Precision Poultry Management Using Smart Sensors

Sureshkumar R

1

, Vignesh A

1

, Ragulnath R

1

, Harish E

1

, Dharanidharan R

1

, Nisha A

2,* a

,

Gunji Bala Murali

3

, Paul Mansingh J

2b

and Nirosha R

2c

1

VIT School of Agricultural Innovations and Advanced Learning (VAIAL), Vellore Institute of Technology,

Vellore, Tamil Nadu, India

2

Department of Agricultural Extension and Economics, Vellore Institute of Technology, Vellore, Tamil Nadu, India

3

Department of Department of Design and Automation, School of Mechanical Engineering, Vellore Institute of Technology,

Vellore, Tamil Nadu, India

Keywords: DHT22, MQ135, ESP8266, ESP32 Cam, Blynk IoT, Poultry Farm.

Abstract: Poultry is a crucial food-supplying sector that is growing at a rapid rate in India and in the world. To meet the

increasing demand for poultry products there is a need to increase production by minimizing the loss. One of

the ways to achieve efficiency in the production of poultry is by using sensors and automation. Automation

in this sector is now emerging as an area of interest for many. Monitoring the farm conditions in poultry

plays a major role in the process of automation. It is required to maintain suitable environmental conditions

for better growth of chicks. We focus on the implementation of a low-cost sensor system that can enhance

the efficiency of maintaining a poultry farm. In this article, we summarise a monitoring system for

environmental conditions in a poultry farm using sensors. This system enables real-time monitoring and data

collection of key parameters such as temperature, humidity, air quality, etc. The chicken's growth is affected

by various environmental factors such as temperature and humidity.

1

INTRODUCTION

The poultry industry has grown significantly over the

years and the demand for poultry products has

increased worldwide (Bosque et al., 2021). The world

market for processed poultry meat was around $252.4

Billion in 2020. The demand for high-quality chicken

meat has grown rapidly in recent years. By 2050, the

demand for poultry meat would be 40% higher than

current demand (Astill et al., 2020).

India is the third-largest producer of chicken eggs

and the fifth-largest producer of chicken meat in the

world. In 2019-20, India produced 8.86 MMT of

chicken meat. In India, the demand for poultry meat

is growing by 15-20%. The backyard market is

growing at 6-7% and the chicken market at 8-10% per

year. In 2020, the Indian poultry market was

estimated to be worth more than $14 billion. In 2022,

the market value of poultry in India was 28.18 Billion

a

https://orcid.org/0000-0001-9347-9038

b

https://orcid.org/0000-0003-3423-8618

c

https://orcid.org/0000-0001-9347-9038

*

Corresponding author

USD. The consumption of meat was found to be more

than 4 MMT in 2022. In India, Tamil Nadu is the

largest producer of chicken meat with a production of

467.51 HMT. The consumption of meat has also

increased in the past years. To meet the growing

demand all over the world, production must be

maximized sustainably and efficiently. Producing

good quality meat and healthy chicken has become an

ideal business area for many. Environmental variation

can affect livestock production systems (Sinha et al.,

2017a). Certain parameters require consistent

monitoring for optimized production (Corkery G. et

al., 2013). Temperature, humidity, and ammonia are

primary conditions to be monitored which can affect

poultry production (Ahmadi et al., 2019; Kocaman et

al., 2006). High temperatures can cause reduced feed

consumption, lower body weight (Sohail et al., 2012)

rough feathers, depression, weak legs and diseases

such as heat stroke, New Castle disease, E. coli

infection, and fowl cholera. High humidity levels can

R, S., A, V., R, R., E, H., R, D., A, N., Murali, G. B., J, P. M. and R, N.

Precision Poultry Management Using Smart Sensors.

DOI: 10.5220/0012869600004519

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Emerging Innovations for Sustainable Agriculture (ICEISA 2024), pages 5-13

ISBN: 978-989-758-714-6

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

5

cause difficulty in breathing and vision (Hitimana et

al., 2018; Mahale 2016). High Ammonia levels cause

conjunctivitis and damage the eye cornea (Aziz and

Barnes, 2010). Traditional poultry farming methods

involve manual inspection, which can be tedious and

time-consuming. The development of technology has

made it possible to monitor and control the

environment in a poultry farm. It can be done by using

sensor technology. Sensors are electronic devices that

can be used to measure or control various parameters

in a poultry farm. Maintaining conditions such as

temperature, humidity, ammonia, etc., requires

accurate data from automation equipment such as

sensors. The purpose of the study is wireless sensor

technology (Sinduja, K et al., 2016). The sensor can

give accurate information on the physical parameters

specified. This information can be used to identify

possible causes or mortality or poor growth or disease

outbreaks in chickens. Thus we require a monitoring

system for optimum production. Smart monitoring

system helps in better understanding of poultry

growth and health (Orakwue et al., 2022). This sensor

technology or monitoring system helps find possible

solutions to problems in a poultry farm either by

automation or taking preventive measures manually.

Proper ventilation (Sheikh et al., 2018) can be one of

the ideal solutions for abnormal parameters such as

temperature, humidity ammonia concentration etc., in

the poultry farm.

2

REVIEW OF LITERATURE

2.1 Poultry Industry

Chatterjee et al. have compared the trends in egg

production and per capita availability of eggs and

found that the poultry industry suffered from major

issues like a rise in the cost of feed, emergence of

diseases, and lack in the prices of the eggs. The

article also discussed the topic of feed resources and

disease management by vaccination and other

possible methods like surveillance and monitoring

systems. To overcome the challenges in the poultry

industry, increasing the adoption of small poultry

farms in backyards will rapidly increase the

economic status of rural people.

Mitra et al., 2021 stated that poultry farm provides

8.8% of employment in India. The poultry industry

contributed 16% income of small farm households

and 14% income of rural households. It also

contributed 4.11% to the total GDP and 25.6% to the

Agricultural GDP. The major constraint in the

poultry industry was found to be a lack of basic

infrastructure. So, a new system should be formed for

maintaining the poultry farms, and the government

should focus on naturally boosting the growth of the

birds.

2.2 Challenges in Poultry Farming

Sridharan. 2017 mentioned the constraints in poultry

farming were due to several factors. Farmers faced

issues such as labor shortages, electricity, high

mortality during the summer season, bird flu, etc. The

outcome of the article was found to be the usage of

the coal method of brooding as it was found to be

economical and more available than electricity or gas.

In the conducted study, 47.2% of farmers in

Coimbatore managed their poultry farm with the help

of family members mostly husband and wife without

external labor, thus solving the labor shortage issues.

Rao 2015, found that the constraints in the poultry

industry as the high cost of feed materials, outbreak

of diseases, inadequate investments, limited access to

the core market, disease control, and water and

electricity-related issues. The nutrition-related

environmental issues were also found to be major

issues. The solution to overcome the challenges was

to provide training programs and implementation of

new policies to implement new scientific

technologies.

Mitra et al., 2021, stated the impediments to

poultry farming in India as the arsenic feeding to

boost growth and weight, growth hormones, poor

poultry practices, improper hygiene and

management, lack of basic infrastructure, lack of

transportation, lack of storage and marketing system

as the major challenges in India.

Jeni et al., 2021, mentioned the constraints are due

to environmental factors such as heat stress, etc.

secondly predation, disease-causing pathogens,

parasitic infestation, etc. These constraints resulted in

heat stress and nutritional and dietary challenges in

poultry farming.

2.3 IoT in the Poultry Industry

Orakwue et al., 2022, presented a system using the

Internet of Things for monitoring environmental

parameters such as temperature, humidity, and air

quality. The designed system utilized DHT11,

MQ135, and PIR motion sensors with ESP32

microcontroller with a buzzer. The system alerted the

farmer by buzzer sound in case of any intruder. It also

helped the farmer to turn the light ON or OFF by using

the Blynk IoT application from anywhere.

Choosumrong et al., 2019, proposed a monitoring

ICEISA 2024 - International Conference on ‘Emerging Innovations for Sustainable Agriculture: Leveraging the potential of Digital

Innovations by the Farmers, Agri-tech Startups and Agribusiness Enterprises in Agricu

6

system for temperature, humidity, NH3, and light

sensors and recorded the data in an SD card-based

Arduino data logger. Temperature and humidity were

checked for the evaporative controller. NH3 and light

for threshold values of 4.0 and 90% respectively. The

proposed system alerted the farmers by SMS in case

the ammonia and light exceeded the limit.

Goswami, et al., 2022, proposed an Arduino-based

system with Arduino UNO as a microcontroller and a

DHT22 temperature humidity sensor for monitoring

the temperature. It also has a fogger system to control

the temperature if it rises too high. It also has an

automatic feeding system which can be controlled by

the farmers using a remote device.

Ayyappan et al., 2017, has used PIC16F877 as a

controller and ESP8266 as a Wi-Fi module. LM35

sensor for temperature detection, SY-HS-220

humidity sensor, MQ6 for ammonia detection, and a

fuel level sensor to measure water level in poultry

farms. He used the level sensor for the automation of

the DC motor automatically turning ON. He designed

a system where if the water level reached below 1

liter the motor switched ON. In the case of the

temperature, the cooling fan switched ON and for the

humidity, exhausting fan switched ON.

Mansor et al., 2018, presented a smart system for

poultry farms by using a Master-Slave module design.

DHT22 temperature sensor and MQ135 gas sensor

were used to monitor temperature, humidity, and

ammonia levels. If the ammonia level is near the fan

zone, it triggers the fan system and pulls out the gas

from the poultry farm. The article stated that the

system was implemented in Myra farms & services

and tested.

3

MATERIALS AND METHODS

This study focuses on integrating various sensor

modules using a common microprocessor. The

integration of the sensor is to sense the parameters

and produce it in a single common platform. This

system focuses on sensing Temperature, humidity,

Ammonia, and Carbon dioxide as the primary

parameters. It also measures smoke levels. Each

parameter is sensed and measured in respective units

such as ˚C, Fahrenheit, percentage, ppm, etc. The

system is to be connected to a Wi-Fi to get the data.

The data can be obtained in an IoT platform. It also

enables us to get alert notifications and buzzer sounds

in case any of the environmental parameter values is

beyond the threshold level specified. Also, we use a

camera module to monitor the farm visually. It can be

monitored in a live stream website specified in the

following topics using the IP address generated by

the module.

3.1 Hardware

This system uses an ESP 8266 Microcontroller, DHT

22 Temperature and humidity sensor, MQ-135 air

quality sensor, and ESP 32–Cam module.

ESP 8266 is the main processor of the system

which receives processes and records the data in the

device. It enables the user to connect to Wi-Fi to

collect data and transfer it to any platform. It works

on a 3.3 V input voltage. It uses a Serial Peripheral

Interface (SPI), which is a short-distance

communication interface. It is used in place of an

Arduino board as a low-cost replacement.

DHT22 is a temperature and humidity recording

sensor that has a higher accuracy than currently used

DHT11 sensors. It gives output as a calibrated digital

signal. It works in an input range of 3.3 V to 6 V. It

can measure temperatures of range - 45˚C to 125˚C

with an accuracy of ±0.5˚C. It can measure humidity

from 0% to 100%. The unit of temperature that can

be detected using DHT22 is Celsius and

Fahrenheit. The ideal condition for detection is 20˚C

±2˚C and 65% humidity.

MQ135 is a gas-detecting sensor that can detect

gases like Ammonia, Carbon dioxide, Sulfur,

Benzene, Alcohol, smoke, and other harmful gases. It

works on an input voltage of 5 V. It can give both

analog and digital output. It is highly sensitive to

Ammonia, sulfur, and Benzene. It can detect

ammonia from a range of 10 ppm to 1000 ppm. It is a

low-cost alternative for MQ137. MQ137 is

specifically designed for industrial purposes which

can detect up to a level of 5 ppm accurately and it is

very expensive to buy and install.

ESP 32 camera module is used to here record the

mobility pattern of the birds. It has a voltage regulator

chip. It works on an input voltage of 5 V. It supports

an SD card and has a holder in which we can save the

data of video or image recorded. It also supports Wi-

Fi image uploads and can also live stream the video

using an IP address. It can also support face

recognition features. We can adjust the resolution of

the live stream. It helps to identify the health patterns

of chicks. It can also detect the presence of any

predators on the farm.

We used a buzzer connected to the ESP8266

board. It can produce alert sounds if any of the

specified parameters is recorded abnormally. It can

produce different sounds according to the frequency

of electrical pulses it receives. It can produce a

periodical beep sound as well as a continuous sound

depending on the codes. We are using an

Precision Poultry Management Using Smart Sensors

7

electromagnetic buzzer in an input voltage of 5 V.

The sound is produced through magnetism with a 2

kHz frequency.

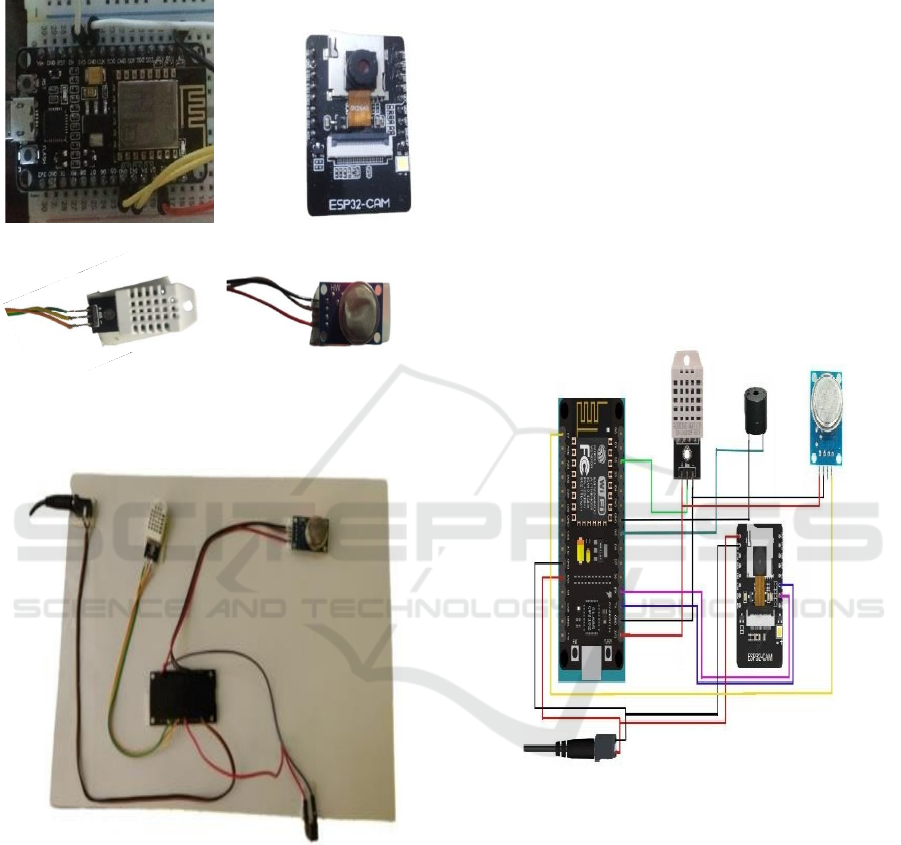

A. ESP8266 B. ESP 32 cam

C.DHT22 Sensor D. MQ135 Sensor

Figure 1 - Hardware devices used

Figure 2 - Hardware setup of sensors

3.2 Software

This system uses the Arduino IDE platform for

coding. We use C++ as the programming language in

the Arduino IDE platform. Blynk IoT platform is used

to get the data from the sensor system. Blynk creates

a Graphical Interface by providing the data in widgets.

It is an app that allows users to create custom

interfaces for IoT devices, making it an excellent

choice for monitoring poultry farm variables.

3.3 Methodology

To begin, the hardware configuration includes using

the ESP8266 as the processor to link the MQ-135 gas

sensor, which can detect various parameters such as

ammonia, carbon dioxide, smoke level, benzene,

alcohol, and so on, and the DHT22 temperature and

humidity sensor. This can be accomplished by

following the sensor pin-out circuit diagrams and

attaching the relevant wires to the ESP8266 board in

the right pins. In the early phases, jumper wires are

utilized to test the sensors. The ESP8266

microcontroller requires an adaptor for a consistent 5

V supply. The Serial Peripheral Interface (SPI) pins,

as well as the power and ground pins, can be used to

link the ESP32-CAM to the ESP8266 board. The

circuit diagram is given in Figure 3. It depicts the

wire connections between the various components

used for this system.

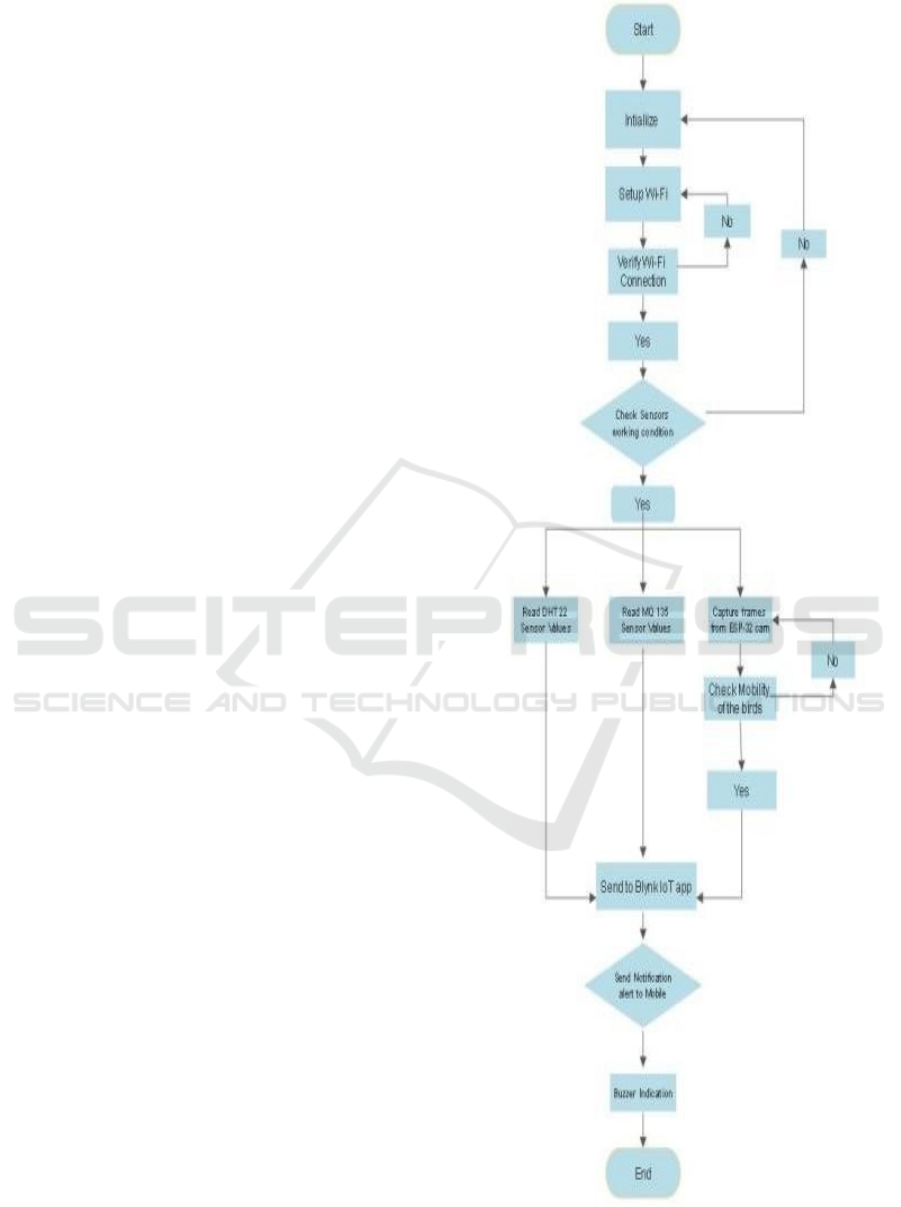

Figure 3 – Circuit Diagram

Once the hardware is in place, applications for

data collecting and video streaming can be created.

The Arduino IDE platform can code the ESP8266,

and libraries can connect with the MQ-135 and

DHT22 sensors. The ESP32-CAM can be

programmed using the ESP-IDF, and libraries to

interact with the camera can be utilized. After

compiling and correcting any mistakes, the codes are

submitted to the board. The code is executed, and the

output is collected from the serial monitor port. The

baud rate is set as 115200.

This system requires and utilizes a Wi-Fi system.

The ESP32 cam and the device should be connected

in the same Wi-Fi for getting the live stream in a web

ICEISA 2024 - International Conference on ‘Emerging Innovations for Sustainable Agriculture: Leveraging the potential of Digital

Innovations by the Farmers, Agri-tech Startups and Agribusiness Enterprises in Agricu

8

browser using the IP address generated but the ESP32

cam in the serial monitor output.

The sensors are used in a poultry cage which had

160 chicks in it. The study was carried out till the

chicken was sold. The sensors are attached inside the

cage at a certain height to prevent damage caused by

the chicks. The power source was made available for

the sensor system and Wi-Fi module from a switch

box attached just outside the cage. ESP8266 and Wi-

Fi require a separate power supply which was given

by a multi-pin holder. A 5V adapter was used

separately for both ESP8266 and Wi-Fi.

One popular way to visualize the data collected

from the sensors is to use the Blynk app. The data

collected from the sensors can be sent to the Blynk app

using the ESP8266's Wi-Fi connectivity, and the app

can be used to display the data in a user- friendly

format. Blynk IoT platform enables us to view current

data and download previous data. It can also show the

data graph of the parameters we use for up to 1-month

duration. We can set the threshold limit and can

enable the notification if the parameter value exceeds

it. It allows the user to get the notification in mobile

by vibrating and also sends a mail if opted. We can

adjust the notification timer refreshing to avoid

continuous alert messages. We can also get the live

stream data by using a URL in a widget. It also

enables a user to make further automations in the

same Blynk platform. It supports multiple users using

the same login credentials to access at the same time.

Finally, the ESP32-CAM can be used for video

streaming, allowing farmers to monitor their poultry

farms. The ESP32-CAM can be programmed to send

video data to a server, which can then be accessed by

the Blynk app or can be accessed by the IP address

generated by compiling and running the code. The IP

address can be obtained from the serial monitor port

of the Arduino IDE platform at a baud of 115200.

This feature can be particularly useful for monitoring

the behavior of the birds, identifying potential health

problems, and detecting any environmental issues that

may affect their growth. The working steps are

expressed as a flow chart in Figure 4.

3.4 Threshold Values

To initiate the alert message system we have to feed

the threshold values to the sensor system. The

threshold values are tabulated in Table 1. The

threshold values are set in the Blynk IoT platform. If

the reading exceeds the threshold level, the

application sends us an alert notification to the

mobile. The alert messages and the readings of the

parameters are given in Figure 5.

Figure 4 - The flowchart of the designed system.

Precision Poultry Management Using Smart Sensors

9

Table 1 - Threshold levels of various parameters

Parameter Threshold Range/Value

Temperature 35˚C

Humidity 80%

Ammonia Gas 25 ppm

Carbon dioxide 10 ppm

Smoke Level 5 pm

3.5 Application

The proposed system is cost-efficient. It can help in

quick identification and address issues like spikes in

temperature or humidity or ammonia or carbon

dioxide levels. The system is easy to use and doesn’t

require deep knowledge. It can be used both in small-

scale and large-scale farms. It also can be used in

disease detection and management. The designed

system helps in maintaining a suitable environment

for better growth of chicks. The increased production

of chicks and eggs thus generated higher income to

farmers.

4

RESULTS

From the study, we present a system of sensors that

can detect various important parameters such as

Temperature, humidity, ammonia, Carbon Dioxide,

and air quality. The study was carried out with 160

chicks in a cage system. The system can give alert

messages via notification and mail. It can also

produce sound from the buzzer attached to the

microcontroller. This system is made of ESP8266

Processor and Wi-Fi. We can get the live video

stream or images from the OV2640 website using the

IP address. The data of specified parameters collected

can be downloaded from the Blynk IoT platform.

Data for one month can be downloaded from the

Blynk platform. The data are downloaded in CSV file

format which gives the readings of various

parameters with time stamps. We can also monitor

the parameters reading as a graph for 3 months. The

minimum and maximum values for various

parameters are found in this study and have been

tabulated in Table 2. The temperature in the daytime

time found to be more than 35˚C at most times and

around 27˚C at night times. The minimum

temperature recorded is found to be 21.29˚C and the

maximum is 39.1˚C. The humidity recorded goes to a

minimum level of 8.49% and a maximum of 92.5%.

The ammonia level was recorded to be around 16

ppm (approx.). Figure 4 shows the alert notification

message from the Blynk platform. The alert message

shown in Figure 5 is due to the exceeded threshold

level of parameters such as temperature and CO2.

Figure 6 shows the parameter readings in the Blynk

IoT Platform. The widget appears as a meter which

shows the level in the specified unit. The temperature

reading shows 35.7˚C which is higher than the

threshold level. The humidity is recorded as 41.8%

which is less than the optimum humidity level

required. Parameters such as Ammonia level, CO2,

and Smoke level are all below the threshold levels.

The sample data we derived from the Blynk IoT

application can be seen in Figure 7. It shows the date

and time in the first column, ammonia level (ppm),

CO2 concentration (ppm), Temperature (in C and F),

humidity (%), and smoke concentration (ppm) in the

successive columns. Figure 8 shows the image of

chicks in a cage captured from the ESP32 cam in the

OV2640 website. The resolution of the video stream

from the camera is 320 x 240 pixels. The resolution

can be changed manually. Figure 9 depicts the

Temperature graph during the period of study. We

can see the variations. It rises above 34˚C during the

day and falls below 27˚C during night time. Figure

10 shows the graph of humidity (%). We can see a rise

in humidity during the night and a fall in humidity

below 60% during the daytime. Figure 11 shows the

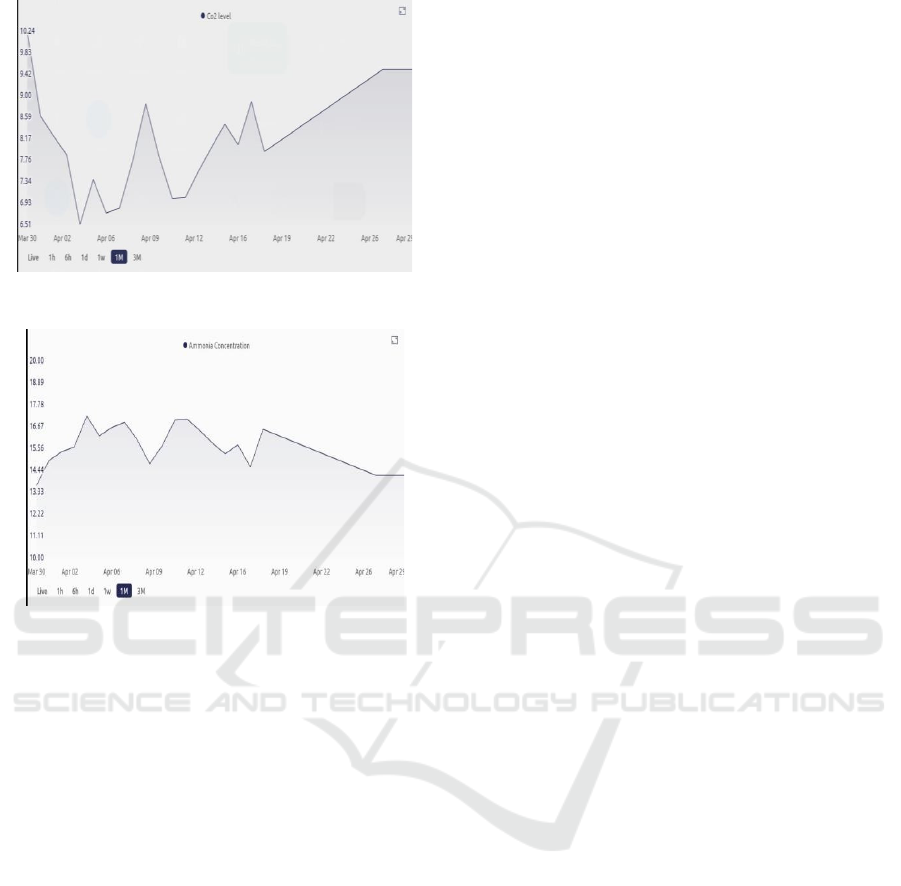

ammonia concentration (in ppm) as a graph. We can

see that the concentration is observed to have very

little changes in the range of 13-17 ppm (approx.).

Figure 12 shows the variations in carbon dioxide

concentrations as a graph which varies from 6-10

(ppm).

The overall minimum, maximum, and average

v a l u e s f o u n d i n t h e f a r m a r e t a b u l a t e d i n T a b l e 2 .

Table 2 - Overall data from the Blynk IoT app

Parameters

Minimum

Value

Maximum

Value

Average

Value

Temperature 21.29˚C 39.1˚ C 30.65˚C

Humidity 7.45% 92.5% 57.16%

Ammonia

level

4.61 ppm 41.66 ppm 16.01 ppm

Carbon

dioxide

1.39 ppm 86.2 ppm 7.75 ppm

Smoke 1.06 ppm 1.26 ppm 0.48 ppm

ICEISA 2024 - International Conference on ‘Emerging Innovations for Sustainable Agriculture: Leveraging the potential of Digital

Innovations by the Farmers, Agri-tech Startups and Agribusiness Enterprises in Agricu

10

Figure 5 - Alert Message from the Blynk IoT app

Figure 6 - Data of various parameters in Blynk Interface

Figure 7 – Sample table of data from Blynk IoT app

Figure 8 – Image of poultry cage from ESP 32 Cam

module

Figure 9 – Temperature Graph (in ˚C)

Figure 10 – Humidity Graph (in %)

Precision Poultry Management Using Smart Sensors

11

Figure 11 – Ammonia Concentration Graph (in ppm)

Figure 12 – Co2 Concentration Graph (in ppm)

4.1 Discussion and Conclusion

The designed system is cost-effective and can be

easily affordable for the farmers. In past years, the

environmental conditions in the poultry farm were

not monitored properly. We all know that the

environmental parameters in the poultry farm can

affect the growth and health of the birds, it also

affects egg production. If the environmental

parameters are maintained properly, we can enhance

egg production. We can also reduce the mortality of

the birds. So, the designed system has the capability

of monitoring the various environmental parameters

and real-time monitoring of the birds through video

streaming in the Blynk IoT app and it also as a feature

of sending notification alerts to the poultry farmers if

any environmental parameters are not in the optimum

level. The designed system helps the farmers to

understand poultry farming more easily and also

improves the economic status of the farmers.

This is an innovative technology that has the

potential to serve as a bridge in connecting traditional

farming practices with modern automation

techniques. It can change the previously followed

management practices. Thus, it is an ideal system to

monitor the growth of chicks continuously.

In this study, we have found that the temperature

in this locality is much higher than the threshold

values given in Table 1. Also, the humidity is very

low and does not meet the minimum requirement of

60%.

In the future, this system can be enhanced by the

addition of automated intimation techniques and

disease detection. This can also be extended to

management practices like automated ventilation by

fans. Automation by sprinklers in case of high

temperatures or low humidity can be used.

REFERENCES

Chatterjee, R.N. and Rajkumar, U., 2015. An overview of

poultry production in India. Indian Journal of Animal

Health, 54(2), pp.89-108.

Choosumrong, S., Raghavan, V. and Pothong, T., 2019.

Smart poultry farm based on the real-time environment

monitoring system using internet of

things.

วารสาร

เกษตร

นเรศวร

, 16(2), pp.18-26.

Corkery, G., Ward, S., Kenny, C. and Hemmingway, P.,

2013. Incorporating smart sensing technologies into the

poultry industry. Journal of World's poultry research,

3(4), pp.106-128.

El Jeni, R., Dittoe, D.K., Olson, E.G., Lourenco, J., Seidel,

D.S., Ricke, S.C. and Callaway, T.R., 2021. An

overview of health challenges in alternative poultry

production systems. Poultry Science, 100(7), p.101173.

Goswami, S. and Dangi, A., 2022. Arduino Based Smart

Chicken Farming Using Temperature Sensor.

International Journal of Agriculture, Environment and

Biotechnology, 15(2), pp.271-276.

Lufyagila, B., Machuve, D. and Clemen, T., 2022. IoT-

powered system for environmental conditions

monitoring in poultry house: A case of Tanzania.

African Journal of Science, Technology, Innovation and

Development, 14(4), pp.1020-1031.

Mansor, H., Azlin, A.N., Gunawan, T.S., Kamal,

M.M. and Hashim, A.Z., 2018. Development of smart

chicken poultry farm. Indonesian Journal of Electrical

Engineering and Computer Science, 10(2), pp.498-505.

Mitra, A., Majumder, D., Mishra, M. and Sarkar, S., 2021.

Poultry farming: prospects and impediments in India.

Saudi J. Humanities Soc Sci, 6(6), pp.193-198.

Orakwue, S.I., Al-Khafaji, H.M.R. and Chabuk, M.Z.,

2022. IoT Based smart monitoring system for efficient

poultry farming. Webology, 19(1), pp.4105- 4112.

Priya, M.M., Pavithraa, K., Devi, B.P. and Sureshkumar, V.,

2021. SMART POULTRY FARM

INCORPORATING GSM AND IoT.

Rao, R.S., 2015. Trends and challenges of poultry industry.

International Journal of Engineering Technologies and

Management Research, 1(1), pp.8- 13.

Sheikh, I.U., Nissa, S.S., Zaffer, B.,Bulbul, K.H.,

ICEISA 2024 - International Conference on ‘Emerging Innovations for Sustainable Agriculture: Leveraging the potential of Digital

Innovations by the Farmers, Agri-tech Startups and Agribusiness Enterprises in Agricu

12

Akand, A.H., Ahmed, H.A., Hasin, D., Hussain, I. and

Hussain, S.A., 2018. Ammonia production in the

poultry houses and its harmful effects. International

Journal of Veterinary Sciences and Animal Husbandry,

3(4), pp.30-33

Precision Poultry Management Using Smart Sensors

13