Analysis of an Event-Driven Data Relay Based Approach in Ramp

Patrols

Yongsheng Shi and Yue Zhang

College of Aeronautical Engineering, Civil Aviation University of China, Tianjin, China

Keywords: Event-Driven Architecture, Application Layer, Information Delay.

Abstract: Aiming at the data relaying task of multiple devices in ramp inspection, this paper proposes an Event-Driven

Architecture data relaying method running at the application layer. The method organizes devices of the same

type through events, performs corresponding data relay operations, and distinguishes different types of data.

The data relay task contains two types of subtasks: the data receive task and the data send task. For the data

receiving task, it is regarded as a kind of event response; for the data sending task, it is regarded as a kind of

class method, which is invoked through the class name. The method in this paper conducts comparative

experiments and analyses the experimental data with the length of data relay as a variable. The results show

that the method in this paper only increases the average transit time by 7.23ms when the length of transit data

grows to 8.6 times of the original one, which can realize the data transit task and has a certain adaptability to

the growth of data length.

1 INTRODUCTION

With the rapid growth of the civil aviation industry,

there is an increasing demand for improved efficiency

in ramp inspections (Rosa-Bilbao, 2023). A crucial

area of research and development is the utilization of

mobile robot inspection formations to optimize the

efficiency of these inspections. Currently, the data

transmission for apron inspection equipment relies

heavily on third-party software, resulting in a

bottleneck in the data interaction process (Lombardi,

2019). Therefore, it is imperative to design and

implement a method that allows for seamless data

interaction for inspection equipment (Li, 2021).

Event-driven based design thinking is widely

used. By utilizing Event-Driven architecture, this

paper proposes a data relay method that operates at

the application layer (Wang, 2021). This method

organizes different robots through Event-Driven

Architecture, allowing for efficient communication

and coordination. When receiving data relay tasks,

the method handles them by responding to the

corresponding events (Pogiatzis, 2020). On the other

hand, when initiating data transfer tasks, the method

is invoked through a class method (Rahmani, 2021).

Event-based forwarding method is more suitable for

real-time data processing (Fertier, 2020). At the same

time, the privacy-preserving end-to-end data

forwarding has also aroused research work (Zhang,

2019). Related work on event-based transit methods

in industrial robots has also been carried out

(Semeniuta, 2019).

This paper also addresses the roles of the server-

side and client-side in this system. The proposed

method is implemented and validated, demonstrating

its effectiveness in improving efficiency and

streamlining data interaction in ramp inspections.

2 DIVISION OF DATA RELAY

TASKS

Ramp inspection equipment in the process of

performing the task will produce a variety of types of

inspection task data, such as inspection log files, etc.,

the above data need to be shared by the inspection

equipment, and through the server which will be

transferred to another inspection equipment. The

above process consists of two basic operation units:

data receiving operation and data sending operation

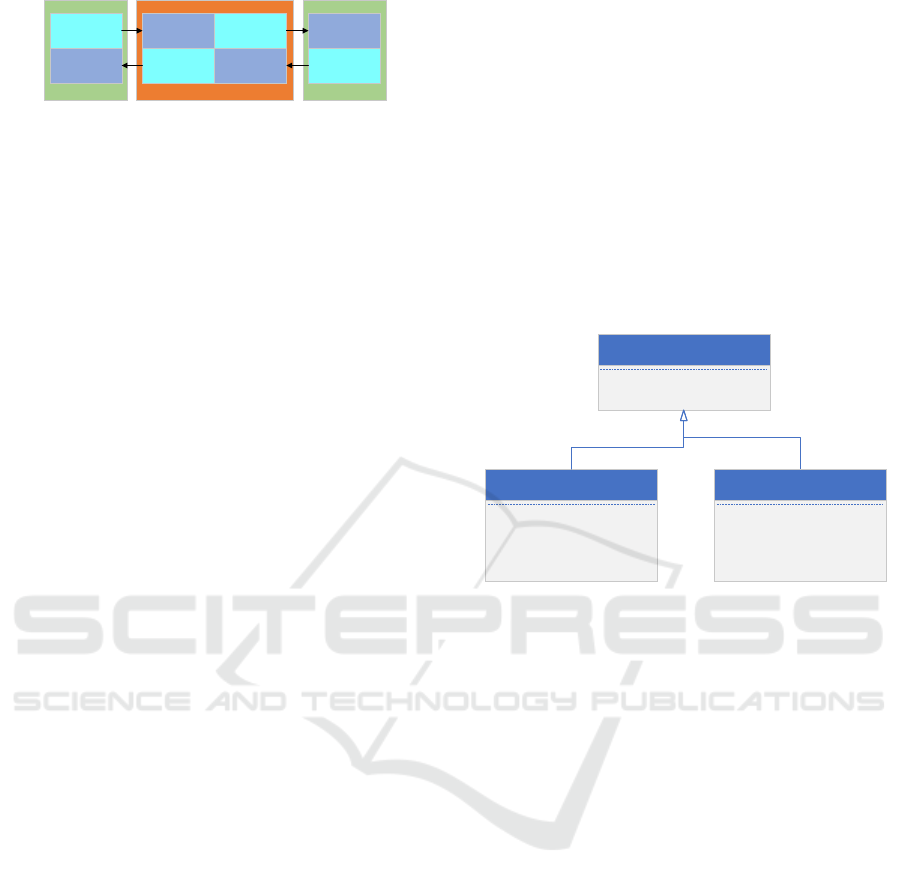

as shown in the Figure 1.

Shi, Y. and Zhang, Y.

Analysis of an Event-Driven Data Relay Based Approach in Ramp Patrols.

DOI: 10.5220/0012880100004536

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Data Mining, E-Learning, and Information Systems (DMEIS 2024), pages 69-74

ISBN: 978-989-758-715-3

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

69

Send

Receive

Robot A

Receive Send

Send Receive

Server

Robot B

Send

Receive

Figure 1: Data relay role interaction diagram.

The data relay method proposed in this paper

involves the interaction of three actors: Robot A,

Robot B, and the server. The process begins with

Robot A and Robot B generating data, which is then

relayed by the server. Each actor is equipped with

communication modules that facilitate data

transmission and reception.

To initiate the data relay process, Robot A's

sending module interacts with the server's receiving

module. This allows the data generated by Robot A to

be relayed to the server. Once the server receives the

data through its receiving module, it proceeds to

forward it to Robot B using its own sending module.

Finally, Robot B obtains the data by utilizing its data

receiving module.

It is important to note that the roles of Robot A

and Robot B can also be reversed in this data relay

process. This means that Robot B can become the

sender, sending data to the server, which then relays

it to Robot A. This interchange of roles enables a

dynamic and flexible data transmission between the

two robots and the server.

By employing this data relay method, efficient

and reliable data transmission is achieved among the

three actors involved in the system. This enables

seamless communication and coordination,

ultimately improving the overall efficiency and

effectiveness of ramp inspections.

3 DESIGN OF DATA RELAY

METHODS

3.1 Server Side Design

The server side plays a crucial role in the data relay

process, as it is responsible for both data reception

and data forwarding. In order to effectively organize

the different types of devices involved, the server side

utilizes separate classes for each device type. This

allows for a structured and organized approach to

managing the data transmission process.

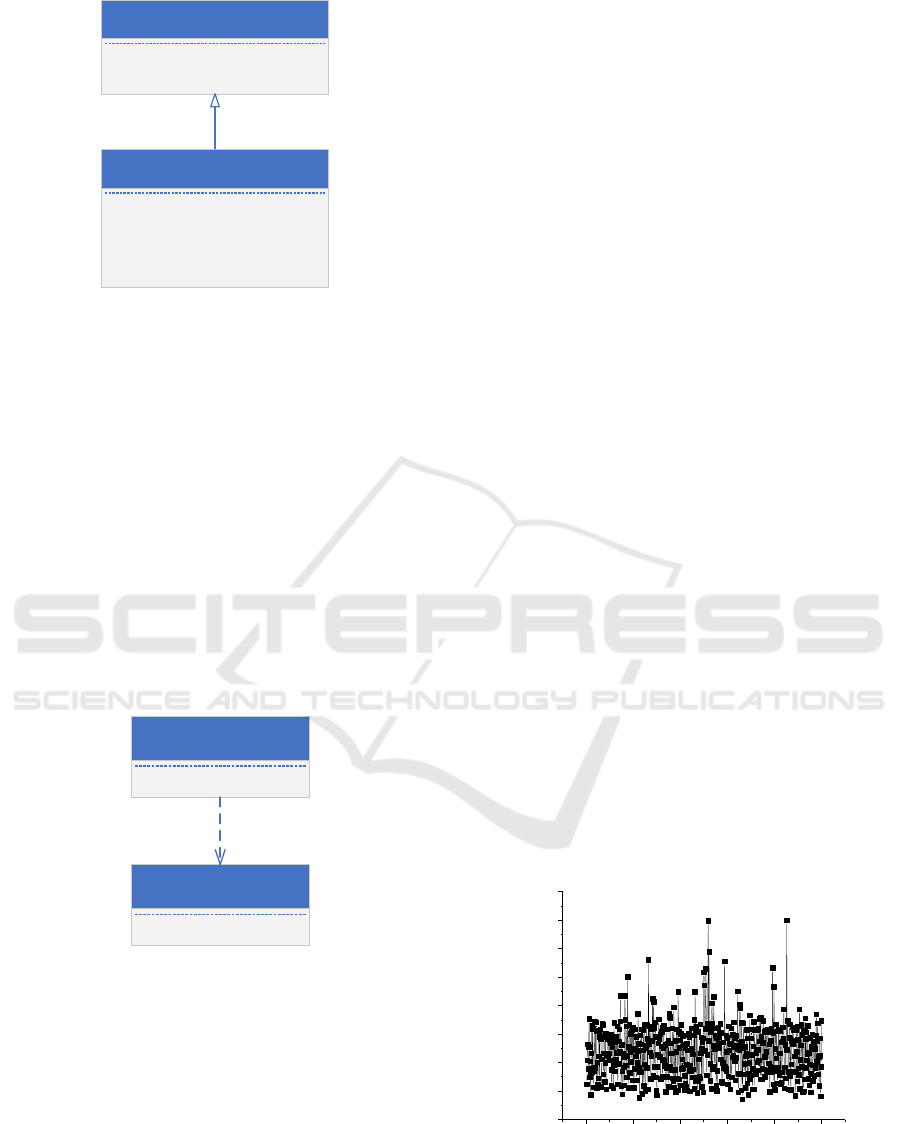

To provide a visual representation of the system's

architecture, a class diagram is drawn. This diagram

depicts the relationships and interactions between the

various classes involved in the data relay process. It

serves as a blueprint for understanding the system's

design and functionality.

The class diagram illustrates the different classes

for each type of device, highlighting the specific

methods and attributes associated with them. It

provides a clear overview of how the server side

organizes and manages the data transmission between

the devices. Utilizing this class diagram as a design

reference, the server side can effectively handle the

tasks of data reception and forwarding. This

structured approach enhances the overall efficiency

and reliability of the data relay process on the server

side.

Namespace

Robot_Type_A Robot_Type_B

+on_disconnect(self)

+on_connect(self)

+on_disconnect(self)

+on_connect(self)

+send_data(cls:Robot_A, data:Object)

+on_connect(self)

+on_disconnect(self)

+send_data(cls:Robot_B, data:Object)

+on_event(self) +on_event(self)

Figure 2: Server-side function class design.

The JSON message at the top of the data relay

process serves as a comprehensive and specific

source of information about the data that needs to be

relayed for the ramp patrol scenario. It includes a

detailed description of the data elements and their

corresponding values that are essential for the

effective implementation of the data relay process.

The data format of the server-side interaction with

the client is encapsulated by json in the following

Table 1.

By encapsulating the relevant data in this JSON

message, it provides a standardized and structured

format for the transmission of information. This

ensures that all the necessary details required for the

ramp patrol scenario are included and can be easily

interpreted by the receiving entities.

The JSON message contains key information such

as the location of the ramp, the time of the patrol, the

status of the inspected objects, and any anomalies or

issues detected during the inspection. Additionally, it

may include details about the robots involved, their

specific roles, and any specific instructions or tasks

assigned to them.

In conclusion, the JSON message at the top of the

data relay process serves as a complete and detailed

repository of information for the ramp patrol scenario.

DMEIS 2024 - The International Conference on Data Mining, E-Learning, and Information Systems

70

Its inclusive nature facilitates smooth and efficient

data transmission, enabling seamless coordination

and effective execution of the inspection tasks.

The event-driven model allows the server to

handle a large volume of inspection events in a non-

blocking manner, without having to create and

manage a thread or process for each event. This

approach can improve server throughput, reduce

resource consumption, and better accommodate peak

traffic.

Table 1: This caption has one line so it is centered.

Key Byte Size of Value

Time Stamp 24

Move Comman

d

45

Control Comman

d

45

Device Data 60

Reserved Data 10

3.1.1 Data Reception Operations

Listening for Events. The server maintains one or

multiple event listeners, which are dedicated to

detecting when new events occur. In the context of

apron inspection data, these events typically represent

notifications of new inspection data. Event listeners

are usually bound to one or more event queues, which

are managed by a messaging middleware to handle

the data flow.

Receiving Events. Once a new inspection event is

generated by robot and sent over the network to the

server, it enters the pre-established event queue. The

server's event listener pulls the event from the queue,

ready for processing. This process is asynchronous to

ensure the server can handle a high volume of

concurrent event streams.

Processing Events. The event handler on the

application server is responsible for processing each

event.

Generating a Response. Once an event is

processed, the server might need to generate a

response to inform the inspector that the data has been

received and processed. The response can be sent

back to the inspector through the same event-driven

mechanism or through other response systems (like

real-time messaging systems or email notifications)

to communicate the outcome.

3.1.2 Data Sending Operations

Triggering Notifications: Should the monitored data

exceed predefined thresholds or reveal anomalies, the

server will generate alarm or notification messages.

Updating Status: The server will transmit data to

the apron monitoring panel or related systems to

update the status of aircraft and equipment or the

results of monitoring. This enables real-time

monitoring, allowing ground staff to be immediately

informed of the latest conditions on the apron.

Scheduling Subsequent Processes: Based on

inspection results, the server may need to

automatically schedule maintenance crews for repairs

or assign follow-up routine inspections. Relevant

scheduling information will be sent to scheduling

systems or posted to workforce management systems.

Data Synchronization: The server may send

processed data to other systems for data

synchronization, such as transmitting safety

inspection results to the safety management system.

Data Backup: Periodically or after a critical event,

the server will also transfer data to backup systems to

ensure data security.

Through this process, the server not only

processes and stores data from the apron inspections

but also feeds back crucial information to relevant

personnel and systems, ensuring the apron operates

safely and efficiently. The application of an event-

driven architecture accelerates server responsiveness,

enabling it to promptly respond to various events,

thus maintaining the operational efficiency of the

entire airport.

3.2 Robot Side Designs

In the context of ramp inspections, the architectural

framework employed for the development of the

robot and server sides exhibits remarkable similarities,

as depicted in Figure 3. This resemblance, however,

belies a crucial divergence in functionality—the robot

side places a far greater emphasis on the autonomous

dispatch of data that is intended for subsequent

relaying. This pivotal feature necessitates the

implementation of a sophisticated event-driven

mechanism capable of local monitoring.

To address this requirement, the event listening

architecture is meticulously crafted and presented in

Figure 4. It is engineered to facilitate real-time

surveillance of specific activities within the robot's

operational environment. At the heart of this system

is the capability to observe and react to changes

occurring in files, a fundamental necessity for the

robot to fulfil its objective of data transmission.

Analysis of an Event-Driven Data Relay Based Approach in Ramp Patrols

71

ParentEvent

Robot_Type_Local

+on_disconnect(self)

+on_connect(self)

+on_disconnect(self)

+on_connect(self)

+send_data(cls:Robot_A, data:Object)

+on_event(self)

Figure 3: Robot-side function class design.

Upon acquisition, the data collated by the

inspection robot undergoes a process of

transformation, relaying into a persistent file-based

format. Consequently, these files are stored within a

designated directory whose alterations must be

closely observed. To that end, the event listening

system is primed to detect any file modification

events within the target folder.

The occurrence of such an event triggers a

meticulously defined response protocol. This

protocol entails the invocation of a corresponding

class method—one that is adept at handling the data

sending operation. The class, specified by its name, is

effectively engaged through this listener system,

thereby catalysing the data forwarding function.

Robot_Type_Local

FileEventListener

<<call>>

+sendData()

+on_modified()

Figure 4: File event listener calling a robot's data sending

static method.

To elaborate, when the designated file directory

experiences an addition, deletion, or amendment, the

event listening system springs into action. It

instantaneously signals the specified class, which, in

turn, powers up the necessary method to process and

expeditiously dispatch the data to its intended

destination. This automated synergy between file

modifications and data transmission ensures a

seamless and uninterrupted flow of information, a

critical aspect of the inspection robot's utility.

Overall, the design philosophy underlying the

inspection robot's class structure is to deliver a robust

and autonomous system tailored for the dynamic

ramp inspection environment. As a result, the

inspection robot performs its duties with a high

degree of efficiency, accuracy, and reliability—key

qualities necessary for the demanding tasks it is

entrusted with.

4 TEST FOR DATA RELAY

METHOD

Experiments are designed to test the relay

performance of the method using the average

statistical time as an index. The method of counting

the relay time is to record the timestamp at the

sending end when sending, and get the current

timestamp at the receiving end to obtain the relay

time.

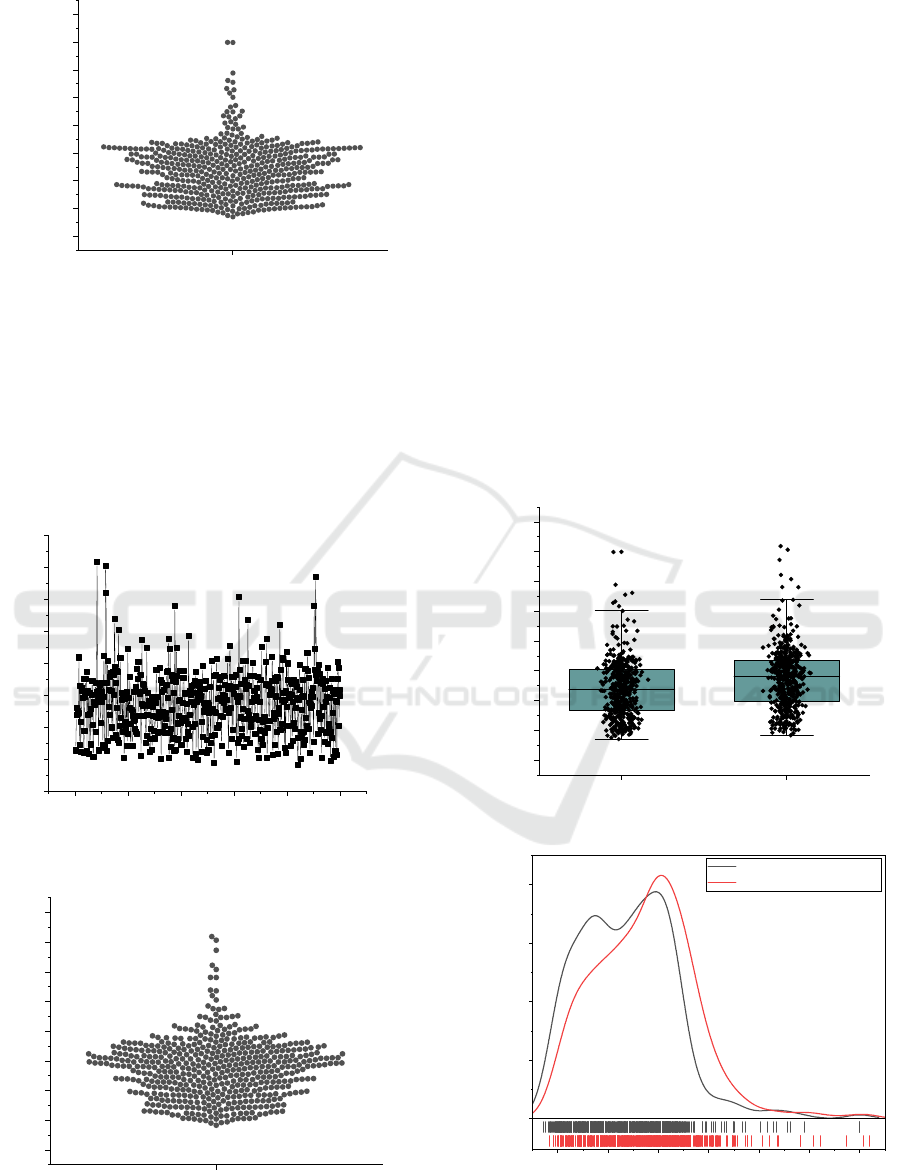

4.1 Experiment 1

Repeatedly forward 500 pieces of data with a data

length of 184Bytes and a time interval of 1s, and

calculate the time for each relay. The vertical axis is

the time difference in milliseconds, and the horizontal

axis is the number of forwarding times. The

experimental results are shown below.

From the above graphs, we can get that with the

data length of 184Bytes in Exp.1, most of the relay

time of this paper's method is between 20-70ms, and

in a few cases, the relay time goes beyond this range,

with a minimum value of 14.169ms or a maximum

value of 139.932ms. In Exp.1, the geometric mean of

the relay time is 43.98ms, the geometric standard

deviation is 19.09 and the median is 47.49ms.

Figure 5: Raw data on relay time of Exp.1.

0 100 200 300 400 500

0

20

40

60

80

100

120

140

160

time cost (ms)

relay times

DMEIS 2024 - The International Conference on Data Mining, E-Learning, and Information Systems

72

Figure 6: Beeswarm plot of Exp.1.

4.2 Experiment 2

Repeatedly forward 500 pieces of data with a data

length of 1584Bytes and a time interval of 1s to

calculate the time of each relay. The vertical axis is

the time difference in milliseconds, and the horizontal

axis is the number of forwarding times. The

experimental results are shown below.

Figure 6: Raw data on relay time of Exp.2.

Figure 7: Beeswarm plot of Exp.2.

From the above graphs, we can get that with the

data length of 1584Bytes in Exp.2, most of the relay

time of this paper's method is between 20-80ms, and

in a few cases, the relay time goes beyond this range,

with a minimum value of 16.682ms or a maximum

value of 143.802ms.In Exp.2, the geometric mean of

the relay time is 51.21ms, geometric standard

deviation is 1.47, and the median is 56.23ms

5 CONCLUSION

In this paper, to provide a comprehensive comparison

of the outcomes from two distinct experiments, we

employ graphical representations in the form of box-

scatter plots and distribution-axis-whisker plots. The

usage of these plots allows for an effective visual

comparison and analysis of the data distributions,

statistical variations, and potential outliers. The

effects of the two experiments are shown in Fig.9 and

Fig. 10.

Figure 8: Box-and-Scatter Chart of Exp.1 and Exp2.

Figure 9: Distribution map - Axis whiskers plot of Exp.2.

Data Length: n = 184 Bytes

0

20

40

60

80

100

120

140

160

Range

0 100 200 300 400 500

0

20

40

60

80

100

120

140

160

time cost (ms)

relay times

Data Length: n = 1584 Bytes

0

20

40

60

80

100

120

140

160

Range

Data Length: n = 184 Bytes Data Length: n = 1584 Bytes

0

20

40

60

80

100

120

140

160

Range

20 40 60 80 100 120 140

0.000

0.005

0.010

0.015

0.020

Density

time cost (ms)

Data Length: n = 184 Bytes

Data Length: n = 1584 Bytes

Analysis of an Event-Driven Data Relay Based Approach in Ramp Patrols

73

From the above graphs, it can be obtained that

with the increase of data length of each relay, the

position of the box in the box plot is shifted upward,

i.e., there is a smaller increase in the relay time of

each relay accordingly. And from Fig. 10, it can be

obtained that with the increase of data relay length,

the density of data distribution decreases in the range

of 20ms-30ms and increases near 70ms-80ms.

Overall, the method proposed in this paper is able

to realize the data relay function in the ramp

inspection scenario, and the data relay time is kept in

a suitable range. The results show that the method in

this paper only increases the average transit time by

7.23ms when the length of transit data grows to 8.6

times of the original one, which can realize the data

transit task and has a certain adaptability to the

growth of data length. The increase in data length has

an effect on the data relay time, but it does not cause

dramatic fluctuations in data relay time.

REFERENCES

Tian, Y., Meng, Y., Zhao, X., Wen, X., Meng, L., Qin, X.,

2023. Age-aware relay strategy with simultaneous

wireless information and power transfer in remote

monitoring systems. IET Communications 17, 1418–

1431.

Rosa-Bilbao, J., Boubeta-Puig, J., Rutle, A., 2023.

CEPEDALoCo: An event-driven architecture for

integrating complex event processing and blockchain

through low-code. Internet of Things 22, 100802.

Lombardi, F., Muti, A., Aniello, L., Baldoni, R., Bonomi,

S., Querzoni, L., 2019. PASCAL: An architecture for

proactive auto-scaling of distributed services. Future

Generation Computer Systems 98, 342–361.

Li, W., Li, H., Wang, S., 2021. An event-driven multi-agent

based distributed optimal control strategy for HVAC

systems in IoT-enabled smart buildings. Automation in

Construction 132, 103919.

Wang, Yahui, Zheng, L., Wang, Yiwei, 2021. Event-driven

tool condition monitoring methodology considering

tool life prediction based on industrial internet. Journal

of Manufacturing Systems 58, 205–222.

Pogiatzis, A., Samakovitis, G., 2020. An Event-Driven

Serverless ETL Pipeline on AWS. Applied Sciences 11,

191.

Rahmani, A.M., Babaei, Z., Souri, A., 2021. Event-driven

IoT architecture for data analysis of reliable healthcare

application using complex event processing. Cluster

Computing 24, 1347–1360.

Fertier, A., Montarnal, A., Barthe-Delanoë, A.-M., Truptil,

S., Bénaben, F., 2020. Real-time data exploitation

supported by model- and event-driven architecture to

enhance situation awareness, application to crisis

management. Enterprise Information Systems 14, 769–

796.

Zhang, W., 2019. A data fusion privacy protection strategy

with low energy consumption based on time slot

allocation and relay in WBAN. Peer-to-Peer

Networking and Applications 12, 1575–1584.

Semeniuta, O., Falkman, P., 2019. Event-driven industrial

robot control architecture for the Adept V+ platform.

DMEIS 2024 - The International Conference on Data Mining, E-Learning, and Information Systems

74