Dynamic Characteristic of the Pleural Cavity Pressure Sensor

T. Mimra

1

, M. Cerny

1

, C. Guerin

2

and N. Noury

3

1

VSB – Technical University of Ostrava, Czechia

2

University Hospital, Hospices Civils de Lyon, France

3

University of Lyon, Lab INL, France

Keywords: Pleural Cavity Pressure, 3D Printing, Implantable Sensor.

Abstract: We are developing an implantable sensor to measure the interface pressure in the pleural cavity. A 3D printing

process was used to evaluate different shapes and materials for the transducer part. The better compromise

resulted in a disk-shaped, 10 cm diameter, printed with biocompatible TPU (Thermoplastic polyurethane)

filaments with a hardness 92A, offering the best compromise in terms of static sensitivity. We now investigate

the dynamic characteristics of our sensor.

1 INTRODUCTION

The first functional model of breathing was

developed in 1674 by John Mayow (J. R. Partington,

1956), reproducing the inhalation mechanism. It was

made with a balloon inserted into a transparent bigger

one. The inner balloon was opened to ambient

pressure, so that when outer balloon expanded, the

inner balloon was undergoing passive expansion, and

thus air started flowing inside the inner balloon.

Graham (Evarts Ambrose Graham, n. d.; Aboud,

F. C, Vergheze, and A. C., Evarts Ambrose Graham,

2002) was the first to observe the negative pressure

inside the intrapleural cavity - located between the

lungs and chest - and to explain its contribution to

respiratory mechanics. Actually, lungs follow the

periodic movements of the chest thanks to this

existing negative pressure inside the intrapleural

cavity (Ppl). The Ppl is approximately -0.6 cmHg

during inhale and -0.25 cmHg during exhale.

In some conditions, the intrapleural pressure Ppl

is measured to access parameters like the Pressure-

Time Product (PT product), the Work of Breathing

(WOB) or the transpulmonary pressure, which are

essential in selecting ventilation strategy and in

preventing patients from lung overdistention.

The intraesophageal pressure (Pes) is currently

preferred to the direct pleural manometry (Milic-

Emili, et al., 1964). It is uncomfortable to the patient,

who must swallow the balloon with catheter, but is

less dangerous. Still, this method suffers limitations.

In particular it is difficult to control the correct

placement of the balloon at the esophageal site

without imagery guidance. Furthermore, it was

recently demonstrated that the intrapleural and

esophageal pressures, are not correlated in some body

orientations (N. Terzi, S., etal., n.d.; C. Guerin, et. al.,

2021).

Therefore, we investigated the development of an

interface pressure sensor to allow the direct

measurement of Ppl inside the pleural cavity. We

earlier described the design of our intrapleural

pressure sensor (T. Mimra, et al., 2022), the clinical

evaluation of our first prototype (N. Terzi, S., et al.,

n.d.), then the production of a 3D-printed model

(FDM) with various shapes and materials. The better

compromise resulted in a disk shape, 10 cm diameter,

printed with biocompatible TPU (Thermoplastic

polyurethane) filaments with a hardness 92A and

offering the best compromise in terms of static

sensitivity. We now investigate the dynamic

characteristics of our sensor.

2 THE 3D-PRINTED

INTRAPLEURAL PRESSURE

SENSOR

2.1 Balloon Designs

Our sensor is mainly composed of a balloon (Figure 1,

2), to be inserted into the pleural cavity.

Mimra, T., Cerny, M., Guerin, C. and Noury, N.

Dynamic Characteristic of the Pleural Cavity Pressure Sensor.

DOI: 10.5220/0012488700003657

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 17th Inter national Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2024) - Volume 1, pages 181-184

ISBN: 978-989-758-688-0; ISSN: 2184-4305

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

181

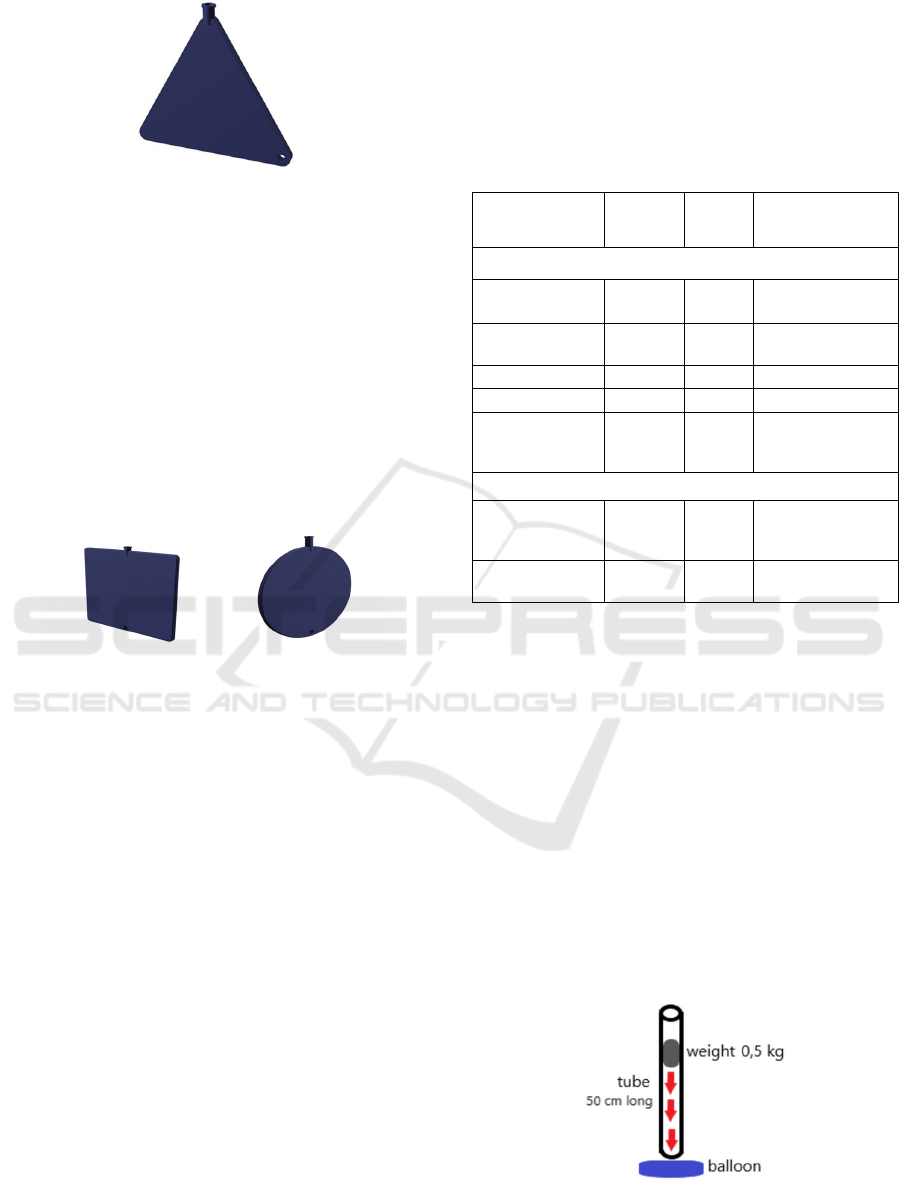

Figure 1: Our first triangle balloon. We notice the Luer

Lock fitting (on top) and the handle (right down).

From the first clinical experimentations, we

understood that we must pay attention to the shape of

the balloon in order to prevent from internal tissue

injuries at insertion and during operations. The

surgeons prefer a form factor thin enough to be

installed inside the pleural cavity but large enough to

be easily manipulated. Therefore, we proposed a

thickness of 5 mm within a 3D frame 10 cm by 10 cm,

which fits in the intrapleural cavity while offering a

maximum mechanical transfer surface and easy

handheld. We envisaged various shapes – square,

triangular and disk – (Figure 1, 2).

Figure 2: The disk balloon (right) has a diameter of 10 cm,

the square balloon (left) has a side of 10 cm.

Furthermore, the material of the balloon must meet

the constraints for biocompatibility (no material

release) and waterproofing. Other operational aspects

concern the mechanical compatibility with the

standard Luer Lock fitting, and the provision of a

handle to facilitate the surgeon task when placing the

balloon into the pleural cavity.

The balloon is currently connected to a

commercial pressure sensor (MLT1199 BP

Transducer, ADinstruments) through a 1-meter long

tubing. The signal of the pressure sensor further feeds

a data-acquisition system (PowerLab 4/26,

ADinstruments), for filtering and digital conversion.

The digital signal is processed with a specific

instrumentation software (LabChart7, AD

Instruments).

2.2 Balloon Materials

Materials selected for printing the balloons must be

biocompatible and flexible enough to conform with

the inner cavity. Materials for 3D FDM printing are

called filaments and resins are used for SLA 3D

printing. The hardness of the flexible filaments is the

shore, ranging from 10 for soft materials up till 100 for

extra hard one. We fabricated 28 balloons with

various shapes and various (7) materials selected for

their biocompatibility (Table 1),

Table 1: Hardeness of filaments used for FDM and resins

for SLA.

Material Marking Shore

Commercial

Name

FDM printing

Thermoplastic

Polyurethane

TPU

92A

Ultimaker TPU 95A

Thermoplastic

Elastomer

TPE 95A Gembird TPE

flexible

Polypropylene PP 32D Ultimaker PP 32D

Polylactic Acid PLA rigid Prusament PLA

PolyEthylene

Terephthalate

Glycol

PETG rigid Prusament PETG

SLA printing

Photopolymer

resin TPU

TPU resin 85 - 90

A

eSUN LCD UV

405nm TPU-Like

Resin

Photopolymer

resin

-Rigid

Resin

rigid

ANYCUBIC 405nm

UV Sensitive Resin

3 TESTS AND RESULTS

In this section, we present the results of our tests for

the 3 shapes of balloons printed in TPU92A

(Thermoplastic polyurethane) and in TPE95A

(Thermoplastic elastomer).

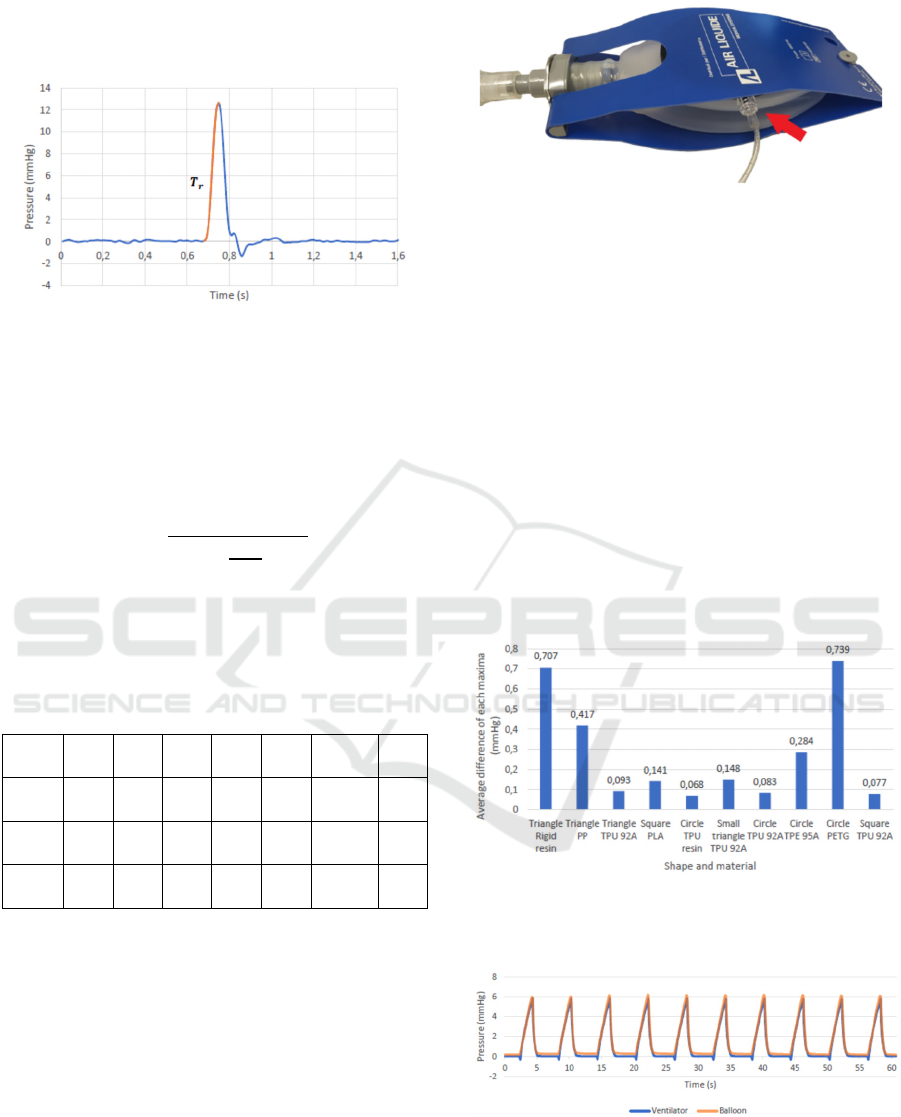

3.1 Percussive Response Tests

The balloon, filled with water, is placed under a tube

guide (diameter 5cm, length 70 cm) in which

a roll-

shaped weight of 500 g is lowered from a height

of 50 cm, thus producing a percussion at impact

on the surface of the balloon (Figure 3).

Figure 3: The experimental set-up for the dynamic

percussive response.

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

182

The transient signal output of the pressure sensor

after impact (Figure 4), is recorded in order to

compute the time constant of the sensor.

Figure 4: Typical transient response after a percussion.

Considering the transfer function of the sensor

being of a first-order type, the temporal response time

(Tr) at 63% of the final (end) response, corresponds to

the time constant of the First-Order model, and thus to

the equivalent cut-off frequency (Fr) following

equation:

𝐹

1

2∙𝜋∙

𝑇

100

∙63

The dynamic tests are repeated 10 times for each

device for averaging the time response at 63% and to

derive the mean equivalent cutoff frequency (Table 2).

Table 2: The equivalent cut-off frequency (Hz) of the Ppl

sensor, for various shapes and materials.

PETG PLA PP

Resin

TPE

95A

TPU

92A

TPU

Resin

Triangle

2.3 3.2 6.2 4.3 26.6 60.6 36.2

Square

2.8 2.4 5.0 4.2 28.8 39.8 47.2

Disk

2.2 2.6 3.6 4.5 27.9 44.0 47.2

Any shape printed from TPU92A and TPU resin

offers a satisfying bandwidth. The normal respiration

rate being 0.2 to 0.34 Hz, the sampling frequency

domain will be 34 Hz if considering a convenient

oversampling ratio of 100.

3.2 Frequency Response Tests

In this test, we now evaluate the frequency response

of the Ppl sensor to a periodic respiratory stimulation.

The respiration is simulated with an artificial lung

connected to a medical ventilator (Monnal T50, Air

Liquide; Figure 5).

Figure 5: The measuring balloon is inserted inside the

artificial lung.

Controlled respiration was measured by a flow

sensor (ML 311, ADinstruments), connected to the

ventilator tube, for comparing recorded curve of the

ventilator and curve of the measuring balloon. The

pressure was recorded from the pressure sensor

(MLT1199 BP Transducer, ADinstruments). This test

was performed with following balloons: all measuring

balloons made from TPU 92A, triangle balloon made

from PP and rigid resin, disk balloon made from TPU

resin, PETG and TPE, squared balloon made from

PLA (Figure 6).

The experiment lasted 60 seconds, the number of

breaths which were recorded depended on the set

frequency of the ventilator. Respiration frequency of

the medical ventilator was set to 10 inhales per minute,

which corresponds to 0,16 Hz (Figure 7).

Figure 6: Average difference of each maxima with

respiratory frequency 10 breaths per minute, for different

shape and material.

Figure 7: Respiration curve of the disk balloon made from

TPU resin (best of frequency 10 breaths per minute).

The best measuring balloons at this breathing

rate are the disk balloons made from TPU resin,

Dynamic Characteristic of the Pleural Cavity Pressure Sensor

183

also disk and square balloons from TPU 92A

(Table 3).

Table 3: Correlation between pressure in balloon and

ventilation flow at a breathing frequency 0.16 Hz (9.6/mn).

Correlation Material Shape

0,93 Disk TPU 92A

0,96 Square TPU 92A

0,89 Triangle TPU 92A

0,87 Disk TPE 95A

1,00 Disk TPU resin

0,87 Square PLA

0,86 Triangle PP

0,84 Triangle Rigid resin

0,86 Disk PETG

4 CONCLUSION

The current measurement method of the intrapleural

pressure (Ppl) from the esophageal site overestimates

Ppl. In addition, it is uncomfortable for the patient

whose exposure must be limited to a few minutes.

It therefore sounds a promising idea to investigate

the realization of a sensor which could be implanted

directly in the pleural cavity, for a couple of days or

week, in order to access anytime the true value of the

Ppl and therefore address its long-term variations.

We proposed a device, in the form of a small disk

(10 cm diameter) or a triangle (side 10 cm) printed

with biocompatible TPU92A or TPU resin. It is filled

with air but a fluid filled will also transmit the

pressure. The device exhibits good static and dynamic

characteristics. We demonstrated, on an artificial

lung, that it can track correctly the respiration at

standard frequencies.

Our next task will be to test it under real

conditions (in vivo animals), to confirm its promising

qualities.

Future developments will focus on the integration

of a wireless pressure sensor so as to make the system

autonomous after implantation. A MEMS

microsystem – integrating a pressure sensor, a

microcontroller, and a wireless communication – will

be placed inside the balloon to collect directly the

inside pressure and to transmit it outside the body, for

instance with passive RFID.

Before to be implemented in the thoracic cavity,

the safety and the impact on patient should be

evaluated through a clinical survey.

REFERENCES

J. R. Partington, The Life and Work of John Mayow (1641-

1679), Isis, The University of Chicago Press, 1956, Vol.

47(4), pp. 405-417

"Evarts Ambrose Graham, Empyema, and the Dawn of

Clinical Understanding of Negative Intrapleural

Pressure" DOI: 10.1086/338148.

Aboud, F. C, Vergheze, A. C., Evarts Ambrose Graham,

Empyema, and the Dawn of Clinical Understanding of

Negative Intrapleural Pressure. Clinical Infectious

Diseases [online]. 2002, 34(2), 198−203

Milic-Emili, J., Mead, J., Turner, J. M., and E. M. Glauser.

Improved technique for estimating pleural pressure

from esophageal balloons. Journal of Applied

Physiology, 1964, 19(2), 207−211

N. Terzi, S., N. Noury, E. Turbil, W. Habre, L. Argaud, M.

Cour, B. Louis, and C. Guerin, "Comparison of pleural

and esophageal pressure in supine and prone position in

a porcine model of acute respiratory distress

syndrome", J. Appl. Physiol, June 2020; 128(6): 1617–

1625.

C. Guerin, S. Bayat, N. Noury, M. Cour, L. Argaud, B.

Louis, and N. Terzi, "Regional lung viscoelastic

properties in supine and prone position in a porcine

model of acute respiratory distress syndrome", J Appl

Physiology, July 2021, Vol 131(1): 15-25

T. Mimra, M. Cerny, C. Guerin and N. Noury,

Experimentaly-guided development of a sensor for

pleural cavity pressure sensing, IEEE EMBC, Glasgow.

Annu Int Conf IEEE EMBS; 2022:4245-4248

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

184