Study of Material and Heat Balances of Rectification Processes

Askarov Xasanjon Abduqaxorovich and Karimov Ikromali Tojimatovich

Department Structural Engineering, Insti Andijan Institute of Economics and Construction, Fergana Polytechnic Institute,

Uzbekistan

Keywords: Heat, Laboratory, Material, Separation.

Abstract: In the article fractionation in a rectification column in a laboratory device separation methods are studied.

Separator rectification using steam the construction of the column, the principle of operation is given.

Rectification column allowing separation of acetic acid without losses in continuous operation plate

constructions are studied.

1 INTRODUCTION

The distillation or rectification process is widely used

in the chemical and oil refining industries

(Yusufbekov et al., 2015; Askarov & Isomiddinov,

2021; Askarov & Mukhammadsodiqov, 2021;

Askarov & Axunboev, 2021; Xidirberdiyevich et al.,

2020). In the implementation of this process, it is

intended to conduct a theoretical study of the material

and heat balances of the rectification column

apparatus using large-scale plate columns (Abdullah

et al., 2023; Uralovich et al., 2023; Rakhmankulovna

& Makhmudovich, 2020; Mirmakhmutovich et al.,

2019; Rahimov et al., 2024; Askarov et al., 2024;

Rakhimov et al., 2024; Makhmudov et al., 2024;

Makhmudov & Abduraimova, 2020). The scheme of

the experimental device of the rectification process is

shown in Figure 1, and a brief classification of the

device is as follows. The steam leaving the column

cube 1 is transferred to the rectification column 2 and,

colliding on the contact surface plates 3, the two-

component phases are separated and fall into the

residue cube 4. In this process, the liquid is separated

into two components, namely, reflux F and distillate.

It is possible to write the material balance

according to the given process scheme (Fig. 1) as

follows:

f

dw

GGG=+

(1)

As for the light volatile component, it is as

follows:

f

fddww

G

х

G х G х⋅= ⋅+ ⋅

(2)

Figure 1: Technological scheme of the experimental device of the rectification process.

402

Abduqaxorovich, A. X. and Tojimatovich, K. I.

Study of Material and Heat Balances of Rectification Processes.

DOI: 10.5220/0013424000004654

In Proceedings of the 4th International Conference on Humanities Education, Law, and Social Science (ICHELS 2024), pages 402-406

ISBN: 978-989-758-752-8

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

2 METHODS

Here

,,

f

dw

GGG

- initial solution distillate and cubic

residue masses; kmol. Concentrations of the light

volatile component in the initial solution distillate and

cubic residue. Wealth shares. From equations (1) and

(2), the masses of distillate and cube residue are

determined:

f

w

df

dw

x

x

GG

x

x

−

=

−

(2)

We determine the ratios of the initial solution

cubic residue and phlegm to 1 kmol of distillate as

follows:

;

f

d

G

F

G

=

;

w

d

G

W

G

=

d

Ф

R

G

=

(3)

The ratio of the reflux ratio to the reflux ratio

is called the reflux ratio R. The supply plate of the

rectification column divides it into 2 upper and lower

parts. Based on the general equation, we construct the

material balance equations for the upper and lower

parts of the column:

()Gdy L dx⋅=⋅−

(4)

Here.

d

LRG=⋅

- the amount of liquid flowing

at the top of the column.

The amount of steam rising up the column is

determined as follows:

(1 )

dddd

GG Ф GRGG R=+=+ = +

(5)

For the top of the column:

(1) ()

R

dy R dx+⋅ =⋅−

(6)

Concentrations x,у desired cross-section and

concentrations of the upper part of the column x

d

, у

d

The equation for the upper part of the column can be

written as follows:

(1) ( )( ) ( )

dd

Rd

y

FR x

y

Rx x+⋅ = + ⋅ − =⋅ −

(7)

Or:

11

d

x

R

yx

RR

=+

++

(9)

For the lower part:

(1) ( )()

R

dy F R dx+⋅ = + ⋅−

(10)

Concentration x,у and concentrations of the

bottom of the column x

w

, у

w

for any cross section of

a cube that is, x

w

=у

w

Taking into account, we write

the following equation:

(1)( )(1)( )( )( )

ww w

RyyRyxFRxx+⋅ − = +⋅ − = + ⋅ −

Or:

1

11

w

RF F

yxx

RR

+−

=+

++

(11)

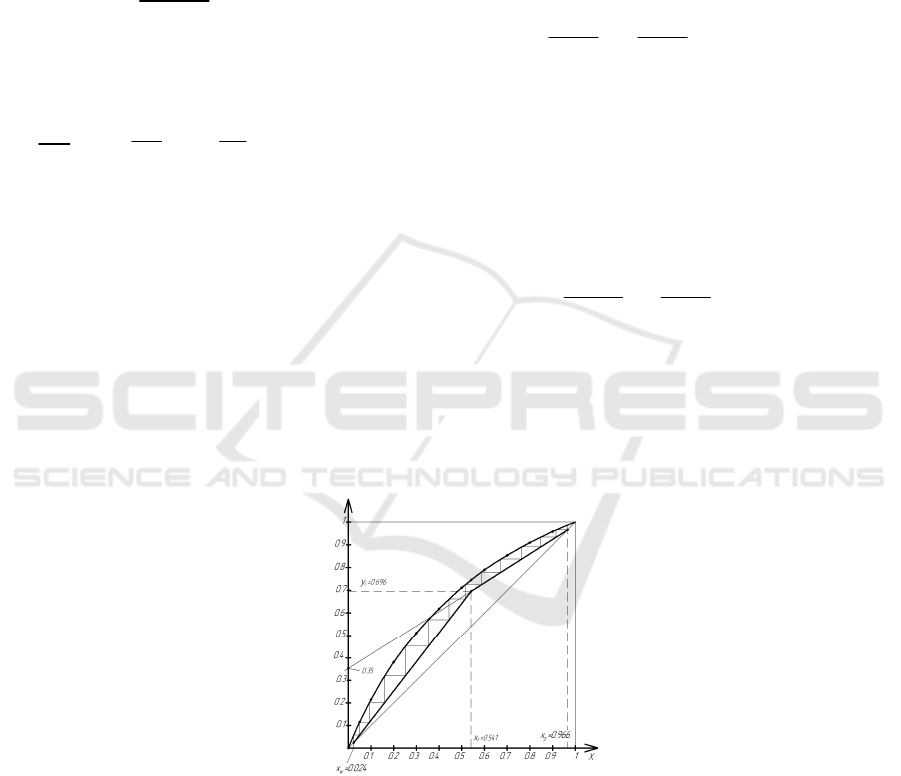

It can be seen that equations (10) and (11)

represent the straight line in Figure 2. Thus, equations

(10) and (11) represent the operating line of the upper

and lower parts of the rectification column. The

operating line is distinguished by its smooth and

uneven state.

Figure 2: Classification of the working line of the rectification process.

Study of Material and Heat Balances of Rectification Processes

403

Figure 3: Recommended laboratory setup.

Table 1: Optimal coefficients for the Rectification process in the column and apparatus.

Installation Column Print, MPa

Acceptable

number of

phlegm

Number of

plates

Atmospheric-vacuum

distillation

Topping 0,4-0,5 2-4 20-30

Atmospheric 0,15-0,20 1,5-2,5 45-55

Each section is

separate

- - 8-12

Acceptable 0,16-0,,18 - 6-8

Vacuu

m

(5-8),10

-3

2-3 14-26

Stabilize

d

0,8-1,4 3-6 35-60

Catal

y

tic

p

rocess Stabilize

d

0,8-1,4 2-3 40-60

Hydraulics (for diesel

fuels)

Ordinary 0,15-0,4 1,5-2 20-40

Catalytic process

Rectification

cleaning

0,15-0,20 4-5 30

Stabilization 0,8-1,4 6-8 40-60

Separation of gases

Ethan 1,3-1,5 1,5-3 30-40

Propane 1,6-1,8 2-4 40-60

Isobutane 1,8-0,85 8-12 80-100

Isobutane 0,3-035 15-20 80-120

The recommended laboratory setup (Figure 1-3)

shows that the advantages of the plate-based

atmospheric-vacuum distillation process over the old

processes are that it does not require complex

technological processes and has a robust and simple

design. Theoretical calculations show that the new

plate surface improves heat transfer, and an increase

in acetic acid regeneration in atmospheric-vacuum

distillation by 19% is achieved.

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

404

Figure 4: Plate construction.

Such a plate construction can be used not only in

the chemical industry, but also in the rectification

column apparatus of the primary oil refining

processes in the oil refining industry.

3 CONCLUSION

This study focuses on the separation methods used in

a laboratory-scale rectification column, particularly

examining the process of fractionation using steam.

The construction and operational principles of the

rectification column are discussed in detail. The

research highlights that the rectification column

facilitates the effective separation of acetic acid with

minimal losses during continuous operation,

specifically utilizing plate constructions for improved

efficiency. These findings contribute to the

understanding and optimization of separation

processes in industrial applications.

REFERENCES

Abdullah, D. G., Artsiyanova, K., Mansur qizi, K.,

Javlievich, E. A., Bulturbayevich, M. B., Zokirova, G.,

& Nordin, M. N. (2023). Caspian Journal of

Environmental Sciences, 21(3), 647–656. doi:

10.22124/cjes.2023.6942.

Askarov, X. A., & Axunboev, O. (2021). International

Journal of Innovations in Engineering, Research and

Technology, 8(6). ISSN 2394-3696.

Askarov, X. A., & Isomiddinov, A. (2021). Ekonomika i

sotsium, 1(80), Russia. ISSN 2225-1545.

Askarov, X. A., & Mukhammadsodiqov, K. J. (2021). The

America Journal of Engineering and Technology, 3(5),

1–8. ISSN 2689-0984.

Askarov, X., Karimov, I., Mirzayeva, U., & Asqarova, M.

B. (2024). E3S Web of Conferences, 538, 01032.

Askarov, X., Abdullayev, I., & Kamilova, O. (2024). E3S

Web of Conferences, 538, 01030.

Askarov, X., Abdullayev, I., & Komilova, O. (2024). E3S

Web of Conferences, 538, 01030.

Asqarov, X., Makhmudov, S., Xasanov, D., & Asqarov, X.

(2024). E3S Web of Conferences, 538, 01033.

Makhmudov, S. M., & Abduraimova, K. R. (2020).

International Journal of Scientific and Technology

Research, 9(1), 3803–3807.

Makhmudov, S. M., Miralimov, M. M., & Akhmadiyorov,

U. S. (2019). International Journal of Scientific and

Technology Research, 8(11), 1333–1336.

Makhmudov, S. M., & Solijonovich, A. U. (2019).

International Journal of Scientific and Technology

Research, 8(11), 1333–1336.

Sadriddin, S., Miralimov, M. M., Makhmudov, S. M., &

Akhmadiyorov, U. S. (2019). International Journal of

Scientific and Technology Research, 8(11), 1333–

1336.

Uralovich, K. S., Toshmamatovich, T. U., Kubayevich, K.

F., Sapaev, I., Saylaubaevna, S. S., Beknazarova, Z., &

Khurramov, A. (2023). Caspian Journal of

Environmental Sciences, 21(4), 965–975. doi:

10.22124/cjes.2023.7155.

Study of Material and Heat Balances of Rectification Processes

405

Xidirberdiyevich, A. E., Ilkhomovich, S. E., Azizbek, K.,

& Dostonbek, R. (2020). Journal of Advanced Research

in Dynamical and Control Systems, 12.

Yusufbekov, N. R., Nurmukhamedov, N. S., & Zakirov, S.

G. (2015). Toshkent: Fan va texnologiya.

ICHELS 2024 - The International Conference on Humanities Education, Law, and Social Science

406