Study on Site Selection Factors of Feed Additive Factories

Zicheng Wei

a

Logistics School, Beijing Wuzi University, Beijing, 100081, China

Keywords: Plant Location, AHP Analytic Hierarchy Process, Feed Factory, Supply Chain Model.

Abstract: Feed mill site selection has always been one of the important issues in the development of agricultural industry.

In this study, Analytic Hierarchy Process (AHP) is adopted to solve this problem. Feed mill site selection is

a complex decision-making problem, involving supply chain management, environmental impact,

transportation convenience and other key factors. This paper uses AHP as a decision-making tool to determine

the optimal feed plant location scheme. AHP helps decision makers to weigh and make decisions among

several interrelated evaluation criteria effectively through hierarchical structure and allocation of expert

opinion weights. First, this paper introduces the basic principle and application steps of AHP method, and

then shows how to use AHP method to quantitatively evaluate and compare different site selection schemes

through concrete cases. Finally, it summarizes the practicability and effectiveness of AHP in the problem of

feed mill location, and its wide application potential in complex decision-making problems. This study

provides a new idea and method for the decision of feed mill location, which is of great significance for

promoting the sustainable development of agricultural industry.

1 INTRODUCTION

In China, the feed industry has developed rapidly

since the 1980s, becoming one of the largest feed

producers and consumers in the world. With the

development of economy and the acceleration of

urbanization, people's demand for high-quality meat

and dairy products has increased, and the feed

industry is facing multiple challenges such as

environmental protection and food safety while

providing high-quality animal protein. In 2024, the

total output value of the national feed industry was

140.83 billion yuan, an increase of 6.5% over the

previous year. Its total revenue was 1.330.44 billion

yuan, up by 5.4% (

Asad

et al.,

2024

). The rapid

development of the feed industry has made more

enterprises focus on the method of reducing cost and

increasing efficiency, of which the feed plant site

construction is a larger plate. Feed additives play an

important role in the livestock and poultry industry,

which can improve the production performance of

animals and also affect the production efficiency and

product quality of the livestock industry (

Gu

et al.,

2015

). Therefore, choosing the right plant location is

crucial to ensure production efficiency, reduce costs,

a

https://orcid.org/0009-0009-7029-815X

meet market demands, and reduce environmental

impact (Li et al., 2017).

When deciding on the location of a feed additive

plant, a number of factors need to be considered,

including but not limited to geographical location,

supply chain convenience, raw material supply,

transportation costs, human resources, environmental

regulations, community response, etc. There is a

complex interrelationship between these factors, and

the rationality of the decision directly affects the

operation efficiency of the plant, the market

competitiveness, and the impact on the surrounding

environment and community (

John

and

Saeid

,

2024)

.

Choosing the right plant location can optimize the

production layout and reduce the distance between

production lines thereby improving production

efficiency and reducing waste in the production

process (Liu, 2005). Reasonable location can reduce

the transportation distance and time of raw materials

and finished products, reduce logistics transportation

costs, and improve the profitability of enterprises.

Reasonable plant location can optimize production

layout, reduce transportation costs, improve supply

chain efficiency, so as to achieve the long-term

development goals of enterprises (Li et al., 2024).

Wei, Z.

Study on Site Selection Factors of Feed Additive Factories.

DOI: 10.5220/0013228800004558

In Proceedings of the 1st International Conference on Modern Logistics and Supply Chain Management (MLSCM 2024), pages 37-42

ISBN: 978-989-758-738-2

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

37

When making a feed plant location decision, a

number of factors need to be considered, including

but not limited to location, land availability,

environmental impact, supply chain convenience,

community response, and laws and regulations. In

addition, with the increasing global concern for

sustainable development, the site selection of feed

factories also needs to take into account the protection

of the environment, the commitment of social

responsibility and the standardization of corporate

governance (Li, 2017). The problem of feed plant

location needs to be considered from a multi-

dimensional direction, such as the policy problem of

plant location, production line layout, labor market

and other aspects. At the same time, in the context of

the development of global green industry, this paper

also needs to consider the solution of pollution

problems. In China, there are strict laws related to

pollutant treatment and strict health management for

feed enterprises. In the preliminary preparation,

Kamran et al. (2024) conducted in-depth discussion on

a series of issues such as whether the general plan is

reasonable, whether the detailed design of the single

building is applicable, and the automation level, labor

intensity, production efficiency, product quality,

production cost and corporate image of the

subsequent feed plant production management. The

multi-mode raw material reception and plant model

are introduced. In terms of supply chain and

personnel management, Iunderstand and analyze. For

example, optimize and adjust the soundness of supply

chain and procurement process management, and

train employees to increase their cost awareness.

Finally, this paper draws more views, and makes

comprehensive consideration from market capacity,

transportation network, sales radius, local laws and

regulations.

2 METHODS

In this study, multidimensional and three-

dimensional analysis of feed mill site selection was

conducted through analytic hierarchy process, and

comprehensive analysis was conducted through

expert scoring.

2.1 Numerical Source

To determine the influencing factors of feed mill site

selection, this paper selects the methods of literature

review and expert scoring. The analytical hierarchy

Process (AHP) is used to analyze the influencing

factors (

Nandi et al., 2024). This method can make up

for the shortcomings of many quality management

analysis methods, such as only qualitative analysis

and unable to judge the influence degree of each

factor. Through the combination of qualitative and

quantitative analysis, the analysis results are more

scientific and intuitive, and provide more favorable

and reliable basis for management decision-making.

2.2 Method Introduction

Hierachy Process was founded by American

professor Satty. The principle is to divide the problem

to be solved into different levels according to the

target layer, criterion layer and index layer. Experts

compare the importance of each index according to

the actual situation and experience (

Liang et al., 2008).

The eigenvectors of the judgment matrix and the

priority weights of indicators at each level relative to

the indicators at the previous level are calculated.

Finally, weighted average method is used to

summarize the weight coefficient of each indicator

relative to the overall target. The largest factor is the

most important influencing factor. The calculation

steps are as follows:

First, establish hierarchical structure model.

Analyze the problem deeply, divide the influence

factors of the problem into different levels, and draw

the hierarchical structure. Second, construct the

judgment matrix. For the influence weight of n

indicators of 𝑋

on the superior target Y, 𝑋

and 𝑋

,

are selected each time for pairwise comparison, 𝑎

represents the ratio of the influence degree of the two

indicators on the target Y, and the judgment matrix A

= (𝑎

)

×

represents the comparison results of n

influential factors. 𝑎

> 0 , 𝑎

=1/𝑎

, 𝑎

=

1 (i,j = 1,2,...,n). In order to quantify the

comparison judgment, the 1-9 scale method is used,

that is, 𝑎

takes 1-9 or reciprocal 1 (See Table 1).

Third, sort hierarchically and perform consistency

checks. For the judgment matrix A, the eigenvector

W of the largest eigenroot 𝜆

of A can be obtained

by formula (1).

𝜆

=

∑

()

(1)

where 𝑊

is the weight value of the single ordering of

the corresponding index. Check the consistency of

judgment matrix A. The formula (2) is used to

calculate the average value of the consistency index

CI, and the average random consistency index RI is

obtained from the known consistency index. If the

consistency ratio CR = CI /RI < 0.1, the consistency

MLSCM 2024 - International Conference on Modern Logistics and Supply Chain Management

38

of the judgment matrix is acceptable. Otherwise,

adjust the judgment matrix.

𝐶𝐼 =

(2)

In accordance with the code for feed mill construction

and site selection, China has a complete specification

system mainly SBJ05-1993 "Feed mill engineering

design Code", GB50187-2012 "Industrial enterprise

graphic design code", GB12348-2008 "Industrial

enterprise factory boundary noise standard",

GB8978-2002 "comprehensive sewage discharge

standard" and so on. The above specification

requirements are taken into comprehensive

consideration as the design bottom line principles and

design restrictions of this paper. Through literature

review and expert questionnaire survey, combined

with the principles of systemization, independence

and comparability of influencing factors, the

influencing factors for the design quality

management of construction drawings of waste

disposal projects are preliminarily determined, as

shown in Table 2.

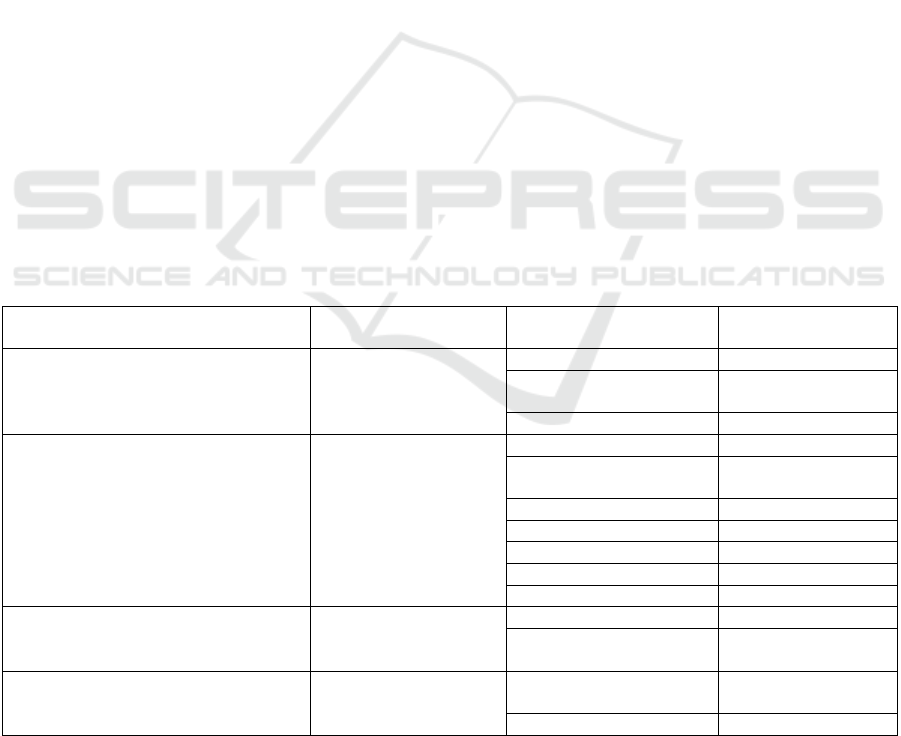

Table 1: AHP Scale evaluation sheet.

Scale Scale mean

1 i factor is as important as j factor

3 i factor is slightly important than j factor

5 I factor is more important than factor j

7 i factor is much more important than j factor

9 i factor is absolutely more important than j factor

2,4,6,8 The importance of the two factors i and j lies between the above two adjacent

judgment scales

count backwards The comparison value between factor ai and factor aj is aji=1/aij

Table 2: Influencing factors of feed mill site selection.

Destination

laye

r

Index level Index Level Descr

Feed mill

location

method

Employee factor

Labor market price Local labor price level

Quality of the local labor

force

Local average educational background and social

environment

Commuting distance Average commuting time for employees

Supply chain

factors

Market capacit

y

Place on feed gap size

Raw material origin

distance

Transportation time and cost of raw materials

Traffic environment Road levels and traffic jams

Logistics service level Logistics speed and service quality

Land

p

rice Local land lease or

p

urchase

p

rice

Surroundin

g

facilities Air

p

orts,

p

orts, railwa

y

hubs, and livin

g

facilities

Energy costs

Electricity, water and other energy-consuming

materials prices

Pollution factor

Pollutant treatment

The distance from the pollution treatment plant and

the local discharge conditions

Impact on the surrounding

communit

y

Odour and the impact of noise pollution on nearby

residential areas

Follow-up

development and

policy factors

Reserved space for

subse

q

uent develo

p

ment

Reserve land for subsequent expansion of

p

roduction scale

Local policy support

Local policy support for the feed industry and

management of pollution or plant construction

p

olicies

Study on Site Selection Factors of Feed Additive Factories

39

3 RESULTS AND DISCUSSION

The decision of plant location is decided by many

factors, and the influence of these factors is not the

same. Therefore, in determining the factors that affect

the location decision, it is necessary to consider from

multiple perspectives and multiple levels. The

previous interviews with experts have statistically

analyzed the most important 14 factors affecting

location decision, and now the analytic hierarchy

process is used to analyze and study them.

3.1 Structural Model Building

Through the interviews with the interviewees, the

relationships between each main factor and each sub-

factor have been thoroughly mastered, and the AHP

analysis method has been used to establish the

hierarchical analysis structure model for the research

objects.

3.2 Construct Judgment Matrix

The general hierarchical analysis method will divide

the goal of the decision, the factors to be considered

(decision criteria) and the object of the decision into

the highest, middle and lowest levels according to

their mutual relations, and draw a hierarchical

structure. The system only shows the goal of the

decision, the factors considered (decision criteria) and

the corresponding weight value of each factor.

Through the data sorting and analysis on the SPSSPO

platform, it can be seen in the table 3.

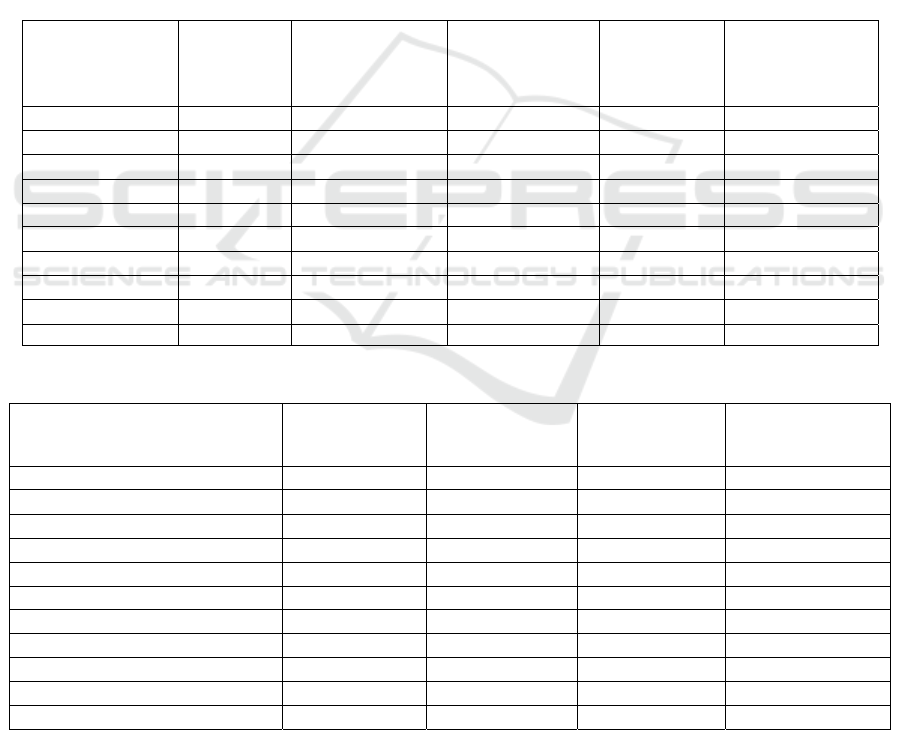

3.3 Check Consistency

The following table shows the CR value of the

judgment matrix constructed by each expert. The

second-order matrix does not need to judge the

consistency, and the third-order and above need to

judge the consistency. Consistency test results require

CR value less than 0.1, which is used to judge

whether there are logical errors in the construction of

judgment matrix. For example, there are three

indicators ABC, this paper judges that A is more

important than B, and B is more important than C, so

logically A is definitely more important than C, but if

C is more important than A when constructing

judgment A is more important than C, then this paper

has made a logical error. Failed the conformance test.

According to the table4, it can be judged that the CR

value of all experts is less than 0.01, so all the weights

can be used (table 4).

Table 3: Judgment Matrix.

Primary index

First-order

Index weight

Secondary index

Secondary index

weigh

Employee factor 8.919%

Labor market

p

rice 4.210%

Quality of the local

labor force

2.991%

Commuting distance 1.717%

Supply chain factors 53.747%

Market ca

p

acit

y

17.34%

Raw material origin

distance

5.956%

Traffic environment 5.975%

Lo

g

istics service level 4.619%

Land

p

rice 7.631%

Surroundin

g

facilities 5.014%

Energy costs 7.207%

Pollution factor 18.336%

Pollutant treatment 8.998%

Impact on the

surrounding communit

y

9.338%

Follow-up development and policy

factors

18.995%

Reserved space for

subse

q

uent develo

p

ment

4.473%

Local

p

olic

y

su

pp

ort 14.522%

MLSCM 2024 - International Conference on Modern Logistics and Supply Chain Management

40

3.4 Factor Weight Analysis

The matrix results of all experts are retained based on

parameters, and the criterion layer indexes of each

expert are weighted respectively. Finally, the

criterion layer weights of these experts are averaged.

The data components in Table 5 show that the 4 main

factors of layer B and the 14 sub-factors of layer C

have a significant impact on the feed mill location

decision, but the importance of the impact is different.

Among the four main factors in layer B, the intensity

of their influence is ranked from strong to weak as

follows: The weight ratios of supply chain factors,

pollution factors, subsequent development and policy

factors, and staff factors are 53.74759%, 18.3366%,

18.99592%, and 8.91989%, respectively, indicating

that the feed mill pays great attention to the factors

affecting its supply chain in the location decision.

Pollution and subsequent development and policy

factors also have a greater impact on feed plant

location decisions, while staff factors have a lesser

impact (see table 5).

4 CONCLUSION

In the study of feed plant location, AHP is an effective

method, which can help decision makers to weigh and

make decisions among many influencing factors.

According to the results of the study, the main site

selection factors in order from strong to weak are

supply chain factors, pollution factors, subsequent

development and policy factors, and staff factors.

Table 4: Summary table of CR values.

Specialist

Level 1 index

matrix

Level 2 indicator

matrix: employee

factor

Level 2 index

matrix: Supply

chain factors

Level 2 index

matrix:

pollution factor

Level 2 indicator

matrix: Follow-up

development and

policy factors

Specialist 1 0.086 0.011 0.018 - -

Specialist 2 0.020 0.093 0.012 - -

Specialist 3 0.010 0.004 0.056 - -

Specialist 4 0.092 0.093 0.071 - -

Specialist 5 0.010 0.080 0.045 - -

Specialist 6 0.048 0.098 0.033 - -

Specialist 7 0.068 0.004 0.052 - -

Specialist 8 0.007 0.004 0.017 - -

Specialist 9 0.007 0.091 0.041 - -

S

p

ecialist 10 0.023 0.049 0.015 - -

Table 5: Summary of factor weight values.

Specialist number Staff factor

Supply chain

factor

Pollution factor

Follow-up

development and

p

olicy factors

Specialist 1 10.103% 33.78429% 50.00634% 6.10551%

Specialist 2 9.907% 64.5359% 3.40134% 22.15482%

Specialist 3 10.849% 65.689% 10.492% 12.968%

Specialist 4 11.041% 66.852% 9.886% 12.219%

Specialist 5 6.507% 57.616% 13.986% 21.889%

Specialist 6 3.825% 64.670% 7.935% 23.567%

Specialist 7 19.966% 15.466% 43.044% 21.522%

Specialist 8 7.652% 62.231% 9.372% 20.743%

Specialist 9 4.794% 49.827% 16.609% 28.768%

Specialist 10 4.549% 56.800% 18.630% 20.019%

Average value 8.919% 53.747% 18.336% 18.995%

Study on Site Selection Factors of Feed Additive Factories

41

Supply chain factors are considered to be one of the

most important influencing factors. The location of

feed mills needs to take into account the availability

of raw materials and the distribution channels of

products. A stable feedstock supply chain and

efficient product distribution are critical to feed mill

operations. In AHP analysis, this factor may include

a comprehensive consideration of supplier reliability,

supply distance, transportation cost and other factors.

Secondly, pollution is listed as the second most

important factor. The production of feed mills may

involve environmental pollution issues, such as

wastewater treatment, noise, air quality, etc.

Choosing the right location and environmental

assessment is crucial to reducing potential

environmental impacts, which is also closely related

to the local government's environmental regulations.

And the subsequent development and policy factors

are considered to be the third influential factors.

These factors include expectations for future

development, local government development plans

and possible policies for new feed mills. The stable

policy environment and good development prospects

will provide favorable conditions for the long-term

operation of the feed mill. Finally, the employee

factor is listed as one of the least influential factors.

This factor involves the recruitment, training and

performance management of feed mill employees.

Although less influential in the AHP analysis, a

qualified staff team is equally critical to the proper

operation of the feed mill, especially in highly

automated and technology-intensive production

environments. In summary, the study of feed mill

location problem through AHP can effectively help

decision makers to clarify the priority and tradeoff

relationship of various influencing factors. In the

actual decision-making process, it is necessary to

comprehensively consider the specific situation of the

above factors, and flexibly adjust and weigh

according to the specific project characteristics and

local actual conditions. This method not only

improves the scientific and accurate decision-making,

but also lays a solid foundation for the long-term

successful operation of the feed mill. In the study of

feed plant location, AHP is an effective method,

which can help decision makers to weigh and make

decisions among many influencing factors.

According to the results of the study, the main site

selection factors in order from strong to weak are

supply chain factors, pollution factors, subsequent

development and policy factors, and staff factors.

REFERENCES

Asad, U., et al. 2024. Beyond bookshelves, how 5/6G

technology will reshape libraries: Two-stage SEM and

SF-AHP analysis. Technology in Society.

Gu, H.P., Lu, X.X., Chen, Y.H., 2015. Application of

Analytic Hierarchy Process in decision weight design

of medical equipment purchase. Compilation of papers

of the 15th National Annual Conference of Chinese

Medical Engineering Society, 235-239.

John, N., Saeid, J., 2024. GIS-based AHP model for

selecting the best direct use scenarios for medium to

low enthalpy geothermal resources with hot springs in

central and Western Kenya. Geothermics.

Kamran, J., et al. 2024. Drivers of municipal water security

and vulnerability in Pakistan: A case study of Mardan,

Khyber Pakhtunkhwa. Groundwater for Sustainable

Development.

Li, L.L., et al. 2017. Design of microbial fermentation feed

factory with an annual output of 200,000 tons. Light

Industry Science and Technology, 11, 19-21.

Li, W.B., et al. 2024. Quality management of construction

drawing design based on AHP-Management view

analysis. Project Management Technology, 3, 130-136.

Li, X.X., 2017. Main points of general plan and

architectural design of feed factory. Feed industry, 9-

16.

Liang, R.W., et al. 2008. Feed factory noise pollution

control. Contemporary Animal Husbandry, 8, 51-52.

Liu, H., 2005. Ten knowledge of selecting feed plant site.

Feed Wide Angle, 9, 41-42.

Nandi, D., et al. 2024. Geospatial analysis of groundwater

potential zones using GIS-based multi-criteria decision-

making AHP approach. Sustainable Water Resources

Management.

MLSCM 2024 - International Conference on Modern Logistics and Supply Chain Management

42