Drainage and Distribution of Heavy Liquids by Mixing Fluid Phases

with Inert Gas in Bubble Extractor

Ikromali Karimov, Rasulion Toljev, Akmaljon Xakimov, Xamidullo Sadulaev, Nasimbek Ergashev,

Ismolijon Xalilov, Ilxomjon Mamarizaev and Ilxomjon Majidov

Technical Sciences, Fergana Polytechnic Institute, Republic of Uzbekistan

Keywords: Distribution, Liquids, Glass, Fluid.

Abstract: Using an experimental bubble extractor, the article investigates the process of pulverizing heavy liquids into

droplets by combining fluid phases with inert gas. Glass makes up the majority of the apparatus's functioning

components, making it simple to see heavy liquid droplets and to see film and photographs. The device's

dispersion phase to total phase ratio is set at 3/1. Gas velocities were provided at various values based on the

mixing duration at constant phase velocity values, and experiments were conducted to ascertain the droplet

distribution and size distribution. The computer was used to process the regression equations. The total surface

diameters of the droplets were calculated using the experimental study data. Theoretical and experimental

values are compared with a formula for determining the total surface diameter of droplets, which is crucial

for estimating mass transfer processes and depends on the physical and chemical characteristics of liquids.

The suggested formula has been fully validated by the computations. One of the key elements influencing the

efficacy of the suggested bubble extractor is the surface diameter and the inter-phase comparison surfaces of

the dispersion phase drop, which could be found as a consequence of the study.

1 INTRODUCTION

The disperse systems used in scientific and

production practice are heterogeneous and contain at

least two phases. One of them is the universal phase,

called the dispersion phase (Frolov, 1982). The

second phase, called dispersion phase, is divided into

particles, which are broken down and distributed in

the first. Fluid - as a result of studying the

hydrodynamics of droplet formation and crushing

process in the fluid system, it is important to develop

scientifically sound methods for the extraction of

fluids. For this purpose, we have been investigating

experimental dispersion of the dispersion phase by

drop and size distribution in the mixing zones of the

bubble extractor created by us (Alimato, Sokolov,

Sadullaev, and Karimov, 1990).

2 MATERIALS AND METHODS

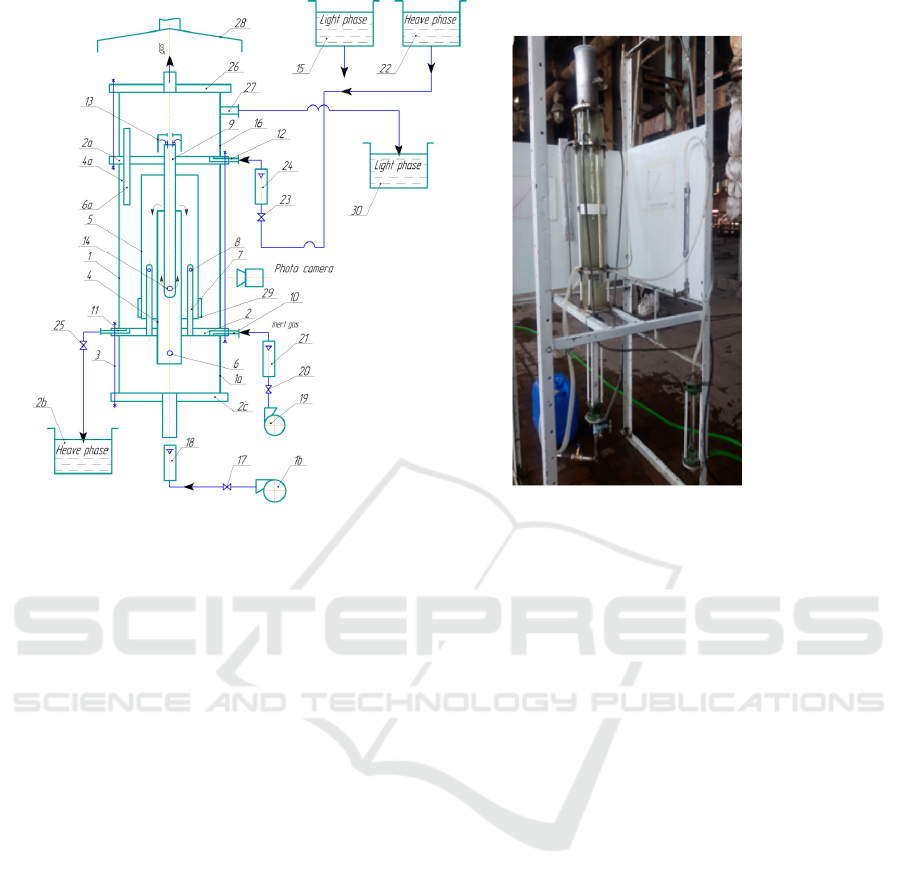

As an object of research, we used an experimental

device created by the Department of Technological

Machines and Equipment to study the hydrodynamic

processes of an extruded bubble extractor (Figure 1-

2).

The principle of operation of the experimental

equipment is as follows. Liquid container 15 is

supplied from the mixing device of the apparatus by

means of pump 16 from the 4-speaker gas distribution

unit. The required amount of fluid consumption is fed

using a RS-5 rotameter and limited to valve17.

Along with the light fluid, the patrol 4 gainert gas

is also supplied through pores 6. A gas cushion is

created to ensure that the gas supplied to the mixers

of the unit is smooth and evenly distributed. The

required value of the gas cushion is provided by the

RS-3 rotameter 21 via the valve 20 with the gas

consumption supplied by compressor 19. Part of the

gas from the gas pipe is fed to the ring channel

through 7 dagiteshik 8. The height of the gas cushion

is monitored using a scale on a paper sheet attached

to the glass turbine 1a.

Once the fluid and inert gas are supplied to the

unit properly, the condenser 4 will begin to flow

through hole 14 of pipe 9. The amount of heavy fluid

supplied from vessel 22 is limited by valve23 and is

measured using RS-3a rotameter 25.

Karimov, I., Toljev, R., Xakimov, A., Sadulaev, X., Ergashev, N., Xalilov, I., Mamarizaev, I. and Majidov, I.

Drainage and Distribution of Heavy Liquids by Mixing Fluid Phases with Inert Gas in Bubble Extractor.

DOI: 10.5220/0013451300004654

In Proceedings of the 4th International Conference on Humanities Education, Law, and Social Science (ICHELS 2024), pages 791-798

ISBN: 978-989-758-752-8

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

791

Fi

g

ure 1: Ex

p

erimental device scheme

Fi

g

ure 2: General view of the ex

p

erimental device

The entry of heavy fluid into the apparatus is

controlled by the glass pipe 1b. The hood 13 is

mounted on the top end of pipe 9 so that heavy fluid

can enter the mixing zones only in full. As the light

fluid phase moves from bottom to bottom in the

drilling rig 4, pipe 9 drops the heavy fluid flowing

through hole 14 and drives upward in the direction of

the shaft. Heavy and light fluid phases are rapidly

interspersed with gas entering the hole 6 on the drip

rig.

Mixed fluids flow through the ring to the ring

between 4 and 5 pipes, where the pipe 7 is further

mixed with the gas coming out of the hole 8. The

bottom of the pipe 5 is mounted below the pipe 7 of

the pipe 7, which ensures that the gas is supplied only

to the circular duct. Mixed fluid phases go from the

ring channel to the deposition zone of the apparatus.

This zone is formed between the glass turbine 1 and

the mixer pad 4. The video camera 28 is used to

determine the diameter of the drilling heavy phase

drops. Fiberglass 29 is mounted on Patrol 5 to prevent

leakage of heavy phase drops with light phase. The

filter holds heavy phase drops of small particles that

are difficult to sink.

As a result of heavy phase drops, homogeneous

layers are formed on the surface of the flannel 2 of the

section. The recycled heavy fluid is pumped out to

vessel 26 using valve 25 through channel 11. The

boundary separating fluid phases is maintained by the

valve 25. Light fluid and gas are released into the

upper section through hole 6a in hole 4a. There, the

gas is released from the liquefied liquid, and the light

fluid is transferred through Channel 27 to the

container 15.

Investigations into the apparatus's hydrodynamic

processes the department of acetic acid regeneration

at JSC "Ferganaazot" conducted a study on the mass

exchange and hydrodynamic processes of the

equipment used in the water extraction of butyl and

ethyl acetate liquids. The process of dissolving heavy

liquids in the apparatus's mixing zones was

investigated using model fluids.

Several experimental investigations have

established the mechanism of pneumatic grinding of

heavy fluid into droplets in heterogeneous L-L-G-

system settings (Alimatov, Sokolov, Salimov, and

Khursanov, 2001; Ermakov, 1986; Ivanenk, 1982;

Sokolov, Metkin, and Domansky, 1968; Shinar and

Charch, 1960).

Unlike other mixing techniques, pneumatic

mixing of unstable liquids results in the formation of

a multi-dispersed system of granular droplets. The

size of the inter-phase contact surfaces determines the

size of the droplets in this multi-disperse system. The

size of the entire phase determines how these droplets

are scattered. The value of drop sizes influences the

extraction process's rate of mass transfer inside the

phase separation phase and, second, the phase

separation of the droplets in the deposition zones at

each stage of the apparatus.

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

792

The mass transfer mechanism is difficult to

theoretically justify in a multi-dispersed system of

drops. A single-dispersive particle size calculation

has replaced a multi-disperse system as a result of

multiple studies to streamline the computation. This

allows the mass transfer coefficient to be calculated

in comparison to a single drop (Moryakov, Nikolaev,

and Nikolaev, 1973).

Gal-or proposes a theory that can theoretically

determine the mean inter-phase contact surfaces of

droplets in a multi-disperse system by calculating

droplet-to-mass mass transfer coefficients based on

the transition from a multi-disperse system to a

single-disperse system.

Comparative phase surfaces F_(v.s) are defined as

follows, depending on the droplet diameter [3,9,10].

φ = V

d

/ (V

g

+V

d

)

(1)

Where V-mixing zone volume, m

3

. φ-the fraction

of the dispersion phase in the total phase, V

g

and V

d

-

Consumption of gross and dispersion phases m

3

/h,

d

v.s

-аverage volume of drop - surface diameter, m

The particular surface area of the droplet created

in the columns of periodic drilling rigs can be

computed using the following formula (Sokolov and

Reshanov, 1960).

(2)

where γ

d

- is the kinematic viscosity of the

dispersion phase,

According to Metkin's experimental research, the

surface of the relative phase interconnectivity of

droplets dispersed throughout a multi-step pipe

extractor's mixing zone looks like this [11].

(3)

Where l- length of the pipe, m

d

tube

-diameter of the pipe, m

An optimal mixer extractor near these devices can

use equation (3) derived from research in the tubular

circulation mixing extractor (Alimatov, Sadullaev,

Karimov, and Khursanov, 2019). Professor B.A.

Alimatov looks into the fact that the extracted fluids

in the multistage bubble extractor's mixing zones are

in direct flow (Sokolov and Yablokova, 1986;

Sokolov and Domansky, 1976; Metkin, 1968;

Alimatov, 2003; Alimatov, 1980).

The multistage bubble extractor, an

experimental apparatus created by B.A. Alimatov,

was used for the investigation (Sokolov and

Yablokova, 1986; Sokolov and Domansky, 1976;

Metkin, 1968; Alimatov, 2003; Alimatov, 1980).

The goal of the study was to determine the

average volume-surface diameter of droplets'

computational equation, which would be utilized to

compute the mass transfer processes in the barbed

extractor. The following formula can be used to

calculate a drop's average volume-surface diameter:

(4)

Where d

max

-is the maximum diameter of the drop

in emulsion, m

а and β - constant

According to recommendation [7], β = 0.725, and

"a" can be found in the following equation:

(5)

where d

50

–drop diameter to 50% relative volume.

In turn;

(6)

Where d

90

and d

10

- drop diameter of 90% and

10%.

It is advised to use the following empirical

formula to determine the surface diameter of droplets

in experimental studies: fluid surface tension, volume

fraction dispersion φ, gas velocity wγ, average

stirring time tav., and mass phase viscosity μg.

(7)

The structural design of the bubble extractor

studied by B.A. Alimatov is based on the mixing of

fluid phases in the drilling rig only. The bubble

extractor we investigate [2] has an additional mixing

zone, with additional phase mixing in the fluid

phases, such as in the bubble seal and the outer ring

channel. The advantage of this extractor is that it

operates in an intensive mode due to the high mixing

time. This, in turn, requires research into the

distribution and size distribution of drops in mixing

zones.

Therefore, the experimental design of the new

bubble extractor unit was investigated and the

distribution and dispersion of dispersion phase

droplets by the size of the apparatus dispersed from

the mixing zones (Sokolov and Yablokova, 1986;

Sokolov and Domansky, 1976; Metkin, 1968;

Alimatov, 2003; Alimatov, 1980).

Drainage and Distribution of Heavy Liquids by Mixing Fluid Phases with Inert Gas in Bubble Extractor

793

Experimental researches were carried out on the

experimental device of the bubble extractor installed

in the shop of SA and SKR of JSC "Ferganaazot".

Video cameras were filmed and filmed during the

extrusion washing of butyl acetate and ethyl acetate

fluids in the experimental device. However, due to the

same color of water and butyl acetate and ethyl

acetate liquids, it was difficult to determine the size

of the droplets using photographs. Therefore, model

fluids were used. A mixture of carbon dioxide +

benzene was obtained as a heavy liquid. Mixture

density was calculated at rd=1120kg/m

3

. Density was

determined using aisometer under laboratory

conditions. The physical and chemical properties of

industrial and model fluids are shown in Table 1. The

selected mixture was colored with a coloring powder

"Ditizon" (1,5-diphenylthiocorbazone S12N2N4S) to

give a clear picture in video and pictures.

Dimensions of the mixing zones of the dredge

extruder unit are as follows: 1. Dimensions of internal

mixing zones: internal diameter d = 0.032m, outer

diameter d

o

= 0.036m, height H

0

= 0.5m. Exterior

mixing zone sizes: inner diameter of glass tube D

i

=

0056m, outer diameter D

o

= 0064m, height H =

0.335m. Experimental device glass pipe internal

diameter - 104 mm;

The experiments were conducted in the following

order. In the first phase of the experiment, inert gas

was supplied to the internal and external mixing

zones of the apparatus by means of the gas supply

holes. The size of the hole for gas injection into the

internal mixing zone is d

0

= 1.5mm, and the hole

extending to the outside mixing zone is d

1

= 1mm.The

apparatus was transferred to the unit at a constant

cost, with Q

h

= 0.23 m

3

/h. In this fluid flow, the fluid

velocity in the internal mixing zone was w

l

и

= 0.051

m/s, and in the external mixing zone, w

с

o

= 0.026 m/s.

Gas was transferred to the mixing zones at constant

fluid rates at values Q

g

=0.55; 0.65; 0.75m

3

/h.

According to these gas consumption, the gas

velocities in the internal mixing zone w

g

i

=0.03; 0.06;

0.09 m/s and in the external mixing zone w

g

o

= 0.08;

0.0803; 0.805; are converted The mixing time was

t

av

= 22 seconds. The cost of the gas cushion in the gas

distribution unit of the unit, according to the gas

consumption, was h=15; 20; 37 mm. The ratio of light

and heavy fluids supplied to the apparatus was chosen

at a constant rate of 3/1 for each experiment. The

process of mixing liquid phases with gas and

dissolving heavy liquid into droplets was filmed and

filmed using a Canon EOS 700 D camera. A 0.8 mm

diameter wire was fitted to the outside mixing zone

for comparison of droplet sizes. Five photographs

were taken to determine the droplet size at each gas

velocity. In the second phase of the experiment, the

total phase consumption was changed to a constant

value Q

с

= 0.31 m

3

/h. The fluid velocities in the

internal and external mixing zones were w

с

i

= 0.11m /

sec and w

с

т

= 0.035m / sec. At these constant fluid

velocities, the gas flow to the mixing zones was

repeated in the first phase of the experiments.

Gas was supplied at Q

g

=0.55; 0.65; 0.75m

3

/hour.

In accordance with this gas consumption, the

velocities in the internal mixing zone w

г

и

= 0.03; 0.06;

0.09 m/s and in the external mixing zone w

г

т

= 0.08;

0.0803; 0.805; are converted. The mixing time was t

av

= 14 seconds. In both experiments, the droplet size for

the selected profiles was determined by photographs.

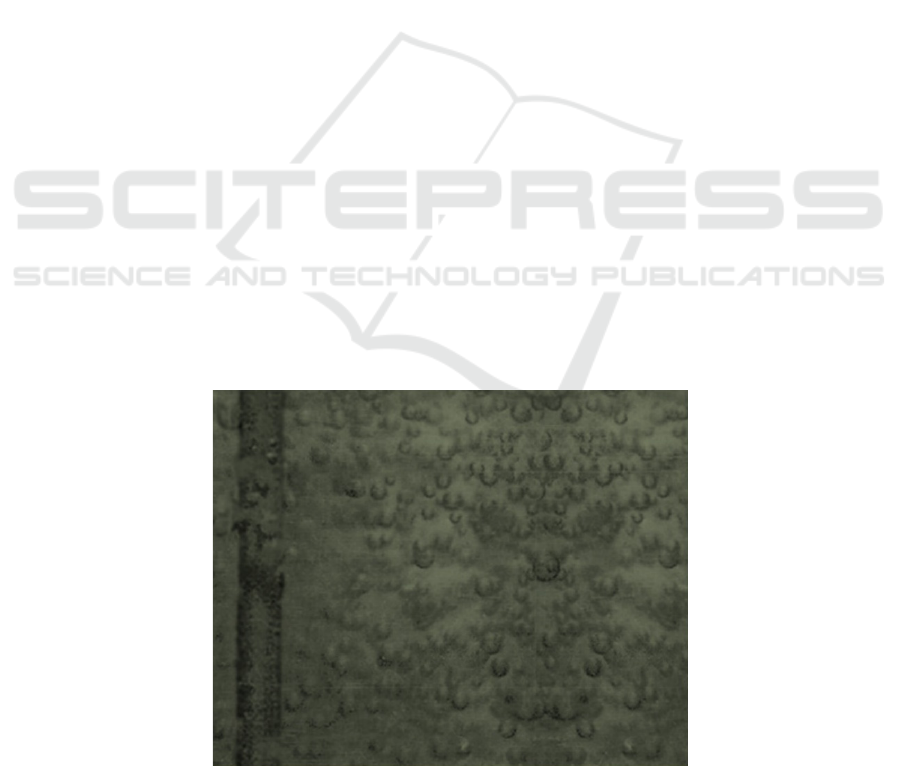

An example of the photographs is shown in Figure 3.

Figure 3: Method for determining the dispersion phase droplet size.

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

794

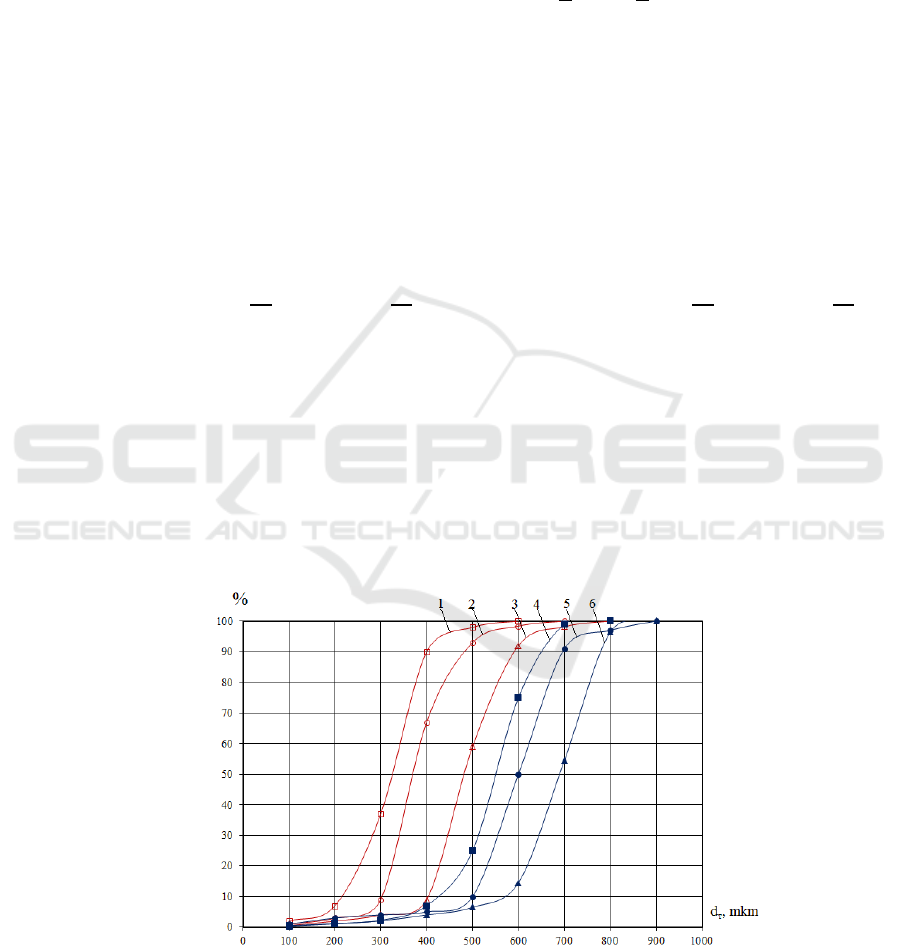

For each stage of the experiments, the size of 400

÷ 600 drops was determined from the photographs,

and the percentage values were found at intervals.

The regression equations were processed using the

ECM, and the droplet distribution diagrams were

constructed (Figure 3). The physical and chemical

properties of liquids are shown in Table 1.

The next task is to produce an equation that

calculates the average volume-surface diameter of

droplets used to calculate the mass transfer processes

in the proposed biodegradable extractor based on the

results obtained.

The results of the experiments determine the

average volume-surface diameter of the main

constituents by equations 4,5,6 (Sokolov and

Yablokova, 1986; Sokolov and Domansky, 1976;

Metkin, 1968; Alimatov, 2003; Alimatov, 1980).

.

Where d

90

and d

10

,90% and 10% for 1 line in

Figure 4

d

90

= 400 mkm , d

5о

=330mkm , d

10

=

240mkm.

When these values are presented in equation

(6), we get:

And d

max

= 491mkm the distribution parameter is

defined

Based on this, d

v.s

is defined;

All calculations based on the results of the

experiments are shown in Table 2.

Table 1: Physic and chemical properties of substances

Fluids

Continuous phase Dispersion phase

σ

ϕ

ρ

с

μ

с

ρ

д

μ

д

kg / m

3

⋅ 10

-3

Pa⋅s

kg / m

3

⋅ 10

-3

Pa⋅s

N/m -

Butyl acetate -water 880 0,685 1000 1,00 0,0248 0,25

Ethyl acetate-water 888 0,423 1000 1,00 0,024 0,25

Water-four-chlorine

carbon + benzene

1000 1,00 1120 0,72 0,073 0,25

Table 2: the results of the experiments

Parameters

Line numberin Figure 5

1 2 3 4 5 6

d

90

, mkm 400 450 575 635 690 784

d

50

, mkm 330 380 490 575 600 685

d

10

, mkm 240 300 410 480 510 580

d

max

, mkm 491 600 735 702 840 1175

А 0,48 0,59 0,68 0,22 0,4 0,49

D

v.s

,mkm

(exper)

317 362 413 561 576 603

d

v.s

,mkm

(theore)

357 375 396 486 523 545

d

v.s

error on % 10 2 4 13,3 9,2 9,6

F

vol

(exper), м

2

473 414 363 267 260 248

F

vol

(theore),м

2

420 400 378 308 286 275

Drainage and Distribution of Heavy Liquids by Mixing Fluid Phases with Inert Gas in Bubble Extractor

795

3 RESULTS AND DISCUSSION

The theoretical study on application of the

recommended formula for calculating the total

surface diameter of crushed drops in the bubble

extractor, created by Professor B.A. Alimatov [13], to

the bubble extractor we investigate. In the apparatus

examined, the gas is distributed inside and outside the

mixing zones. The liquids are mixed in the internal

mixing zone with the gas velocity

and then flow

into the external mixing zone, further mixing with the

gas velocity

. As a result, the time of mixing and

stopping of fluid phases in these zones increases and

the size of heavy phase drops decreases. Experiments

confirmed this.

Therefore, formula 7 includes the arithmetic mean

and constant multiplier of gas velocities in the

internal and external mixing zones.

The formula is as follows.

(8)

Using this formula, the total surface diameter of

the droplets was determined.

For line 1.

σ=0,073n/m, t

av

=22sec,

μ

g

=0,001Pac, φ=0,25.

=3,3·10

-

5

(0,132)/(0,00122)=357mkm.

For the other lines, the surface surface diameters

of droplets were determined. The results of the

calculations are shown in Table 2. As can be seen

from the table, the percentage of error between the

drops and the experimental values of the droplets

calculated using the proposed formula is 2 ÷ 13.5%.

t

av

=22sec

t

av

=14sec

The resulting regression equations are as follows.

1.y = 0,0002x

2

+ 0,3619x - 43,1 R² = 0,9915

2.y = 0,0002x

2

+ 0,2699x - 38,486 R² = 0,9985

3.y = 0,0001x

2

+ 0,0834x - 18,627 R² = 0,9812

4. y = 0,0002x

2

- 0,0514x - 0,6393 R² = 0,9751

5. y = 0,0002x

2

- 0,0272x - 2,2381 R² = 0,9961

6. y = 0,0003x

2

- 0,1474x + 15,838 R² =

0,9842

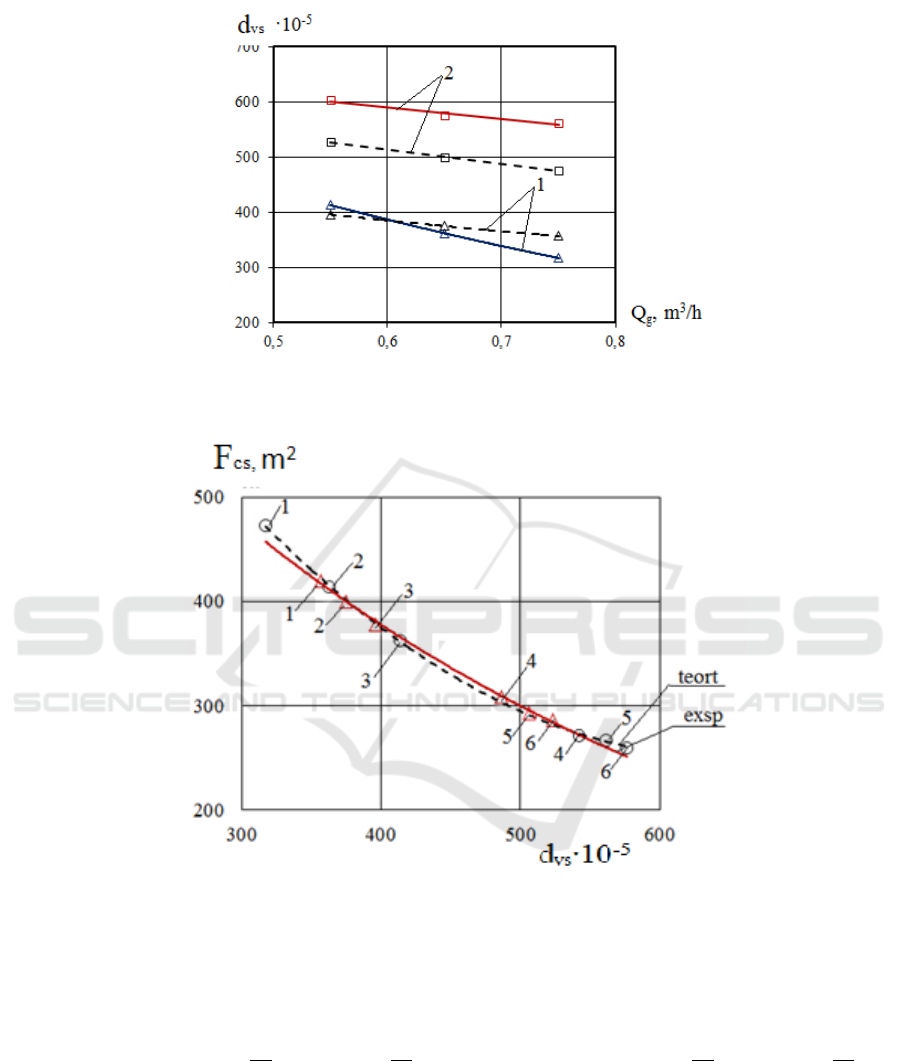

A graph was constructed to compare the

experimental and theoretical values of the surface

diameters of the drops (Figure 5).

Figure 4: Distribution chart of dimensions.

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

796

t

av

=22s; 2. t

av

=14s.

Figure 5: Graph of changes in volume of surface drops depending on gas consumption (comparative graph).

Figure 6: Graph of change of inter-phase relative surface depending on the surface surface diameter of the droplet

(comparative graph)

Using the aforementioned formula 1, the

experimental and theoretical drops of the droplets

were determined and the values of the comparative

phase surfaces depending on the volume surface

diameters shown in Table 2 and a comparative graph

were constructed.

t

av

=22sec

t

av

=14sec

The regression equations of the experimental and theoretical values were obtained.

Experimental: y = 0,0018x

2

- 2,4665x + 1067,7 R² = 0,9994

Theoretical: y = 0,0018x

2

- 2,3598x + 1036,4 R² = 0,9999

Drainage and Distribution of Heavy Liquids by Mixing Fluid Phases with Inert Gas in Bubble Extractor

797

4 CONCLUSION

The process of dissipating heavy liquid into droplets

by mixing fluid phases with inert gas was performed

on the experimental device of the dredge extractor.

Depending on the mixing time at the constant phase

velocity values, the distribution of the droplets on

different gas velocity values by grinding and size was

determined by experiments. The regression equations

were processed using the computer.

Based on the results of the experimental studies,

the total surface diameters of the droplets were

determined. A formula for calculating the total

surface diameter of droplets, which is important for

the calculation of mass transfer processes, depending

on the physical and chemical properties of liquids,

was proposed, and theoretical and experimental

values were compared.The calculations carried out

completely confirmed the proposed formula. As a

result of the research, it was possible to determine the

surface surface diameter of the dispersion phase drop

and the relative phase contact surfaces, which is one

of the key determinants of the efficiency of the

proposed bubble extractor.

REFERENCES

Alimato, B. A., Sokolov, V. N., Sadullaev, H. M., &

Karimov, I. T. (1990). Multistage bubbling extractor.

A.S. No. 1607859 (USSR), BI No. 43.

Alimatov, B. A. (1980). Multistage bubbling extractor. No.

751409 (USSR), BI No. 28.

Alimatov, B. A. (2003). Development of scientific and

technical foundations for the design of liquid extractors

with pneumatic mixing. Diss ... Ph.D. Toshkent:

Tashkent State Technical University.-270s.

Alimatov, B. A., Sokolov, V. N., Salimov, Z. C., &

Khursanov, B. Zh. (2001). Investigation of the

distribution of droplets by size in a multistage bubbling

extractor. Scientific-technical. Zhurn. FerPI. Ferghana,

70-73.

Alimatov, B. A., Sadullaev, Kh. M., Karimov, I. T., &

Khursanov, B. Zh. (2019). Methods and design and

design of equipment for processing complex

heterogeneous liquid-gas-liquid systems. Monograph.

Belgorod: BSTU.-191s.

Ermakov, S. B. (1986). Multistage gas-lifting apparatus for

washing polymers. Diss ... Ph.D. Leningrad:

im.Lensoviet.

Frolov, Y. G. (1982). Course of colloid chemistry (Surface

phenomena and dispersed systems). M.: Chemistry.

Ivanenk, A. Yu. (1982). Hydrodynamics and mass transfer

by bubbling mixing - slop extractor. Diss ... Ph.D.

Leningrad: LTI named after Lensovet.

Metkin, V.P. (1968). The study of pneumodispersion and

mass transfer by a bubble tubular extractor. Diss ...

Ph.D. Lensoviet.-182s.

Moryakov, V. S., Nikolaev, N. A., & Nikolaev, A. M.

(1973). The effect of droplet size distribution on mass

transfer in polydisperse systems. Izv. Universities.

Chemical technology, 16(10), 1580-1583.

Shinar, R., & Charch, J. M. (1960). Statistical theory of

turbulence in predicting particle size in agitated

dispersions. Ind. Eng. Chem., 52(3), 253-256.

Sokolov, V. N., & Domansky, I. V. (1976). Gas-liquid

reactors, L.: Engineering.-216.

Sokolov, V. N., Metkin, V. P., & Domansky, I. V. (1968).

Pneumodispersion of immiscible liquids in a tubular

bubble extractor. Housing and communal services, 41,

1029-1036.

Sokolov, V. N., & Reshanov, A. S. (1960). On the effect of

time on the fragmentation of droplets in a stream

turbulized by bubbling gas. ZhPKh, 33, 1068-1075.

Sokolov, V. N., & Yablokova, M. A. (1986). Devices for

dispersing immiscible liquids. A.S. No. 1258465

(USSR), BI No. 35.

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

798