Investigation of Lossy Mode Resonance Phenomenon

in High Index Cladding Optical Fiber

Sukanya Choudhary, Flavio Esposito

a

, Stefania Campopiano

b

and Agostino Iadicicco

c

Department of Engineering, University of Naples “Parthenope”, 80143 Napoli, Italy

Keywords: Fiber Optic Sensor, Lossy Modes, Refractometer, Bio-Chemical Sensor.

Abstract: Here, we report the novelty of inducing the lossy mode resonance (LMR) phenomena without usage of any

additional coating onto the fiber device. Instead, a high refractive index cladding (HIC) optical fiber is utilized,

eliminating the need for additional coatings. This kind of optical fiber has a cladding whose refractive index

is higher than the core. The outer cladding with high refractive index permits the generation of lossy modes,

a key component of the LMR phenomenon. The diameter of the fiber is modified through chemical etching.

This modification serves as a tuning mechanism for the LMR phenomenon, influencing the number of modes

guided, order of mode, and resonant wavelength of LMR bands. The developed device is noted for its

simplicity and cost-effectiveness. The sensor exhibits a maximum sensitivity of 1700 nm/RIU to surrounding

refractive index (SRI) around region of water refractive index. The higher sensitivity and simplification of

the device make it suitable for applications in biological and chemical sensing.

1 INTRODUCTION

Lossy mode resonance (LMR) is a phenomenon that

occurs in waveguide structures, such as optical fibers

or planar waveguides. These waveguides support

different modes of light propagation, and the term

“lossy mode” refers to modes that experience optical

losses while propagating in this case. The resonance

condition is achieved when light is coupled into the

lossy modes of the waveguide structure (Del Villar et

al., 2017). This coupling occurs when the propagation

constant of the incident light matches that of the lossy

modes (Fuentes et al., 2022), leading to enhanced

light absorption and transmission characteristics.

Lossy mode resonance can be highly sensitive to

changes in the refractive index of the surrounding

medium. When a biomolecule or analyte binds to the

waveguide surface, it induces changes in the

refractive index of the surrounding environment,

leading to shifts in the resonance condition. These

shifts in resonance can be measured and correlated

with the concentration or presence of the target

analyte, forming the basis for optical sensing. The

high sensitivity of LMR-based sensors makes them

a

https://orcid.org/0000-0003-1187-5825

b

https://orcid.org/0000-0002-2987-9122

c

https://orcid.org/0000-0002-3540-7316

suitable for real-time monitoring and detection of

biological interactions. The resonant condition in

LMR sensors is dependent on changes in the

refractive index of the material layer. While the field

of LMR-based sensors is still evolving, it has seen

considerable growth in the last years.

Various configurations have been explored for

LMR-based devices, including: 1) Optical prism:

LMR can be observed when a thin film coats an

optical prism, influencing the behaviour of light as it

interacts with the prism surface. 2) Optical fiber:

Fiber optic configurations are particularly popular for

studying LMR. The inherent features of fiber optics,

such as the ability to guide light over long distances

and the ease of incorporating thin films, make them

well-suited for exploiting LMR for various

applications. 3) Planar waveguide: LMR can also be

observed in these waveguides, which are flat, layered

structures that guide light along their surface.

The reason why fiber optic LMR devices are

preferred over other configurations are: the small size

of fiber optics makes them suitable for compact and

portable devices. Fiber optics are lightweight, making

them easy to handle and integrate into different

Choudhary, S., Esposito, F., Campopiano, S. and Iadicicco, A.

Investigation of Lossy Mode Resonance Phenomenon in High Index Cladding Optical Fiber.

DOI: 10.5220/0012589700003651

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 12th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2024), pages 103-109

ISBN: 978-989-758-686-6; ISSN: 2184-4364

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

103

systems. The cost-effectiveness of fiber optic

technology contributes to its widespread adoption in

research and practical applications. Fiber optics allow

for remote sensing and monitoring, making them

valuable in applications such as environmental

sensing and distributed sensing. The immunity of

fiber optics to electromagnetic interference is a

significant advantage in applications where a stable

signal is crucial (Paliwal & John, 2015).

The research explores materials that support the

LMR phenomenon and its applications in optical

sensing of chemical and biological analytes. Various

oxide materials such as zinc oxide (ZnO), indium tin

oxide (ITO) (Śmietana et al., 2020), indium oxide

(In

2

O

3

), tin oxide (SnO

2

) (Sanchez et al., 2014),

titanium oxide (TiO

2

) (Hernaez et al., 2019), and

some polymers have been reported to support lossy

mode resonance. The LMR phenomenon in these

devices is controlled through a proper selection of

material refractive index (RI) and thickness. This

implies that the choice of coating materials and their

characteristics plays a crucial role in manipulating the

LMR effect.

Suitable materials for LMR generation exhibit: a

permittivity with a positive real part of refractive

index; absorption coefficient is low. A thin film

overlay is introduced with a specific thickness. For

this thin film, certain modes guided in the optical

fiber core undergo a transition to guidance in the thin

film, where losses are introduced (acting as a new

cladding). Modes that transition to the thin film (new

cladding) undergo a change in their imaginary part of

refractive index and increases, indicating the

introduction of losses altering the characteristics of

these modes. As a consequence of the mode transition

and reorganization (Srivastava et al., 2023) (Esposito

et al., 2023) the transmission spectrum of the fiber

undergoes changes. Attenuation bands appear in the

spectrum at wavelengths where a mode is near about

cutoff condition in the thin film coating (Corres et al.,

2015). High index materials in LMR sensors offer

high sensitivity, label-free sensing, short response

time, and fast recovery. LMR-based sensors compete

with established optical techniques like scattering,

absorption, fluorescence, surface plasmon resonance

(SPR), and localized surface plasmon resonance

(LSPR) in terms of optical sensing performance.

LMR in fiber optics has gained much importance

for its applications in sensing across various

interdisciplinary domains (Esposito et al., 2022).

LMR in fiber optics can be employed for label-free

biosensing (Chiavaioli et al., 2022), enabling the

detection of biomolecules without the need for

fluorescent or other labels. This is valuable in

applications like medical diagnostics and

biotechnology for detecting biomarkers (Zubiate et

al., 2019) associated with diseases. LMR-based fiber

optic sensors can be designed to detect specific gases

or chemicals. LMR devices in chemical sensing,

allows the identification and analysis of chemical

compositions in a given sample (Esposito, 2021).

This is relevant in fields such as industrial process

control and quality assurance. Changes in the

refractive index due to the presence of the target

substance can alter the resonance conditions,

providing a basis for sensitive environmental

monitoring.

Chemical or biosensors (Chiavaioli et al., 2020,

2022) typically involve a sensing layer that interacts

with the target analyte. The interaction induces

changes in the properties of the material layer, which

can be optical, electrical, or mechanical. Optical

chemical and biosensors often rely on changes in the

refractive index of the material-analyte interface.

Chemical and biochemical reactions at this interface

alter the optical properties, such as refractive index.

Functionalization is important step in biosensor

design and optimization. Indeed, the

functionalization stage is pivotal because it involves

modifying the sensing surface to enable the

immobilization of bioreceptors, which play a crucial

role in interacting with the analyte and generating a

detectable signal. There are some key aspects which

are mentioned: 1) Transducing mechanism: the

transducing mechanism of a biosensor refers to how

the biological recognition event is converted into a

measurable signal. Common transducing

mechanisms include optical, electrochemical, and

piezoelectric methods. The choice of surface

modification strategy often depends on optimizing

the sensing surface for a particular transduction

mechanism to enhance signal transduction efficiency.

2) Substrate: the substrate is the underlying material

on which the biosensor is built. It could be made of

materials such as silicon, glass, polymers, or metals.

The compatibility of the surface modification strategy

with the substrate is crucial for the stability and

performance of the biosensor. 3) Bioreceptor: the

bioreceptor is the biomolecule that specifically

interacts with the target analyte. It can be an enzyme,

antibody, DNA, or a whole cell. The nature of the

bioreceptor influences the choice of surface

modification. Different bioreceptors may require

specific functional groups or attachment chemistries

for effective immobilization. 4) Surface modification

strategies: various surface modification strategies are

available, and the choice depends on the factors

mentioned above. Common strategies include self-

AOMatDev 2024 - Special Session on Advanced Optical Materials and Devices

104

assembled monolayers (SAMs), polymer coatings,

crosslinking agents, physical adsorption, and the use

of nanomaterials. Each strategy offers unique

advantages and may be more suitable for specific

applications or sensor configurations.

In this context, the work focuses on transducer

part and reports on the generation of LMR without

usage of any additional high refractive index coating

on the fiber. This approach is highlighted for its

advantages in terms of simplification and cheapness.

An unconventional optical fiber is used, having a

cladding with a refractive index higher than the core.

This is referred to as a high index cladding (HIC) fiber

to facilitate the generation of LMR phenomena. With

control of thickness of the high index cladding region,

the tuning of the phenomena can be performed in

order to increase the device sensitivity. This tuning

capability suggests that the optical characteristics of

the system can be tailored to meet the needs of a

particular application (Chiavaioli & Janner, 2021).

2 DEVELOPMENT OF LMR

SENSOR

The LMR is a direct consequence of the “mode

transition” phenomena (Cusano et al., 2006). As light

undergoes these mode transitions, it can lead to

resonances that manifest as lossy mode resonance

bands in the transmitted spectrum.

To excite LMR in optical fibers, a combination of

factors such as an overlay with a high refractive

index, controlled absorbance loss in the overlay, and

specific fiber configurations (e.g., coated cladding

removed MMF or polished single mode fibres) are

employed. These configurations are designed to

optimize the conditions for the occurrence of LMR,

which can have applications in various optical

systems and devices.

The design involves a coating with a higher

refractive index than the core, causing the extension

of core mode fields into the overlay (Del Villar et al.,

2012). The thin overlay with a low absorption

coefficient initially has minimal impact on the core

modes, but this state can be altered abruptly when

mode transition events are initiated. In addition to the

core modes, there are some modes which guides in

the overlay region are called as lossy modes. The

existence and number of these lossy modes depend on

the two main factors which are: refractive index and

thickness of the overlay. The tuning of overlay

features can lead to mode transitions, changes in

electrical field distribution, and the manifestation of

LMR in collected transmission spectra (Choudhary et

al., 2023). The absorption coefficient of the thin film

coating or overlay plays a crucial role. If the

absorption coefficient increases significantly, the

LMR resonance will broaden.

2.1 Sensor Fabrication

For LMR excitation, the use of a double cladding

fiber (DCF) with a W-shaped refractive index profile

serves as a practical alternative to the custom-

designed HIC fiber (Choudhary et al., 2023). This

choice allows for more accessible procurement while

still offering flexibility in tailoring the optical

properties for the intended purpose.

The DCF has specifications mentioned below:

- Core diameter (dco): 9 μm.

- Inner cladding diameter (dcl,inn): 95-100 μm.

- Outer cladding diameter (dout): 125 μm.

Achieved through Flourine doped core and inner

cladding regions (at different concentrations), and

outer cladding made of pure silica.

DCF is strategically utilized between two MMFs

to facilitate efficient coupling between the MMF

cores and the inner cladding of the DCF. The W-

shaped refractive index profile is designed to support

the desired optical characteristics, and the outer

cladding of the DCF allows for the presence of lossy

modes, contributing to the LMR phenomena.

The sensor setup involves illuminating the DCF

with a white light source, collecting the transmitted

light, and analyzing the transmission spectrum using

a spectrometer in the visible range, as reported in

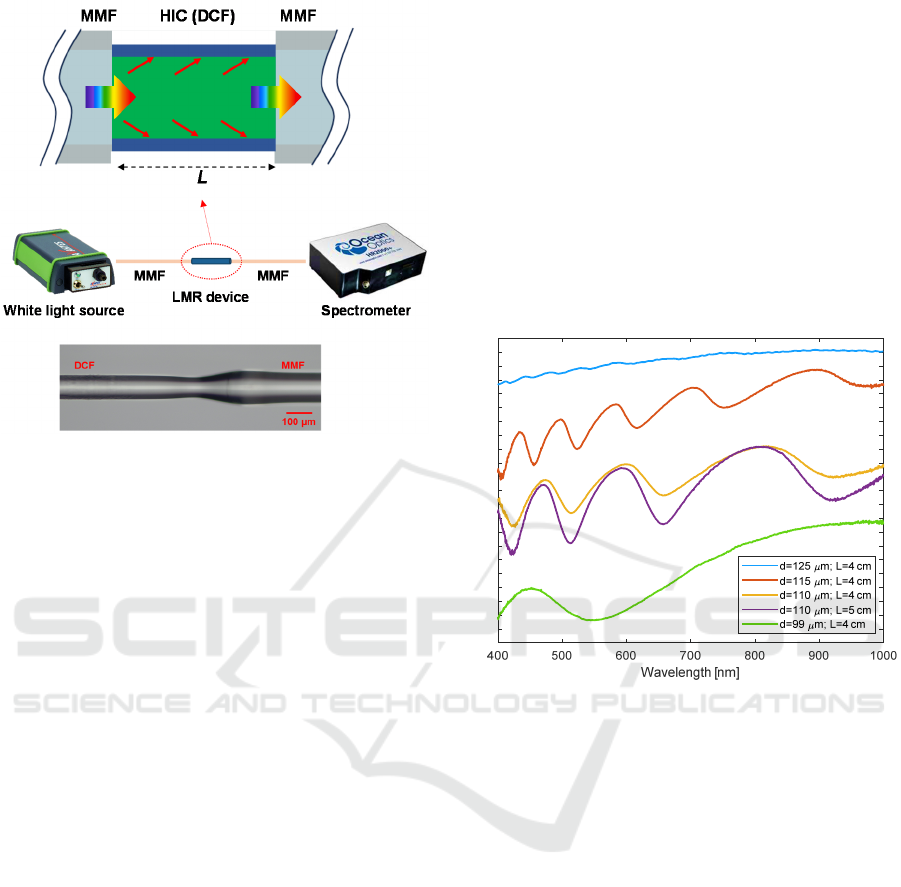

Figure 1.

Tuning of the LMR phenomena in the sensor

involves modifying the DCF thickness, specifically

reducing the outer cladding thickness to achieve low-

order bands. Additionally, positioning the resonant

band at higher wavelengths is a key design strategy to

increase the sensitivity of the fiber sensor, based on

LMR working principle. The chemical etching

process, using a 24% HF solution with a known

etching rate, is employed to tailor the thickness of the

DCF fiber. This control over fiber thickness provides

a way to influence the guided modes.

2.2 Tuning the Device Properties

Tuning the LMR phenomenon in optical waveguides

is crucial for optimizing the performance of

biosensors and other optical devices. The physical

dimensions of the waveguide, including its width,

thickness, and geometry, can influence the LMR

Investigation of Lossy Mode Resonance Phenomenon in High Index Cladding Optical Fiber

105

Figure 1: LMR device based on HIC: schematic

representation of interrogation setup and microscope

picture of spliced between DCF and MMF.

wavelength and sensitivity. Tuning these dimensions

allows for optimization based on the target

application and desired spectral characteristics.

Multiple devices have been fabricated with variations

in the diameter and length of the double cladding

fiber. Different diameters imply variations in the

thickness of the high refractive index outer cladding

of the double cladding fiber. The primary goal of the

experiment is to find the capability to adjust the LMR

phenomena. The variations in DCF diameter and

length are likely intended to observe how these

parameters affect the resonant characteristics.

DCFs with four different outer cladding diameters

are compared in Figure 2: 125 µm (unetched), 115

µm, 110 µm and 99 µm. The DCF with a diameter of

125 µm (blue line), which is unetched, shows several

LMR bands, but they are challenging to observe. The

double cladding fiber with a diameter of 115 µm

(orange line) exhibits six clear resonances. These

resonances are associated with mode transitions

between the core and outer cladding. The DCF with a

diameter of 110 µm (yellow curve) shows fewer

resonant peaks in the desired wavelength region. The

decrease in diameter results in a reduction in the

number of dips. Another device with the smallest

diameter of 99 µm (green line) produce a single

resonant LMR peak located at 550 nm. The visibility

of LMRs in Figure 2 is generally enough, with peak

depth up to 4-5 dB, except for the spectra related to

fiber with unetched part. The presence of surface

roughness is due to the HF-based chemical treatment

during the etching process is identified as a key factor

affecting the visibility of LMRs. While the pristine

fiber shows no significant power losses in guided

modes, the introduction of surface roughness in the

etched fiber induces scattering power losses,

particularly during mode transitions. In future our

work will to further improve the depth of LMR bands.

The comparison of devices with different lengths

and the same diameter i.e., for 110 µm indicates that

varying the length has a clear impact on the depth of

the resonant peaks. However, the overall shape and

the number of resonances remain consistent,

suggesting that the observed resonant peaks are solely

related to LMR phenomena.

Figure 2: Spectral results of LMR devices for four different

outer diameter values (125 µm, 115 µm, 110 µm and 99

µm) of DCF.

3 CHARACTERIZATION

Here, refractometer characterization (Urrutia et al.,

2019) is a predominant area of investigation for LMR

devices. This focus is driven by the understanding

that refractometer characterization serves as a key

indicator of sensitivity in LMR fiber optic devices,

especially concerning their response to chemical and

biological species. LMR devices are highly sensitive

to changes in the refractive index of the surrounding

medium. By characterizing the sensor using a

refractometer, researchers can precisely measure and

quantify the shifts in resonance conditions in response

to variations in the refractive index. This sensitivity is

paramount for detecting and monitoring chemical and

biological species (Benítez et al., 2022). Rigorous

refractometer characterization ensures the quality

control and reproducibility of LMR devices.

Refractometer characterization helps evaluate the

Transmission with offset [1 dB/div]

AOMatDev 2024 - Special Session on Advanced Optical Materials and Devices

106

versatility of LMR devices across different types of

analytes for the broad applicability of LMR sensors

in various fields, ranging from environmental

monitoring to medical diagnostics.

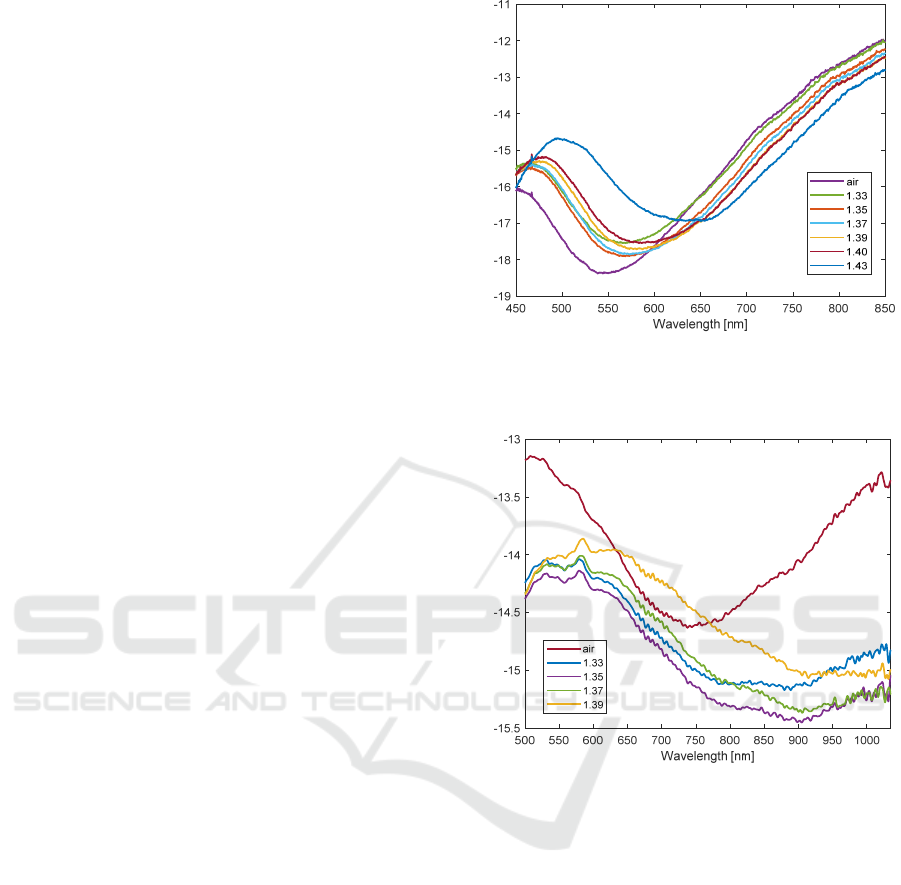

In this specific study case, we perform the

characterization for two devices with different

diameters i.e., 99 and 96 μm where the outer cladding

of the DCF is decreased using chemical etching

results in a single attenuation band associated with a

first order LMR.

The modified DCF exhibits a single resonant peak

positioned near around 550 nm for device with

diameter 99 μm as shown in Figure 3 whereas in case

of 96 μm, peak is positioned at 750 nm in Figure 4.

The visibility of the attenuation band is mentioned,

even though it might be limited due to low RI

contrast. Despite the limitations, the attenuation band

allows for the identification of the resonance

wavelength.

The primary focus is on assessing how the device

responds to variations in the SRI. For same purpose,

glycerol-water mixtures at different concentrations

are used as the surrounding medium. The refractive

index of each mixture is determined to be in the range

of 1.33-1.43. An Abbe refractometer is employed to

measure and verify the refractive index of the

glycerol-water mixtures. Changes in the refractive

index of the surrounding medium are likely to affect

the sensing behaviour of the device. Each device is

immersed in each glycerol-water mixture for a

sufficient duration. This immersion period allows for

the device to reach a stable response in each SRI

condition. Spectra are measured during or after the

immersion to capture the optical response of the

device under each SRI condition. After each

measurement, the device is cleaned using deionized

water. This cleaning step is crucial to ensure the

removal of any residual materials from the previous

measurement and to maintain accuracy in subsequent

readings. The procedure is repeated for different

glycerol-water mixtures, each with varying refractive

indices within the range of 1.33-1.43.

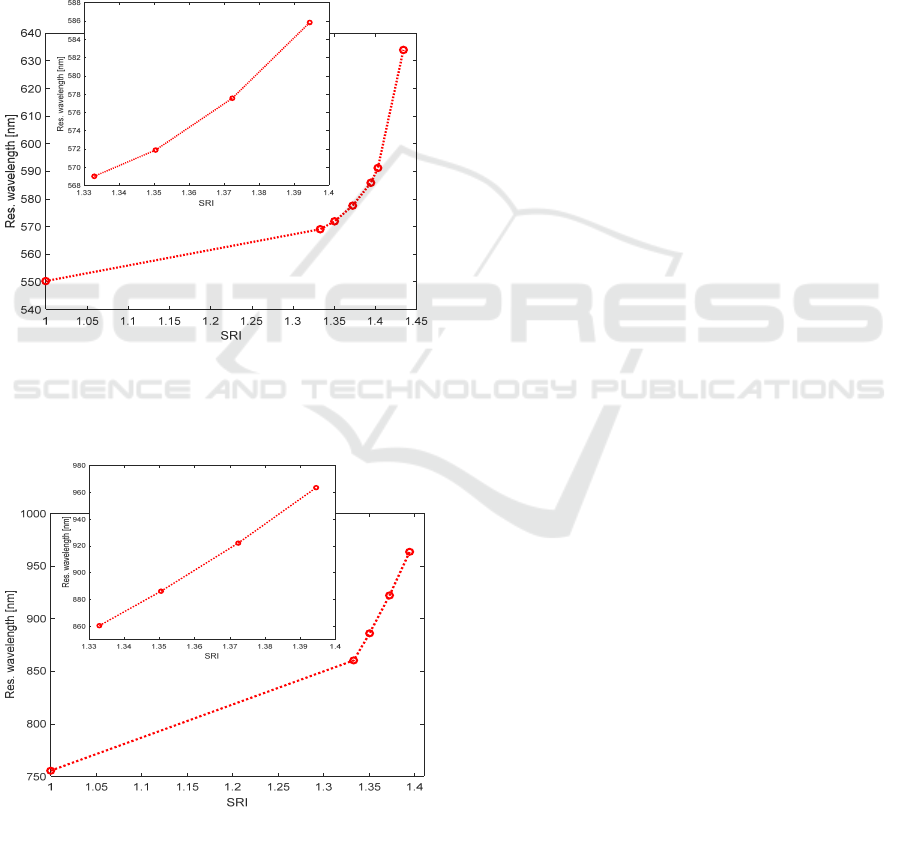

The response of device with diameter 99 μm to

change in surrounding refractive index is depicted in

Figure 5. Here, the resonant wavelength is identified

and LMR band is initially found at 550 nm and with

increase in SRI a red shift has been observed, moving

this LMR band to higher wavelength i.e., from 550

nm to 650 nm, when the SRI is increased from 1.33

to 1.43, respectively. The red shift is comparable to

what reported in literature while dealing with

refractometric characterization of LMR sensors and

due to the impact of change in SRI on the mode

effective refractive indices. The trend of the LMR

Figure 3: Characterization of the LMR device to SRI for

diameter 99 µm: spectral results with immersion of fiber

sensor in solutions at different refractive indices.

Figure 4: Characterization of the LMR device to SRI for

diameter 96 µm: spectral results with immersion of fiber

device in solution at different refractive indices.

resonance wavelength peak with surrounding

refractive index is thus reported in the inset of Figure

5, where the linear fit on the trend shows a sensitivity

of nearly 300 nm/RIU (refractive index unit).

Achieved sensitivity is not much higher as compared

to previous works reported in literature (Ozcariz et

al., 2017) with tens of thousands of nm/RIU.

The device sensing features are further tuned by

reducing the diameter of the DCF outer cladding to

96 μm. In this case, we observe, LMR band of 1

st

order now around 750 nm wavelength as shown in

Figure 6 showing a significantly higher shift, i.e.,

more than device with diameter 99 μm, shifting the

resonant peak from 860 nm to around 960 nm when

surrounding refractive index is increased from 1.33 to

1.39. Here, achieved sensitivity is 1700 nm/RIU,

Transmission [dB]

Transmission [dB]

Investigation of Lossy Mode Resonance Phenomenon in High Index Cladding Optical Fiber

107

which is considered adequate for the intended

applications.

The maximum sensitivity achieved with the

presented LMR devices was compared with that of

materials reported in literature and found to be lower

than that achieved with widely employed metal

oxides. The lower sensitivity in comparison to metal

oxides is attributed to the lower refractive index

difference between the outer and inner claddings of

the DCF. Despite the lower sensitivity compared to

metal oxides, the proposed configuration using DCF

outer cladding has several advantages i.e., simplicity,

cost-effectiveness and long-term performance.

Figure 5: Characterization of the LMR device to SRI for

diameter 99 µm: response of resonance wavelength with

surrounding refractive indices and inset illustrating the

sensitivity around water RI.

Figure 6: Characterization of the LMR device to SRI for

diameter 96 µm: response of resonance wavelength with

surrounding refractive indices and inset illustrating the

sensitivity around water RI.

4 CONCLUSIONS

We have developed LMR devices by using high index

cladding fiber without need of any extra high

refractive index coating onto the fiber. The sensor

features were further tuned with usage of chemical

etching done with HF acid to reduce fiber diameter.

Specific cases with diameters of 99 μm and 96 μm are

highlighted and achieved high sensitivity of 300

nm/RIU and 1700 nm/RIU in the refractive index

range of 1.33-1.43. These results indicate that

modifying the fiber diameter significantly impacts the

sensitivity of the LMR transducer. In future, our focus

will be on improving the visibility of LMR devices

and employ these devices further for bio-chemical

applications.

ACKNOWLEDGEMENTS

The work of Flavio Esposito was supported by

the D.M. 1062/2021 - FSE REACT EU - PON

Ricerca e Innovazione 2014-2020 - Azione IV.4

“Dottorati e contratti di ricerca su tematiche

dell'innovazione” under contract nr. 41-I-15372-1

CUPI65F21001200001.

REFERENCES

Benítez, M., Zubiate, P., Del Villar, I., Socorro-Leránoz, A.

B., & Matías, I. R. (2022). Lossy Mode Resonance

Based Microfluidic Platform Developed on Planar

Waveguide for Biosensing Applications. Biosensors,

12(6), 403. https://doi.org/10.3390/bios12060403

Chiavaioli, F., Baldini, F., Giannetti, A., Del Villar, I.,

Zubiate, P., Santano, D., Urrutia, A., Zamarreño, C. R.,

Díaz, S., Arregui, F. J., & Matias, I. R. (2020). Lossy

Mode Resonance Excitation in Fiber-Optics:

Applications in Biosensing. Asia Communications and

Photonics Conference/International Conference on

Information Photonics and Optical Communications

2020 (ACP/IPOC), S4G.1. https://doi.org/10.1364/

ACPC.2020.S4G.1

Chiavaioli, F., & Janner, D. (2021). Fiber Optic Sensing

With Lossy Mode Resonances: Applications and

Perspectives. Journal of Lightwave Technology,

39(12), 3855–3870. https://doi.org/10.1109/JLT.202

1.3052137

Chiavaioli, F., Santano Rivero, D., Del Villar, I., Socorro

Leránoz, A. B., Zhang, X., Li, K., Santamaría, E.,

Fernández-Irigoyen, J., Baldini, F., van den Hove, D. L.

A., Shi, L., Bi, W., Guo, T., Giannetti, A., & Matias, I.

R. (2022). Ultrahigh Sensitive Detection of Tau Protein

as Alzheimer’s Biomarker via Microfluidics and

Nanofunctionalized Optical Fiber Sensors. Advanced

AOMatDev 2024 - Special Session on Advanced Optical Materials and Devices

108

Photonics Research, 3(11). https://doi.org/10.1002/

adpr.202200044

Choudhary, S., Esposito, F., Sansone, L., Giordano, M.,

Campopiano, S., & Iadicicco, A. (2023). Lossy Mode

Resonance Sensors in Uncoated Optical Fiber. IEEE

Sensors Journal, 23(14), 15607–15613. https://doi.org/

10.1109/JSEN.2023.3280675

Corres, J. M., Villar, I. Del, Arregui, F. J., & Matias, I. R.

(2015). Analysis of lossy mode resonances on thin-film

coated cladding removed plastic fiber. Optics Letters,

40(21), 4867. https://doi.org/10.1364/OL.40.004867

Cusano, A., Iadicicco, A., Pilla, P., Contessa, L.,

Campopiano, S., Cutolo, A., & Giordano, M. (2006).

Mode transition in high refractive index coated long

period gratings. Optics Express, 14(1), 19.

https://doi.org/10.1364/OPEX.14.000019

Del Villar, I., Arregui, F. J., Zamarreño, C. R., Corres, J.

M., Bariain, C., Goicoechea, J., Elosua, C., Hernaez,

M., Rivero, P. J., Socorro, A. B., Urrutia, A., Sanchez,

P., Zubiate, P., Lopez, D., De Acha, N., Ascorbe, J., &

Matias, I. R. (2017). Optical sensors based on lossy-

mode resonances. Sensors and Actuators B: Chemical,

240, 174–185. https://doi.org/10.1016/j.snb.2016.08.1

26

Del Villar, I., Hernaez, M., Zamarreño, C. R., Sánchez, P.,

Fernández-Valdivielso, C., Arregui, F. J., & Matias, I.

R. (2012). Design rules for lossy mode resonance based

sensors. Applied Optics, 51(19), 4298. https://doi.org/

10.1364/AO.51.004298

Esposito, F. (2021). (INVITED)Chemical sensors based on

long period fiber gratings: A review. Results in Optics,

5, 100196. https://doi.org/10.1016/j.rio.2021.100196

Esposito, F., Campopiano, S., & Iadicicco, A. (2022).

Miniaturized Strain-Free Fiber Bragg Grating

Temperature Sensors. IEEE Sensors Journal, 22(17),

16898–16903. https://doi.org/10.1109/JSEN.2022.319

2355

Esposito, F., Stancalie, A., Srivastava, A., Śmietana, M.,

Mihalcea, R., Neguţ, D., Campopiano, S., & Iadicicco,

A. (2023). The Impact of Gamma Irradiation on Optical

Fibers Identified Using Long Period Gratings. Journal

of Lightwave Technology, 41(13), 4389–4396.

https://doi.org/10.1109/JLT.2022.3191163

Fuentes, O., Del Villar, I., Dominguez, I., Corres, J. M., &

Matías, I. R. (2022). Simultaneous Generation of

Surface Plasmon and Lossy Mode Resonances in the

Same Planar Platform. Sensors, 22(4).

https://doi.org/10.3390/s22041505

Hernaez, M., Mayes, A. G., & Melendi-Espina, S. (2019).

Lossy Mode Resonance Generation by Graphene Oxide

Coatings Onto Cladding-Removed Multimode Optical

Fiber. IEEE Sensors Journal, 19(15), 6187–6192.

https://doi.org/10.1109/JSEN.2019.2906010

Ozcariz, A., Zamarreño, C. R., Zubiate, P., & Arregui, F. J.

(2017). Is there a frontier in sensitivity with Lossy mode

resonance (LMR) based refractometers? Scientific

Reports, 7(1), 10280. https://doi.org/10.1038/s41598-

017-11145-9

Paliwal, N., & John, J. (2015). Lossy Mode Resonance

(LMR) Based Fiber Optic Sensors: A Review. IEEE

Sensors Journal, 15(10), 5361–5371. https://doi.org/

10.1109/JSEN.2015.2448123

Sanchez, P., Zamarreño, C. R., Hernaez, M., Matias, I. R.,

& Arregui, F. J. (2014). Optical fiber refractometers

based on Lossy Mode Resonances by means of SnO2

sputtered coatings. Sensors and Actuators B: Chemical,

202, 154–159. https://doi.org/10.1016/j.snb.2014.05.0

65

Śmietana, M., Koba, M., Sezemsky, P., Szot-Karpińska, K.,

Burnat, D., Stranak, V., Niedziółka-Jönsson, J., &

Bogdanowicz, R. (2020). Simultaneous optical and

electrochemical label-free biosensing with ITO-coated

lossy-mode resonance sensor. Biosensors and

Bioelectronics, 154, 112050. https://doi.org/10.1016/

j.bios.2020.112050

Srivastava, A., Esposito, F., Campopiano, S., & Iadicicco,

A. (2023). Mode transition phenomena into an in-fiber

Mach-Zehnder interferometer. Optical Fiber

Technology, 80, 103481. https://doi.org/10.1016/j.yoft

e.2023.103481

Urrutia, A., Del Villar, I., Zubiate, P., & Zamarreño, C. R.

(2019). A Comprehensive Review of Optical Fiber

Refractometers: Toward a Standard Comparative

Criterion. Laser & Photonics Reviews, 13(11).

https://doi.org/10.1002/lpor.201900094

Zubiate, P., Urrutia, A., Zamarreño, C. R., Egea-Urra, J.,

Fernández-Irigoyen, J., Giannetti, A., Baldini, F., Díaz,

S., Matias, I. R., Arregui, F. J., Santamaría, E.,

Chiavaioli, F., & Del Villar, I. (2019). Fiber-based early

diagnosis of venous thromboembolic disease by label-

free D-dimer detection. Biosensors and Bioelectronics:

X, 2, 100026. https://doi.org/10.1016/j.biosx.2019.10

0026

Investigation of Lossy Mode Resonance Phenomenon in High Index Cladding Optical Fiber

109