Implementation of Bigdata Techniques in Supply Chain

Management: Evidence from Predictive Analytics

Fanrong Liu

Eurasia Internation School, Henan University, Kaifeng, China

Keywords: Bigdata Analysis, Supply Chain Management, Risk Management.

Abstract: Supply chain management (SCM) is changing as a result of several technologies that are propelling significant

digital trends. Numerous supply chain situations, such as demand forecasting, supplier management, risk

management, transportation management, and sales and marketing analysis, make use of big data analytics.

Supply chains are changing as a result of big data analytics breakthroughs that enable these connections. This

study summarizes the progress with an emphasis on the supply chain's two modules of risk management and

prediction analysis. In addition to analysing the tenets and outcomes of big data analysis technology in these

two connections, this article highlights the significance of predictive analysis and risk management modules

in supply chains. This research delves into the difficulties that predictive analytics and risk management

encounter while utilizing big data analytics, as well as the future prospects. Overall, these results offer a

synopsis of the constraints and potential applications of big data analysis in the two fields.

1 INTRODUCTION

Oliver and Webber made their original proposal for

supply chain management (SCM) in 1982. Supply

chain challenges are getting more and more

complicated in today's globalized world, where there

is an increasing need for innovation, diversity in

products, and offshore manufacturing. International

material and financial flows, foreign policy,

responsibility for society, economic dangers, and

other intricate processes are among these complicated

frameworks. In this case, SCM continues to be an area

that requires substantial scholarly attention (Yalcin,

Shi & Rahman, 2020). Over the past ten years, the

supply chain has seen a significant transformation,

evolving from a merely operational function to an

autonomous supply chain management function. The

supply chain management role now prioritizes

sophisticated planning techniques including

analytical demand planning; ensure sure that supplier

and customer operations are connected. Furthermore,

partner cooperation and trust are highly valued in

supply chain management (Attaran, 2020).

Businesses have been driving the development of Big

Data Analytics (also known as BDA) for supply

chains (SC) over the past few years because of the

increasing demand in big data. The goal of SC is to

obtain valuable information that will improve their

ability to estimate, anticipate, and identify hidden

patterns—all of which will increase their

competitiveness. This most recent development

offers companies fresh chances to develop new trade

patterns and improve current operations, which will

help the market but also present unforeseen

difficulties (Chehbi-Gamoura et al., 2020).

SCM unifies supply and demand management

both within and between businesses. The supply

chain management process begins with the purchase

of raw materials. The product manufacturer's supplier

obtains the raw ingredients. The manufacturer

provides the finished product after refining the raw

material. The product's distribution is beneath the

distributor's control. Customers usually purchase

things from merchants, while retailers get these

products from wholesalers (Taj et al., 2023). Superior

supply chain performance has strategic importance

since it can result in quick financial gains, increased

earnings and productivity, and advancements in

important worldwide competitive advantages. The

impact of the digital economy on supply chains is

significant. The digital economy, which conducts

commercial activity both online and on mobile

devices, is built on electronic computing technologies.

In this economy, connections between individuals,

devices, channels, and organizations, all made

Liu, F.

Implementation of Bigdata Techniques in Supply Chain Management: Evidence from Predictive Analytics.

DOI: 10.5220/0013208100004568

In Proceedings of the 1st International Conference on E-commerce and Artificial Intelligence (ECAI 2024), pages 143-147

ISBN: 978-989-758-726-9

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

143

possible by technology, create value. Customers

explore and purchase products using digital channels

like social media, mobile networks, and e-commerce.

Customers can purchase whenever and wherever they

choose, tailor their requirements to their

specifications, and anticipate delivery in a few days.

Businesses are able to get real-time data about the

locations, products, and methods of consumers'

purchases, and customized product delivery is

starting to spread over the world. The transformation

of traditional supply networks is imperative in the

digital age. Important components of supply chain

operations are currently digitizing more quickly.

Innovation and technology are two major aspects

influencing how the supply chain is evolving. With

the use of contemporary technologies like big data,

the cloud, IoT, and sophisticated computing driven by

algorithms that utilize machine learning, intelligent

digital models of supply chains are being produced.

These technologies are starting to replace traditional

supply chain structures. Shorter response times,

increased collaboration, improved visibility, and

better insight are all made possible by this new digital

supply chain (Attaran, 2020).

Big data analytics techniques can be used to

analyse the data gathered by numerous businesses in

order to create business growth plans, forecast market

instructions and simulate the manufacturing process,

optimize delivery, manage inventory, reduce risk, and

carry out numerous additional supply chain tasks like

marketing and sales procedures. In the framework of

big data technology, this article examines the

pertinent uses of risk management and predictive

analytics in the supply chain and offers opinions on

their drawbacks and future directions. The application

scenarios of SCM and big data technology are

introduced in the second section. The theory and

findings of the supply chain prediction analysis are

presented in the third section. An introduction to risk

management application is provided in the fourth

section. Lastly, an analysis is conducted regarding

these two application scenarios' future development

and constraints. This work began the literature review

by searching electronic databases, such as

ScienceDirect and Google Scholar, among others.

Using different keyword combinations such as "risk

management," "supply chain management,"

"predicting analytics," "applications," and "positive

effects" ensures a comprehensive search of academic

journals, conference proceedings, and related

publications.

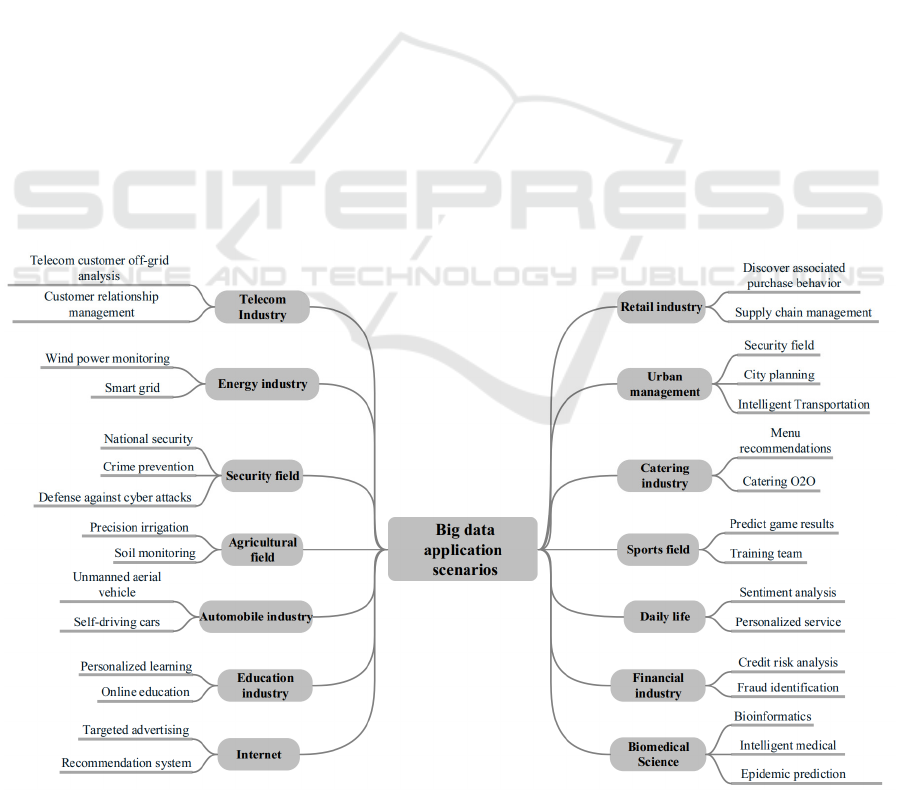

Figure 1: Big data application scenarios (Wang et al., 2020).

ECAI 2024 - International Conference on E-commerce and Artificial Intelligence

144

2 DESCRIPTIONS OF BIGDATA

The advent of big data, one of the key themes of this

century, is a result of recent information technology

advancements. Big data, describes the practice of

businesses gathering vast volumes of data from

various sources. This data is analyzed by

sophisticated computer systems to provide business

insights that can boost the organization's

productivity(Albqowr et al., 2024).

Big data technologies can advance scientific

research and increase production efficiency.

Innovative algorithms are needed to tackle certain

difficult and complex jobs that are outside the scope

of conventional methods. Big data technology has

permeated every area of people's life and been used

in a wide range of sectors (including energy, sports,

entertainment, banking, Internet, catering, and

healthcare). Fig. 1 illustrates how big data is used in

a variety of sectors. (Wang et al., 2020) The ideas and

outcomes of pertinent application scenarios of risk

management and predictive analysis in the context of

big data in the supply chain will be the main topics of

this presentation.

3 PREDICTIVE ANALYTICS

The application of statistical algorithms, machine

learning, and data mining approaches to historical

data analysis and future event or trend prediction has

been referred to as predictive analytics. Predictive

analytics offers a proactive solution to supply chain

management (SCM) problems such inventory control,

supply chain interruptions, and fluctuating demand

(Oyewole et al., 2024). Early supply chain

management (SCM) predictive analytics research

concentrated on simple forecasting techniques that

relied on historical data and employed

straightforward statistical models for computations.

More advanced predictive analytics methods have

been developed as a result of improvements in

processing power and data storage. Understanding the

fundamental terms and concepts is crucial to

comprehending the predictive analytics environment

in supply chain management. Machine learning, data

mining, and predictive modeling are essential

elements. The predictive analytics environment

inside SCM is depicted in the Fig. 2.

Figure 2: Predictive analysis environment.

The application of predictive analytics in the

supply chain visibility, inventory management, and

demand forecasting domains of supply chain

management (SCM) has been the subject of numerous

research that have looked at its practical ramifications.

These domains range from more conventional

statistical methods to more sophisticated artificial

intelligence (AI) and machine learning algorithms.

These studies offer insightful information about

applications that are successful, difficulties

encountered, and the overall effect on supply chain

performance. Utilizing past data, current market

conditions, and outside variables, predictive analytics

creates complex models that increase the precision of

demand projections. These models can optimize

inventory levels, predict changes in client demand,

and streamline production procedures. Accurate data

integration and information exchange improve supply

chain performance by lowering inventory and

squeeze, improving demand visibility, and reducing

inventory. One of the most important components of

an efficient supply chain is inventory management

optimization. Analytics that predict Determine the

ideal inventory levels by looking at lead times, past

sales information, and outside variables that impact

demand. Organizations can use sophisticated

algorithms to find patterns and connections that help

them decide on order quantities, safety stock levels,

and stock replenishment. A primary advantage of

implementing predictive analytics is enhanced

visibility across the whole supply chain. Predictive

analytics provides firms with information on supplier

performance, the efficiency of their transportation,

and general logistics management, enabling real-time

tracking of critical supply chain indicators.

Simultaneously, the elasticity of the supply chain

and overall efficiency are enhanced by the control of

potential hazards. Estimating future demand, optimal

utilization of inventory, and supply chain

transparency are just a few real-world examples of

how predictive analytics can revolutionize supply

chain management processes. These applications,

which demonstrate the significant advantages of

predictive analytics in SCM processes, are not merely

Implementation of Bigdata Techniques in Supply Chain Management: Evidence from Predictive Analytics

145

theoretical ideas; rather, they are supported by actual

data and real-world instances.

4 RISK MANAGEMENT

Any supply chain that has to make decisions while

dealing with uncertainty does so in part by using a risk

management strategy. Information ignorance is the

source of risk, and many risk factors (e.g., COVID-

19), are uncontrollable by humans, but big data

analytics may help us create a robust supply chain

system that can strengthen the information system

and reduce risk (Araz et al., 2020). Big data analytics

can generally be used to protect against hazards

associated with shipping, default between merchants

and suppliers, dangerous chemicals during the

connection between recyclers and remanufacturers,

and environmental harm (Ghalehkhondabi et al.,

2020).

Risks in supply chain management (SCM) include

globalization, shorter product life cycles, demand

forecasts, cost pressures, outsourcing, and offshore.

The business environment is become more uncertain

as a result of the increasing complexity of SCM and

networks. These are supply chain risk events that

have an impact on the network as a whole. An

indication of a potential disruption to the supply chain

is a risk event. Global supply chains are more

vulnerable to risk and confront several obstacles.

Increased openness and information exchange

amongst supply chain actors are necessary for this.

Globalization and nations' economic interactions with

partner nations have altered global production

methods. Each of these raises the supply chain's risk

and complexity. Distribution centers are another

name for distribution centers in contemporary global

supply networks. The needs of buyers are fulfilled at

the operations center. Because their effectiveness

influences the overall SCM value, these centers must

be efficient. Pay close attention to how the disaster

affects the supply chain and make sure it has an effect

on operational performance as well. In the current

global marketplace, supply chain interruptions and

the related risks to operations and finances are among

the most urgent problems affecting rival businesses.

Still, there's a distinction between danger and

disruption. An indication of supply chain risk is

disruption. However, the risk is still remained

unaffected (Gurtu & Johny, 2021).

5 LIMITATIONS AND

PROSPECTS

Supply chain management is now much more

efficient thanks to big data analysis. Although supply

chain management can benefit greatly from

predictive analytics, there are certain drawbacks to its

application. First, historical records provide the data.

Inadequate historical data can have an impact on how

well predictive analysis works. The second issue is a

compatibility issue brought on by predictive analysis

tool upgrades. It will be possible to thoroughly

examine how the forecasting tool improvement

affects the forecasted results in the future.

There are also restrictions on this paper's use of

risk management. This document only chooses a

small number of key phrases; an article may go

unresearched if it does not have the word "risk" in its

title, keyword, or abstract. Further research on

particular under- or undiscovered areas can be

conducted using the summary results of this paper. It

is anticipated that this study of the literature will help

scholars investigate supply chain risk management

(SCRM) more thoroughly. The way supply chains

function across industries will continue to change as

a result of these applications. Supply chains will

depend more and more on big data analytics as

technology continues to change the world around us.

This will increase the reliance of these networks on

ubiquitous digital information at every link. Big data

analytics will play a significant role in the ongoing

development and improvement of the supply chain. It

may also provide solutions to the various issues that

various sectors are facing as a result of market trends.

The foundation of the world economy, supply chains

promote trade, consumption, and growth in the

economy.

6 CONCLUSIONS

To sum up, the foundation of the world economy,

supply chains promote trade, consumption, and

growth in the economy. The rapid advancement of

modern information technology has made data an

essential basis for the development of manufacturing

supplies and techniques. In this study, the architecture

of big data services, some existing big data

application scenarios, and predictive analytics based

on big data and risk management services are

analysed. This study first provides an overview of the

history, state of development, and future prospects of

SCM. The big data analysis technology and its

ECAI 2024 - International Conference on E-commerce and Artificial Intelligence

146

application scenarios are then briefly introduced.

Next, this study presents the use of big data in two

supply chain components: risk management and

predictive analytics. This study concludes by

summarizing the drawbacks and potential

applications of big data analysis to these two areas.

REFERENCES

Albqowr, A., Alsharairi, M., Alsoussi, A., 2024. Big data

analytics in supply chain management: a systematic

literature review. VINE Journal of Information and

Knowledge Management Systems, 543, 657.

Araz, O. M., Choi, T. M., Olson, D. L., Salman, F. S., 2020.

Data analytics for operational risk management. Decis.

Sci., 516, 1316.

Attaran, M., 2020. Digital technology enablers and their

implications for supply chain management. Supply

Chain Forum: An International Journal, 21(3) 9258-172.

Chehbi-Gamoura, S., Derrouiche, R., Damand, D., Barth,

M., 2020. Insights from big Data Analytics in supply

chain management: an all-inclusive literature review

using the SCOR model. Production Planning Control,

315, 375.

Ghalehkhondabi, I., Ahmadi, E., Maihami, R., 2020. An

overview of big data analytics application in supply

chain management published in 2010-2019. Production,

30, e20190140.

Gurtu, A., Johny, J., 2021. Supply chain risk management:

Literature review. Risks, 91, 16.

Oyewole, A. T., Okoye, C. C., Ofodile, O. C., Ejairu, E.,

2024. Reviewing predictive analytics in supply chain

management: Applications and benefits. World Journal

of Advanced Research and Reviews, 213, 568-574.

Taj, S., Imran, A. S., Kastrati, Z., Daudpota, S. M., Memon,

R. A., Ahmed, J., 2023. IoT-based supply chain

management: A systematic literature review. Internet of

Things, 24, 100982.

Wang, J., Yang, Y., Wang, T., Sherratt, R. S., Zhang, J.,

2020. Big data service architecture: a survey. Journal

of Internet Technology, 212, 399.

Yalcin, H., Shi, W., Rahman, Z., 2020. A review and

scientometric analysis of supply chain management

SCM. Operations and Supply Chain Management: An

International Journal, 132, 123.

Implementation of Bigdata Techniques in Supply Chain Management: Evidence from Predictive Analytics

147