The Influence of the Digital Economy on the Transformation of SMEs

in the Manufacturing Industry

Ziyue Yuan

School of Public Finance and Public Administration, Jiangxi University of Finance and Economics,

Nanchang, Jiangxi, China

Keywords: Digital Transformation, Digital Economy, Manufacturing, SMEs.

Abstract: With the deepening execution of the ‘fourteenth Five-Year Plan’, the digital transformation of manufacturing

small and medium-sized enterprises, which is also called SMEs, has reached a new peak in development.

Within the framework of the digital economy, embracing digitalization has become a necessary means of

survival for SMEs. This paper focuses on the manufacturing sector, outlining the challenges faced during the

transformation of these enterprises. It highlights the benefits and risks posed by the digital economy in this

process and proposes solutions in three key areas: technology, strategy and talent, which offer theoretical

support and guidance for the digital transformation and sustainable growth of SMEs in China’s manufacturing

industry.

1 INTRODUCTION

1.1 Research Background

As an important engine of development in the new

era, the digital economy has flourished globally and

become the backbone of promoting the intelligent

development of society. China's digital economy has

seen continuous expansion, hitting 53.9 trillion yuan

in 2023, which represents 42.8% of the country's

GDP. This underscores the critical role the digital

economy plays in the national economy. The scope of

influence of the digital economy is not only limited to

the rise of new industries, but it significantly affects

the way traditional industries operate, how they

produce goods, and how their value chains are

organized. The core of the digital economy lies in

data, which is regarded as a key production factor,

and the deep integration of digital technology and the

real economy is realised through modern information

networks. This integration drives the development

and change of production and lifestyle towards

unprecedented areas, and becomes a powerful driving

force for stable social development.

The manufacturing sector has emerged as a new

avenue for development for manufacturing

enterprises as a result of the rapid advancement and

widespread application of information technology,

including big data, cloud computing, the Internet of

Things, and artificial intelligence. Since China's

economic opening and reform, the manufacturing

sector has grown exponentially, serving as the

backbone of the country's economy and playing a

crucial role. However, with the weakening of the

demographic dividend advantage, rising resource

costs, coupled with the intensification of international

competition, resulting in China’s traditional

manufacturing industry’s living space has been

squeezed. In this environment, enterprises urgently

need to seek new production dynamics and

development paths.

The Chinese government and

businesses are implementing a number of initiatives

to encourage the digital transformation of the

industrial sector in order to address this challenge.

The Chinese government has clearly proposed in the

strategic plan of Made in China 2025 to focus on

building a green manufacturing system, placing

innovation at the core of the overall development of

the manufacturing industry, and leveraging the

advantages of the digital economy in order to

optimise the upgrading of the manufacturing

structure, which is not only a strategic need to create

a new competitive advantage for the digital

manufacturing industry, but also an important issue

for the realisation of the country’s high-quality

development.

360

Yuan, Z.

The Influence of the Digital Economy on the Transformation of SMEs in the Manufacturing Industry.

DOI: 10.5220/0013230800004568

In Proceedings of the 1st International Conference on E-commerce and Artificial Intelligence (ECAI 2024), pages 360-367

ISBN: 978-989-758-726-9

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

1.2 Research Significance and

Research Method

Even while the digital economy offers manufacturing

companies a favorable environment in which to

undergo digital transformation, SMEs continue to

face numerous risks and obstacles in their quest for

digital transformation. SMEs are important and

irreplaceable in the economic system, and thanks to

their large number and wide coverage, they are an

important source of economic vitality. Due to their

smaller size, manufacturing SMEs tend to be more

flexible and responsive than larger firms. Therefore,

studying the innovation and transformation of

manufacturing SMEs can not only quickly identify

and solve problems, but also promote the overall

progress of the manufacturing industry and drive the

development of the whole industry. Future research

must focus on one of the main problems: how to

encourage businesses to become digital while making

sure SMEs profit and participate fairly?

Based on this, this paper summarises the current

demand for transformation of manufacturing

enterprises through literature combing and the driving

benefit mechanism brought by the digital economy,

explores the positive effect of digital economy

development planning on the transformation of

manufacturing SMEs, highlights the essential

elements of the digital economy that support

businesses' transformation processes, and deeply

analyses the risks existing in the process of digital

transformation, and explores relevant

countermeasures and recommendations, to encourage

the evolution of the manufacturing sector and

sustainable development by providing theoretical

support, and to draw attention to China's digital

economy background of small and medium-sized

manufacturing enterprises transformation related

research.

2 TRANSFORMATION NEEDS

OF MANUFACTURING

ENTERPRISES AND DRIVING

EFFECTS OF THE DIGITAL

ECONOMY

2.1 Dilemma and Innovation of

Manufacturing Enterprises

Studies have shown that R&D expenditures of

enterprises should account for at least 2 to 4 per cent

of turnover in order to ensure sustainable

development and market competitiveness. However,

many enterprises in China currently spend less than 1

per cent of their turnover on R&D, a phenomenon that

severely hampers innovation and limits their market

adaptability. The total amount of R&D funding at the

national level is also insufficient, further limiting the

innovation capacity of manufacturing enterprises. In

addition, Chinese enterprises have a relatively single

source of funding structure, relying mainly on

internal inputs and credit funds, while venture capital

and stock market funds account for a small

proportion. The limitations of this funding structure

can lead to a lack of flexibility and diversity in the

introduction of innovative technologies, which can

easily lead to the loss of the opportunity to enhance

innovation capacity due to a lack of funds, or the

conservative performance of R & D investment,

which can be hampered in the process of long-term

development. At the same time, Chinese

manufacturing enterprises also face problems such as

insufficient investment in technology level and aging

production equipment, which further reduces

production efficiency, raises operating costs, and

further erodes product quality and competitiveness,

diminishing the marketability of companies.

To solve this dilemma, several alternatives to the

enterprise innovation strategy have been proposed by

domestic and international academics. Noni Ngisau

and Nurhani Aba Ibrahim (2020), from Malaysian

manufacturing enterprises, found that government

support can regulate the promotion of enterprise

innovation. Jing et al. (2021), on the other hand, used

fsQCA analysis to prove that lean digitisation in the

Jing et al. (2021) used fsQCA analysis to demonstrate

that the differentiated implementation paths of Lean

digitalisation in the ‘point, line, surface and body’

phases can help firms to allocate and utilise resources

in a more rational way.

2.2 Driving Mechanisms of Digital

Transformation

The change of digital technology not only promotes

the intelligent change of manufacturing enterprises,

but also promotes the significant improvement of

enterprises in terms of operational efficiency.

Academic research on digital drivers mainly focuses

on the economic and technical dimensions, but in

recent years, scholars have gradually explored the

influencing factors of digital transformation and its

driving mechanism from multiple dimensions. Jun Jin

et al. (2020) discuss cases from the technological

dimension, organisational dimension and

The Influence of the Digital Economy on the Transformation of SMEs in the Manufacturing Industry

361

environmental dimension, and propose a synergistic

evolutionary relationship between them and digital

transformation. While Stentoft et al. (2020) showed

in their study that policy support can help firms to

improve the level of awareness and thus enhance the

recognition of opportunities due to technology

facilitation. Zhao Qingqing and Li Siqi (2023) argued

that digital transformation evolves synergistically

with corporate strategy and organisational model in a

dual-path dynamic that provides a power source for

corporate innovation. From the strategy of ‘smart

change and digital transformation’, Peng, Yan (2023)

provided a dual internal and external driving

mechanism and clarified the fundamental connection

between digital transformation and intelligent

transformation of SMEs.

The digital transformation of industrial firms is

being propelled by a multitude of intricate elements.

Manufacturing companies' ability to adapt quickly to

changes in the market in a highly competitive

environment is made possible by the interplay of

organizational change, policy support, technological

advancement, and other factors. These factors

collectively propel the process of digital

transformation in manufacturing companies.

2.3 Enabling Role of the Digital

Economy

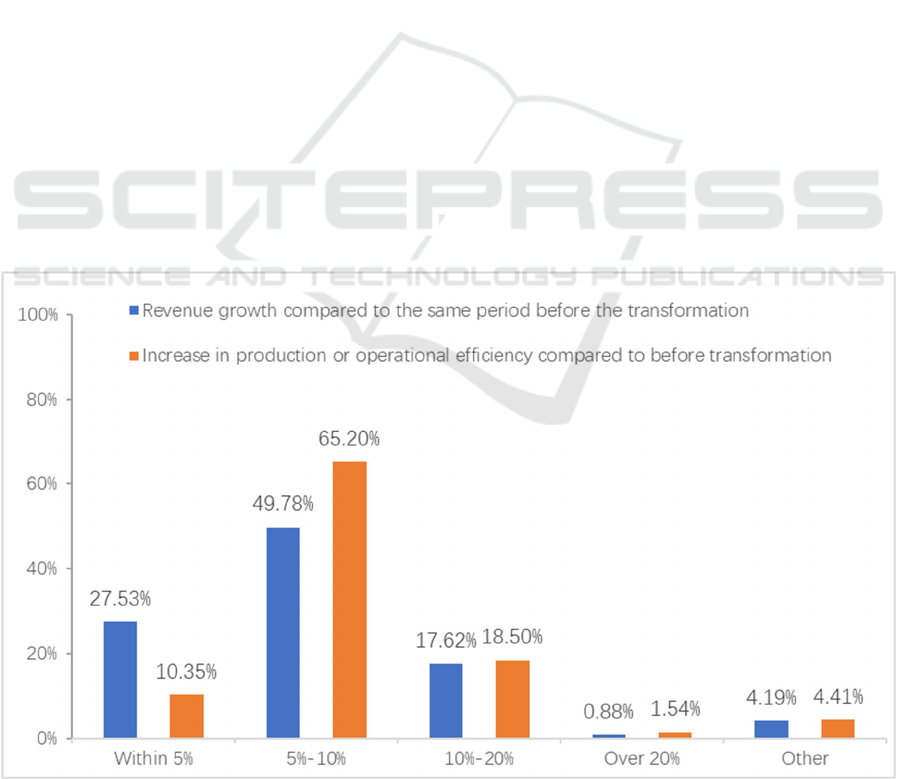

According to the data released by the ‘Analysis

Report on the Status of Digital Transformation of

China’s Micro, Small and Medium-sized

Enterprises’, after launching digital transformation,

enterprises saw a significant increase in production or

operational efficiency as well as business revenue.

Among them, 85.24% of the enterprises in the sample

saw their production or operational efficiency

increase by more than 5% after undergoing digital

transformation; 68.28% of the enterprises in the

sample saw their revenue increase by more than 5%

during the same period. This shows that accelerating

digital transformation is an inevitable choice for

MSMEs to get rid of difficulties and enhance

competitiveness. The relevant data can be seen in

Figure 1.

It is easy to see that the development and

deployment of artificial intelligence plays a crucial

role in helping businesses achieve digital

transformation in the real-world application of the

digital economy. The digital economy provides a

strong enabling role for manufacturing enterprises,

through big data, industrial Internet of Things and

other advanced technologies, to promote the

enterprise in decision-making, production efficiency,

market adaptability of the three aspects of the

improvement. Vice versa, the manufacturing

environment provides a huge opportunity to make

better decisions using AI technologies (Sharma et al,

2021), according to McKinsey, 40% of all potential

value that can be created by today’s businesses

Data from: China Association of Small and Medium Enterprises

Figure 1: Production or operational efficiency and revenue growth after digital transformation.

ECAI 2024 - International Conference on E-commerce and Artificial Intelligence

362

comes from AI and machine learning technologies,

which shows the key role of AI in business innovation

and value creation. Rai et al. (2021) proposed the

Industrial Internet of Things (IoT) as a key enabler in

the manufacturing environment, facilitating AI to

utilise big data for real-time monitoring applications.

The digital economy enables firms to effectively

utilise data-driven decision support systems (Sahu et

al,2021), which can lessen the negative effects of

market volatility and boost firm resilience by

assisting businesses in adapting swiftly to changes in

the market.

The digital economy provides manufacturing

firms with a wealth of tools to help improve

productivity and resource efficiency, which enhances

firm competitiveness while promoting sustainable

development. Henfridsson et al. (2018) suggest that

for SMEs, digital infrastructure facilitates the optimal

allocation of digital resources and the creation of new

value by integrating software and hardware

components. Liu et al. (2023), on the other hand,

explored that digital tools can significantly enhance

SMEs’ digital capabilities, reduce associated costs,

and play an important role in improving productivity.

Huang Hao et al. (2023) study the digital platform

capability of manufacturing SMEs, and propose to

combine the current resources of enterprises with new

digital technologies, so as to optimise the hardware

configuration of enterprises and fully release the

facilitating effect of digitalisation on innovation

output.

3 RISKS AND CHALLENGES OF

DIGITAL TRANSFORMATION

IN MANUFACTURING SMES

For manufacturing SMEs looking to increase their

competitiveness and achieve sustainable

development, digital transformation has emerged as a

critical route. However, according to the findings of

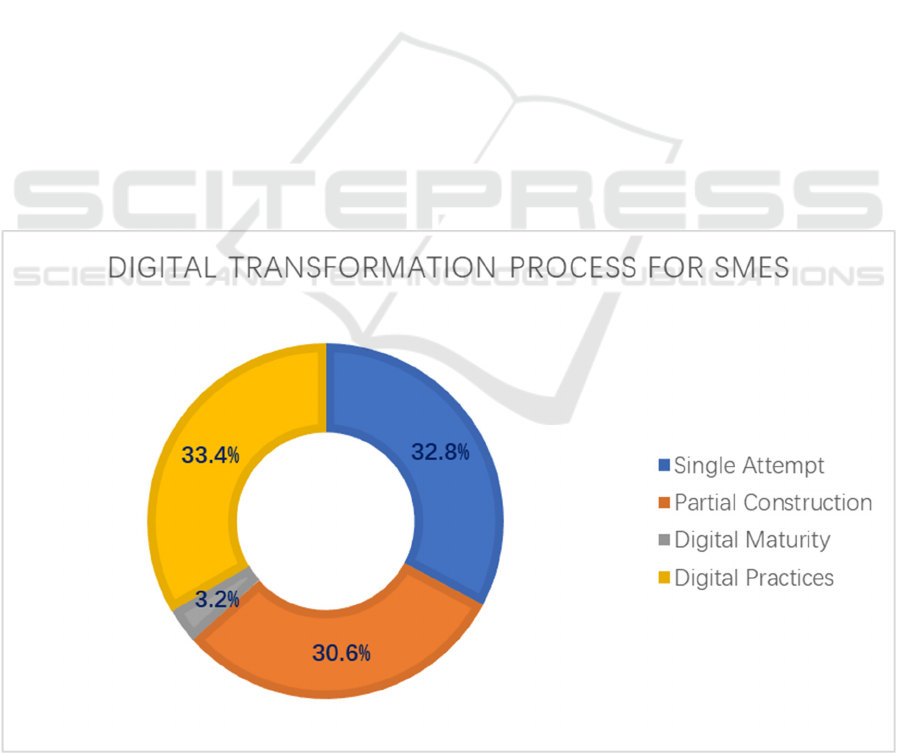

China SME Digital Transformation Report 2024, it is

not difficult to find that although the vast majority of

SMEs have started digital transformation, they are

still in the early stage of development and face many

risks and challenges. The data shows that 98.8% of

SMEs have started digital transformation, of which

about 32.8% have only tried digital applications in a

single scenario; about 30.6% have carried out partial

digital construction within the value chain; and the

proportion of SMEs with a higher level of

digitisation, driven by intelligence, is only 3.2%. As

shown in Figure 2.

Data from: 36 Krypton Research Institute

Figure 2 Digital transformation process in SMEs.

The Influence of the Digital Economy on the Transformation of SMEs in the Manufacturing Industry

363

With the rapid development of intelligence, the

current Chinese SMEs have a strong willingness to

digital transformation, but still 60% of enterprises are

still in the early stage of development. In terms of

industry distribution, compared with the Internet,

finance and other industries with better infrastructure,

the manufacturing sector is undergoing a slower and

more difficult digital transition. Overall, the digital

transformation of SMEs is still in the exploration

stage, and there are still certain risks and challenges.

3.1 Digital Divide and Technology Gap

In the digital economy, there are significant

differences between SMEs and large manufacturing

enterprises in terms of their access to technology,

their ability to apply it, and the benefits of digitisation,

creating a ‘digital divide’. Large manufacturing

enterprises are more likely to succeed in digital

transformation due to their strong financial and

technological resources, and they invest in new

technologies to achieve digital innovation to maintain

their competitiveness in the market in a changing

economic environment, while SMEs encounter more

obstacles in the transformation. Due to limited

financial resources, SMEs lack sufficient capital to

bear the high costs of technology investments and

upgrades.

Digital transformation requires a large amount of

initial capital to upgrade existing equipment,

introduce new technologies, and set up information

systems, and these investments may not immediately

improve business performance or generate direct

returns in the short term. This investment risk is huge

for SMEs, and if digital transformation fails to deliver

the expected returns, the enterprise may experience

greater financial pressure or even affect normal

business operations. The lack of ability of SMEs to

innovate results in a greater challenge for them to stay

ahead of the curve in the digital economy. This

widens the gap between SMEs and large corporations

and hinders the digital transformation of the

manufacturing sector in general.

3.2 Insufficient Pool of Digitisation-

Related Talent

Successful digital transformation relies not only on

technology, but also requires talent with digital

technology and data analytics skills. However, many

SMEs have significant deficiencies in digital talent

pool and retention, which seriously affects the

effectiveness of digital transformation. In the

manufacturing sector, the digitalisation process is

usually led by middle managers who do not possess

digital skills, and there is a lack of digital talent

capable of leading the change, leading to blind spots

and shortcomings in the process of strategy

development and implementation, essentially

creating a clear disconnect with digital change. This

shortage of talent leaves companies with more than

they can handle in the digital transformation process.

In addition, due to limited resources, SMEs are

usually unable to offer salary packages, training

opportunities and career paths comparable to those

offered by large enterprises, making it difficult to

retain digital talent for long periods of time, even if

they are able to recruit it. This turnover of talent

increases the time and capital costs of business

transformation, undermining its long-term

sustainability.

3.3 Lack of a Complete Digital

Transformation Strategy and

Framework Support

The primary obstacle to an enterprise's ability to

undergo digital transformation is that it ‘does not

have the support of complete digital transformation

strategies and frameworks’, according to the 2023

China Association of Small and Medium Enterprises

(CASME) publication, ‘Analysis Report on the

Digital Transformation Status of China's Micro,

Small and Medium Enterprises’, which means that

SMEs often lack a clear direction and systematic

planning when they formulate and implement their

digital transformation strategies. Clear direction and

systematic planning. In the face of a fast-changing

market, they are often prone to strategic

shortsightedness.

From an internal governance perspective,

businesses are unable to closely align their digital

transformation strategy with their long-term

development plan because they do not have a

thorough understanding of the meaning and

implications of digital transformation; limited by the

cognitive limitations of the management and the

shortage of internal resources, it is difficult for SMEs

to form a logical and clear framework for the

implementation of digital transformation, which leads

to the irrational allocation of resources and weak

implementation when implementing the strategy.

This leads to irrational allocation of resources and

ineffective implementation.

The complexity of the manufacturing industry's

transformation, the non-replicability of the successful

cases that have already been established, and the

external environment's perspective all contribute to

SMEs' lack of forward-looking macro-environmental

prediction and their inability to make timely

adjustments to the strategic direction of digital

ECAI 2024 - International Conference on E-commerce and Artificial Intelligence

364

transformation. This tendency of SMEs to prioritize

the short-term results of the fast digital strategy

severely limits the sustainability of the transformation.

4 COUNTERMEASURE

SUGGESTIONS FOR THE

TRANSFORMATION OF

MANUFACTURING SMES

4.1 Bridging the Technology Gap

In response to the lack of technical resources, SMEs

can adopt flexible and low-cost digitalisation tools. In

this way, they can reduce the investment cost in the

early stage of transformation, shorten the

implementation cycle, and enable enterprises to

achieve rapid transformation in the early stage of

transformation, so as to accumulate digital experience

and gradually enhance the depth of digital

transformation. In addition, SMEs should make full

use of the current government support policies at the

financial level, such as loan subsidies, loan

guarantees, risk compensation and other services,

increase investment in the technical level, actively

apply for special government funds, and take

advantage of the policy advantage to reduce the cost

of digital transformation investment and improve risk

response capabilities, so as to bridge the existing

technological disadvantages.

4.2 Optimise Talent Introduction and

Training Mechanisms

SMEs should pay attention to the cultivation of

internal talents, enhance the quality of existing

employees through regular training, and improve the

digital ability of employees; at the same time, they

should maintain friendly relations with scientific

research institutes and high efficiency, and through

the signing of university-enterprise cooperation

agreements, while realising the interaction of human

resources, they should combine the job requirements

of enterprises with the objectives of talent cultivation

in universities, so as to achieve the effect of seamless

connection between the cultivation of talents in

universities and the demand of talents in enterprises,

and to convey the Fresh digital talents.

In terms of compensation system, in the case of

insufficient internal resources, the company has set

up equity incentive mechanism for high-end technical

talents, and at the same time, provided clear career

promotion paths to enhance the sense of belonging of

talents, and to a certain extent, reduced the turnover

rate of talents.

4.3 Clarify Strategic Planning for

Digital Transformation

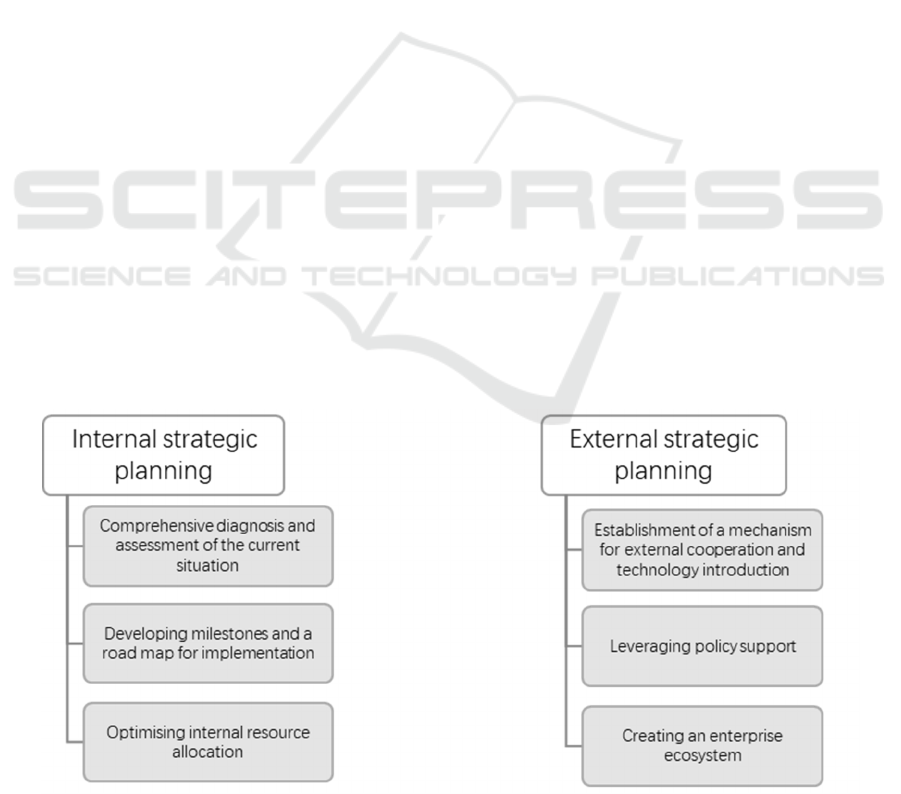

In order to achieve the dual goals of improving

internal efficiency and adapting to the external

environment, companies should think about strategic

planning from two dimensions, internal and external,

respectively, so as to better formulate and implement

digital transformation strategies. As shown in figure

3.

Figure 3 Internal and external strategic planning.

The Influence of the Digital Economy on the Transformation of SMEs in the Manufacturing Industry

365

SMEs conduct a comprehensive diagnosis from

the internal level, assess the existing level of

digitization, identify the strengths and shortcomings

of the enterprise, set milestones based on the actual

situation of the enterprise, and specify the resource

allocation and implementation steps for each stage,

while introducing digital tools and management

platforms to improve the level of management and

push the enterprise towards a data-driven intelligent

operation mode. At the external level, SMEs should

actively seek the support of external technology

providers, scientific research institutions and industry

alliances through technology introduction, resource

sharing and joint research and development. Enhance

their own technology development level, shorten the

transformation cycle, and gradually establish

enterprise ecosystems through cooperation with

friends to promote resource integration and enterprise

win-win.

5 CONCLUSIONS

The results of the study show that the digital economy

provides unprecedented opportunities for the survival

and development of SMEs, especially in improving

productivity, optimizing resource allocation and

enhancing enterprise resilience, but at the same time,

the lack of resources in terms of technology and

capital restricts the equal competition with large

enterprises in the process of digital transformation.

This paper identifies and analyzes the risks that may

be encountered in the digital transformation of SMEs,

and puts forward targeted recommendations to

provide transformation ideas for manufacturing

SMEs from three dimensions: bridging the

technology gap, optimizing the talent cultivation

mechanism, and clarifying the strategic plan to help

narrow the gap between SMEs and large-scale

enterprises, which to a certain extent solves the

problem of SMEs' fair participation in the market

competition. However, as this paper mainly

researches through literature combing and case study

analysis, lacking field investigation and empirical

analysis, there are certain limitations in the

universality of research conclusions; in addition, this

paper focuses on exploring Chinese manufacturing

SMEs, and has not yet analyzed in-depth the

differences between SMEs in different countries and

regions in terms of digital transformation.

Based on this, future research can start from the

data and construct relevant empirical analysis models,

so as to more comprehensively identify and analyze

potential risks and countermeasures, and guide more

manufacturing SMEs on the path of digital

transformation. In addition, drawing on successful

cases of digital transformation around the world, the

formation of a cross-country comparative research

framework for the digital transformation path of

China's manufacturing enterprises has an excellent

guiding role, and better help enterprises to develop

transformation strategies in accordance with local

conditions and time. Digital transformation is a

strategic move toward sustainable development as

well as a crucial tool for businesses to increase their

competitiveness. It affects not just the growth and

survival of certain businesses but also significantly

influences societal stability and economic expansion.

Future research should focus on how to ensure that

businesses in the digital economy are fairly able to

benefit from technological advancements.

REFERENCES

Henfridsson, O., Nandhakumar, J., Scarbrough, H., &

Panourgias, N. (2018). Recombination in the open-

ended value landscape of digital innovation.

Information & Organization, 28(2), 89–100.

https://doi.org/10.1016/j.infoandorg.2018.03.001

H. Huang, W. Song, W. Wang & H. Lin. (2023). A study

on the impact of data-enabled capabilities of

manufacturing SME platforms on disruptive

innovation. Research Management (11), 32-40.

doi:10.19571/j.cnki.1000-2995.2023.11.004.

Jing, S., Feng, Y., & Yan, J. (2021). Path selection of lean

digitalization for traditional manufacturing industry

under heterogeneous competitive position. Computers

& Industrial Engineering, 161, N.PAG. https://doi.org/

10.1016/j.cie.2021.107631

Jun Jin, Shijia Li & Liangbin Huang. 2011 A new species

of the genus Pseudourostyla (Hymenoptera,

Staphylinidae). (2020). Research on the Influencing

Factors of Digital Transformation of Traditional

Manufacturing Enterprises. Innovative Technology

(06), 22-34. doi:10.19345/j.cxkj.1671-0037.2020.

06.004.

Liu, X., Jiang, Y., Wang, Z., Zhong, R. Y., Cheung, H. H.,

& Huang, G. Q. (2023). imseStudio: blockchain-

enabled secure digital twin platform for service

manufacturing. International Journal of Production

Research, 61(12), 3984–4003. https://doi.org/10.1080/

00207543.2021.2003462

Ngisau, N., & Ibrahim, N. A. (2020). Technological

Innovation Adoption in Manufacturing Sector: The

Moderator Role of Government Support. ECON -

Journal of Economics, Management & Business, 8(3),

200–205. https://doi.org/10.18178/joebm.2020.8.3.637

Peng, Yan. (2023). Countermeasures for the development

of small and medium-sized enterprises' “intelligent

transformation and digital transformation” in the

context of digital economy--Taking the manufacturing

industry as an example. Modern Business (20), 128-

131. doi:10.14097/j.cnki.5392/2023.20.007.

ECAI 2024 - International Conference on E-commerce and Artificial Intelligence

366

Rai, R., Tiwari, M. K., Ivanov, D., & Dolgui, A. (2021).

Machine learning in manufacturing and industry 4.0

applications. International Journal of Production

Research, 59(16), 4773–4778. https://doi.org/10.1080/

00207543.2021.1956675

Sahu, C. K., Young, C., & Rai, R. (2021). Artificial

intelligence (AI) in augmented reality (AR)-assisted

manufacturing applications: a review. International

Journal of Production Research, 59(16), 4903–4959.

https://doi.org/10.1080/00207543.2020.1859636

Sharma, A., Zhang, Z., & Rai, R. (2021). The interpretive

model of manufacturing: a theoretical framework and

research agenda for machine learning in manufacturing.

International Journal of Production Research, 59(16),

4960–4994. https://doi.org/10.1080/00207543.2021.

1930234

Stentoft, J., Adsbøll Wickstrøm, K., Philipsen, K., & Haug,

A. (2021). Drivers and barriers for Industry 4.0 readiness

and practice: empirical evidence from small and

medium-sized manufacturers. Production Planning &

Control, 32(10), 811–828. https://doi.org/10.1080/

09537287.2020.1768318

Zhao, Qingqing & Li, Siqi. (2023). Strategy-organization

synergy mechanism in the digital transformation of

traditional enterprises: a case study based on the strategy

alignment model. Journal of Management (02), 61-79.

doi:10.19808/j.cnki.41-1408/F.2023.0015.

The Influence of the Digital Economy on the Transformation of SMEs in the Manufacturing Industry

367