Optimization of Cold Chain Logistics Based on Dynamic Planning

Under Green Perspective

Yujie Ren

1a

, Guo Tang

2b

and Wenyue Zhou

3c

1

Reading Academy, Nanjing University of Information Science and Technology, Nanjing, 210044, China

2

College of Logistics and e-Commerce, Zhejiang Wanli University, Ningbo, 315100, China

3

College of Politics and Public Administration, Soochow University, Suzhou, 215127, China

Keywords: Cold-Chain Logistics, Path Optimization, Genetic Algorithm, Cost Analysis.

Abstract: This paper improves the solving effect of path optimization through ameliorate the traditional genetic

algorithm. As the optimization goal of the total cost of cold-chain distribution, with the constraint condition

of vehicle load capacity and customers’ requirement, build the optimal model. This research analyses the

influence of temperature and time on refrigeration cost and cargo damage cost, and applies exponential

function to describe the decay rule of fresh agricultural products. And this paper makes simulation experiment

in different strategy algorithm through improving the choosing strategy, crossover strategy and mutation

strategy in genetic algorithm, the result shows that improving strategy significantly impact the local solution

accuracy and convergence speed of algorithm. Thus, it effectively avoid to sink into the problem of local

optimum. This research provides a better plan of path optimization for distribution of cold-chain logistics. For

practical cases, this paper chooses Nanjing Weigang Dairy Co., Ltd and 15 residential quarters in Nanjing as

client site to analyse. In this case, through multiple runs to improve genetic algorithm, this paper gains a more

economic and more friendly-environment way to distribution, dramatically reduces the total cost and carbon-

dioxide emission, at the same time, also shortens the distribution time.

1 INTRODUCTION

With the improvement of economic growth and

residents’ life quality, the requirements of fresh

agricultural products increase daily, prompting the

quick development of cold-chain logistical industry

(Xu, 2021). Particularly, not only vehicles would

produce carbon emission, but also refrigerating

equipments are the important source of it. Facing the

global warming and the stress of carbon emission

reduction, optimizing the distribution path of cold-

chain logistics have become an urgent problem that

need to be solved.

Cold-chain logistics encompass the entire process:

manufacturing, consumption, disposal, storage,

transportation, and sale of products under low-

temperature conditions to ensure the safety and

quality products. In whole supply chain, the transport

link is crucial particularly, reasonable distribution

a

https://orcid.org/0009-0008-5876-2987

b

https://orcid.org/0009-0009-9999-8520

c

https://orcid.org/0009-0006-3993-3280

path optimization not only can guarantee the quality

of products and satisfy the needs of client, but also

can reduce the logistical cost actively.

Based on its national circumstances, China, being

a major agricultural country, has seen continuous

increases in the production of agricultural products

like vegetables, fruits, and meat (Xu, 2024).

In the current context of environmental policies,

reducing the carbon emission have become the global

focus (Cai et al., 2024; Hu et al., 2024; Wang et al.,

2024). Especially in logistical industry, because cold-

chain logistics have traits which are high energy

consumption, high carbon emission, so its feature

become the crucial point to optimize.

With the increasing global emphasis on

environmental protection, green cold-chain logistics

become the research highlights. Liu et al. developed

an optimization model for cold-chain logistics

distribution paths for fresh agricultural products,

490

Ren, Y., Tang, G. and Zhou, W.

Optimization of Cold Chain Logistics Based on Dynamic Planning Under Green Perspective.

DOI: 10.5220/0013444300004558

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Modern Logistics and Supply Chain Management (MLSCM 2024), pages 490-496

ISBN: 978-989-758-738-2

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

incorporating freshness deterioration penalties and

carbon emission costs in addition to traditional fixed

costs, fuel costs, and time window penalty costs (Liu

et al., 2019). This study utilized an improved genetic

algorithm based on taboo search and validated the

model and algorithm with real-world cases,

demonstrating that including eco-friendly factors in

path optimization can promote sustainable cold-chain

logistics development. Wang optimized cold-chain

logistics distribution paths with time windows using

a genetic algorithm, incorporating a penalty function

and time window to accurately describe multi-path

distribution problems, effectively reducing

distribution costs and mileage (Wang, 2022). Lv et al.

focused on the application of the simulated annealing

algorithm (Lv et al., 2020). They enhanced the

algorithm's local solution accuracy and convergence

speed by adjusting the Metropolis Rules' acceptance

rate, emphasizing the importance of algorithm

parameter selection on optimization effectiveness and

encouraging further development. Ni and Katarzyna

optimized urban agricultural products' cold-chain

distribution systems from a low-carbon perspective,

analyzing factors affecting carbon emissions

comprehensively (Ni and Katarzyna, 2024). They

built a corresponding mathematical model and

validated its feasibility and effectiveness by

optimizing distribution paths using a genetic

algorithm. The study of Pan and Gan focused on

introduce optimization of cold-chain logistics

distribution paths about carbon emission costs (Pan

and Gan, 2016). Jia used ant colony heuristic

algorithm and MATLAB to gain solution. Jia put

forward the research about optimizing cold-chain

logistics distribution path for agricultural product e-

commerce from carbon neutral perspective, using

ecological theory approach and combining Ant

Colony Optimization (ACO) algorithm to explore

cold-chain logistics distribution in city ecological

systems, and the author sought to minimize operating

costs while taking ecological and environmental

considerations into account (Jia, 2022). Qian

introduced a carbon tax into the model by

constructing carbon emission functions while Zhou

and Lu built a multi-objective model with time

window (Qian, 2016; Zhou and Lu, 2019). Two

researches all used genetics algorithm and ACO

algorithm to build models to solve, and then validated

the validity of model through actual cases.

2 HYPOTHESIS AND SYMBOL

DESCRIPTION

2.1 Problem Hypothesis

Traditional logistics distribution optimization has

primarily focused on minimizing economic costs,

often overlooking environmental factors. However,

with global emphasis on energy conservation and

emission reduction policies, reducing carbon

emissions during logistics distribution has become a

critical research area. To define the research scope,

this paper will establish some basic assumptions.

Hypothesis 1: Consider only one distribution

centre. The deliver goods are all temperature sensitive

products which customers need.

Hypothesis 2: Each delivery truck begins its route

at the distribution center and returns there after

completing its deliveries.

Hypothesis 3: All delivery trucks have the same

known load capacity, and the total demand served by

each truck must not exceed this capacity.

Hypothesis 4: It is assumed that the distribution

trucks travel at the same speed at a constant rate,

without taking into account the restrictions of vehicle

flow and road conditions and natural disasters in the

delivery process.

Hypothesis 5: To save delivery resources and

improve vehicle utilization, each customer is served

by one delivery truck, and each truck can provide

delivery services to multiple customers.

Hypothesis 6: The geographic locations of the

distribution center and customers are known. The

quantities demanded by customers, the expected

delivery service times, and the pickup and delivery

service hours are known. Each delivery task must be

completed within a service time frame acceptable to

the customer. It is advisable to maintain all given

values.

Based on these hypotheses: A fleet of vehicles

used for transportation with identical refrigeration

equipment starts from a fresh produce distribution

centre, serving for several customers, and go back to

delivery centre after completing the distribution tasks.

Each specific location of the customer and the

quantity of fresh produce required are predetermined.

Each customer can be served only by a delivery truck.

In the delivery process, fresh products may

experience a decrease in freshness, which can lead to

lower customer satisfaction and thus incur additional

penalty costs. Even so the freshness of products can

be considered in a perfect condition (100%). No

customer will return the products because of the

Optimization of Cold Chain Logistics Based on Dynamic Planning Under Green Perspective

491

reduction of the freshness. On the premise of ensuring

the need of customer products, following time

window restrictions below the load capacity of each

delivery truck, the research takes the penalty costs

caused by carbon emission and the loss of freshness

into consideration, aiming to plan a distribution route

with the lowest total cost to maximize the distribution

efficiency and minimize the cost of cold chain

logistics enterprises.

2.2 Symbol Description

The correlation parameter quantity can be described

as: There are M delivery trucks are available for

deployment, and the truck is numbered as1~m. It

defines a completely symmetric network diagram

G=

𝑣, 𝜀

, 𝑣=

0,1,2, ⋯, 𝑛, 𝑛+1

represents a

collection of all nodes, point 0 and point 𝑛+1 are

considered as the delivery centers, 𝑁

= {1,2, ⋯, 𝑛}

represents a collection of all the customer, ε=

{

𝑖, 𝑗

|𝑖, 𝑗∈𝑁, 𝑖≠𝑗} represents a collection of all the

paths. Other symbols are shown in Table 1.

Table 1: Description of model symbols.

S

y

mbol Instruction

𝐶

The overall cost of cold-chain logistics from

an eco-friendly perspective

𝐶

Fixed operating cost

𝐶

Vehicle transportation cost

𝐶

Refrigeration cost

𝐶

Cost of goods loss

𝐶

Time window cost

𝐶

Cost of carbon emissions

𝑃

Fixed cost of delivery vehicle delivery

𝑠

Fuel cost per unit distance of the delivery

vehicle

𝑠

Cooling cost per unit distance travelled by the

delivery vehicle

𝑠

Cooling cost per unit time of unloading of

delivery vehicle

𝑠

Waiting cost of the delivery vehicle per unit

time

𝑠

Overtime cost of the delivery vehicle per unit

of time

𝑑

Distance between customer point 𝑖 and 𝑗

𝑣

Speed of the delivery vehicle

𝑇

Time required for the delivery vehicle to

unload at the customer's point 𝑗

𝐹

Initial freshness of goods

𝐶

Maximum potential loss cost per unit of good

𝐾

Attenuation index

𝑐

Cost per unit of carbon emissions

𝑒

Emission coefficient of 𝐶𝑂

𝑄

Maximum cargo capacity of the delivery

vehicle

3 MODELING PROCESS

3.1 Objective Function Analysis

This paper considers that the total cost of cold chain

logistics and distribution of agricultural products

includes the following components: fixed usage cost,

vehicle transportation cost, refrigeration cost, cargo

damage cost, time window cost, and carbon emission

cost.

Fixed utilization cost: Fixed costs refer to the

costs spent on vehicle wear and tear, maintenance,

depreciation, and hiring drivers for distribution

vehicles during the distribution process. Where the

decision variables are:

𝑥

=

1, 𝑣𝑒ℎ𝑖𝑐𝑙𝑒 𝑚 𝑡𝑟𝑎𝑣𝑒𝑙𝑠 𝑓𝑟𝑜𝑚

𝑐𝑒𝑛𝑡𝑒𝑟 𝑡𝑜 𝑐𝑢𝑠𝑡𝑜𝑚𝑒𝑟 𝑝𝑜𝑖𝑛𝑡 𝑗

0, 𝑣𝑒ℎ𝑖𝑐𝑙𝑒𝑠 𝑛𝑜𝑡 𝑑𝑒𝑝𝑎𝑟𝑡𝑒𝑑

(1)

Fixed cost of use is:

𝐶

=

∑∑

𝑥

∙𝑃

(2)

Vehicle Transportation Costs: These costs primarily

pertain to the fuel expenses incurred during vehicle

operation. They are proportional to the distance

traveled by the vehicle and can be calculated

accordingly, can be obtained as vehicle transportation

costs:

𝐶

=

∑∑∑

𝑥

∙𝑠

∙𝑑

(3)

where 𝑠

is the cost of fuel consumption per unit

distance traveled by the delivery vehicle and 𝑑

is the

distance traveled by the vehicle between customer

points 𝑖 and 𝑗.

Refrigeration costs: Since all distribution vehicles

are equipped with refrigeration equipment, which

works mainly by consuming refrigerant, the

refrigeration cost of the vehicle during transportation

mainly refers to the total cost of refrigerant consumed

by the refrigeration equipment. It is assumed that each

delivery vehicle can deliver all the fresh food in the

vehicle in only one transportation, and the

refrigeration equipment will not work on the way

back because there is no fresh food in the vehicle.

Considering that the refrigerant consumption is

affected by the external environment, it is necessary

to calculate the total refrigeration cost by considering

the refrigeration cost during transportation and

unloading separately 𝐶

. The cost of refrigeration

during transportation is:

𝐶

=

∑∑∑

𝑥

∙𝑠

∙𝑑

(4)

The cost of refrigeration during unloading is:

𝐶

=

∑∑∑

𝑥

∙𝑠

∙𝑇

(5)

where 𝑠

is the cost of refrigeration per unit distance

traveled by the delivery truck, 𝑠

is the cost of

refrigeration per unit time unloaded, and 𝑇

is the time

MLSCM 2024 - International Conference on Modern Logistics and Supply Chain Management

492

required to unload at the customer point 𝑗. Thus, the

cost of refrigeration 𝐶

is:

𝐶

= 𝐶

+ 𝐶

(6)

Cargo damage costs: Cargo damage cost refers to the

corruption cost of fresh food due to time and

temperature changes during transportation. Among

them, the time-induced spoilage cost accompanies

both transportation and unloading processes, while

the temperature-induced spoilage cost mainly occurs

in the unloading process. Therefore, it is necessary to

consider the cargo spoilage costs in the two stages of

transportation and unloading separately.

Meanwhile, this paper introduces the food

spoilage function based on exponential decay to

describe the process of food freshness decreasing

with time, and assume that all delivery trucks are

traveling at a uniform speed with speed 𝑣. The

expense incurred due to damage to cargo during

transportation is: 𝐶

=

∑∑∑

𝑥

𝐶∙

1 −𝐹

∙𝑒

. The cost of cargo damage

during unloading is: 𝐶

=

∑∑∑

𝑥

𝐶∙

1 −𝐹

∙𝑒

.

where 𝐹 is the initial freshness (100%); 𝐶 is the

maximum potential cost of loss per unit of

commodity, i.e., the cost at 100% freshness; and 𝐾 is

the decay index, which indicates the rate of decay of

freshness over time, and whose value depends on the

rate of spoilage of a particular food item and the

storage conditions. Therefore, the cost of cargo

damage 𝐶

is:

𝐶

= 𝐶

+ 𝐶

(7)

Time Window Costs: These costs arise when a

delivery vehicle fails to arrive at the customer's

location within the specified time window. This

includes waiting costs for vehicles that arrive too

early and overtime costs for delayed arrivals.

𝐶

𝑖

=

𝑠

𝑖

−𝑡

,0≤𝑡

< 𝑖

0, 𝑖

≤𝑡

≤𝑖

𝑠

𝑡

−𝑖

, 𝑖

< 𝑡

(8)

Where 𝑠

is the waiting cost of the delivery truck per

unit of time and 𝑠

is the overtime cost of the delivery

truck per unit of time. Therefore, the time window

cost 𝐶

is:

𝐶

=

∑∑

𝐶

𝑖

(9)

Carbon Emission Costs: According to the standards

of green logistics, not only fuel costs but also carbon

emission costs need to be considered when

calculating costs. Carbon emission cost refers to the

expense incurred from purchasing the necessary

carbon emission allowances in the carbon trading

market. The carbon emissions caused by the logistics

process are mainly due to the direct and indirect

carbon dioxide emissions brought about by the

consumption of various energy sources and

substances in the logistics process, so carbon dioxide

emissions are an important part of the study of carbon

emission costs. Specifically, the cost of carbon

emissions is the product of the carbon dioxide

emission factor of the fuel, the fuel consumption and

the carbon trading price. The carbon emission cost

𝑒

𝑖, 𝑗

incurred by the distribution trucks traveling at

customer point 𝑖 and customer point 𝑗 is:

𝑒𝑦

= 𝑐

𝑒

∅

+

∅

∗

∅

𝑦

𝑑

(10)

where 𝑐

is the cost per unit of carbon emissions, 𝑒

is the 𝐶𝑂

emission factor, ∅

and

∅

∗

∅

are the

intercept and slope, respectively. 𝑄 is the maximum

load capacity of the delivery truck, and 𝑦

is the load

capacity of the delivery truck between customer point

𝑖 and customer point 𝑗. Thus, the cost of carbon

emissions 𝐶

is:

𝐶

=

∑∑

𝑀∙𝑒𝑥

(11)

3.2 Constraints Analysis

Combined with the real situation of the problem, the

cold chain logistics optimization model under the

specific green perspective makes the following

constraints:

Constraint 1: All transport vehicles return to the

distribution center uniformly after the distribution is

completed.

∑

𝑥

=

∑

𝑥

≤1

, 𝑖=0,𝑚=1,2,⋯, 𝑀 (12)

Constraint 2: Distribution is completed by one and

only one transportation vehicle per customer point.

∑∑

𝑥

=1,∀𝑖∈𝑁

(13)

Constraint 3: The load of all transportation

vehicles shall not exceed the maximum load of the

vehicle itself.

∑

𝑦

≤𝑀𝑄, ∀𝑗∈𝑁 (14)

3.3 Planning Model

In summary, this paper establishes a cold chain

logistics optimization model under the green

perspective, and the objective function is to minimize

the total cost 𝐶 of cold chain logistics and

distribution:

𝑀𝑖𝑛𝑪= 𝐶

+ 𝐶

+ 𝐶

+ 𝐶

+ 𝐶

+ 𝐶

(15)

Optimization of Cold Chain Logistics Based on Dynamic Planning Under Green Perspective

493

𝑠. 𝑡.

⎩

⎪

⎨

⎪

⎧

∑

𝑥

=

∑

𝑥

≤1, 𝑖=0,

𝑚=1,2,⋯, 𝑀

∑∑

𝑥

=1,∀𝑖∈𝑁

∑

𝑦

≤𝑀𝑄, ∀𝑗∈𝑁

(16)

4 METHODOLOGIES

By simulating biological evolution, genetic algorithm

helps improve the quality of solutions. Genetic

algorithm is widely used in path planning, scheduling,

and resource allocation.

4.1 Genetic Algorithm Process

The vehicle path planning problem is a significant

topic in operations research. Currently, heuristic

algorithms are primarily used to address this problem,

with genetic algorithms from modern heuristic

methods being widely applied. Genetic algorithms are

global probabilistic search methods that mimic

biological evolution, combining survival of the fittest

with random information exchange. Their core

characteristics are reflected in basic genetic

operations and population exploration strategies.

Genetic algorithms begin with a population

containing potential solutions, composed of a certain

number of genetically coded individuals. Through

continuous processes of selection, crossover, and

mutation, individuals are optimized, passing

excellent genes to the next generation to improve

offspring adaptation. During this iterative evolution,

the optimal or satisfactory solution to the problem is

eventually decoded from the best individual in the

final generation population. The specific operations

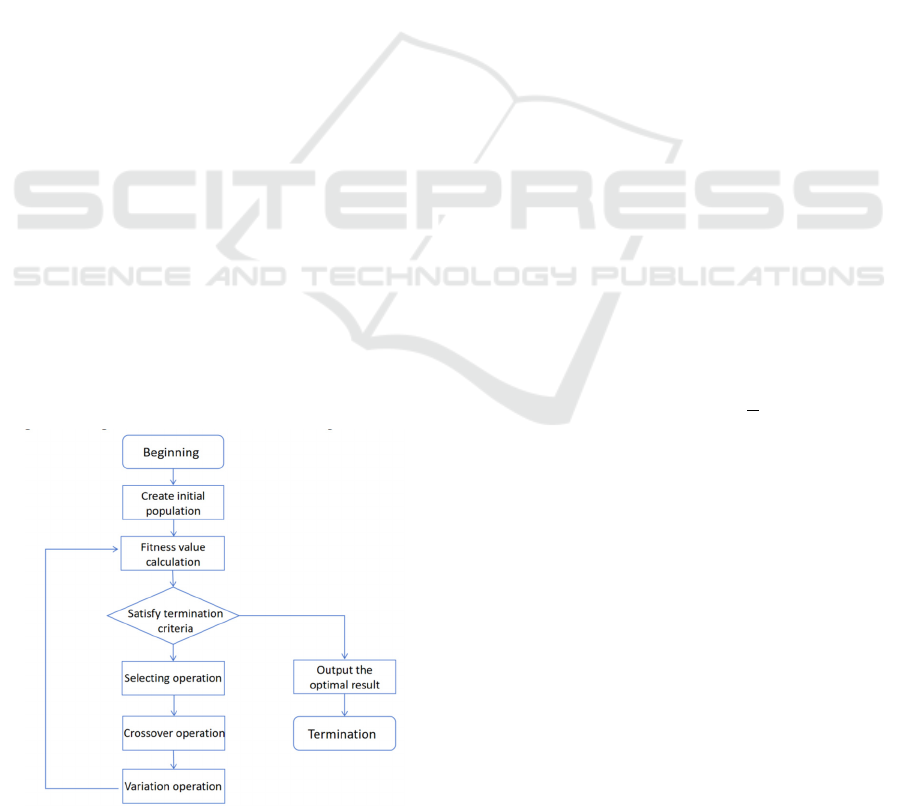

of genetic algorithms are illustrated in Figure 1 below:

Figure 1: Brief flowchart of the genetic algorithm

4.2 Genetic Algorithm Design

According to the analysis above, the main steps of the

genetic algorithm include encoding, initial

population, fitness calculation, termination, choosing,

crossover, variation.

Step 1: Encoding. Vehicle routing planning is a

sequential optimization problem. Though the binary

coding is widely used, it is not suitable to solve this

kind of problems, because it can result in a large

number of invalid solutions.

In the natural number coding method, No. 0 for

Distribution Centre. 𝑀Cars start from the delivery

center, delivering goods which is numbered as

1,2, ⋯, 𝑁 to the fresh supermarket stores, and go back

to the delivery centre. Once the number of a grocery

store is determined, it will not be changed. The

chromosome length of each distribution line is 𝑀+

𝑁+1.

Step 2: Initial population. The beginning of the

genetic algorithm is forming the initial population. If

the scale of the population is too small, it may result

in insufficient samples and affect the result of

searching. If the scale is too large, the amount of

computation will increase, which may extend

convergence time. Thus, the author uses

randomization to generate an initial population of

100.

Step 3: Fitness value calculation involves

assessing each chromosome by its fitness value. A

higher fitness value indicates an individual with better

quality, whereas a lower fitness value signifies a

poorer quality individual. Poorer individuals are

eliminated through selection or competition.

Expressed by the formula is 𝑓

=

and 𝑓

represents

the fitness value of the 𝑖

chromosome.

Step 4: The termination principle determines

when to stop the algorithm. If the termination criteria

are met, evolution stops. If not, selection, crossover,

and mutation are performed, followed by another

fitness calculation. The individual with the best

fitness value in the final generation, which

corresponds to the lowest cost delivery path, is

considered the optimal solution for path optimization

in cold chain logistics from a green perspective.

Step 5: Selecting operation. Selecting operation is

a process to select relatively good individuals from

the parent population. The research uses roulette

selection strategy, ensuring the differences and

diversity of the progeny population individual, and

can make full use of all available paths to improve

bandwidth utilization.

MLSCM 2024 - International Conference on Modern Logistics and Supply Chain Management

494

To calculate the probability of selection 𝑃

, it will

use the fitness value 𝑓

of individual 𝑖:

P

𝑖

=

𝑓

∑

𝑓

(17)

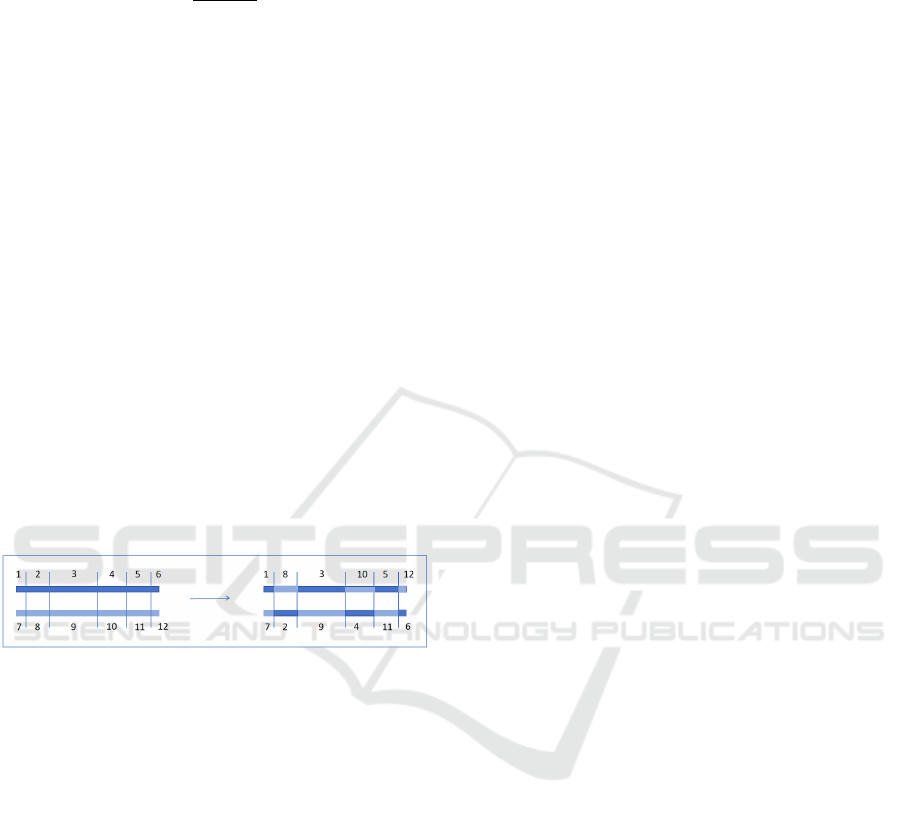

Step 6: Crossover operation. Crossover operation

in the genetic algorithm is to select a certain location

in two or more individuals and swap or replace these

positions to form new individuals. The multi-point

crossover approach to crossover operations is used. It

random selects multiple intersections and exchange

the part between these points of the two individuals.

The numbers and positions of the

Individuals can be different. The multi-point

crossover approach can intersect more gene

fragments and increase the Individual diversity

according to Figure 2. The operation process is as

follows:

Step 1: Segment and number two individuals of

the parent-Parent entity 1: 1,2,3,4,5,6;Parent entity

2: 7,8,9,10,11,12.

Step 2: Find the corresponding customer location

in two parent individuals to start the crossover

operation: 2-8, 4-10, 6-12.

Step 3: Retain positions 1, 3, and 5 of parent entity

1 and positions 7, 9, and 11of parent entity 2.

Step 4: Form two new individuals.

Figure 2: Multipoint crossover.

Variation operation: Variation operation in the

genetic algorithm is to replacement and change

certain genes in the selected individual's

chromosomes to form new individuals. According to

the difference of the coding method, the Binary

variation and real-valued variation are used in this

research.

Binary variation: Choose a variable position

randomly. Then change the value of the gene at the

location of the mutation from "0" to "1", or change

from "1" to "0" to create a new individual.

Real-valued variation: Use another random real

number in the fixed scope to replace genetic value in

the original variant position to generate a new

individual.

Location-based mutation methods: First, two

variation positions are randomly selected. Then the

gene at the second mutation location was moved to

the front of the first mutation location;

Variation based on order: First, two variation

positions are randomly selected. Then exchange the

genes on the two variation positions.

4.3 Example Analysis

In the optimization study of the delivery task of

Nanjing Weigang Lotion Co. Ltd, the author used an

improved genetic algorithm with parameter settings

for 15 neighborhoods in Nanjing as customer points.

The algorithm parameters are set as follows:

population size ( 𝑃

= 100 ), crossover probability

(𝑃

=0.82), mutation probability (𝑃

=0.14), and

maximum number of iterations (𝑀𝑔= 500).

Statistical analysis of 20 runs of the algorithm

gives us the following average results:

The average results reveal that the total cost is

approximately $3,670.15, with a total time

expenditure of about 490.29 minutes and a CO2

emission of 45.56 kilograms.

In all runs, the optimal distribution scenario

consistently involves using five transportation

vehicles. This scenario achieves a total cost of

$3,645.88, a total time of 470.92 minutes, and a CO2

emission of 42.89 kilograms.

These data suggest that the use of improved

genetic algorithms can significantly optimize

distribution efficiency while reducing total cost,

distribution time, and environmental impact.

Therefore, the author recommend that Nanjing

Weigang Emulsion Co. consider implementing this

strategy to improve distribution efficiency and

environmental friendliness.

5 CONCLUSION

The distribution of fresh agricultural products not

only require high efficiency, but also the quality and

timeliness of products, it make that cold-chain

logistics have higher cost than traditional logistics.

Besides, not only vehicle, but also refrigerating

equipment all would produce carbon emission. Thus,

when facing the stress of global warming, optimizing

the distribution path of cold-chain logistics have

become the urgent problems.

Based on this, the paper considers various

components contributing to the total cost of cold-

chain logistics distribution for fresh agricultural

products, including fixed-use costs, vehicle

transportation costs, refrigeration costs, cargo

damage costs, time-window costs, and carbon

emission costs. By combining these factors with the

actual conditions of the issue, the paper develops an

Optimization of Cold Chain Logistics Based on Dynamic Planning Under Green Perspective

495

optimization model aimed at minimizing the total cost

from a green perspective. This research contributes to

achieving green logistics and sustainable

development by ensuring food freshness and quality

while reducing carbon emissions. By utilizing

MATLAB software, the study employs selection,

crossover, and mutation operations to implement the

genetic algorithm solving process. In the case study

of Nanjing Weigang Dairy Co., Ltd.'s distribution

mission, the research successfully reduced the total

cost, overall time consumption, and carbon dioxide

emissions to a certain extent, thereby enhancing

distribution efficiency and environmental friendliness.

Although the contents of this paper could provide

some reference value for cold-chain logistics

distribution path for fresh agricultural products, and

prompt green cold-chain logistics industry to have

further development, the model built by this paper is

confined to some hypothesis and constraint

conditions, so this research also exist some

deficiencies. In further research, the temperature

outside the vehicle in actual distribution could be

taken into cold-chain distribution account to optimize

distribution path from deeper and more diverse

directions.

AUTHORS CONTRIBUTION

All the authors contributed equally and their names

were listed in alphabetical order.

REFERENCES

Cai, W., et al. 2024. Report on carbon emissions from urban

infrastructure in China (2023). Urban and Rural

Construction, 6, 52-61.

Chunrong, N., Katarzyna, D., 2024. Research on

optimization of agricultural products cold chain

logistics distribution system based on low carbon

perspective. Inter. Journal of Information Systems and

Supply Chain Management (IJISSCM), 17(1).

Hu, W., Zhang, J., Wang, H., 2024. Current situation and

improvement path of carbon emission data quality

management in China. Social Science Dynamics, 18-23.

Liu, Y., Wang, K., Yang, Z., et al. 2019. Optimization of

cold chain logistics distribution path considering

carbon emissions and freshness. Journal of Jiangxi

Normal University (Natural Science Edition), 43(2),

188-195.

Lü, C., Shao, K., Zhang, S., et al. 2020. Optimization of

fresh food cold chain logistics distribution path.

Computer Technology and Development, 30(11), 168-

173.

Lü, P., 2013. Research on optimization model of logistics

network considering carbon emissions. Computer

Applications and Research, 30(10), 2977-2980.

Pan, Q., Gan, H., 2016. Optimization of cold chain logistics

distribution path considering carbon emissions.

Practice and Recognition of Mathematics, 46(2), 62-68.

Pei, Y., et al. 2021. Genetic algorithm with embedded

screening operation and its application in welding path

planning. Journal of Mechanical Design and Research,

37(2), 109-113.

Qian, G., 2016. Research on optimization of fresh

agricultural products cold chain distribution path

considering carbon emissions. Beijing Jiaotong

University.

Qiu, X., 2024. Current status and enlightenment of foreign

agricultural products cold chain logistics development.

National Circulation Economy, 37-40.

Wang, J., 2022. Optimization of cold chain logistics

distribution path based on genetic algorithm. Academic

Journal of Computing & Information Science, 5(13).

Wang, J., Li, D., Wang, H., et al. 2024. Status, influencing

factors, and reduction measures of carbon sequestration

and emission reduction in typical agricultural

ecosystems in China. Chinese Agricultural Science

Bulletin, 40(6), 67-74.

Xu, C., 2024. Analysis of factors affecting high-quality

development of agricultural products cold chain logistics.

Logistics Technology, 47(2), 150-152+156.

Xu, P., 2021. "The 14th Five-Year" Cold Chain Logistics

Development Plan Released: A Modern Cold Chain

Logistics System Will Be Fully Established by 2035.

China Food Industry.

Xin, J., 2022. Research on the optimization of cold chain

logistics distribution path of agricultural products e-

commerce in urban ecosystem from the perspective of

carbon neutrality. Frontiers in Ecology and Evolution,10.

Zou, J., Lu, Z., 2019. Research on optimization of fresh

agricultural products cold chain logistics distribution

path considering carbon emissions. Logistics

Technology, 42(8), 46-52.

MLSCM 2024 - International Conference on Modern Logistics and Supply Chain Management

496