Research on Various New Technologies of Shuttle Tankers and Their

Optimization of Offshore Platform-Based Oil Supply Chain

Lixing Deng

a

College of Transport & Communication, Shanghai Maritime University,

1550 Hai Gang Avenue, Pudong New District, Shanghai, 200025, China

Keywords: Shuttle Tankers, Key Technology, Dynamic Positioning, Bow Loading, Lithium-Ion Battery.

Abstract: In December 2023, COSCO Shipping Heavy Industry Company's latest design project ‘Methanol Dual-Fuel

154,000 DWT Shuttle Tanker’ received the principle-based approval of multiple classification societies. As

a special type of ship, the shuttle tankers are always equipped with the latest shipping and loading technology.

This paper aims to analyse a series of shuttle tanker research projects undertaken by COSCO in recent years,

studying the innovative new technologies related to these projects such as Dynamic Positioning System,

which helps the ship stay steady in working position; Bow Loading System, which allow the ship to extract

the oil from offshore platform much more efficiently; And Lithium-ion Battery, which enables the ship to

reduce carbon emission. The paper will introduce the latest shuttle tankers of COSCO, then talk about the

fundamental diagram of those new technologies. After that, the paper will assess their positive effects on

offshore platform supply chains with data from its market performance, and propose constructive suggestions

for shipbuilding enterprises.

1 INTRODUCTION

Nowadays, Oil and gas produced by modern offshore

platforms are transported to terminal warehouses

before entering the market in a general sense. Due to

the lack of complete storage and docking systems on

offshore platforms, this transfer process significantly

relies on shuttle tankers which are technically

demanding and equipped with numerous complex

devices. These tankers, with their large carrying

capacity, complex structure and additional

technological systems such as cargo monitoring

system and dynamic positioning system, are very

costly. Therefore, maximizing the efficiency of

limited shuttle tankers, akin to buses shuttling back

and forth, in terms of vessel energy efficiency and oil

and gas transfer efficiency has become a worthy

operational research problem.

In recent years, China has applied various

advanced equipment and designs to shuttle tankers,

diversifying their application prospects. The question

now is-whether these new technologies can bring

considerable data benefits or even revolutionary

a

https://orcid.org/0009-0004-7049-5720

progress to offshore platform oil and gas supply after

thorough application.

This paper aims to introduce recent leading new

technologies in domestic shuttle tankers, such as the

latest dynamic positioning system and bow loading

system. By collecting relevant literature online,

learning about the operating principles of these

technologies, and analysing the changes they have

brought to the tanker market and offshore oil and gas

supply chain, the paper will identify which new

equipment and technological improvements have the

most significant positive effects on offshore platform

oil and gas supply. Based on this, the paper further

considers and proposes future trends in shuttle tanker

equipment development, providing inspiration for

daily research on the offshore oil and gas market.

In recent years, there have been numerous

documents studying technological innovations in

shipbuilding. Liu from Zhoushan China Ocean

Shipping Company Shipping Heavy

Industrysummarized (COSCO) the tanker design and

key technologies of his company several years ago

(Liu, 2019). Scholar Zhao studied the supply chain of

offshore platforms as a whole and obtained the

18

Deng, L.

Research on Various New Technologies of Shuttle Tankers and Their Optimization of Offshore Platform-Based Oil Supply Chain.

DOI: 10.5220/0013228400004558

In Proceedings of the 1st International Conference on Modern Logistics and Supply Chain Management (MLSCM 2024), pages 18-23

ISBN: 978-989-758-738-2

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

optimization strategies through mathematical

modelling (Zhao, 2015). Other scholars such as Xu

etc studied the dynamic positioning system of

COSCO shuttle tankers and proposed several

optimization schemes for the highest-level DP-3

dynamic positioning system (Xu, 2023). Scholar Li

introduced the composition of dynamic positioning

system of 152,000-ton shuttle tanker (Li, 2021).

Scholar Zhang etc studied a new oil loading and

unloading mode: the bow loading system. By

analysing the shortcomings of the systems on the

market, they attempted to propose their own new

horizontal bow loading system and presented various

innovative design points (Zhang, 2024). Chen and

other scholars focused on analysing the advantages of

the bow loading mode in oil extraction work in 2018,

when the bow loading method had not been widely

introduced in China (Chen, 2018). Moreover, scholar

Zhuang etc studied the detailed structure of bow

loading system and listed its typical shortage

(Zhuang, 2013). Zhang studied the design and

installation of gas detection system for shuttle oil

tankers (Zhang, 2024). Feng further studied the

compound energy storage of shuttle tanker and

discussed about their prospects, which includes the

latest lithium battery system (Feng, 2023).

2 COSCO SHUTTLE TANKERS

In March 2015, COSCO Shipping Heavy Industry

constructed the first 152,000-ton shuttle tanker of the

world-the RAQUEL KNUTSEN, with a total length

of 276.3 meters, a beam of 46 meters, a depth of 24.3

meters, a service speed of 14.5 knots, and a range of

22,000 nm. The ship is capable of operating in

unlimited navigation areas and is equipped with

adjustable pitch propellers for the main propulsion

system. To ensure dynamic positioning requirements

under different sea conditions, the ship is also

equipped with five lateral thrusters and retractable

full-rotatable thrusters in total at both bow and stern,

respectively. Its manipulation, speed, and fuel

consumption indicators are among the world's top

levels in similar vessels. This series of 152,000-ton

shuttle tankers, with high technological content and

complete intellectual property rights owned by

COSCO, can be considered the starting point for

recent technological innovations in domestic shuttle

tankers.

Since March 27, 2015, COSCO Shipping Heavy

Industry has continuously delivered four 152,000-ton

shuttle tankers to KNUTSEN of Norway. In

November 2021, COSCO Shipping Heavy Industry

completed the first 154,000-ton shuttle tanker of the

world-the N786 project, further strengthening its

cooperation with KNUTSEN in shuttle tanker orders.

Despite being built during the COVID-19 pandemic,

the ship still achieved a high level of design

completion, with successful trial operations of vessel

manipulation, navigation systems, DP systems, and

other functions. It also applied green ship

technologies such as reduced main engine power, hull

shape optimization, hull weight reduction design, and

energy-saving device installation, receiving high

praise from shipowners and ship inspections (Liu,

2019).

Although shuttle tanker orders from COSCO

Shipping Heavy Industry are relatively scarce due to

their high technological content, a series of

technological accumulations have gradually borne

fruit. As China's national tanker brands go global,

China's offshore platforms will gradually begin to

operate with domestically produced shuttle tankers.

3 INNOVATIVE TECHNOLOGIES

3.1 Dynamic Positioning System

The Dynamic Positioning System (DPS), also known

as the DP system, refers to a system that utilizes the

vessel's own power to overcome external interference

forces, enabling the vessel to automatically maintain

a certain position (fixed position or preset track). Due

to the sharp increasing demand for modern offshore

operations, the dynamic positioning technology

which enables vessels to maintain a fixed berthing

position in various complex sea conditions, was born

in the 1970s. Its basic principle is to collect wind

waves and sea current-related parameters through

advanced sensors and input them into the computer to

calculate the vessel's movement state which is

affected by sea conditions. Then, it controls the thrust

of propellers and the positions of rudders and

propellers at various locations of the hull to offset the

impact, achieving the purpose of maintaining vessel

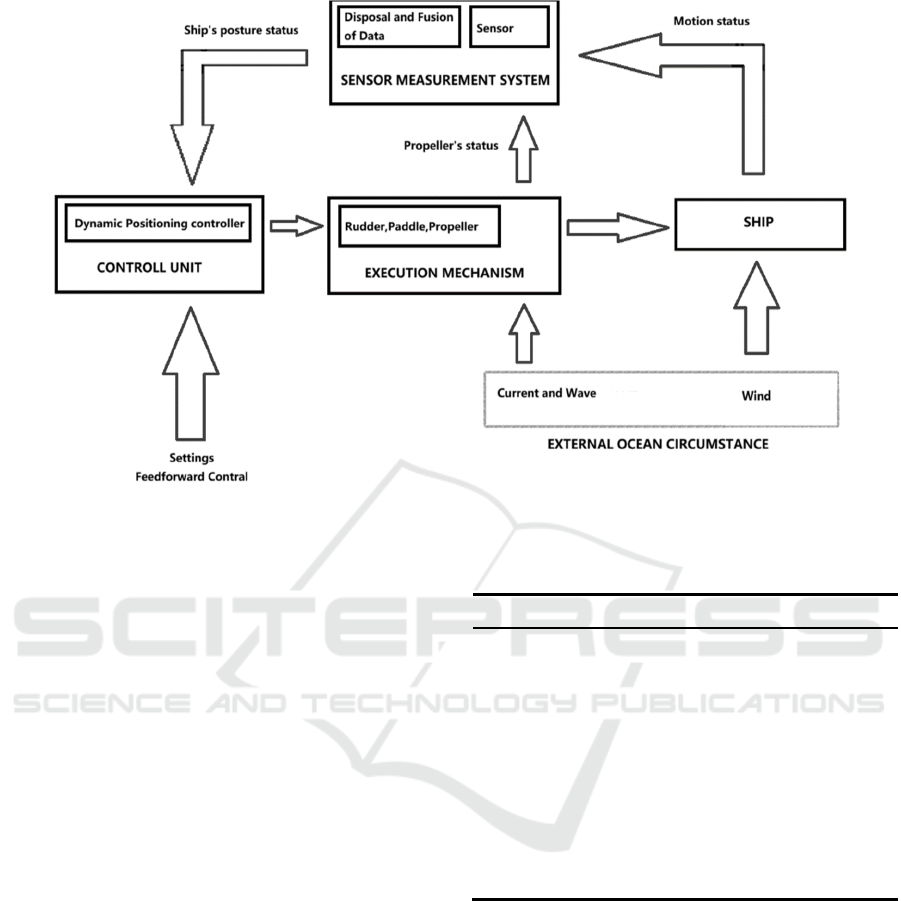

stability. Figure 1 shows the operation diagram of the

dynamic positioning system. A dynamic positioning

system installed on a vessel can be divided into three

parts: measurement, control, and execution.

Research on Various New Technologies of Shuttle Tankers and Their Optimization of Offshore Platform-Based Oil Supply Chain

19

Figure 1: Basic operating principle diagram of dynamic positioning system (Li, 2021).

With the development of ship control systems and

automation technology, the stability of dynamic

positioning systems has been continuously improved.

Nowadays, dynamic positioning systems are

classified into three levels named DP-1, DP-2, and

DP-3 according to their performance (Jiang, 2018). In

2011, the "CNOOC 201", a deepwater pipelaying

crane ship subject independently developed and

constructed by Rong Sheng Heavy Industries with

investment from China National Offshore Oil

Corporation, was launched. This was the first deep-

sea operation vessel with DP-3-level dynamic

positioning capabilities of the world, marking China's

leading position in the technical level of dynamic

positioning systems. Several years later, the 152,000-

ton shuttle tanker series produced by COSCO

Shipping Heavy Industry was fully equipped with

DP-3-level dynamic positioning. The ship is

equipped with six power generation auxiliary engines

to power the thrusters, along with a new single-point

fault-tolerant design of dual-redundant controller

units and high-precision error estimation using an

extended Kalman filter. The dynamic positioning

capability of this ship is such that, under conditions

of a wave height of 5m, wave period of 8.6s, wind

speed of 20.5m/s, and current speed of 1.1m/s, it can

still maintain the angle between the ship and the wind

and current within 20° in the worst-case scenario,

even when one set of equipment or system fails. The

detailed classification of dynamic positioning

capability can be consulted in Table 1.

Table 1: The Classifications of DNV for DP system. (Jiang,

2018).

Classifications Function standards

DYNPOS(AUTS) No equipment redundancy.

Automatically maintaining ship

p

osition

DP-1 Equipped with thrust remote-

control backup and position

reference backup. Automatically

maintainin

g

the shi

p

's

p

osition.

DP-2

It has redundancy in technical

design. Automatically maintains

the

p

osition of the shi

p

.

DP-3

It has redundancy in practical use.

Automatically maintaining the

ship's

p

osition.

3.2 Bow Loading System

As an oil tanker that travels between terminals and

offshore platforms, its oil loading process also

features advanced design. Shuttle tankers generally

adopt external hoses for loading and unloading oil,

with bow loading being the most advanced method.

Unlike the traditional midship loading method

commonly used in oil extraction in the South China

Sea, the bow loading system transfers the towing

hawser and the guide line of the oil hose to the shuttle

tanker simultaneously during the process of reeling in

the hawser to the shuttle tanker. After the friction

chain of the mooring hawser is locked on the chain

MLSCM 2024 - International Conference on Modern Logistics and Supply Chain Management

20

stopper, the guide line of the hose can be guided to

the dedicated winch and the oil hose can be

transferred immediately

(Zhang, 2024), reducing the

excessive frequent contact loss of the external long

hose and reducing maintenance costs. At the same

time, the special winch at the bow of the shuttle tanker

can get rid of manual operations, and be remotely

controlled through mechanical means. It also has a

safety emergency release mechanism that midship

loading lacks. Both safety and docking efficiency

have been significantly improved (Chen, 2018).

Currently, the shuttle tankers produced by

COSCO Shipping Heavy Industry have not fully

applied bow loading in their loading system. After

investigation, it is found that the standard bow

loading system equipment costs about 30 million

yuan, has a long order lead time, and is affected by

the shipping cycle. The retrofit cycle is about half a

year, making it difficult to retrofit old ships. The

standard bow loading mode requires adding a new

deck to the original deck, placing a series of mooring

system equipment on the upper part of the new deck,

and placing oil hose auxiliary equipment on the lower

part of the new deck. This mode centrally lays out the

oil pipeline, requiring high land occupation,

suspending the oil hose, and making docking

difficult. However, it is convenient for equipment

inspection and maintenance. Nowadays, COSCO

Shipping Heavy Industry's technology is gradually

upgrading. The recently launched N787 project, the

world's largest shuttle tanker "NS Pioneer", is

equipped with multiple advanced technologies

including the bow loading system. At the same time,

in order to break the monopoly of foreign MacGregor

companies in the manufacturing of bow loading

systems, COSCO's independently developed new

bow loading system project has also been put on the

agenda.

3.3 Lithium Battery System

Lithium-ion battery (li-ion batteries for short) is a

secondary battery that uses lithium-containing

compounds as the positive electrode and achieves

charging and discharging through the embedding and

de-embedding of lithium ions between the positive

and negative electrodes of the battery during the

charging and discharging process. Compared with

traditional batteries, lithium batteries have higher

energy density, larger charge-discharge rate, simpler

maintenance, and longer lifespan. Relying on lithium

batteries, large-scale machinery such as ships can use

electricity as a new energy source on a large scale. In

ships, a li-ion battery energy storage system can

effectively assist the ship's auxiliary generator. It can

serve as a supplementary power source to replace the

generator for energy supply in emission-restricted

areas, and it can fully absorb excess electricity

generated by the generator in non-emission-restricted

areas. When there is a temporary high-power demand

for the load, the li-ion battery can effectively alleviate

the power pressure of the generator through

discharging.

In recent years, the IMO's energy conservation

and emission reduction targets have become

increasingly stringent, which has also forced the

shuttle tanker market to choose vessels with lower

emissions. Therefore, COSCO Shipping Heavy

Industry has been adopting the highest standards of

green and environmentally friendly design to produce

new ships, and li-ion battery energy storage systems

have been widely used in the latest 154,000-ton series

of shuttle tankers. Due to the special nature of shuttle

tanker operations, their energy consumption during

navigation accounts for a relatively small proportion,

but their energy consumption during frequent port

calls and berthing at sea accounts for a larger

proportion. Therefore, the energy-saving benefits of

auxiliary engines are greater than those of main

engines. Li-ion battery energy storage systems can

meet these needs and effectively improve the

economy and environmental protection of engines.

Assuming that the shuttle tanker operates 50 voyages

annually on average, with 15 hours of dynamic

positioning operation during each oil loading cycle,

the configuration of three sets of 420 kW/h lithium

battery packs can reduce the operation of one

generator (capacity of about 4MW) for 750 hours per

year. This can significantly save fuel consumption,

extend the service life of diesel generators, and

provide convenience for operation and maintenance.

However, as part of the composite energy storage

system of shuttle tankers, the li-ion battery system

still has room for optimization in terms of discharge

capacity, energy storage service life, and performance

under different temperature environments (Feng,

2023).

4 MARKET PERFORMANCE

In the first cooperation with the shipowner of

Norway's KNUTSEN-the world's second largest

shuttle tanker operator and the earliest customer of

old shuttle tankers, four 152,000-ton shuttle tankers

and five 154,000-ton shuttle tankers have been

delivered, and another six orders for 154,000-ton

shuttle tankers are still in progress. It is estimated that

Research on Various New Technologies of Shuttle Tankers and Their Optimization of Offshore Platform-Based Oil Supply Chain

21

the unit price of each tanker can reach about USD 100

million, which is approximately RMB 719 million.

From January to September 2023, as one of the

important shipbuilding clusters in China, the total

profit of Zhejiang's above-scale shipbuilding

enterprises reached RMB 2.55 billion, and the

profitability of the industry hit a new high since 2009.

Among them, the shuttle tankers, which represent the

high-end shipbuilding industry, contributed 28% to

the profit with only one 154,000-ton order. This series

of oil tankers, which are completely independently

developed, designed and built, are qualified to be

classified by Det Norske Veritas (DNV), completely

breaking the market monopoly of Europe, America

and South Korea.

5 OPTIMIZATION OF SUPPLY

CHAIN

The advancement in shuttle tanker manufacturing

technology also provides inspiration for the offshore

platform supply chain in the South China Sea.

Offshore oil and gas fields are production lines for

petroleum products manufacturing, which differ from

conventional oil fields in terms of their heavy reliance

on vessels for transportation and limited production

space. Under such conditions, the manipulation,

speed, and fuel consumption of China's oil tanker

hulls are among the world's leading levels in their

respective categories, thus playing a leading role in

the construction of oil and gas supply chains.

Dynamic positioning and float-over installation

technology can be applied to offshore platform

installation, and research has begun on new bow

loading systems suitable for the operating

environment in the South China Sea. However, the

cutting-edge technology centres around li-ion

batteries, which use lithium-containing compounds as

the positive electrode and achieve charging and

discharging through the embedding and de-

embedding of li-ion between the positive and

negative electrodes during the charging and

discharging process. Compared with traditional

batteries, Li-ion batteries have higher energy density,

higher charge and discharge rates, simpler

maintenance, and longer life. Relying on Li-ion

batteries, large-scale machinery such as ships can use

electricity as a new energy source on a large scale. In

ships, a li-ion battery energy storage system can

effectively assist the ship's auxiliary generator,

serving as a supplementary power source to replace

the generator in emission-restricted areas, while fully

absorbing excess power generated by the generator in

non-restricted areas. When there is a temporary high-

power demand from the load, the Li-ion battery can

effectively alleviate the power pressure on the

generator through discharging, which can

significantly reduce the voyage cost of the shuttle

tanker.

6 CONCLUSION

According to the paper, shuttle tanker construction is

becoming more and more complicated nowadays to

involve the latest technologies mentioned above

while the proceeding trend of optimizing oil supply

chain is also getting bloom. In the view of shipping

market where the shuttle tanker remains unexpected

part of offshore platform-based oil supply chain,

technologies applied in shipbuilding have their

potentials. Besides, the author can also learn that

there is still room for improvement in adaptability.

For example, the 152,000-ton series equipped with a

bow loading system suffers from a bow-down

phenomenon, which necessitates reducing the cargo

capacity by adding ballast water to the stern.

Therefore, innovative design in ship types can be

explored to address the weight distribution issue.

However, when designing new ship types, it is

necessary to solve the problem of excessive fuel

consumption and reconfigure the dynamic

positioning system. As a high-end vessel type, it is

evident that efficiently integrating innovative

technologies on shuttle tankers remains a challenging

task for Chinese shipbuilding enterprises.

REFERENCES

Chen, D., Zhao, X., 2018. Exploring the advantages of bow

loading mode in oil extraction operations. Navigation,

2018 (06): 47-50.

Feng, L., Tang, X., Yuan, C., 2023. Development Status

and Prospects of Composite Energy Storage

Technology for New Energy Ships. Journal of Harbin

Engineering University, 2023, 44 (09):1453-1464.

Jiang, C., An, Z., 2018. Application research of dynamic

positioning shuttle oil tankers in offshore marginal oil

field transportation. Tianjin Science and Technology,

2018, 45 (02): 44-46.

Liu, Q., 2019. Research and Industrialization of Key

Technologies for the Design and Construction of

Shuttle Tankers. 2019 (11): 38-40.

Li, J., 2021. Analysis of the Dynamic Positioning System

of a 152000 Heavy Duty Shuttle Oil Tanker. Ship and

Ocean Engineering, 2021, 37 (05): 56-59.

MLSCM 2024 - International Conference on Modern Logistics and Supply Chain Management

22

Xu, D., Yu, H., Zhang, W., 2023. Research and evaluation

test methods for ship dynamic positioning systems.

Automation Application, 2023, 64(17): 191-193.

Zhao, X., 2015. Allocation and Route Optimization for

Shuttle Tanker. Dalian Maritime University.

Zhang, S., Dong, Y., Dong, Y., 2024. Design and research

on a new horizontal bow loading system for shuttle oil

tankers. Tianjin Science and Technology, 2024, 51 (04):

31-35.

Zhang, J., 2024. Design and installation of gas detection

system for shuttle oil tankers. China Shipyard Repair,

2024,37 (01): 37-40.

Zhuang, J., Wu, J., Wang, Z., 2013. Analysis of the bow

loading system for shuttle oil tankers. Ship Materials

and Market, 2013, 46 (05): 28-30+34.

Research on Various New Technologies of Shuttle Tankers and Their Optimization of Offshore Platform-Based Oil Supply Chain

23