Improved PID Control Based on Temperature Compensation for the

Incubation Plate of Chemiluminescent Immunoassay Analyzer

Zhaoyang Wang

1a

, Jing Wang

2

, Bo Liang

1

, Xuesong Ye

1

and Congcong Zhou

2b

1

Biosensor National Special Laboratory, College of Biomedical Engineering and Instrument Science,

Zhejiang University, Hangzhou, Zhejiang, 310027, China

2

Sir Run Run Shaw Hospital, School of Medicine, Zhejiang University,

National Engineering Research Center for Innovation and Application of Minimally Invasive Devices,

East Qingchun Road, Hangzhou, Zhejiang, 310016, China

Keywords: Temperature Compensation, Improved PID Control, Incubation Plate, Constant Temperature Incubation.

Abstract: This paper proposes an improved PID control based on temperature compensation strategy, which can

dynamically adjust the target temperature value of the PID controller according to the ambient temperature

and the preset temperature compensation curve, thus basically eliminating the influence of ambient

temperature on the reaction liquid temperature, and ultimately achieving stable reaction liquid at the preset

temperature under different ambient temperature conditions. Through experiments, it was found that after

adding temperature compensation strategy to the PID control, the maximum steady-state temperature

difference of the reaction liquid decreased from 0.31℃ to 0.11℃, and the coefficient of variation (CV) of

Relative Light Units (RLU) decreased from 4.22% to 1.43%.

1 INTRODUCTION

Chemiluminescence immunoassay (CLIA) is an

analytical method based on the principle of immune

reaction. It utilizes the specific binding between

antigen and antibody to detect the presence and

quantity of specific substances in samples, including

proteins, hormones, tumor markers, etc(Boolani et al.,

2019; Khan et al., 2023; Xiao & Xu, 2020). Constant

temperature incubation is an important step in CLIA,

aiming to enhance the efficiency of antigen-antibody

binding and reduce non-specific reactions, thus

improving the sensitivity and accuracy of detection

results(Suan Ng, Ling Lee, Bothi Raja, & Doong,

2022). In chemiluminescent immunoassay analyzers,

constant temperature incubation is usually performed

in an incubation plate, with the incubation

temperature typically set at 37℃, similar to human

body temperature(Yalcin, oezkan, & Shah, 2022).

Studies have shown that different incubation

temperatures can affect the rate of antigen-antibody

binding and the accuracy and reproducibility of the

luminescence signal(Yufeng, Shizhou, Bo, &

a

https://orcid.org/0009-0004-8996-8743

b

https://orcid.org/0000-0001-8397-1491

Jianwen, 2010). Therefore, it is of great significance

to control the temperature of the reaction solution in

the incubation plate at a stable 37℃ for the accuracy

and reliability of detection results.

The current incubation strategy of the instrument

is to control the temperature of the incubation plate to

remain stable at the preset temperature, and then place

the reaction cups containing the reaction liquid into

the incubation plate for incubation(Feng-Mei, Da-

Qing, Jian-Ning, & Pan-Fei, 2019). Due to the open

top of the reaction cup, the reaction liquid is in direct

contact with the air, and in fact, the temperature of the

reaction liquid is affected by both the temperature of

the incubation plate and the ambient temperature.

In temperature sensing technology, studies have

shown that monitoring environmental temperature

has a significant impact on sensor design and

measurement results(Ren, Zhang, Ye, & Zhou, 2023).

However, most existing instruments set the

incubation temperature on a fixed value using the PID

algorithm, without considering the influence of

environmental temperature. This leads to differences

in the incubation temperature of the reaction liquid at

Wang, Z., Wang, J., Liang, B., Ye, X. and Zhou, C.

Improved PID Control Based on Temperature Compensation for the Incubation Plate of Chemiluminescent Immunoassay Analyzer.

DOI: 10.5220/0012573300003657

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 17th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2024) - Volume 1, pages 811-816

ISBN: 978-989-758-688-0; ISSN: 2184-4305

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

811

different ambient temperatures, resulting in variations

in the detection results of the same sample.

This paper proposes an improved PID control

based on temperature compensation, which can

dynamically adjust the target temperature value of the

PID controller based on different environmental

temperatures. The ultimate goal is to ensure that the

reaction liquid remains stable at the preset

temperature under different ambient temperatures.

The application of this improved PID control based

on temperature compensation for the incubation plate

will help improve the accuracy and reliability of

chemiluminescent immunoassay detection results,

especially in cases where laboratory environmental

temperatures fluctuate significantly. Furthermore,

this control strategy can also be applied to other

experimental scenarios requiring precise temperature

control, demonstrating a certain degree of

universality and practicality.

2 IMPROVED PID CONTROL

BASED ON TEMPERATURE

COMPENSATION

2.1 Principle of the Improved PID

Control

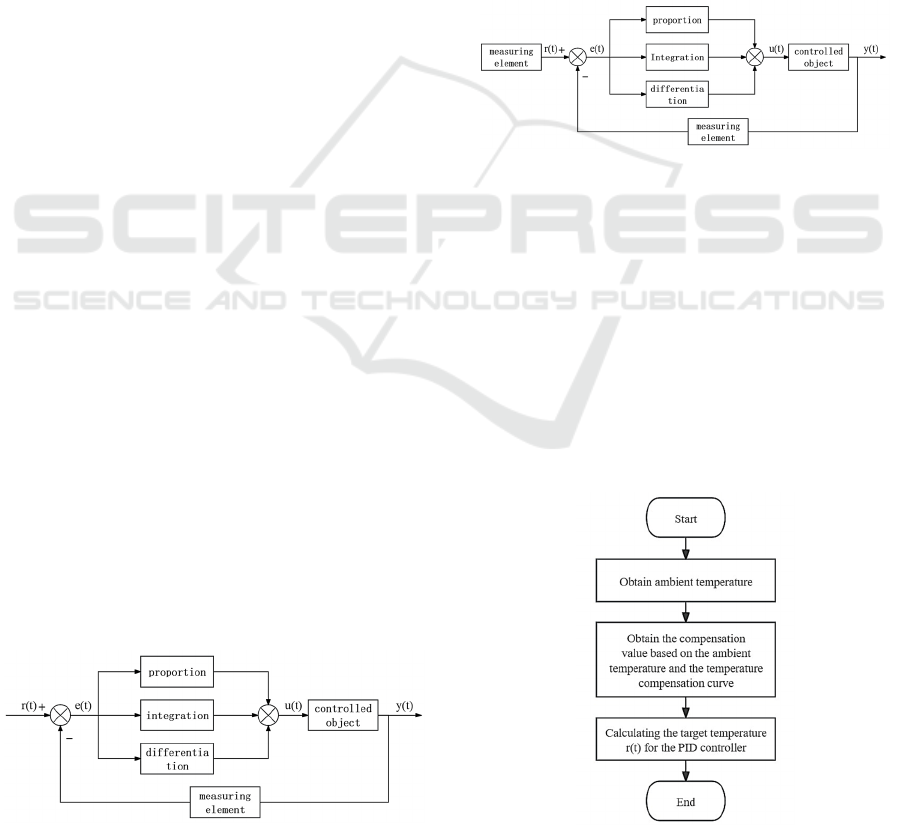

Conventional PID control is a closed-loop control

method based on three components: proportional,

integral, and derivative(Borase, Maghade, Sondkar,

& Pawar, 2021). It is used to regulate the output of a

system to stabilize target variables such as

temperature at a set value. The proportional, integral,

and derivative components work together to adjust

the controller's output to influence the actuator,

thereby achieving precise control of the target

variable of the controlled object(Kaul, Tiwari, Yadav,

& Kumar, 2021; Phu Nguyen, Hung Nguyen,

Ahmadian, & Senu, 2020). The schematic diagram of

conventional PID control is shown in the Figure 1,

where r(t) represents the set value, y(t) represents the

measurement value, e(t) is the error value, and u(t) is

the output value of the PID controller.

Figure 1: Conventional PID control.

In conventional PID control, the set value r(t) is a

fixed value(Joseph, Dada, Abidemi, Oyewola, &

Khammas, 2022; Kaul et al., 2021). However, in a

constant-temperature incubation module, the

temperature of the reaction solution may be affected

by the ambient temperature. Therefore, we propose an

improved PID control based on temperature

compensation, where the set value of the PID

controller can be dynamically adjusted according to

the ambient temperature. Specifically, at high

ambient temperatures, the set value r(t) needs to be

appropriately reduced to avoid overheating of the

reaction solution, while at low ambient temperatures,

the set value r(t) needs to be correspondingly

increased to maintain stable temperature of the

reaction solution. The schematic diagram of the

improved PID control is shown in the Figure 2.

Figure 2: Improved PID control.

The dynamic adjustment of the set value r(t) is

mainly achieved through the ambient temperature and

a preset temperature compensation curve. The

adjustment block diagram of r(t) is shown in the

Figure 3. The temperature sensing sensor collects the

ambient temperature in the first step. In the second

step, the controller calculates the temperature

compensation value for the incubation plate based on

the acquired ambient temperature and the preset

temperature compensation curve. Finally, the target

temperature value for the incubation plate r(t) is

determined in the third step.

Figure 3: Adjustment block diagram of the set value r(t).

BIOSIGNALS 2024 - 17th International Conference on Bio-inspired Systems and Signal Processing

812

2.2 Acquisition of the Temperature

Compensation Curve

The core of improved PID control lies in obtaining

the temperature compensation curve. The steps to

obtain the temperature compensation curve are as

follows:

Step 1: Place the incubation plate in an

environment with adjustable temperature and use the

ambient temperature as the independent variable 𝑥

、

𝑥

、

⋯

、

𝑥

. Adjust the incubation plate

temperature to stabilize the reaction liquid

temperature at a preset temperature of 37℃. Record

the corresponding incubation plate temperature

compensation values 𝑦

、

𝑦

、

⋯

、

𝑦

at different

ambient temperatures. Obtain a set of data points

𝑝

𝑥

,𝑦

,𝑖1,2,⋯,𝑛.

Step 2: Obtain the temperature compensation

curve through polynomial fitting. Select the fitting

curve based on the principle of minimizing the sum

of squared deviations, ensuring that the fitted curve

deviates minimally from the actual temperature

compensation curve 𝑦𝑓𝑥.

The process of polynomial least squares fitting is

as follows:

1. Assume the 𝑘

-order polynomial for the fitting is

given by equation (1):

𝑦𝑎

𝑎

𝑥⋯𝑎

𝑥

(1)

2. The sum of squared deviations, which represents

the distance between each temperature

compensation value point and the fitted curve, is

denoted as the sum of squared errors in equation

(2).

𝑅

𝑦

𝑎

𝑎

𝑥

⋯𝑎

𝑥

(2)

3. In order to minimize the sum of squared errors, 𝑎

、𝑎

、 ⋯、𝑎

should satisfy the condition that

the partial derivatives of equation (2) with respect

to 𝑎

are equal to zero.

2

𝑦

𝑎

𝑎

𝑥

⋯𝑎

𝑥

0

2

𝑦

𝑎

𝑎

𝑥

⋯𝑎

𝑥

𝑥

0

⋯

2

𝑦

𝑎

𝑎

𝑥

⋯𝑎

𝑥

𝑥

0

(3)

4. By simplifying each equation in equation (3) and

representing them in matrix form, we obtain the

matrix shown in equation (4).

⎣

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎡

𝑛𝑥

⋯𝑥

𝑥

𝑥

⋯𝑥

⋮⋮⋱⋮

𝑥

𝑥

⋯𝑥

⎦

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎤

𝑎

𝑎

⋮

𝑎

⎣

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎡

𝑦

𝑥

𝑦

⋮

𝑥

𝑦

⎦

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎤

(4)

5. Let matrix X, A, and Y be defined as follows:

𝑿

11⋯1

𝑥

𝑥

⋯𝑥

⋮⋮⋱⋮

𝑥

𝑥

⋯𝑥

,𝑨

𝑎

𝑎

⋮

𝑎

,𝒀

𝑦

𝑦

⋮

𝑦

(5)

According to equation (4), we have 𝑿𝑿

𝑻

𝑨𝑿𝒀.

Therefore, the coefficient matrix of the fitting

polynomial can be obtained 𝑨

𝑿𝑿

𝑻

𝟏

𝑿𝒀. This

provides us with the coefficients of the fitting

polynomial and thus the temperature compensation

curve.

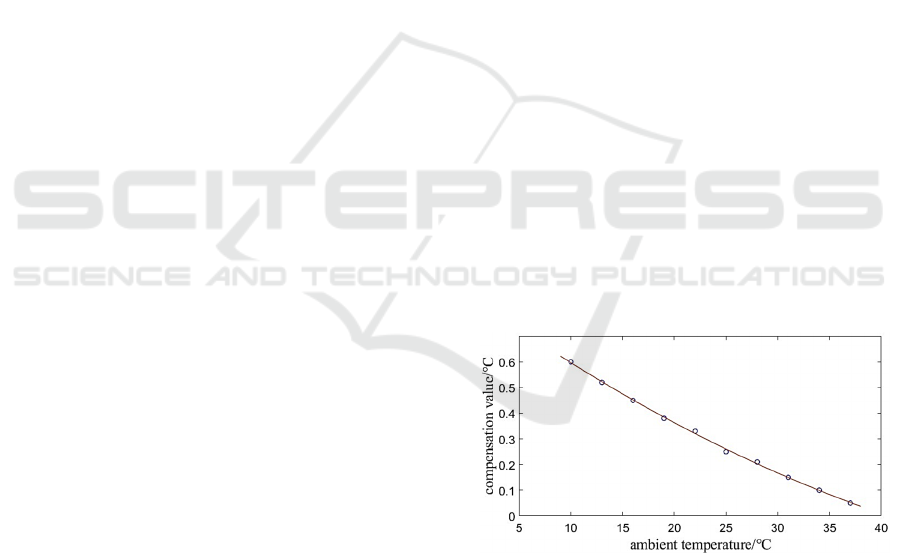

With the help of Matlab, the results of third-order

polynomial fitting can be visualized. By inputting

different ambient temperatures and their

corresponding temperature compensation values, the

polyfit function can be used to achieve polynomial

curve fitting and obtain the temperature

compensation curve. The third-order polynomial

fitting result is shown in Figure 4.

Figure 4: The results of third-order polynomial fitting.

2.3 The Construction of a Constant

Temperature Incubation Platform

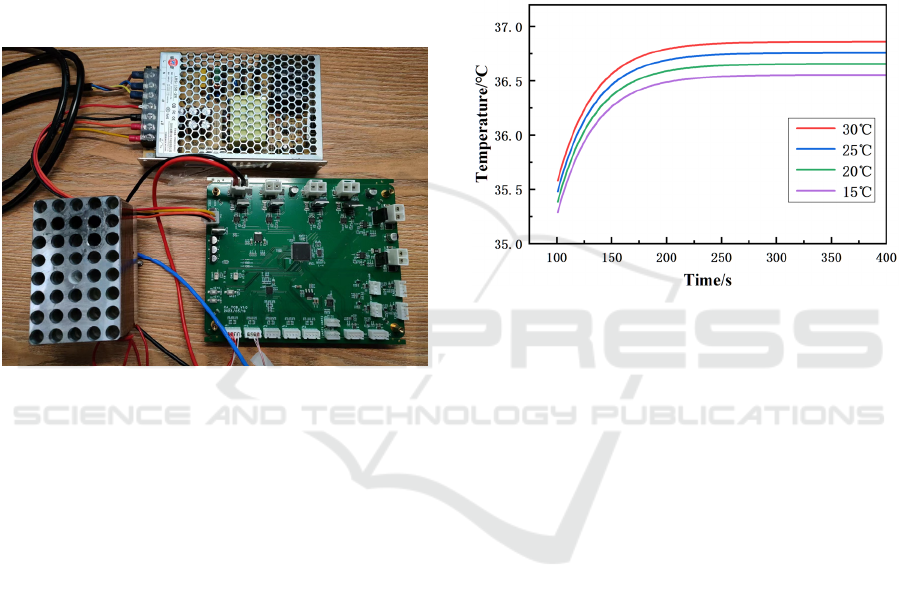

We constructed a constant temperature incubation

platform according to the experimental requirements,

as shown in the

Figure 5

. The constant temperature

incubation platform includes an aluminum incubation

plate, heating film, temperature sensor, and controller.

The aluminum incubation plate is used to hold the

Improved PID Control Based on Temperature Compensation for the Incubation Plate of Chemiluminescent Immunoassay Analyzer

813

reaction vessels, providing a stable incubation

environment for the reaction solution. The heating

film is pasted around the incubation plate to heat it.

The constant temperature incubation platform is

equipped with two temperature sensors, one of which

is embedded inside the incubation plate to collect the

temperature of the incubation plate, while the other

temperature sensor is placed in the air to collect the

ambient temperature. The core of the controller is an

STM32 microcontroller, which changes the duty

cycle of the Pulse-Width Modulation (PWM) signal

output pin through the PID temperature control

algorithm to achieve precise control of the

temperature of the incubation plate.

Figure 5: Constant temperature incubation platform.

3 RESULTS AND DISCUSSION

3.1 Effects of Improved PID Control

To compare the effects of temperature compensation

strategies versus no temperature compensation

strategy on the incubation temperature of the reaction

solution, we placed the incubation plate in a

temperature-controlled incubator and varied the

temperature of the incubator to simulate changes in

ambient temperature. We added 300 μL of reaction

solution with an initial temperature of 7°C to the

reaction vessels and measured the temperature

changes of the reaction solution during incubation at

different ambient temperatures.

In the first set of experiments, the PID

temperature control algorithm did not consider

temperature compensation strategies. The incubation

plate temperature was fixed at 37°C, and the

temperature changes of the reaction solution were

observed at ambient temperatures of 15°C, 20°C,

25°C, and 30°C. To clearly observe the steady-state

temperature differences of the reaction solution, only

the temperature change curves from 100-400 s after

placing the reaction solution in the incubation plate

are shown in the

Figure 6

. From the test results, it can

be observed that the ambient temperature has a

significant impact on the steady-state temperature of

the reaction solution. At an ambient temperature of

30°C, the steady-state temperature of the reaction

solution is 36.86°C. However, at an ambient

temperature of 15°C, the steady-state temperature of

the reaction solution is 36.55°C, resulting in a

difference of 0.31°C.

Figure 6: Temperature of reaction liquid under different

ambient temperatures (without temperature compensation).

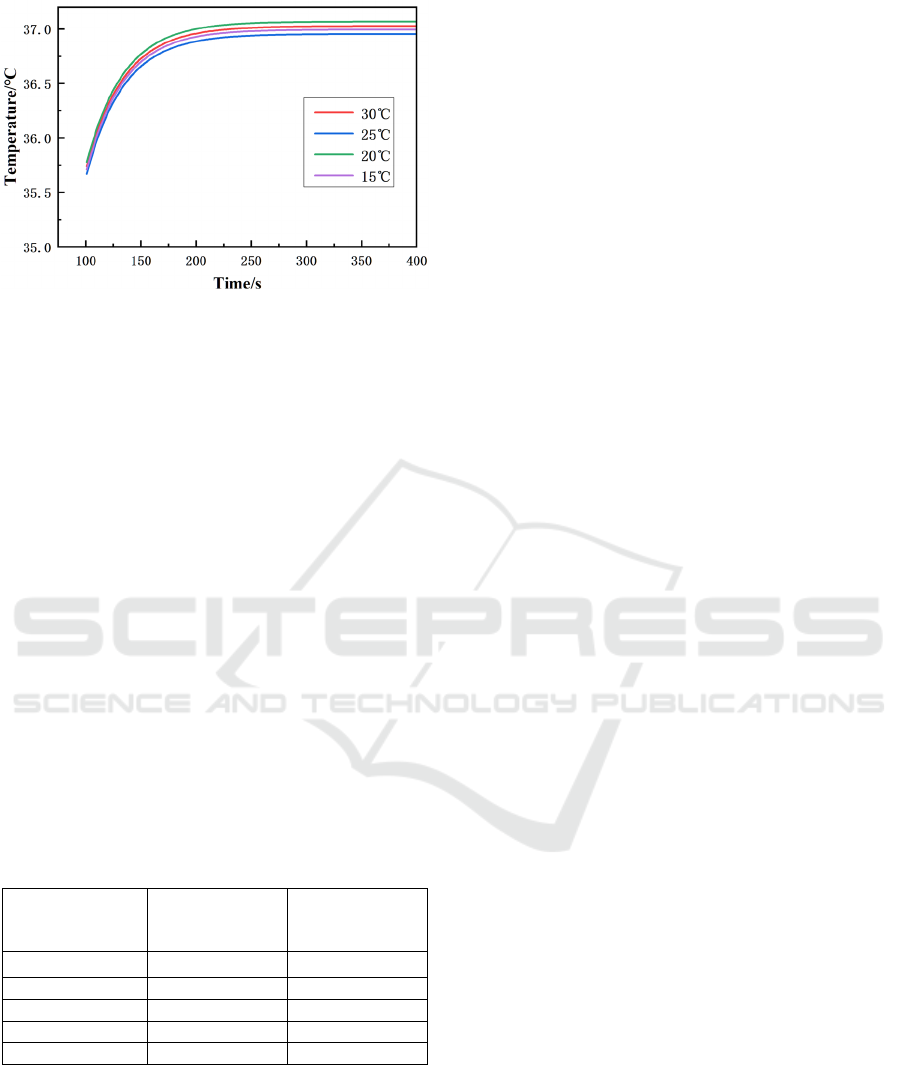

In the second set of experiments, the PID

temperature control algorithm considered

temperature compensation strategies, and the set

temperature of the incubation plate was dynamically

adjusted according to the ambient temperature and the

preset temperature compensation curve. The

temperature changes of the reaction solution during

incubation at ambient temperatures of 15°C, 20°C,

25°C, and 30°C were observed. Similarly, the

temperature change curves from 100-400 s after

placing the reaction solution in the incubation plate

are shown in the

Figure 7

. From the test results, it can

be observed that with temperature compensation at

different ambient temperatures, the steady-state

temperature difference of the reaction solution is very

small. The steady-state temperature of the reaction

solution is maintained at 37 ± 0.1°C after temperature

compensation, with a maximum temperature

difference of 0.11°C.

Comparing the results of the

two experimental groups, it can be observed that

improved PID control can significantly reduce the

steady-state temperature difference during incubation

of the reaction solution at different environmental

temperatures.

BIOSIGNALS 2024 - 17th International Conference on Bio-inspired Systems and Signal Processing

814

Figure 7: Temperature of reaction liquid under different

ambient temperatures (with temperature compensation).

3.2 Impact of Improved PID Control

on the RLU

Taking the Interleukin-6 (IL-6) chemiluminescence

system as an example, we explored the influence of

improved PID control on the results of

chemiluminescence immunoassay. In the first set of

experiments, the PID temperature control algorithm

did not consider temperature compensation strategies.

The same samples were incubated at ambient

temperatures of 15°C, 20°C, 25°C, and 30°C for 30

minutes. After magnetic separation and washing, the

reaction cups were placed in a photomultiplier tube

for reading. In the second set of experiments, the PID

temperature control algorithm considered

temperature compensation strategies, and the

subsequent experimental procedures were the same as

those of the first set. By analyzing the differences of

RLU between the two sets of experiments, the final

results are shown in the Table 1.

Table 1: The impact of improved PID control.

Ambient

temperature/℃

RLU without

temperature

com

p

ensation

RLU with

temperature

com

p

ensation

15 1921244 2163580

20 2063019 2188961

25 2125171 2143365

30 2143024 2226606

CV 4.22% 1.43%

From preliminary experimental results, it can be

observed that when temperature compensation

strategy is not considered, there is a significant

difference in the steady-state temperature of the

reaction solution at different ambient temperatures,

resulting in a high CV in the RLU, reaching 4.22%.

However, when temperature compensation strategy is

taken into account, the steady-state temperature

difference of the reaction solution at different ambient

temperatures is reduced, leading to a lower CV in the

final RLU, which is only 1.43%.

The above experiments demonstrate that by

incorporating temperature compensation strategy into

the PID algorithm, the influence of environmental

temperature on the steady-state temperature of the

reaction solution can be effectively eliminated. This

ensures that the reaction solution remains stable at the

set temperature under different environmental

conditions. This finding is of great significance in

reducing the CV in the detection results and

improving the accuracy of the detection results.

4 CONCLUSIONS

In this work, we propose an improved PID control

algorithm based on temperature compensation. By

sensing the environmental temperature and obtaining

the temperature compensation value through the

preset temperature compensation curve, the influence

of environmental temperature on the reaction solution

temperature can be effectively eliminated. The

temperature compensation curve is fitted using a

third-order polynomial.

By comparing the steady-

state temperatures of the reaction solution before and

after considering the temperature compensation

strategy, it can be observed that the improved PID

control can reduce the maximum steady-state

temperature difference of the reaction solution from

0.31°C to 0.11°C.

The improved PID control also

reduces the CV of the detection results for the same

sample at different environmental temperatures. By

considering the temperature compensation strategy,

the CV of the RLU decreases from 4.22% to 1.43%.

This is of significant importance in improving

instrument performance and enhancing the accuracy

of the detection results.

In future work, we plan to explore alternative fitting

methods to further reduce the steady-state temperature

difference of the reaction solution under different

environmental temperatures. Additionally, we will also

explore other chemiluminescence systems to further

investigate the impact of improved PID control on the

results of chemiluminescence detection.

ACKNOWLEDGEMENTS

This work was supported in part by Zhejiang

Provincial Natural Science Foundation of China

Improved PID Control Based on Temperature Compensation for the Incubation Plate of Chemiluminescent Immunoassay Analyzer

815

under Grant No. LY22H180006 and the National Key

R&D Program of China under Grant No.

2017YFF0210803.

REFERENCES

Boolani, A., Channaveerappa, D., Dupree, E. J.,

Jayathirtha, M., Aslebagh, R., Grobe, S., . . . Darie, C.

C. (2019). Trends in Analysis of Cortisol and Its

Derivatives. In A. G. Woods & C. C. Darie (Eds.),

Advancements of Mass Spectrometry in Biomedical

Research, 2nd Edition (Vol. 1140, pp. 649-664).

Borase, R. P., Maghade, D. K., Sondkar, S. Y., & Pawar, S.

N. (2021). A review of PID control, tuning methods and

applications. International Journal of Dynamics and

Control, 9(2), 818-827. doi:10.1007/s40435-020-

00665-4

Feng-Mei, F., Da-Qing, L., Jian-Ning, Z., & Pan-Fei, H.

(2019). Performance Verification of CA125 in Roche

Cobas6000 Automatic Electrochemiluminescence

Immunoassay Analyzer. World Latest Medicine

Information.

Joseph, S. B., Dada, E. G., Abidemi, A., Oyewola, D. O., &

Khammas, B. M. (2022). Metaheuristic algorithms for

PID controller parameters tuning: review, approaches

and open problems. Heliyon, 8(5).

doi:10.1016/j.heliyon.2022.e09399

Kaul, S., Tiwari, N., Yadav, S., & Kumar, A. (2021).

Comparative Analysis and Controller Design for BLDC

Motor Using PID and Adaptive PID Controller. Recent

Advances in Electrical & Electronic Engineering,

14(6), 671-682. doi:10.2174/235209651466621082315

2446

Khan, M., Shah, S. H., Salman, M., Abdullah, M., Hayat,

F., & Akbar, S. (2023). Enzyme-Linked

Immunosorbent Assay versus Chemiluminescent

Immunoassay: A General Overview. Global Journal of

Medical Pharmaceutical and Biomedical Update,

18(1). doi:10.25259/gjmpbu_77_2022

Phu Nguyen, D., Hung Nguyen, N., Ahmadian, A., & Senu,

N. (2020). A New Fuzzy PID Control System Based on

Fuzzy PID Controller and Fuzzy Control Process.

International Journal of Fuzzy Systems, 22(7), 2163-

2187. doi:10.1007/s40815-020-00904-y

Ren, X., Zhang, Y., Ye, X., & Zhou, C. (2023). Study of

perfusion based theoretical model and experimental

evaluation for wearable CBT measurement.

Measurement, 206. doi:10.1016/j.measurement.2022.1

12338

Suan Ng, S., Ling Lee, H., Bothi Raja, P., & Doong, R.-a.

(2022). Recent Advances in Nanomaterial-based

Optical Biosensors as Potential Point-of-Care Testing

(PoCT) Probes in Carcinoembryonic Antigen

Detection. Chemistry-an Asian Journal, 17(14).

doi:10.1002/asia.202200287

Xiao, Q., & Xu, C. (2020). Research progress on

chemiluminescence immunoassay combined with

novel technologies. Trac-Trends in Analytical

Chemistry, 124. doi:10.1016/j.trac.2019.115780

Yalcin, S., oezkan, S., & Shah, T. (2022). Incubation

Temperature and Lighting: Effect on Embryonic

Development, Post-Hatch Growth, and Adaptive

Response. Frontiers in Physiology, 13. doi:10.3389/

fphys.2022.899977

Yufeng, Y., Shizhou, L., Bo, H., & Jianwen, Z. (2010).

Automated Chemiluminescence Immunoassay

Analyzer. Paper presented at the 2010 International

Conference on Intelligent Computation Technology

and Automation.

BIOSIGNALS 2024 - 17th International Conference on Bio-inspired Systems and Signal Processing

816