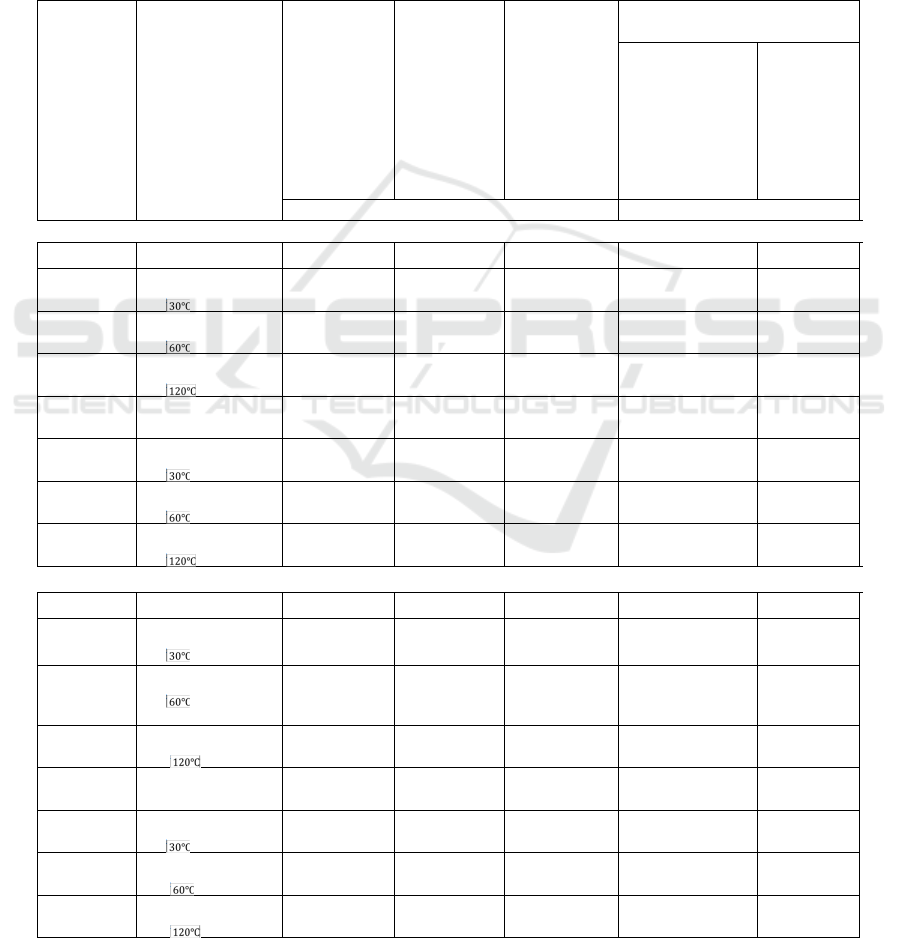

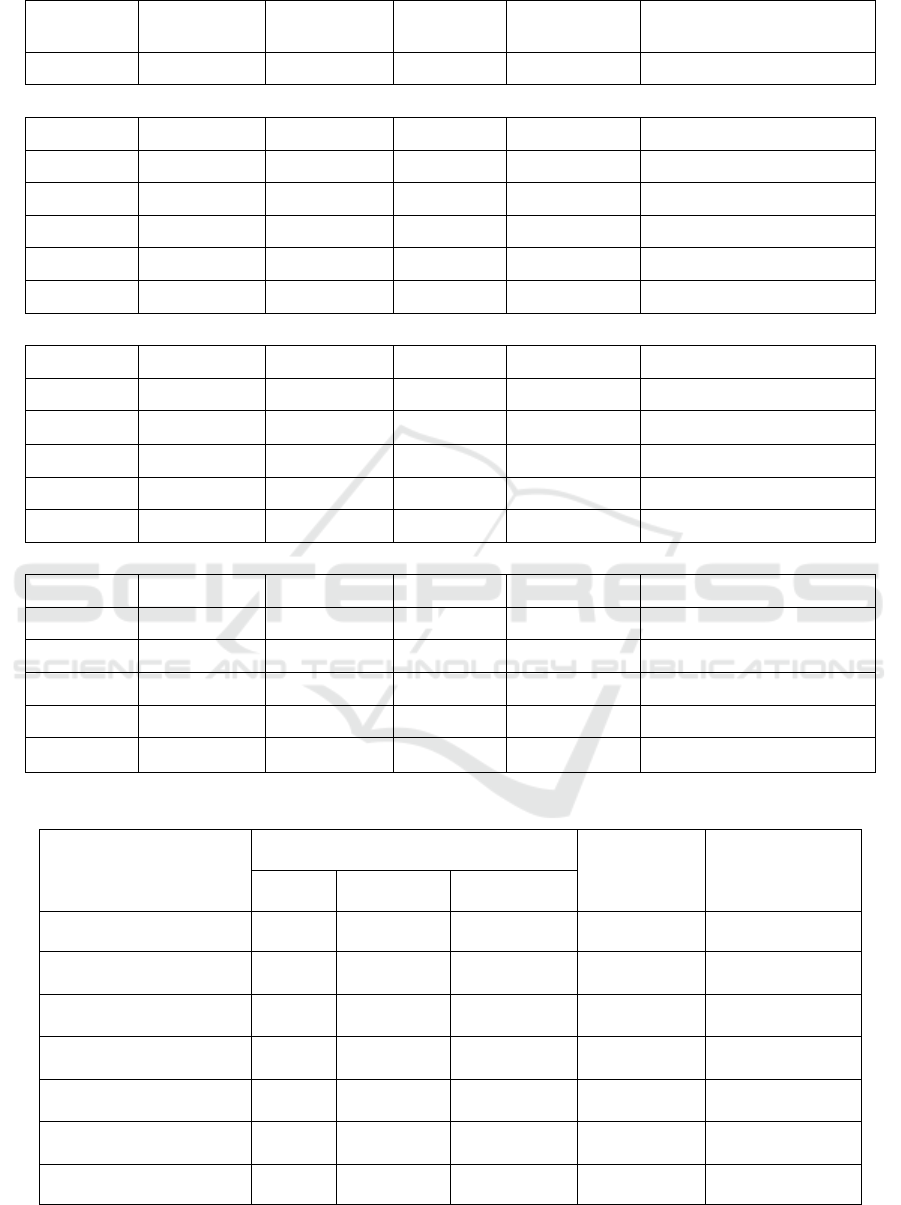

Table 1a: Dynamics of sprout development

Seed

condition

Options Germinatio

n %

Average

length of the

above-

ground part

of a sprout

kov, cm

Average

length of the

above-

ground part

of a sprout

kov, cm

Dynamics of sprout

develo

p

ment

Average length

of the root part

of a sprout kow,

in cm

Average

length of

the above-

ground

part of a

sprout

kow, in cm

during 3 days during 10 days

White durra

Dry Control 90 2 2.5 4 6.5

Processing

t =

100 4 2.7 6 6.8

Processing

t =

100 2 1.9 7 7

Processing

t =

100 6 2.5 6.5 8

Moisturiz

e

d

Control 100 3 1.1 6 5

Processing

t =

100 2.8 2.4 9 7.8

Processing

t =

100 3.6 4.2 11 9.4

Processing

t =

100 4.2 2.6 6 8.2

CORN

Dry Control 100 2.1 0.3 5.5 2.5

Processing

t =

100 2.8 1.1 7 8

Processing

t =

100 3 0.9 11 8

Processing

t =

100 3 0.9 6.5 3.2

Moisturiz

e

d

Control 100 4 1.06 5 5.5

Processing

t =

100 6 1.2 6 5

Processing

t =

100 6.5 2.2 6.5 6.5.

Processing

t =

100 4.5 1.8 4.8 6.4

Agrotechnical and Agrochemical Studies of Gas-Dynamic Effects on Soil and Plants

801

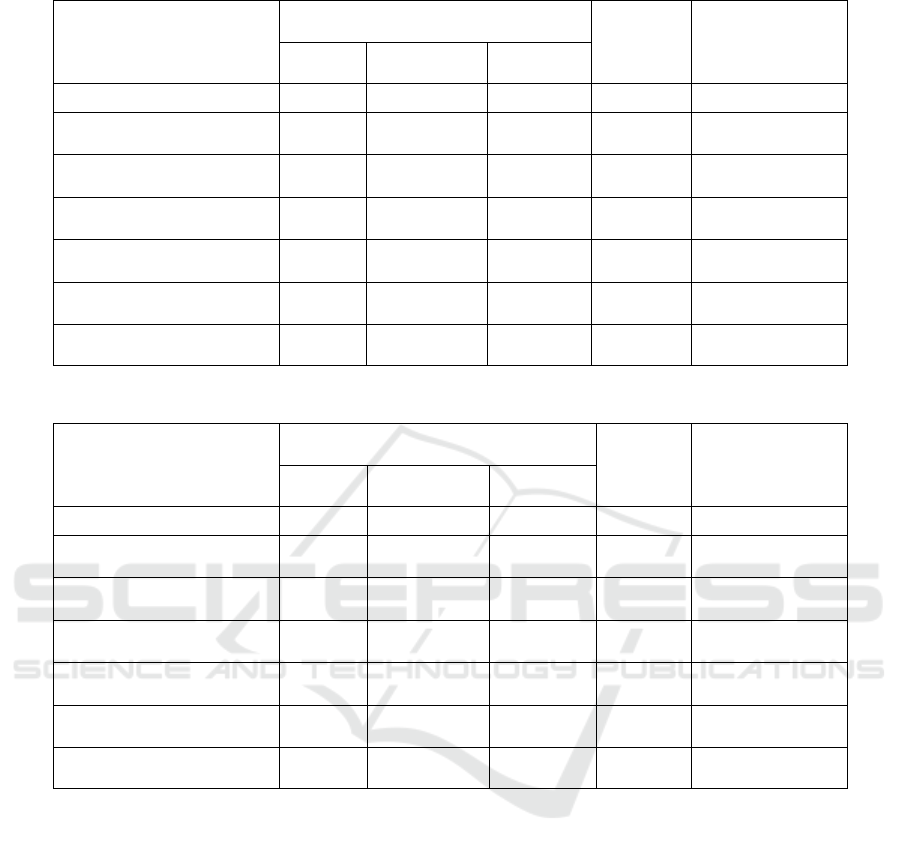

Table 1b: Date of Experiments Conducted from 08/18/2020 to 08/28/2020.

Seed

condition

Options

G

ermination

%

Average

length of the

above-

ground part

of a sprout

kov, cm

Average

length of the

above-

ground part

of a sprout

kov, cm

Dynamics of sprout

development

Comment

Average

length of the

root part of a

sprout

kow, in cm

Average

length of the

root part of a

sprout

kow, in cm

During 3 days During 10 days

1 2 3 4 5 6 7 8

White durra

dry Control 90 0.8 1.2 3.5 8 The stem is thick,

the root is strong

Processing t =

100 2 0.5 4.5 10

Processing t =

100 0.9 0.6 5 11.5

Processing t =

100 0.97 0.4 4 11

moisturized Control 100 0.9 1.3 3 8 The stem is thick,

the root is strong

Processing t =

100 2 0.9 6 10

Processing t =

100 1.5 1.1 4 12

Processing t =

100 2 0.8 5 12

CORN

dry Control 100 0.5 0.45 4.5 4.6

Processing t =

100 3 0.97 5.5 7

Processing t =

100 2 0.6 11 8 The stem is thick,

the root is strong

Processing t =

100 1 0.68 11 4.5

moisturized Control 100 0.9 1.1 6 5 The stem is thick,

the root is strong

Processing t =

100 2 1.3 7 7

Processing t =

100 3 2.5 13.5 10

Processing t =

100 1.5 1.2 10 5

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

802

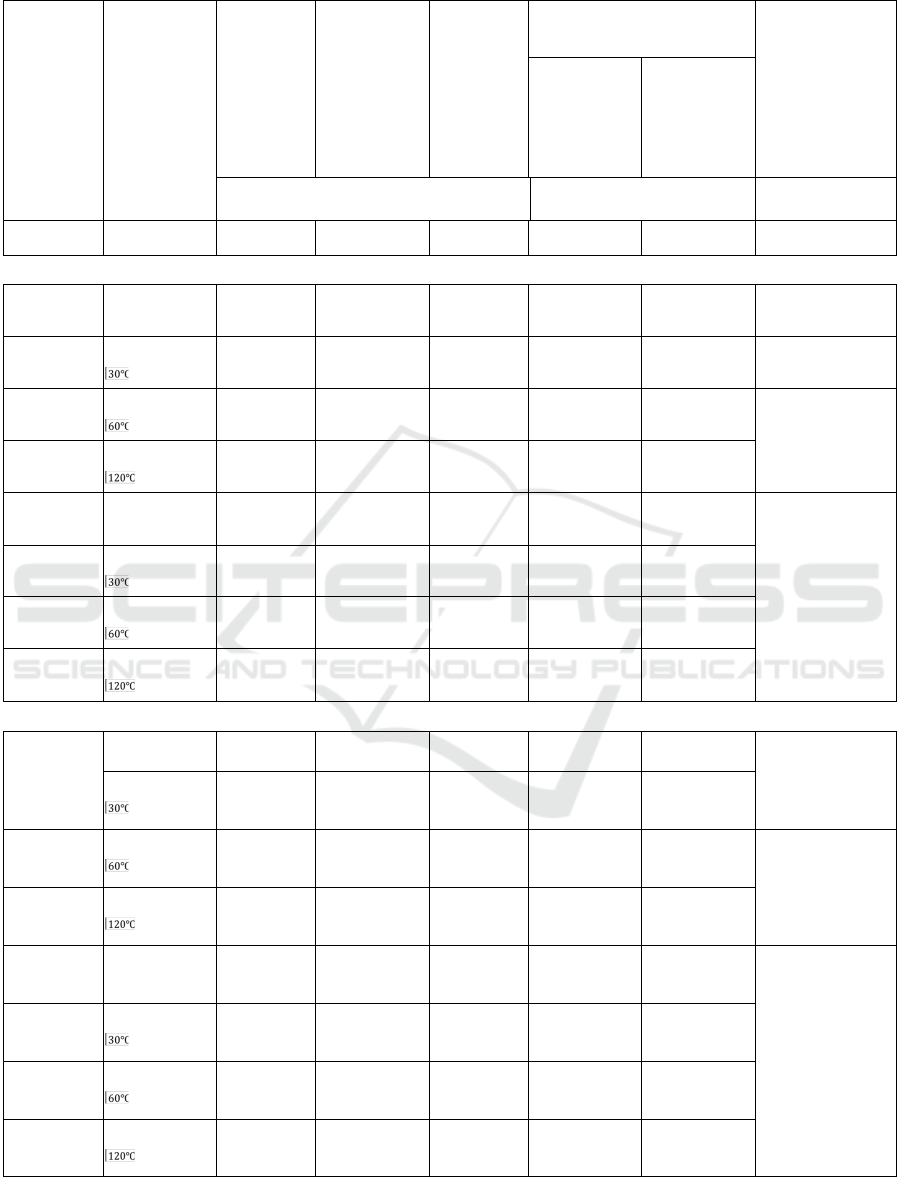

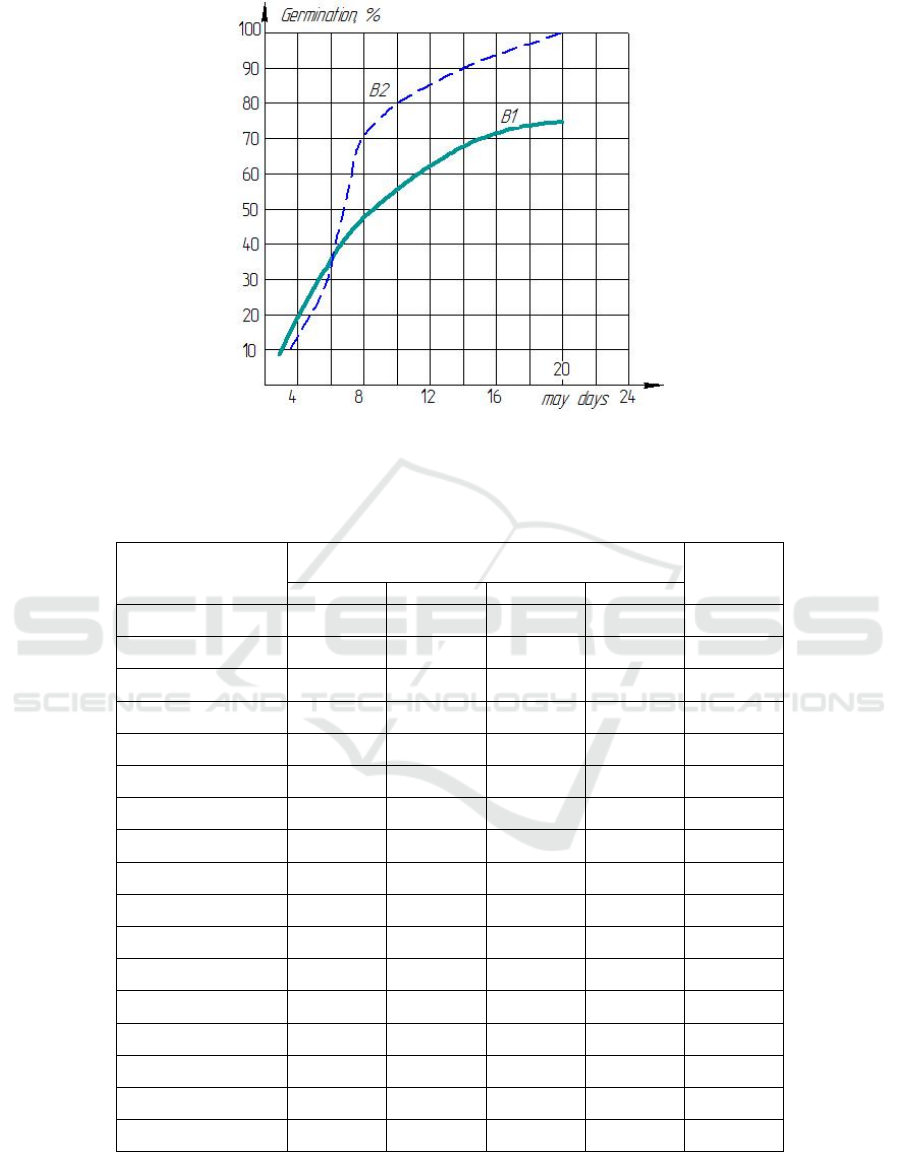

Table 2: Emergence of seedlings as a percentage of the total number of seedlings

Experiment number

according to the method

Emergence of seedlings as a percentage of the total number of seedlings

2 may 5 may 8 may 11 may 15 may 20 may

B1 (control section) 17,7 % 32,3 % 48,5 % 60 % 72,3 % 73,3 %

B2 (treatment with HDRP

b

efore emer

g

ence

)

15,3 % 28,2 % 74 % 85,3 % 95,9 % 100 %

Table 3: Results of phenological observations at the end of the growing season

Processing

options

Plant height, cm Number of sympodia, pcs.

Number of boxes,

p

cs.

1 2 3 4

Zone 1

В1 76 11,7 9,0

В2 75,4 11,3 10,1

В3 77,9 12,3 10,1

В4 76,4 11,4 10,0

В5 76,8 12,5 9,2

С

р

76,5 11,87 9,63

Zone 2

В1 79,1 13,1 11,3

В2 75,3 13,4 12,8

В3 78,6 13,9 12,6

В4 74,6 13,7 12,3

В5 76,6 12,0 12,1

С

р

76,8 13,61 12,4

Zone 3

В1 80,3 12,4 10,1

В2 80,6 13,7 12,8

В3 81,3 13,9 12,6

В4 79,9 12,4 12,5

В5 77,9 12,2 10,4

С

р

79,9 12,5 11,7

According to the above observations, not only the

percentage of germination increases, but also, starting

from a certain period, the process of germination of

cotton treated with HDRP accelerates.

In the period following germination, cotton

growth dynamics were observed. In the phase of

several true leaves, the roots of the plants were

washed (the plants were removed from the ground

with the necessary amount of soil to preserve the root

system and washed with water according to the

accepted methodology).

Averaged data for a large number of samples

show that the development of the root system in all

experimental plots treated with HDRP before

germination (B-2) and after germination (B-3) is

significantly ahead of development compared to the

control plot.

Examination of the root system of cotton after

ripening (after harvest) gives the same results. Figure

10 shows a photograph of the roots of a mature cotton

plant in comparison with a specimen from a control

plot. Thus, the fact of enhanced development of the

cotton root system in the case of impact on the soil

and seeds by shock waves has been recorded (Tojiyev

and Rajabova, 2021).

The results of further phenological observations

(after germination) gave the following results (see

Table 3÷7). From the analysis of experimental data

(see Table 3÷7) it follows that the growth and

development of cotton improves in all variants after

treatment of crops with shock waves of HDRP. The

best results are obtained by options B-2 and B-3

(treatment with HDRP before germination and after

mass germination).

Taking into account the results of observations of

the development of the cotton root system presented

above, it can be argued that it is a more powerful root

system that ultimately leads to such results.

However, closer attention should be paid to the

fact that starting from germination and further

throughout the entire period before ripening, there is

a tendency to advance (accelerate) the development

of cotton treated with shock waves.

Agrotechnical and Agrochemical Studies of Gas-Dynamic Effects on Soil and Plants

803

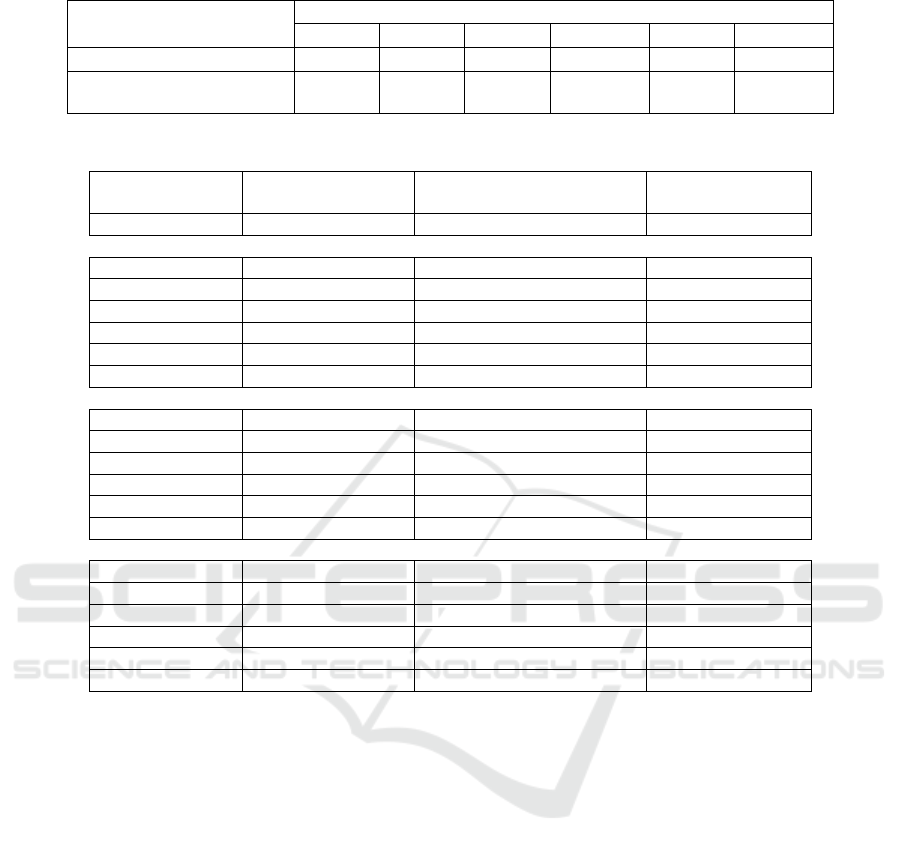

Table 4: Weight of Raw Cotton Per Boll (g)

Processing

options

Sympodial

branch №3

Sympodial

branch №6

Sympodial

branch №9

Average

weight

Increase in box weight

relative to the control variant

1 2 3 4 5 6

Zone 1

В1

5,13 5,60 5,40 5,40 -

В2

5,35 5,64 5,63 5,54 +0,14

В3

5,25 5,70 6,00 5,65 +0,25

В4

5,22 5,97 5,79 5,66 +0,26

В5

5,37 5,90 5,76 5,64 +0,24

С

р

5,22 5,74 5,79 5,59 +0,22

Zone 2

В1

5,29 5,14 5,54 5,32 -

В2

5,62 5,60 5,55 5,59 +0,27

В3

5,33 5,81 6,09 5,74 +0,42

В4

5,29 5,64 5,89 5,60 +0,28

В5

5,32 5,71 5,67 5,57 +0,25

С

р

5,33 5,58 5,83 5,56 +0,3

Zone 3

В1

5,43 5,75 5,31 5,49 -

В2

5,47 5,82 5,70 5,66 +0,17

В3

5,30 5,85 5,99 5,71 +0,22

В4

5,56 5,94 5,54 5,68 +0,19

В5

5,58 5,46 5,44 5,70 +0,21

С

р

5,47 5,80 5,54 5,65 +0,20

Table 5: Effect of HDRP treatment on cotton yield c/ha Section 1

Processing options

Repeatability of the experiment on the site

Avg. Yield a/y

Increase in yield,

a/y

I II III

1 2 3 4 5 6

Control plot (without

HDPR treatment), B1

29,9 30,0 28,3 29,2 -

Treatment with HDRP

b

efore emergence, B2

30,5 30,4 29,5 30,1 +0,9

Treatment with HDRP

durin

g

mass shoots, B3

29,5 30,1 34,4 31,3 +2,1

Treatment with HDRP at

the stage of 2-4 leaves, B4

29,2 28,9 32,7 30,3 +1,1

Treatment with HDRP

after flowering, B5

30,3 30,2 31,5 30,6 +1,4

Average values 29,9 29,9 31,3 30,3 +1,4

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

804

Table 6: Effect of HDRP treatment on cotton yield c/ha (Section 2)

Processing options

Repeatability of the experiment on the

site

Avg.

Yield a/y

Increase in yield,

a/y

I II III

1 2 3 4 5 6

Control plot (without HDPR

treatment

)

, B1

33,0 35,7 37,6 35,4 -

Treatment with HDRP

b

efore emergence, B2

38,4 37,2 35,9 37,2 +1,8

Treatment with HDRP

durin

g

mass shoots, B3

32,5 34,5 43,2 36,7 +1,3

Treatment with HDRP at the

sta

g

e of 2-4 leaves, B4

38,4 35,6 38,6 37,5 +2,1

Treatment with HDRP after

flowering, B5

36,4 36,0 37,8 36,7 +1,3

Average values 35,7 35,8 38,6 36,7 +1,6

Table 7: Effect of HDRP treatment on cotton yield c/ha (Section 3)

Processing options

Repeatability of the experiment on the

site

Avg.

Yield a/y

Increase in yield,

a/y

I II III

1 2 3 4 5 6

Control plot (without HDPR

treatment

)

, B1

37,3 33,8 34,9 35,3 -

Treatment with HDRP

b

efore emergence, B2

37,5 36,1 41,0 38,2 +2,9

Treatment with HDRP

durin

g

mass shoots, B3

38,2 37,6 37,9 37,9 +2,6

Treatment with HDRP at the

sta

g

e of 2-4 leaves, B4

41,3 32,1 35,3 36,2 +0,9

Treatment with HDRP after

flowering, B5

38,9 34,3 33,9 35,7 +0,4

Average values 38,6 34,8 36,6 36,7 +1,7

To illustrate this fact, let us return once again to

the analysis of germination. Germination data similar

to those given in Table 2 are presented in the form of

a graph in Fig.2. And according to the table. 2 and

according to the graphical dependence in Fig. 2 it can

be seen that, starting from some, the number

increases, and the germination of seeds in the control

(without HDRP treatment) areas begins to advance in

time. At the germination stage, the advance in terms

of timing reaches at least two thirds of days.

Further observations of plant development

showed that at each phase (appearance of sigmoidal

branches, beginning of flowering, etc.) cotton treated

with shock waves is ahead of cotton in control plots

in terms of phase timing. By the time of ripening, this

advance reaches 10–12 days.

As is known, when the soil is sufficiently enriched

with carbonic acid (H

2

CO

3

), soil stratification occurs,

and at the same time, plants absorb the necessary

elements well and develop better.

When treating the soil with a HDRP unit, the soil

is enriched with carbon monoxide (CO2), and there is

always a sufficient amount of moisture (H

2

O) in the

soil, which causes the reaction to occur.

СО

2

+Н

2

О=Н

2

СО

3

(1)

Research by Academician I.N. Antipov-Karataev

and his colleagues show that calcium carbonate

contained in the soil reacts according to the following

scheme:

Н

2

СО

3

+ Н

2

О+ СО

2

=Са(НСО

3

)

2

Са(НСО

3

)

2

+2Н

2

О=Са(ОН)

2

+2Н

2

О+ 2СО

2

Са(ОН)+Са

2

+2ОН (2)

Agrotechnical and Agrochemical Studies of Gas-Dynamic Effects on Soil and Plants

805

Figure 2: Germination of cotton when treated with HDRP before emergence. B1 – control; B2 – treatment with HDRP before

germination.

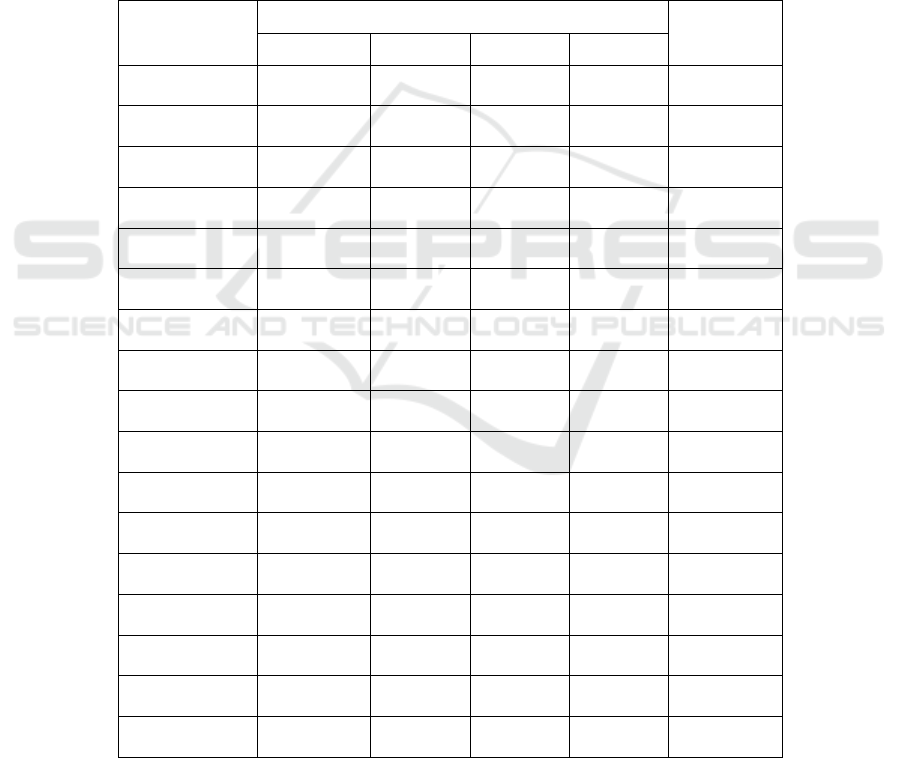

Table 8: Determination of maturity, breaking load and metric number of cotton fiber in polarized light (cotton from the control

plot without HDRP treatment).

Fields of view Number of fibers by group Total

I II III IУ

I 29 10 3 1 43

II 25 12 2 - 39

III 27 14 2 - 43

IУ 28 12 3 1 44

У 23 8 5 2 38

УI 27 10 6 - 43

УII 25 8 4 1 38

УIII 27 9 6 1 43

Total 211 83 31 6 331

% % 63,7 25,1 9,4 1,8 100

Сорт 2 2 2 2

Coef. Fortresses 5,2 2,7 1,6 04

Work 331,2 67,8 15,0 072 41472

Coef. 130 80 55 40

Work 8281 2008 317 72 10878

Coef. Fortresses 2,3 1,3 1,0 05

Work 146,51 32,63 9,4 090 18944

Results: Coef. maturity 1.9

strength 4.1 gs

Metric number 163

Breaking length 25.1

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

806

The concentration of calcium ions in the soil

increases, which displaces hydrogen, and the nitric

acid formed during the nitrification process is

ultimately neutralized. This is confirmed by the

results of experimental studies, which showed rapid

germination and development of cotton seedlings.

Earlier ripening provides significant advantages

in cotton growing - there is a longer period for

harvesting, the quality of the delivered fiber

increases, and the risk of crop loss is reduced. Experts

consider this property of the developed soil crust

loosener (SCR) to be very important (Tojiyev and

Rajabova, 2022).

Determining the maturity, breaking load and

metric number of cotton fiber in polarized light

(cotton from the area treated with HDRP) leads to

rather unusual consequences (accelerated

development of cotton at all stages), we checked the

grown fiber in order to make sure there were no

negative effects consequences of shock wave

treatment. Tables 8 and 9 show the results of the

analysis of the technological quality of cotton from

the control plot and from the plot treated with HDRP.

Comparison of data from table. 8 and 9 gives

grounds to assert that the properties of cotton fiber do

not change from the processing of HDRP.

Table 9: Determination of maturity, breaking strength and metric number of cotton fibers in polarized light (cotton from areas

treated with HDRP).

Fields of view

Number of fibers by group

Total

I II III IУ

I 30 13 4 - 47

II 38 12 2 1 49

III 32 12 4 - 48

IУ 30 8 5 1 44

У 26 11 4 1 42

УI 21 10 5 2 38

УII 24 9 3 - 36

УIII 26 6 5 2 38

Total 22,2 80 33 7 342

% % 64,9 23,4 9,6 2,1 100٪

sort 2 2 2 2

Coef. fortresses 5,2 2,7 1,6 04

work 337,5 63,2 15,4 084 41694

Coef. 130 80 55 40

work 8437 1872 528 84 10921

Coef. fortresses 2,3 1,3 1,0 05

work 149,27 3042 9,6 1,0 19029

Results: Coef. maturity 1.9

strength 4.2 gs

Metric number 164

Breaking length 25.6

Agrotechnical and Agrochemical Studies of Gas-Dynamic Effects on Soil and Plants

807

Experimentally, in laboratory and field

conditions, an enhanced development of germination

of cotton, jugara and corn seeds pre-treated with

shock waves with an intensity of up to 35 atm and

treatment times of up to 2 minutes was established.

4 CONCLUSION

The destruction of the soil crust in the period between

sowing cotton and germination leads to an increase in

the rate of mass germination of cotton by an average

of 25٪ and to a decrease in the total period of one

hundred percent germination by 2–3 days. The same

effect is observed after shock wave treatment of crops

in the absence of soil crust.

Two modes of treating crops with shock waves of

HDRP, namely in the period before germination and

after mass germination, lead to enhanced

development of the cotton root system.

REFERENCES

GOST 3274.1-72 (ISO 1973-76, ISO 3060-74). Cotton

fiber. Technical conditions.

Tojiyev, R. (1993). Mechanico-technological solutions for

non-contact impact on soil and plants with the

development of gas-detonation units for highly efficient

cotton cultivation. Dissertation for the degree of Doctor

of Technical Sciences, Ferghana.

Tojiyev, R. (2019). Application of the gas-dynamic

principle in agricultural technology. Monograph,

Ferghana, p. 140.

Tojiyev, R., Erkaboyev, X., Rajabova, N., & Odilov, D.

(2021). Scientific Progress, 2(7), 694-698.

Tojiyev, R., & Rajabova, N. (2021). Scientific Progress,

2(8), 153-163.

Tojiyev, R., & Rajabova, R. N. (2021). Innovative

Technological Methodical Research Journal.

Tojiyev, R. Zh., Mukhamadsodikov, K. Zh. (2020).

Agrochemical and agrobiological studies of soil treated

by a gas-dynamic method. Republican conference on

solving theoretical and mechanical engineering issues,

Ferghana.

Tojiyev, R. Zh., Mukhamadsodikov, K. Zh., &

Sulaymonov, O. N. (2021). Scientific-technical journal

FerPI, No. 2 (3), Ferghana, pp. 33-35.

Tojiyev, R. Zh., & Rajabova, N. H. (2021). Scientific-

technical (STJ FerPI, FarPI ITZh, NTZh FerPI), 25, 6.

Tojiyev, R. Zh., & Rajabova, N. R. (2022). Scientific-

technical journal (STJ FerPI, FarPI ITZh, NTZh FerPI),

Vol. 26, No. 3.

Tojiyev, R. Zh., & Rajabova, N. R. (2022). Scientific-

technical journal (STJ FerPI, FarPI ITZh, NTZh FerPI),

2023, 27, Special Issue No. 19.

Tojiyev, R. Zh., Sadullaev, K. M., & Isomidinov, A. S.

(2021). Scientific-technical journal FerPI, 4, Ferghana.

Tojiyev, R. Zh., & Rajabova, R. N. (2022). Scientific-

technical journal (STJ FerPI, FarPI ITZh, NTZh FerPI),

Vol. 26, No. 3.

Tojiyev, R. Zh., & Rajabova, R. N. (2021). Scientific

Progress, 2, 8, ISSN: 2181-1601.

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

808