Research of the Process of Briquette Preparation from Coal Powder

in a Screw Press

Akmaljon Xakimov

1a

, Rasuljon Tojiev

1b

, Ikromali Karimov

1

, Nasiba Vokhidova

2

,

Abdurasul Davronbekov

2

, Avazbek Xoshimov

2

, Muxammadbobir Xusanboyev

2

, Oybek Soliyev

2

and

O’tkirbek Hamdamov

2

Fergana Polytechnic Institute, Uzbekistan

Keywords: Briquette, Coal, Powder, Granulometric.

Abstract: The article analyzes the granulometric composition of unusable coal grains mined from the Angren coal mine.

For making briquettes from coal fines of selected size, percentage amounts of fine coal grains were determined

by intervals, and depending on these values, average diameters and relative contact surfaces were determined.

As a binder, alcohol cask, which is a distillery waste, was selected, and briquettes were prepared in a press,

and the limit of compressive strength was determined. The number of nozzle revolutions, the percentage of

coal fine fractions and the optimal values of binder moisture are recommended for obtaining quality

briquettes.

1 INTRODUCTION

The need for oil, gas, coal and other types of fuels is

increasing year by year as a result of the growth of the

population and the growth of the economy. Among

these fuels, coal has a special place. Coal fuels are

economical and widely used raw materials for various

industrial zones. Coal does not always meet the

required standards. An example of this is the crushing

of coal under the influence of external forces and the

loss of mechanical strength. Therefore, briquetting in

special devices with the help of binders is of great

importance to increase the flammability of the formed

coal particles.

Currently in the worldimprovement of coal powder

briquetting technology and justification of the

following scientific solutions for its implementation:

determination of physico-chemical properties of coal;

systematic study of the composition and properties of

coal fines from local industrial waste; increasing the

porosity of coal briquettes by adding combustible

substances and materials; improving environmental

safety in the use of coal briquettes; use of industrial

waste in the production of highly porous coal

a

https://orcid.org/0000-0003-0840-9305

b

https://orcid.org/0000-0001-5636-5840

briquettes; it is necessary to improve the pressing

structure to obtain high porosity coal briquettes.

All over the world, scientists are doing extensive

work in large industrial areas to keep atmospheric

ecology clean. In Uzbekistan, on the basis of

innovative projects for keeping the environment

clean, work is being carried out on the rational use of

local coal raw materials.

2 RESEARCH OBJECT

It is known that in the process of coal mining,

transportation, sorting and storage, a large amount of

small pieces of coal are formed, which require

briquetting in special devices using effective binders.

In recent years, a number of binders have been

proposed for briquetting small pieces of coal, most of

which are polluting the air with harmful and toxic

gases. For example, when burning coal briquetted

with petroleum bitumen and its derivatives, it does not

burn completely and at the same time pollutes the

environment. As a result of incomplete combustion of

coal, the amount of ash increases and accumulates in

770

Xakimov, A., Tojiev, R., Karimov, I., Vokhidova, N., Davronbekov, A., Xoshimov, A., Xusanboyev, M., Soliyev, O. and Hamdamov, O.

Research of the Process of Briquette Preparation from Coal Powder in a Screw Press.

DOI: 10.5220/0013425100004654

In Proceedings of the 4th International Conference on Humanities Education, Law, and Social Science (ICHELS 2024), pages 770-778

ISBN: 978-989-758-752-8

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

the furnaces, while the coal lumps reduce the burning

rate. Regulating the porosity of the obtained coal

briquettes is one of the important tasks of increasing

their combustibility and environmental cleanliness of

the atmosphere.

We should consider the scientific basis of the

formation of the structure of coal briquettes with

binders and additives as one of the types of bonding of

dispersible solid materials using binders. The mixture

forms the basis of the formation of the interconnection

of individual contact particles in the structure, which

are self-regulating and self-regulating processes, and

determine the attachment process. As the initial stage

of the bonding process, adhesion is associated with the

formation of an adhesive film on the surface of a solid

body (substrate). Adhesion is characterized by the

viscous liquid state of the binder. Further processes

lead to an increase in the maximum strength of the

binder. As a result, separated solid particles coated

with a binder are attached in the form of briquettes

(Petrova, Latyshev, & Burenina, 2007).

In this process, the diffusion coefficient is the

difference between the adhesion energy of the binder

to the substrate and the adhesion of the binder. It

serves as a measure to evaluate the wettability of the

binder, which describes the relationship between the

structure of the binder and the orientation of its

molecules on the surface of the substrate. Substances

containing binding and multipolar groups have a high

scattering coefficient. With higher values, the binder

is sufficiently wetted. If its value is negative, it does

not spread to the solid body and wraps in the form of

a lens (Aleksandrova, Rasskazova, & Prokhorov,

2012; Semenov, Podolskaya, Buzaeva, & Klimov,

2009).

The granulometric structural value is determined

by the total contact surface of the grains, the number

and size of the voids in the structural frame of the

briquettes, the content of sharp-cornered grains, the

relief and impact of the hard surface. The principle of

choosing a mixture of coal particles of different sizes

is to create a structural composition that meets the

standard requirements (Podolskaya, Buzaeva, &

Klimov, 2011; Chiari, 1990) .

Small grains are more angular than large ones, and

the heat content of hydration is about 4 times higher

than that of the latter. The addition of large grains to

briquettes (more than 6 mm) negatively affects the

strength of coal briquettes, that is, new surfaces that

are not covered with binder appear. The porosity of the

structure significantly affects the packing density of

coal briquettes. No matter how carefully the solid

grains are packed into briquettes, there will always be

holes between them. The number and size of voids

affect the durability of briquettes. Briquettes made of

fine coal particles have small holes and are mostly

filled with binder. If there are few defects in the form

of voids, the strength of coal briquettes is high.

Briquettes consisting of large grains will have many

defects. The adhesive layer will not be enough to fill

the gaps in them. Therefore, these briquettes are

considered to have low strength. To increase the

strength, it is recommended to add dust-like coal

particles to the briquette mixture, which easily

penetrate into the voids. The unevenness and

unevenness of the material has a positive effect on the

mechanical fastening of the binder and increases the

strength of the briquettes. If the composition of the

sieve is homogeneous, the strength of the briquettes

decreases. A homogeneous mixture does not allow to

ensure compaction density. Grains accumulate in the

briquette with a significant number of voids [6; 7;]. To

increase the strength, it is recommended to add dust-

like coal particles to the briquette mixture, which

easily penetrate into the voids. The unevenness and

unevenness of the material has a positive effect on the

mechanical fastening of the binder and increases the

strength of the briquettes. If the composition of the

sieve is homogeneous, the strength of the briquettes

decreases. A homogeneous mixture does not allow to

ensure compaction density. Grains accumulate in the

briquette with a significant number of voids (Gos,

2021; Salikhanova, Abdurahimov, & Jumayeva,

2020). To increase the strength, it is recommended to

add dust-like coal particles to the briquette mixture,

which easily penetrate into the voids. The unevenness

and unevenness of the material has a positive effect on

the mechanical fastening of the binder and increases

the strength of the briquettes. If the composition of the

sieve is homogeneous, the strength of the briquettes

decreases. A homogeneous mixture does not allow to

ensure compaction density. Grains accumulate in the

briquette with a significant number of voids (Gos,

2021; Salikhanova, Abdurahimov, & Jumayeva,

2020);]. Grains accumulate in the briquette with a

significant number of voids (Gos, 2021; Salikhanova,

Abdurahimov, & Jumayeva, 2020). Grains

accumulate in the briquette with a significant number

of voids (Gos, 2021; Salikhanova, Abdurahimov, &

Jumayeva, 2020).

In nature, there are several types of coals, formed

underground at different times and conditions from

different types of plant and animal sources.

Therefore, coals mined in opposite continents and

regions of our planet have significant differences in

composition and physical and chemical properties.

Their composition and properties should be taken into

Research of the Process of Briquette Preparation from Coal Powder in a Screw Press

771

account in their transportation, sorting, storage, use,

etc.

Thus, the problem of rational use of these coals is

primarily related to the briquetting of small fractions,

which make up 50-60% of the total amount mined.

Efficient use of coal and rational methods of its

storage include, first of all, briquetting of small

particles, which solves the problem of converting low-

grade fuel with limited sales into complete lump fuel,

convenient for transportation, long-term storage and

burning.

3 MATERIALS AND METHODS

The granulometric composition of coal fines is the

main indicator for the preparation of briquettes and

the selection of its binders. In Angren coals, these

indicators are mainly determined in average (50-

60%) percentages, which makes it difficult to carry

out the process of briquetting without excessive

consumption of binders. Taking this into account, we

analyzed the granulometric composition of coal fines

selected from different areas of the Angren coal mine

(Table 1).

As can be seen from Table 1, depending on the

sampling location of the coal mine, the granulometric

composition of coal fines changes significantly,

which requires adjusting the consumption of binders

and additives. At the same time, it indicates that there

will be changes in the technological modes of

obtaining coal briquettes.

The study of the granulometric composition of

coal fines from the Angren mine by the method of

saturation analysis made it possible to determine that

the amount of coal dust (less than 0.2 mm) reaches an

average of 8%, and this indicator ranges from 3 to

14%, which indicates the need for briquetting.

As mentioned above, one of the important

components in the production of coal briquettes are

binders, which include: bentonite clay soil, starch,

liquid glass, gossypol tar, beer wort, etc.

There are more than 100 alcohol production plants

in Uzbekistan, where beer kegs are produced as

waste. Its composition is protein (7-8%), starch (up to

3%), ash (up to 2.5%), connective tissue (up to 10%),

and the rest is water.

When obtaining combustible briquettes, it is

necessary to pay attention to their granularity. The

mass fraction of coal powder in briquettes is 80-85%,

and the remaining 15-20% is the binder, i.e. alcohol

waste in the bar. Due to the presence of a combustible

layer in the briquettes, they are highly flammable.

This makes it convenient to use (Salikhanova,

Abdurahimov, & Jumayeva, 2020).

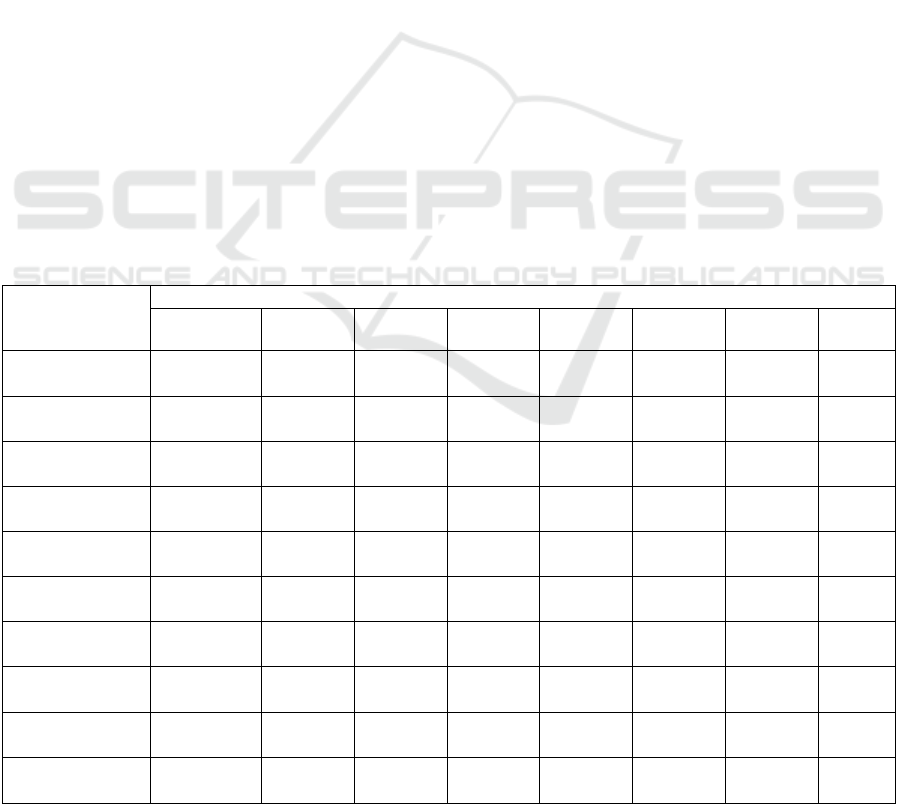

Table 1: Granulometric composition of Angren mine coal fines

Name of

samples %

The size of the granules, mm

3-5 2-3 1-2 0, 5-1 0.2-0.5 0, 1-0,

2

0-0, 1 total

1 33, 99 6, 51 18, 13 16, 2 13, 08 4, 12 7, 97 100

2 60, 61 3, 85 12, 47 8, 29 6, 76 2, 25 5, 77 100

3 60, 07 3, 88 10, 77 9, 83 8, 91 3, 11 3, 43 100

4 65, 0 4, 27 9, 58 8, 33 8, 38 2, 19 2, 25 100

5 71, 97 5, 06 7, 96 7, 13 4, 93 1, 42 1, 53 100

6 43, 0 6, 15 10, 52 16, 2 12, 91 4, 12 7, 1 100

7 62, 30 4, 22 13, 10 6, 29 5, 22 3, 10 5, 77 100

8 42, 6 3, 88 14, 37 9, 83 15, 65 7, 17 6, 5 100

9 63, 99 5, 26 10, 1 8, 12 7, 24 2, 03 3, 26 100

10 69, 0 7, 2 6, 88 7, 13 3, 15 2, 34 4, 3 100

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

772

Coal powder grain size is determined in a linear

dimension as follows,

length -a

width-b

thickness-s

These three dimensions can generally be

characterized by its diameter.

That is

3

abs

d

⋅⋅

=

– arithmetic mean size,

3dabs=⋅⋅

- average geometric size,

or

22

das=+

(mm)

To determine the average characteristic size of

crushed pieces, the average size of the largest and

smallest pieces in several fractions of the material,

mm, is determined using a sorting machine.

max min

2

average

dd

d

+

=

(1)

To determine the average characteristic size of

coal powder, it is determined from the following

formula, mm.

11 2 2 3 3

..

.......

100

nn

av char

dm d m dm d m

d

++

=

( 2 )

where d

1

,d

2

,d

3

…..dn is the average size of classes

or fractions, m

1

, m

2

, m

3

….mn is the percentage of

given classes.

The density of coal powder intended for research

is equal to ρ=880 kg/m

3

. We determine the amount of

material allocated to the experiment in % for a 10 kg

sample and calculate the total surface area of the

particles in volume, m

3

0.011

n

XV==

(3)

The following formula is used to determine the

particle size of coal powder, m3

3

3

4

3

VR

π

=⋅

(4)

using this formula, it is possible to derive the

number of particles of size Vn, pcs

3

n

B

n

V

=

(5)

We determine the surface area of a particle of coal

powder, m2

2

4SnR

π

=⋅⋅⋅

(6)

The obtained results are presented in Table 2

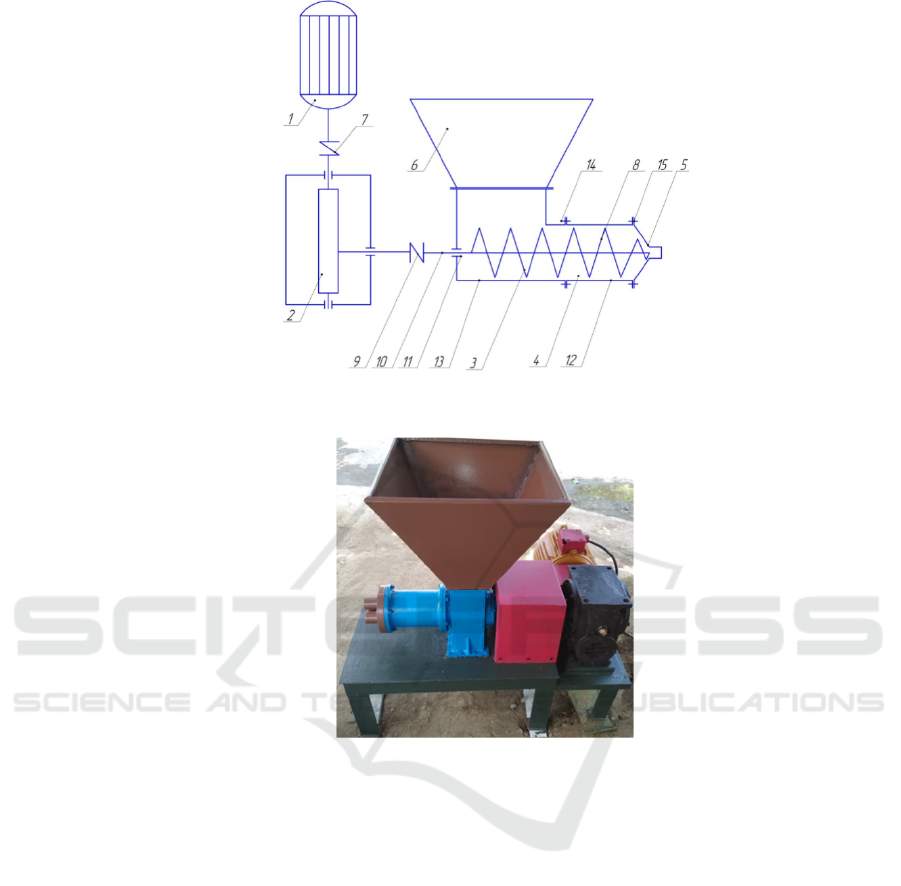

Table 2: Results obtained in determining the surface area of coal particles

N

o

Average

character

istic size

of coal

grains,

..av char

d

,

mm

Coal powder

particle size,

B

z

= m

3

Number

of

particles,

p

Particle

surface area,

S = m

2

B = total

surface

area of

particles

with a

volume of

0.011m

3

Coal powder

density,

kg/m

3

10 kg sample

volume, m

3

1 0.9 0.0000000004 22000000 0.0000025 69.94

ρ =880

X=V

n

=0,011

2 1.1 0.0000000007 15714285 0.0000038 59.7

3 1.4 0.0000000014 7857142 0.0000061 48.3

4 1.6 0.0000000021 5238095 0.0000080 41.9

5 1.8 0.0000000031 3548387 0.0000101 36.1

6 2.0 0.0000000042 2619047 0.0000125 32.9

7 2.3 0.0000000064 1718750 0.0000166 28.55

8 2.5 0.0000000082 1341463 0.0000190 26,32

9 2.7 0.0000000103 1067961 0.0000229 24.44

Research of the Process of Briquette Preparation from Coal Powder in a Screw Press

773

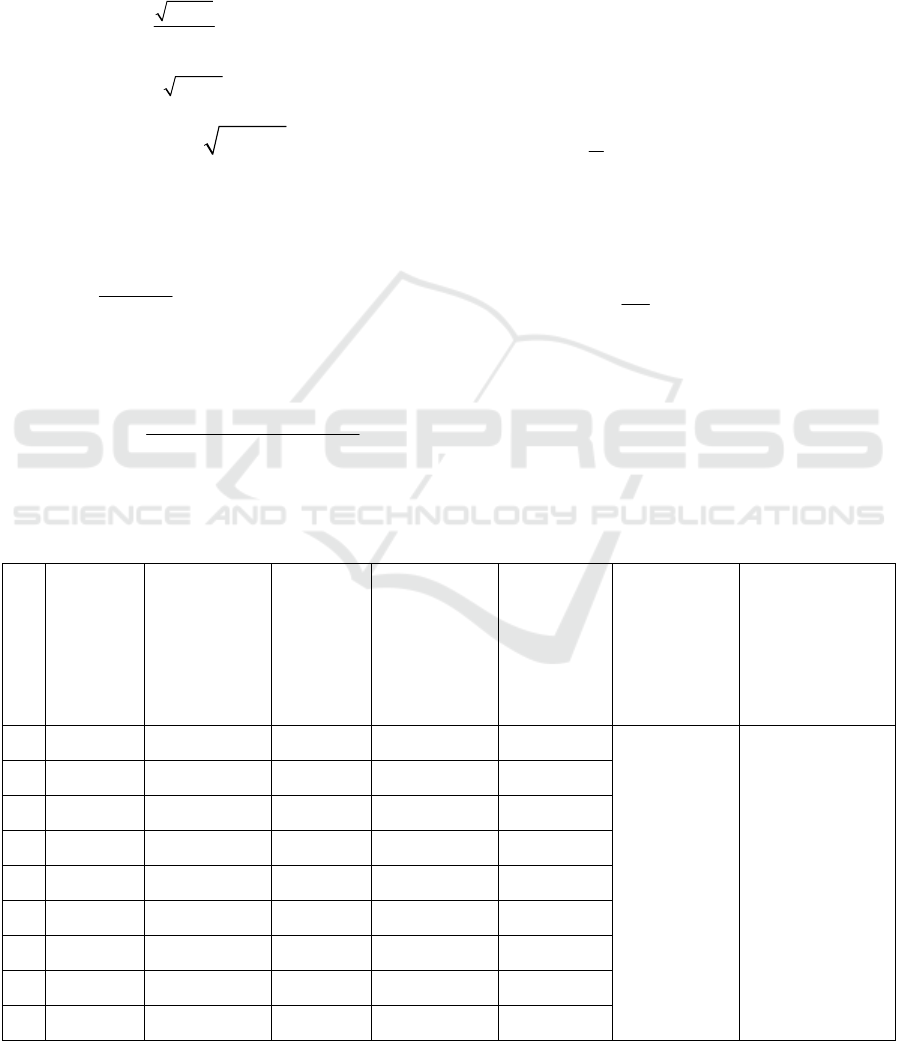

Figure 1: Scheme of the screw press.

Figure 2: Overview of the experimental device of the screw press.

When entering the press, the required size of the

coal powder mixture fraction is 0-5 mm. The moisture

content of the coal mixture should be between 5 and

20%. To increase the strength of briquettes, a fraction

of up to 5 mm is recommended, but the share of up to

5 mm should not exceed 10% of the total mass.

Briquettes must withstand a static load of 3 kg/sm

2

to

meet the condition of resistance to accidental

collisions.

When the briquette falls from a height of 1.5-2 m,

the breakage rate should not exceed 15%. [9; 10].

In the further course of experiments, research

work was carried out on the pilot device of the screw

press for briquetting of coal powder. The kinematic

scheme of the screw press is shown in Fig. 1, and its

general view is shown in Figure 2.

1-electric motor, 2-worm reducer, 3-product

receiving part, 4-pressing part, 5-mouthpiece,

6-hopper, 7,9-coupling, 8-screw, 10-screw shaft,

11-bearing, 12- pressing part, 13-product receiving

case.

4 RESULTS

In the preparation of briquettes from coal powder,

alcohol waste, which is considered as a waste of an

alcohol production enterprise, was selected. The

chemical composition of the alcohol bar is given in

Table 3.

Coal briquettes with varying values of coal fine

fractions and moisture content were prepared and

dried in an oven at a temperature of 120

0

C for 8 hours.

Coal briquette samples are shown in Fig. 3.

The limit of compressive strength of these

briquette samples was determined using a universal

device of brand WP 300 (Fig. 4).

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

774

The compressive strength of these briquette

samples was determined using the WP 300 universal

device (Fig. 4). The results of the experiments are

presented in Tables 4, 5, and 6.

Table 3: Bardani chemical composition.

Indicators

Dry

matter

Protein in

tissues (protein)

protein fat Fiber

Biologically

effective

substances

Ash

Wheat bar

d

11.5 2.9 1.7 0.6 0.7 5.7 0.6

Mouthpiece diameter,

d

m

=35 mm

Mouthpiece diameter,

d

m

=30 mm

Mouthpiece diameter,

d

m

=25 mm

Figure 3: Samples of coal briquettes produced in a screw press

Figure 4: WP 300 universal device for determining the limit of compressive strength of coal briquettes

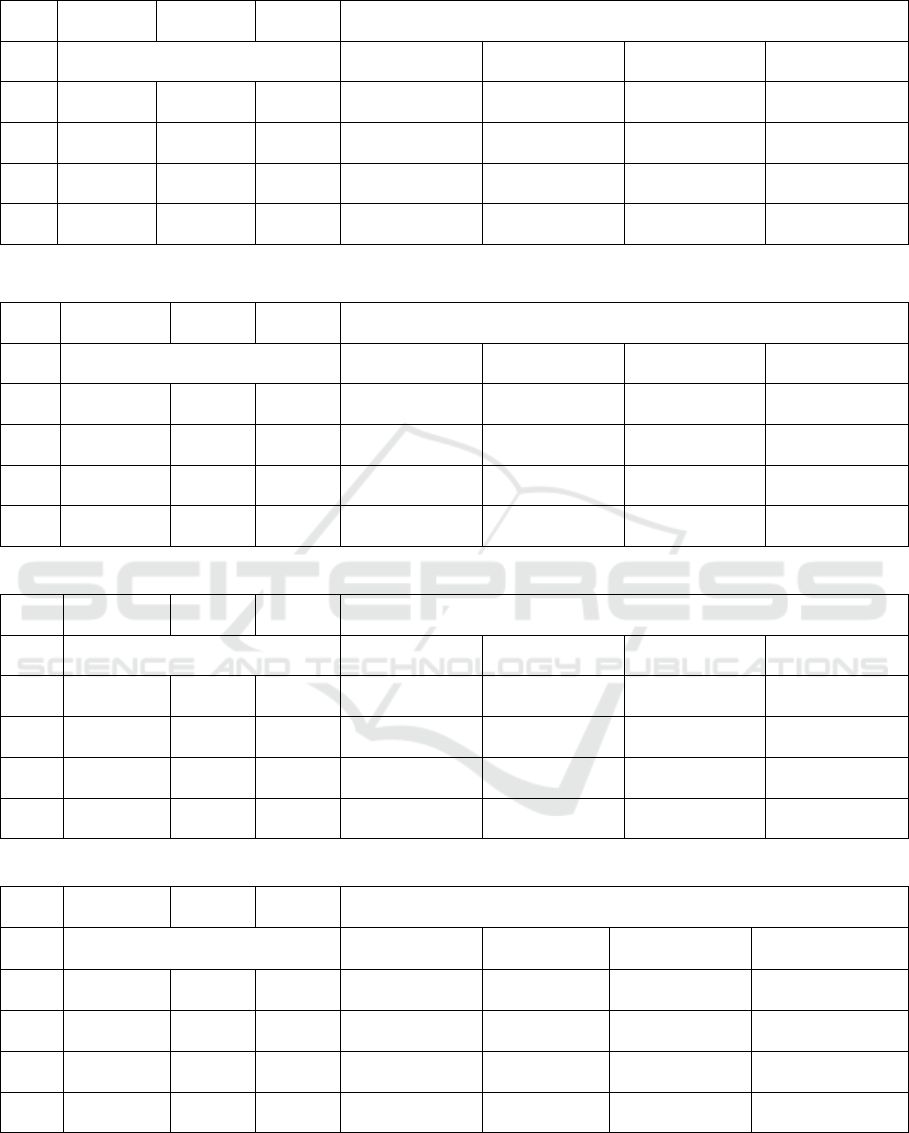

Table 4: Device productivity Q=200kg/hour, the number of revolutions of the screw is 1.5 revolutions/sec. Mouthpiece

diameter d

m

=25 mm – const

0-1mm 1-2 mm 2-5 mm Compressive strength limit, N/mm

2

Amount of fraction, % Humidity 10% Humidity 15% Humidity 20% Humidity 25%

1 20 40 40 96.5 147.5 212.4 325.1

2 40 30 30 192.2 292.6 425.7 652

3 60 20 20 205 314 638.6 977.2

4 80 10 10 288 440.1 851.3 1302

Mouthpiece diameter d

m

=30 mm – const

0-1mm 1-2 mm 2-5 mm Compressive strength limit, N/mm

2

Amount of fraction, % Humidity 10% Humidity 15% Humidity 20% Humidity 25%

1 20 40 40 68.3 104.6 152 232

2 40 30 30 136.6 209.3 304 465

3 60 20 20 205 314 456 698

4 80 10 10 273.3 418.6 608 930

Research of the Process of Briquette Preparation from Coal Powder in a Screw Press

775

Mouthpiece diameter d

m

=35 mm – const

0-1mm 1-2 mm 2-5 mm Compressive strength limit, N/mm

2

Amount of fraction, % Humidity 10% Humidity 15% Humidity 20% Humidity 25%

1 20 40 40 53.3 81.2 121 181.2

2 40 30 30 106.2 163.5 237 363.2

3 60 20 20 160.1 245.3 356 545.3

4 80 10 10 213.2 326.6 475 726.5

Table 5: The number of revolutions of the auger is 1 rot/sec. The diameter of the nozzle is d

m

=25 mm – const

0-1mm 1-2 mm 2-5 mm Compressive strength limit, N/mm

2

Amount of fraction, % Humidity 10% Humidity 15% Humidity 20% Humidity 25%

1 20 40 40 63.3 100.3 140.9 215.8

2 40 30 30 124.9 201.3 280.7 429.1

3 60 20 20 143.5 206.8 420.4 645.8

4 80 10 10 184.3 291.2 563.6 862.1

Mouthpiece diameter d

m

=30 mm – const

0-1mm 1-2 mm 2-5 mm Compressive strength limit, N/mm

2

Amount of fraction, % Humidity 10% Humidity 15% Humidity 20% Humidity 25%

1 20 40 40 45.12 69.1 100.23 153.12

2 40 30 30 90,21 136.87 200.1 306.94

3 60 20 20 136.9 207.66 300.96 460.05

4 80 10 10 181.09 276.01 401.25 613.12

Mouthpiece diameter d

m

=35 mm – const

0-1mm 1-2 mm 2-5 mm Compressive strength limit, N/mm

2

Amount of fraction, % Humidity 10%

Humidity

15%

Humidity 20% Humidity 25%

1 20 40 40 35,21 53.96 80.5 124.5

2 40 30 30 71.25 106.86 155.9 235.86

3 60 20 20 104.88 161.93 232.9 359.9

4 80 10 10 141.02 217.91 313.45 478.83

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

776

Table 6: The number of revolutions of the screw is 2 revolutions/sec. The diameter of the nozzle is d

m

=25 mm – const

0-1mm 1-2 mm 2-5 mm Compressive strength limit, N/mm

2

Amount of fraction, % Humidity 10% Humidity 15% Humidity 20% Humidity 25%

1 20 40 40 128.6 196.1 282.4 429.8

2 40 30 30 254.9 388.53 566.1 867.45

3 60 20 20 275.8 418.05 849.3 1301.1

4 80 10 10 385.1 587.2 1132.4 1729.8

Mouthpiece diameter d

m

=30 mm – const

0-1mm 1-2 mm 2-5 mm Compressive strength limit, N/mm

2

Amount of fraction, % Humidity 10% Humidity 15% Humidity 20% Humidity 25%

1 20 40 40 91.02 139.6 202.5 305.56

2 40 30 30 180.98 279.5 405.6 618.8

3 60 20 20 275.4 418.2 607.1 928.34

4 80 10 10 362.1 557.3 802.9 1234.9

Mouthpiece diameter d

m

=35 mm – const

0-1mm 1-2 mm 2-5 mm Compressive strength limit, N/mm

2

Amount of fraction, % Humidity 10% Humidity 15% Humidity 20% Humidity 25%

1 20 40 40 71.01 109.4 160.1 241.6

2 40 30 30 141.6 214.9 314.9 485.3

3 60 20 20 212.8 326.3 475.2 724.8

4 80 10 10 283.9 432.9 637.4 966.4

It can be seen from the given tables 4, 5, 6 that

when the number of revolutions of the screw is 2

revolutions/sec, the diameter of the nozzle is d

m

=25

mm – const, when the fractions are 0-1mm-80%, 1-

2mm-10%, 2-5mm-10% , according to 10%, 15%,

20%, 25% humidity, the compressive strength limit

was σ =385.1, σ = 587.2, σ =1132.4, σ =1729.8

N/mm

2

. It can be seen that the mixture with 15%

moisture content in order to obtain briquettes at the

required level, the number of revolutions of the auger

is 2 revolutions per second, the diameter of the nozzle

is d

m

=25 mm - const, are the optimal parameters for

obtaining high-quality briquettes.

5 CONCLUSION

As a result of the conducted scientific research, small

particles of unusable coal mined from the Angren

coal mine were sorted, and their granulometric

composition was analyzed. For making briquettes

from coal fines of selected size, percentage amounts

of fine coal grains were determined by intervals, and

depending on these values, average diameters and

relative contact surfaces were determined. As a

binder, alcohol cask, which is a distillery waste, was

selected, and briquettes were prepared in a press, and

the limit of compressive strength was determined.

The number of nozzle revolutions, the percentage of

coal fine fractions and the optimal values of binder

Research of the Process of Briquette Preparation from Coal Powder in a Screw Press

777

moisture were recommended for obtaining quality

briquettes.

REFERENCES

Aleksandrova, T. N., Rasskazova, A. V., & Prokhorov, K.

V. (2012). Mining Information and Analytical Bulletin,

9, 284–289.

Chiari, G. (1990). On metal-oxygen coordination. A

statistical method to determine coordination number.

Acta Crystallographica Section B: Structural Science,

46, 717–723.

Gos, A. A. (2021). 83, 40–44.

Influence of the physicochemical properties of coals on the

compressibility and conditions for producing briquettes

and molded adsorbents. (Year not specified).

Dissertation, 144 pages.

Ismanjanov, A. I., Dzholdosheva, T. Dzh., Badalov, A. A.,

& Adylov, Ch. A. (2012).

Petrova, L. A., Latyshev, V. G., & Burenina, O. N. (2007).

Production of household fuel briquettes using

petroleum binders. Online Journal. Oil and Gas

Industry, 1–14.

Podolskaya, Z. V., Buzaeva, M. V., & Klimov, E. S. (2011).

Journal of Applied Chemistry, 84(1), 39–43.

Salikhanova, A. A., Akhunbaev, D. S., & Vokhidova, N.

Kh. (2019). Scientific and Technical Journal, 3, 69–74.

Salikhanova, A. A., Abdurahimov, D. S., & Jumayeva, A.

Kh. (2020). Universum: Chemistry and Biology, 4(70),

17–21.

Semenov, V. V., Podolskaya, Z. V., Buzaeva, M. V., &

Klimov, E. S. (2009). Technical Sciences, 6, 99–101.

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

778