Blockchain Technology in Banana: An Experience from FPO

Farmers

Janaki Rani A

1a

, Murugan P P

2,* b

, Arunkumar R

1c

, Seevagasinthamani R

1d

and N. Hariraj

1e

1

Department of Agricultural Extension & Rural Sociology, Tamil Nadu Agricultural University,

Coimbatore, Tamil Nadu, India

2

Extension Education, Tamil Nadu Agricultural University, Coimbatore, Tamil Nadu, India

Keywords: Block Chain, Traceability, QR Code, Supply Chain, Consumers.

Abstract: Block chain technology ensures food safety and quality for customers while streamlining operations for

stakeholders by improving supply chain transparency, traceability, and efficiency. Since consumers are

looking for food sources that are more dependable and transparent, it is critical to integrate cutting-edge

technologies to maintain the integrity of the agricultural supply chain. In Tamilnadu, Block chain technology

has been used to banana farms, giving the fruit a digital identity and optimizing its value chain—that is, how

it is grown, processed, and sold to customers. After the fruits are collected, they are packaged in boxes, and

each batch has its own QR code. The creation and consumption of a banana are re-enacted via the QR code.

The banana boxes are delivered to nearby marketplaces and are also exported. The implementation of block

chain technology in the banana supply chain transforms the industry by providing a secure, transparent, and

efficient platform. This not only addresses consumer concerns about food safety and quality but also brings

operational benefits to farmers, distributors, processors, and retailers

1 INTRODUCTION

Block chains are a kind of database that often hold

data that can be accessed by scanning a QR code.

Blockchain technology has been applied to solve

problems in many different industries. However,

Abeyratne and Monfared (2016) noted that because

they have responsible shopping habits, customers

today demand the supply chain to be more transparent.

Block chain is being utilized in agriculture to record

each growing stage of agricultural products that are

difficult to modify, therefore speeding up transactions

and improving food safety. Consumers are better

equipped to understand the social and environmental

implications of the products they buy when the origin

and production process of the product are transparent.

Maintaining an open dataflow throughout the

supply chain has proven to be quite challenging in

a

https://orcid.org/0009-0000-0683-1022

b

https://orcid.org/ 0000-0003-4232-1876

c

https://orcid.org/ 0000-0001-5580-5170

d

https://orcid.org/0009-0007-3269-785X

e

https://orcid.org/ 0009-0005-3006-2952

*

Corresponding author

focus should be placed on the political and scientific

agri-food value chains, nevertheless and greater

agendas (Abeyratne & Monfared, 2016). Especially

considering that supply chains are become

increasingly opaque and complex due in part to

globalization (Baker & Steiner, 2015). In an effort to

increase supply chain transparency, products are being

handled by new tracking technologies (such RFID,

GPS, GIS, and NFC) more and more in product chains

(Thiruchelvam et al., 2018). With the aid of these

technologies, stakeholders can store, share, and access

product data within centralized data management

systems tailored to their particular industries

(Abeyratne & Monfared, 2016; Meyer et al., 2009).

The data will give information on the

manufacturer, production process, means of storage,

and modes of transit of the goods. As a result, it can

be used to assess how a product affects the

A, J. R., P, M. P., R, A., R, S. and Hariraj, N.

Blockchain Technology in Banana: An Experience from FPO Farmers.

DOI: 10.5220/0012886000004519

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Emerging Innovations for Sustainable Agriculture (ICEISA 2024), pages 161-167

ISBN: 978-989-758-714-6

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

161

environment and society. Furthermore, as customers

demand more ethical industrial practices, the

significance of ensuring that these obligations related

to social and environmental responsibility are fairly

assessed is growing (Fowler, 2017). Information

asymmetries between data copies are made possible

by the current supply chain management techniques,

while every participant produces a portion of the

product data. Data is updated and accessible by

various stakeholders across various software

platforms and information management systems as

products move through the supply chain. According to

Mattila et al. (2016), this can cause data to become

erroneous or out-of-date, which reduces transparency

and produces less-than-ideal outcomes throughout the

supply chain. Because it necessitates chain-wide

monitoring, the verification of certification criteria is

already an expensive and time-consuming operation.

These discrepancies in product information make it

even more perplexing.

Furthermore, certification procedures regarding

the effects on society and the environment are less

credible due to the inequalities. This is particularly

valid for the labeling of products manufactured in

countries that are prone to corruption (Abeyratne &

Monfared, 2016). In the context of certification

programs like Fairtrade, a decentralized data system

developed on the block chain technology creates

greater potential for verification by enhancing the

transparency and traceability in nearby future. (White,

2017A consensus-based cryptographic protocol

enables all parties participating in BT to exchange and

store transaction data without the requirement for

middlemen (Risius & Spohrer, 2017). According to

Verhoeven et al. (2018), this can save costs, increase

processing speed and quality, and lessen

administrative labor and data mistakes. It creates the

opportunity to follow or retrace a product from

manufacturer to consumer along the entire supply

chain (Baker & Steiner, 2015). This could cover the

full supply chain or the effects of production on the

environment and society.

This way, for instance, consumers or other

stakeholders can confidently verify that a product has

the carbon footprint disclosed on its packaging.

Customers that purchase Fairtrade certified goods do

so at a higher cost, but in exchange, they are assured

that the goods are made in socially and

environmentally responsible ways (Shreck, 2002).

Therefore, as BT would lend credibility to a

certification label and maybe increase chain

efficiency, it could be advantageous for both

conventional commodity supply chains and fair trade

certified ones.

According to Awaysheh & Klassen (2010),

increased supply chain openness encourages suppliers

to adopt socially conscious business practices, which

in turn affects customer purchasing decisions.

Moreover, BT may serve as a marketing platform for

certification programs to guarantee that customers are

making informed purchases felt by Galvez et al., 2018.

To be more precise, this would mean that vendors and

buyers could swiftly assess all pertinent product

information, learning more about the history of a

product.

The abundance of nutrients and minerals found in

bananas makes it one of the main staple crops

consumed in India. Society is very concerned about

the integrity and quality of bananas during their

growth. Every step in the banana fruit's growing

process is essential. Because banana fruit quality is

dependent on how well it is supervised throughout its

whole growth cycle, fruit protection is essential from

the planting stage to the marketing stage.

Negative effects of banana cultivation, such as

increased water use, biodiversity loss, and

environmental degradation, put strain on modern

banana supply chains (Roibás et al., 2015; Worobetz,

2000). Additionally, the unequal distribution of

income from the profits of the banana trade was

created by social inequality amongst stakeholders

along the supply chain (Fairtrade Foundation, 2014;

Roibás et al., 2015; Shreck, 2002). Produced in more

than 135 tropical and subtropical nations, bananas are

one of the important and most traded among the fruits

in the world, with a $52 billion total commercial value

(Kema & Drenth, 2018 of the whole crop, Eighty-five

percent is consumed on the continent, with the

remaining portion being transferred to nations with

less hospitable growing conditions (Fair trade

Foundation, 2009). Notwithstanding, the Fairtrade

Foundation (2009) notes that there is limited capacity

for investing in sustainability enhancements because

to the low retail expenses. Businesses who reduce

these issues by putting money into more

environmentally friendly operations may want to

increase supply chain transparency as a means of

encouraging customers to purchase their goods. It is

unclear how tracking technology like BT can affect

the sustainability of imported items like bananas.

(Hull & Liu, 2018). Block chain technology is

employed as a method to store the characteristics of

every stage of a banana's growth. Block chain

technology offers a safe way to manage and store data,

which promotes the creation and use of data-driven

transformation for intelligent farming systems.

ICEISA 2024 - International Conference on ‘Emerging Innovations for Sustainable Agriculture: Leveraging the potential of Digital

Innovations by the Farmers, Agri-tech Startups and Agribusiness Enterprises in Agricu

162

2 NEED OF THE STUDY

To evaluate the real-world effects of applying BT in

the banana supply chain management, a case study

was carried out.

3 METHODOLOGY

The current investigation was conducted in Erode

district of Tamil Nadu, India where FPO members

have used BCT in red banana farming to sell their

products with traceability. To raise farmers' income

and enhance their level of living, Kazhani-FPO,

situated in the Erode district, focuses on organic

farming, smart IoT-based agriculture, block chain-

based traceability, and banana exports. Myrada Krishi

Vigyan Kendra (KVK) founded the Kazhani Farmer

Producer Company in 2016, with its headquarters

located in Gobichettipalayam. Case study method

was employed for in-depth analysis of Kazhani FPO

since it is an intensive investigation method which

study in-depth rather than breadth. Case study is one

of the most popular technique of qualitative analysis

which involves careful and complete observation of

any institution, a person, enterprise or social unit and

gathers qualitative information rather than

quantitative information. Kazhani FPO was selected

in particular as it implemented block chain

technology in banana among its farmers.

According to Stuart et al. (2002), this type of

research is suitable when there is a lack of theory,

which is the case with blockchain application in

(agricultural) supply chains. So far, its success has

mostly come from its bold experimentation with other

business models, particularly exporting bananas.

Given that FPO supports the organic farming

practices and Low External Input Sustainable

Agriculture), the low input sales should not be

shocking. The Madurai Agribusiness Incubation

Forum is a business incubator that helps and promotes

the expansion of agribusiness. Kazhani FPC has

included BCT into the cultivation of red bananas with

the help of red banana growers. BCT users input data

into the food sign mobile application on harvesting

details, cultural customs, and red banana crop

cultivation. Bulk farmer's food was purchased by

Kazhani FPC, who then provided shops with QR

codes to scan. Information about the banana, from its

cultivation to its consumption, was produced by the

QR codes. Customers were able to track down Red

Banana information by using their smartphone's

scanner to scan the QR codes.

4 FINDINGS AND DISCUSSION

Mr.Saravananan, Farmer and member of Kazhani

FPO shared the experience on Block Chain

Technology Mr.Saravananan told that the

Gobichettypalayam, Erode district smallholder

farmers faced many challenges in the cultivation of

banana, crop management, harvest and selection of

fruits, marketing etc., The major Banana varities

prevailing are Nendran, ,G9, Karpuravalli, monthan,

kathali, poovan, and sevvazhai /Red Banana. The

supply chain requires a lot of resources, and manual

record-keeping is done.

Claims and practices pertaining to sustainability

must be validated, procedures must meet quality yield

standards, and export regulations must be met. In the

marketing industry, intermediaries and traders (90%)

hold a significant position in setting prices and

promoting produce, among other tasks. The

intermediary has the farmers in its grip. Only roughly

30 to 35 percent of the produce produced by primary

producers is valued. Farmers are getting nearly

Rs.50,000/- as advance from the middleman. The

whole harvest process is done by middleman and

traders. Further for one kilo Banana they are getting

Rs.1 as commission. With 1200 members, the

Kazhani

Farmer Producer Company was founded during

2016 by Myrada KVK based in Gobichettipalayam

after it became apparent that farmers needed a more

effective alternative marketing method. Kazhani has

been working to give the approximately 500 banana

growers who would otherwise be forced to participate

in the conventional middleman-controlled marketing

system. The Kazhani FPC has been actively looking

for alternate marketing method for the produce to its

members. These channels range from establishing its

own grocery store to directly supplying vegetables to

consumers and exporting bananas for bulk sale.

Figure 1: Supply chain Management (Conventional).

Blockchain Technology in Banana: An Experience from FPO Farmers

163

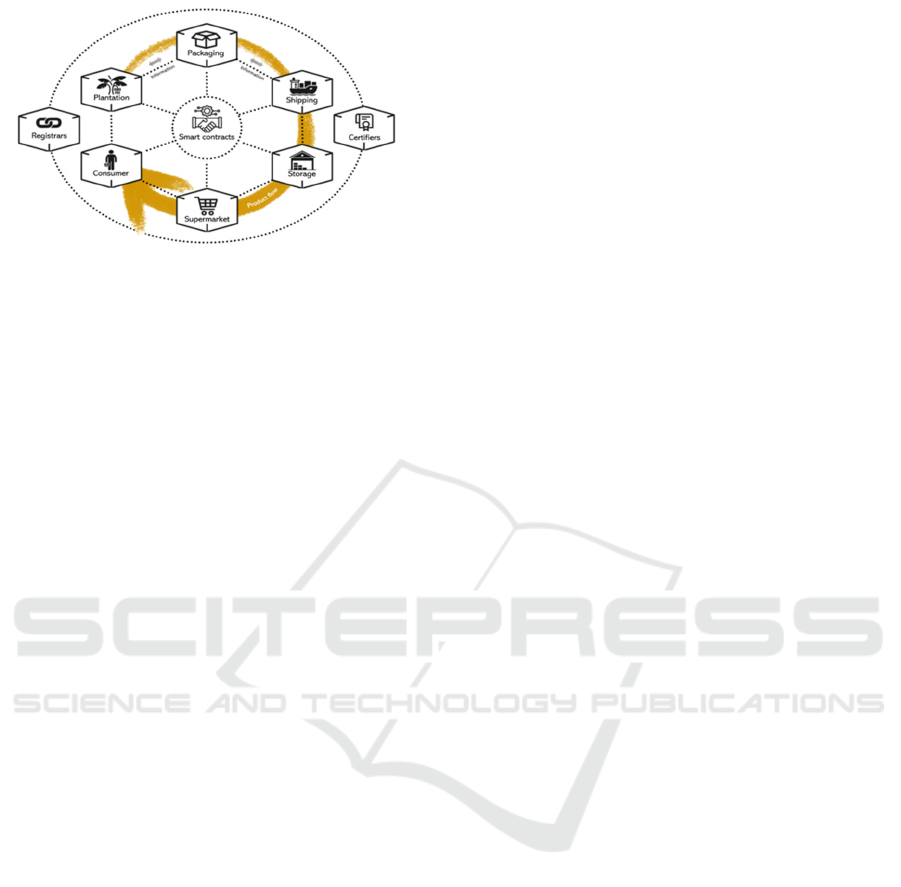

Figure 2: Smart contracts and Simplified Block Chain

(Badzar, 2016 & Galvez et al., 2018).

At the global level, opaque supply chains

frequently leave consumers in the dark about the

provenance of goods and the methods used in their

manufacture (Badzar, 2016). The Transparency and

food traceability are interrelated. Food authentication

entails adhering to the label specifications that specify

its origin, processing method, and composition

(Galvez et al., 2018). Nowadays, this information

about the quality of a product is a target of fraud,

especially for expensive food products. Globally,

consumers demand the origin, content and quality of

the food to be in line with the provided information on

the label (Galvez et al., 2018). A global concern

beyond provenance, food safety damages people's

health and erodes trust in food markets. (Tian, 2018).

One of the main initiatives carried out by

MYRADA KVK prior to Kazhani's registration was

exposure visits to successful FPOs. The purpose of

these visits was to familiarize the local farmers with

the concept of FPOs and help them comprehend the

potential for value addition and marketing in the main

commodities especially in bananas, which are grown

widely in the region. Exposure visits to FPCs in Theni

and Thottiyam made a shape to the FPO's vision,

which was centered on the banana industry.

Understanding the various economic opportunities

and advantages that farmers receive from FPCs was

made easier by these visits. In 2017, Kazhani began

operating in the banana industry following a meeting

with Waycool at an exhibition. As part of a one-year

CSR program, Kazhani received an order for the

delivery of bananas to Chennai. For the school lunch

program, almost three tons of cleaned and graded

bananas had to be provided every day for five days a

week.

When the one-year contract ended, Kazhani tried

to continue the banana business by selling on the local

market. FPO faced difficulty to engage with the local

market, in contrast to the previous approach of

delivering to a single institutional buyer. Aside from

payment collection, they had problems with logistics

and pricing, which dealers could handle because they

formulated network of buyers, something it did not

have. Despite being an organization, FPO has

obstacles obtaining supplies at the farmer level as well

since, typically, dealers give farmers an advance

payment in exchange for the right to reserve their

standing banana plantations and harvest them when

the time is right. Due to a lack of funding to provide

growers these kinds of advances, as well as a

competitive market with razor-thin margins locally,

Kazhani was unable to compete on price and was

forced to change its approach to the banana industry.

During 2020, Kazhani took a major step forward

in its efforts to improve bananas by entering the export

market. Initially, Kazhani partnered with Green Agro

(a banana and mango exporter) in Cochin to supply

bananas for export markets because it lacked expertise

and infrastructure required for export. The majority of

the export destinations were European nations as well

as Southeast Asian nations. Bananas cultivated by the

growers were attached to FPO are normally exported

to other countries and some of the produce is sold

locally in the markets. The quality of the product is

important as it is an export product and banana

production and yields are affected by many factors.

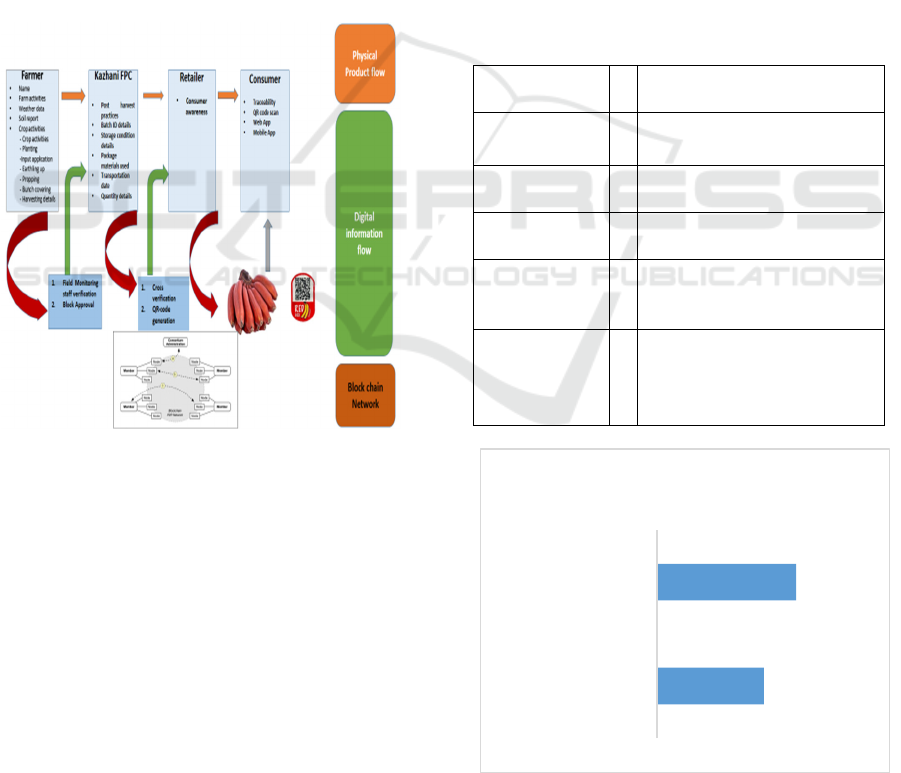

The Agri business forum linked with TraceX

technologies initiated as a pilot project as block

chain for the red bananas, simplifying the Banana

value chain and developing a digital brand for the

product with NABARD financing as a test project.

The harvested fruits are packed in boxes and the QR

code is generated for the batches. The QR code

recreates the journey of the banana from production to

consumption. The boxes of bananas are transported to

local markets and are also exported. The business

forum is able to showcase the traceability of the red

bananas to satisfy consumers all around the world,

assuring food safety, transparency, and sustainability

of the product with TraceX’s solutions. It is also a

sense of satisfaction for TraceX to have helped the

digitization of their product supply chain and bring

trust and transparency among the various stakeholders

in the supply chain. Information about the banana,

from its production to its consumption, was produced

by the QR codes. By scanning the QR codes with the

scanner on their smartphone, customers were able to

identify and locate Red Banana information.

Initially, under this arrangement, Kazhani sent 4

sample consignments of red bananas intended for the

European market. Once they met the strict quality

requirements of the European market with their third

and fourth shipments, Based on experimental

marketing and consumer response, the exporter gave

ICEISA 2024 - International Conference on ‘Emerging Innovations for Sustainable Agriculture: Leveraging the potential of Digital

Innovations by the Farmers, Agri-tech Startups and Agribusiness Enterprises in Agricu

164

them the go-ahead for Red Banana. Every time, they

were provided with comments and recommendations

on quality standards by the exporter. For the Nendran

variety, Kazhani has also been successful in getting

export samples approved. After that, Kazhani and

Green Agro signed a deal for the export of bananas.

Kazhani's responsibility under this arrangement is to

obtain, wash, sort, and package the product.

The packaging is provided by Green Agro. All

logistics after packaging, including transportation and

custom clearances is handled by Green Agro. Since

the lockdown has interfered with routine container

transit by ship, the supply has been provided via air.

Kazhani receives a service charge in addition to the

processing cost from the farmers for the red banana,

which is purchased at the going rate in the market.

Since its founding in 2016, the firm has grown its

revenue steadily, reaching over 1.4 Cr in the current

fiscal year (2020–21).

Figure 3: Network of Block Chain.

These contracts can regulate certification,

approval, and process management in a blockchain-

based supply chain based on conditional rules (Saberi

et al., 2018). A basic blockchain diagram for the

supply chain of bananas is shown in Figure 3. A smart

contract governs transactions between parties, and the

decentralized nature of the blockchain links all of

them together. If the blockchain's design and user

interface permit it, customers may be able to examine

these contracts to confirm the supply chain's

sustainability requirements.

In 2020–21, the FPO began demand-based red

banana cultivation in collaboration with producers;

however, lockdown issues prevented the export order

from being fulfilled. The farmers sold the food on

their own, and the company had no backup plan for

local sales. However, the company and farmers are

looking forward to a stronger season the following

year, and the management and members are

encouraged by the reception of the goods in export

markets.

FPO has planned to launch and incorporate its

pilot programs, which include providing high-quality

inputs, utilizing the technology for traceability,

implementing organic production methods and

obtaining certification, and providing financial

services like crop insurance and credit for banana

cultivation focused on exports after the export

industry has stabilized. With banana exports expected

to remain primary activity, the company hopes to

become acquainted with all facets of the industry over

the next three to five years. This strategy and shared

vision are readily apparent to all stakeholders.

Table 1: Yield and Profit from Conventional & Block

Chain.

Yield/acre : 9 ton (750 bunches x 12

k

g

/bunch =9000k

g

)

Net Income : Rs.2,70,000/- (9000 kg x

Rs.30/kg)

Expenses : Rs.63,750 (750 trees x

Rs.85/tree)

Other

expenses

: Rs. 94,000/-

Profit

(Conventional

suppl

y

chain

: Rs.1,76,000-

BCT supply

chain and

Export

Benefits

: Rs.2, 28,800

(Rs.1, 76,000x 30%)

Figure 4: Profit comparison of conventional &Block chain

supply chain management.

0 100 000 200 000 300 000

Profit (conventional

supply chain)

Profit (BCT supply

chain & Export)

Profit comparison of conventional

&Block chain; Yield- 9 ton of

Banana/acre

Blockchain Technology in Banana: An Experience from FPO Farmers

165

Table 2: SWOC of Block Chain Technology.

Strength Traceability at any time–Farm to

Fork.

Transparency among the various

stakeholder.

Single source of truth that cannot

be tampered with or changed.

Customers were able to track

down Red Banana information by

QR codes.

Weakness Quality parameters and stringent

quality specifications in European

countries.

Quality of Red Banana reduced

due to the dominance of Nendran

and G9.

Lack of skilled persons to work to

meet the quality criteria for

export.

Lack of fundin

g

from NABARD.

Opportunity Kazhani has got export samples

accepted for Nendran variety.

Trial marketing can be done to get

the feedback from

customers/buyers.

12,000 acre is available and the

area can be increased in future.

In the next 3-5 years’ time,

Kazhani is looking to familiarize

itself with different aspects of

banana exports and banana export

is likel

y

to be the main business.

Challenges More than 200 brokers in the area

difficult to overcome

conventional Supply Chain.

Providing high-quality inputs

utilizing block chain technology

for traceability.

Implementing organic production

methods and obtaining

certification.

Providing financial services like

credit and crop insurance for

expor

t

-

b

ased banana cultivation.

5 CONCLUSION

India is the largest producer of Banana (27%). Seven

billion Indian Rupee worth fresh bananas exported

during 2021-22.TamilNadu is the 3

rd

largest producer

among the states. The export volumes are less due to

domestic consumption. Strengthening export in

Southeast Asian countries – Singapore, Malaysia,

Maldives and European countries - Austria, Italy &

UK. Hence Blockchain has been one of the solution

for different supply chain management. Blockchain is

being used in agriculture to speed up transactions and

improve food safety. With an eye toward the future,

Kazhani is preparing to introduce and integrate its

pilot programs, which include supplying premium

inputs, tracing supply using blockchain technology,

certifying and implementing organic production

practices, and offering crop insurance and credit as

financial services for export-based banana cultivation

once the export market stabilizes. Over the following

three to five years, FPO focused to become more with

various facets of the banana export industry, as it is

anticipated to become the company's primary source

of income.

All stakeholders are in agreement with this

strategy and common point to achieve and the

implementation of block chain in the supply chain is

yet to achieve mainstream adoption as high-level

expertise is required to reap the benefits.

Additionally, because block chain technology is still

in its initial stage, it is governed by various laws in

many nations, which would affect supply networks.

In future, it is anticipated that block chain-based

solutions will slowly replace the role of traditional

supply chain networks and processes. The only

solution is to eliminate middlemen and focus on

sustainability is Block chain Technology.

REFERENCES

Abeyratne, S. A., & Monfared, R. P. (2016). Blockchain

Ready Manufacturing Supply Chain Using Distributed

Ledger. International Journal of Research in

Engineering and Technology, 05(09), 1– 10.

Awaysheh, A., & Klassen, R. D. (2010). The Impact of

Supply Chain Structure on the Use of Supplier Socially

Responsible Practices. Int. J. Oper. Prod. Manag, 30,

1246–1268.

Baker, J., & Steiner, J. (2015). Blockchain: the solution for

transparency in product. Provenance.

Badzar, A. (2016). Blockchain for securing sustainable

transport contracts and supply chain transparency. Lund

University, 1–52.

Fairtrade Foundation. (2009). Unpeeling the banana trade,

(February), 1–16. Retrieved June 19, 2019,

from:http://www.fairtrade.org.uk/includes/documents/

cm_docs/2009/f/1_ft_banana_reportw eb.pdf.

Fowler, M. D. (2017). Linking the Public Benefit to the

Corporation: Blockchain as a Solution for Certification

ICEISA 2024 - International Conference on ‘Emerging Innovations for Sustainable Agriculture: Leveraging the potential of Digital

Innovations by the Farmers, Agri-tech Startups and Agribusiness Enterprises in Agricu

166

in an Age of Do-Good Business. Vanderbilt Journal of

Entertainment & Technology Law, 20(3), 881–917.

Galvez, J. F., Mejuto, J. C., & Simal-Gandara, J. (2018).

Future challenges on the use of blockchain for food

traceability analysis. TrAC - Trends in Analytical

Chemistry, 107, 222–232.

Gert H. J. Kema and André

Drenth ed.(2018). Achieving sustainable

cultivation of bananas. Volume 1, cultivation

techniques. Burleigh Dodds Series in Agricultural

Science, Cambridge, United Kingdom: Burleigh

Dodds Science

Publishing.https://doi.org/10.19103/as.2017.0020

Vanessa Hull, Jianguo Liu(2018)Telecoupling: A new

frontier for global sustainability,Ecology and Society

23(4)

Meyer, G., Främling, K., & Holmström, M. (2009).

Intelligent Products: A survey. Computers in Industry,

Vol. 60, 137–148.

Roibás, L., Elbehri, A., & Hospido, A. (2015). Evaluating

the sustainability of Ecuadorian bananas: Carbon

footprint, water usage and wealth distribution along the

supply chain. Sustainable Production and

Consumption, 2(March), 3–16.

Mattila, J., Seppälä, T., & Holmström, J. (2016). Product-

centric Information Management: a case study of a

shared platform with Blockchain Technology.

Conference Paper, (Industry Studies Association

Conference).

Risius & Spohrer, 2017, A Blockchain Research

Framework: What We (don’t) Know, Where We Go

from Here, and How We Will Get There, 2017,

Business & Information Systems Engineering

59(6):385-409

Saberi, S., Kouhizadeh, M., Sarkis, J., & Shen, L. (2018).

Blockchain technology and its relationships to

sustainable supply chain management. International

Journal of Production Research, 0(0), 1–19.

Shreck, A. (2002). Just bananas? Fairtrade banana

production in the Dominican Republic. International

Journal of Sociology of Agriculture and Food, 10(2),

13–23.

Stuart, I., McCutcheon, D., Handfield, R., McLachlin, R.,

& Samson, D. (2002). No Title. Journal of Operations

Management, 20(5), 419–333.

Verhoeven, P., Sinn, F., & Herden, T. T. (2018). Examples

from Blockchain Implementations in Logistics and

Supply Chain Management: Exploring the Mindful Use

of a New Technology. Logistics, 2(3), 20.

Thiruchelvam, V., Mughisha, A. S., Shahpasand, M., &

Bamiah, M. (2018). Blockchain-based 69 technology in

the coffee supply chain trade: Case of Burundi coffee.

Journal of Telecommunication, Electronic and

Computer Engineering, 10(3–2), 121–125.

Tian, F. (2018). An information system for food safety

monitoring in supply chains based on HACCP,

blockchain and internet of things. Doctoral

Dissertation.

White, G. R. (2017). Future applications of blockchain in

business and management: A Delphi study. Strategic

Change, 26(5), 439–451.

Worobetz, K. 2000. The growth of the banana industry in

Costa Rica and its effect on biodiversity. Department of

Biological Sciences, University of Alberta.

Blockchain Technology in Banana: An Experience from FPO Farmers

167