Hybrid Mechanistic Neural Network Modelling of the Degree of Cure

of Polymer Composite

Samuel Sells and Jie Zhang

a

School of Engineering, Merz Court, Newcastle University, Newcastle upon Tyne NE1 7RU, U.K.

Keywords: Polymer Composite, Degree of Cure, Neural Networks, Hybrid Modelling, Machine Learning.

Abstract: A hybrid mechanistic/neural network model was developed for the industrial polymer composite curing

process of a fibre-reinforced polymer composite. A hybrid model with parallel scheme and a hybrid model

with the combination of series and parallel schemes were developed. It is found that the hybrid model with

the combination of series and parallel schemes gives better performance. It is shown that the developed hybrid

model is more accurate than its mechanistic and neural network counterparts in predicting the degree of cure

based upon the temperature and time data. The hybrid model is 7.7% and 17.1% more accurate than the neural

network model and the mechanistic model respectively in terms of sum of absolute errors.

1 INTRODUCTION

Fibre-reinforced polymer composites (FRPCs), or

simply composites, are materials that consist of two

phases: the matrix phase, delivered by a tough but

structurally weak thermoset resin, and the reinforcing

phase, delivered by filaments (diameter ~10μm) of a

strong and stiff material (Smallman & Bishop, 1999).

This combines the properties of both constituents (Taj

et al., 2007) and gives the final composite material

with high stiffness to weight ratio and improved

strength in comparison to other structural materials

(Ahmad et al., 2021). Common fibres used in modern

composites include carbon, boron, glass, aramid and

naturally occurring plant fibres. The fibres are

impregnated with the matrix phase, setting the fibres

into place and providing lateral support, while also

minimising damage to the composite by providing

plastic deformation characteristics lacking in the

reinforcing phase (Soutis, 2005).

Originally developed for the aerospace industry to

reduce the weight of aircraft (Ahmad et al., 2021), but

due to the reduction in price of composites in recent

years, many other applications have been found.

Aerospace now only accounts for 20% of the carbon

fibre market (Soutis, 2005). The same properties that

make composites appropriate for use in aeroplanes

make them useful for increasing fuel efficiency in

a

https://orcid.org/0000-0002-9745-664X

modern cars. Roughly 75% of fuel consumption of a

car is directly related to its mass and, thus, lightweight

composite panels have been the material of choice for

hybrid and battery powered cars to maximise their

driving range, and on high performance supercars to

increase performance. Due to the energy absorption

of an epoxy matrix phase, composite materials

provide increased passenger safety when compared to

metal components, and now composites are used to

create entire cabs for heavy trucks and large panels on

buses (Friedrich & Almajid, 2013). This study uses

data from an automotive industry composite curing

process.

Composites are also used extensively outside of

transport applications. Composites have almost fully

replaced conventional materials, particularly in

conjunction with ceramics (Grand View Research,

2019), in the ballistic armour industry. Polymer

composite materials are also finding extensive use in

civil construction, particularly in repair and

rehabilitation of existing concrete structures

(Pendhari, et al., 2008) (due to strength and

toughness). Fibreglass is an incredibly common

material in the building of yachts and high

performance dinghies (to reduce weight and increase

speed). Polymer and ceramic composites are being

introduced into systems involving corrosive chemical

storage (due to the chemical resistive nature of the

polymer matrix phase).

614

Sells, S. and Zhang, J.

Hybrid Mechanistic Neural Network Modelling of the Degree of Cure of Polymer Composite.

DOI: 10.5220/0012469300003636

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 16th International Conference on Agents and Artificial Intelligence (ICAART 2024) - Volume 2, pages 614-621

ISBN: 978-989-758-680-4; ISSN: 2184-433X

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

In the manufacturing of epoxy composites and

other thermosetting resins, a technique called resin

transfer moulding (RTM) is used (Liu et al., 2019).

This is where the matrix-phase monomer resin is

applied to the reinforcing phase already in the mould,

mixed with a curative, usually an amine or anhydride

(Hara, 1990), to harden the resin by polymerisation

around the fibre structure in the shape of the mould.

The temperature control of the curing process is

delivered by placing the mould in an oven and the

energy supplied to the part activates the exothermic

curing reaction. The temperature profile of the

reaction is dependent on the heat produced and the

energy supplied to the reaction by the mould system,

which can be used to control the degree of cure (Joshi

et al., 1999).

However, improper curing via incorrect

temperature control can cause irregularities in the

final mechanical properties of the composite. A key

parameter in the strength of the composite is the

strength of the bond between the fibre and the

polymer, and due to the difference in coefficients of

thermal expansion between the two phases, the

incorrect heating of the composite during cure can

lead to residual micro-stresses in the composite

structure after the cure has been completed

(Kondyurin, et al., 2012). Thus in order to exert

optimal control over the final properties of the

composite, accurate models of the curing process

must be created.

Models for degree of cure in polymer composite

moulding processes can be generally classified into

two catagories: mechanistic models and data-driven

models. Mechanistic models are based on first

principles such as reaction kinetics. They should be

accurate and reliable if precise mechanistic

knowledge is available. However, some mechanistic

knowledge can be complex and only partially known.

In such cases simplifications and assumptions have to

be made leading to reduced model accuracy.

Furthermore, the development of mechanistic models

are typically time consuming and effort demanding.

Data-driven models can be developed quickly and can

give accurate predictions when used within the range

covered by the training data. However, they are of

black box nature and are difficult to interpret. They

can also give large errors when applied outside the

range covered by the training data. A hybrid model

combining both mechanistic model and data-driven

model could exhibit the advantages of both types of

models.

The most common technique to model the cure of

polymer composite is the use of semi-empirical

mechanistic modelling. These models state a general

order for the reaction process replacing the

concentration of the present species in the kinetic

equation with a measure of the degree of cure (Halley

& Mackay, 1996). The model parameters are found

via experimentation much like that of first-principle

mechanistic modelling. Simple semi-empirical

models were used by (Karkanas et al., 1996) and (Du

et al., 2004) for modelling a composite curing

process, and both managed to produce models that

were accurate for ~80% of the experimental data.

However, these models did not have consistent

reaction orders as the temperature changed and

required other equations, such as the diffusion factor

used by (Du et al., 2004) to manipulate the reaction

rate constant in the latter stages of the reaction. To

improve the areas of poor accuracy, first principle

models can be used, such as those developed by

(Blanco et al., 2005) and (Riccardi et al., 2001),

which provide a consistent reaction order for the

system that does not change with the temperature, but

the accuracy is still only acceptable for ~80% of the

cure process, thus not justifying the added complexity

of these models. Alternatively, Joshi et al. (1999)

used two separate semi-empirical models to model

their composite curing process, with the Arrhenius

parameters and reaction order changing after degree

of cure reaching 0.18, but there were significant

inaccuracies in this investigation at the boundary

between models despite the model being accurate at

the beginning and end of the cure process.

Data-driven models, in particular neural network

(NN) models, have been reported for the modelling of

degree of cure in reactive polymer composite moulding

processes. Zhang & Pantelelis (2011) developed a

bootstrap aggregated neural network model that

predicted the electrical resistance of a polymer/carbon

composite part during curing and used this to predict

the degree of cure. The one-step ahead model used for

effective process optimisation which increased the

maximum degree of cure for a part by as much as 0.2

in offline optimisation. Similar results were found from

the model produced by Lee & Price (1996), who

modelled the curing of epoxy by a NN that directly

predicted the degree of cure rather than resistance. It

was found that the NN model was more accurate when

predicting degree of cure (DOC), with the absolute

error consistently lower (< 0.04) than that of the

analytical model (≤ 0.12). What is observed is, similar

to that found by Zhang & Pantelelis (2011) that the NN

model tended to underpredict the degree of cure as the

curing neared completion (𝛼 > 0.8) opposed to the

analytical model which overpredicts. In addition to

this, Su et al. (1998) found that their NN models for

controlling a curing process exhibited poor adaptability

Hybrid Mechanistic Neural Network Modelling of the Degree of Cure of Polymer Composite

615

when the system to be modelled lies outside of the

training data limits, a problem that was not apparent

with analytical models.

Hybrid mechanistic/neural-network models

(HNN) use a mechanistic component and a NN

component to strike the balance between the speed

and accuracy of a neural network and the applicability

of a mechanistic model (i.e. allowing the HNN to

operate outside of the range of training data

effectively). To the authors’ knowledge, there are no

known examples of applying a HNN to the curing

process of reactive polymer composite moulding, but

in other complex systems, HNNs have found

successes. Lee et al. (2002) developed 4 models for

analysis of the treatment of coke-plant wastewater

(mechanistic, NN, serial-HNN, parallel-HNN). The

serial-HNN used a single NN to estimate the

parameters for the two types of biomass which fed

into the mechanistic model, and the parallel-HNN

model used a single NN to produce error estimations

for the mechanistic model to be combined to guide

the mechanistic model output. The parallel-HNN was

the most accurate of the two HNNs investigated, and

while the NN outperformed the parallel model in

training but for the validation on unseen data, the

hybrid model was more accurate. This shows the

advantage of using a hybrid model, in that it has

greater ability to estimate unseen data than a standard

neural network or mechanistic model. Tian et al.

(2001) applied a parallel hybrid neural network model

to a polymerisation process of methyl methacrylate.

In the reported study, rather than one neural network,

a stacked neural network (bootstrap aggregated

neural network) was used to predict the error from the

mechanistic model to compare to using a single

optimised neural network for the parallel hybrid. The

stacked neural network was more successful, but

most interestingly the confidence bounds (used as an

indication of reliability on unseen data) were

incredibly tight for the parallel model’s prediction of

conversion.

This paper presents a hybrid mechanistic and

neural network model for the modelling of degree of

cure in an industrial polymer composite moulding

process.

2 MODELLING OF DEGREE OF

CURE

2.1 Data Collection

The cure-process raw data was provided by SOTIRA,

a subsidiary of the SORA Composites Group, who

manufacture plastic/carbon composite parts for the

automotive and agriculture industries. The raw data

consisted of resistance and temperature

measurements of the composite part at minute

intervals during the industrial manufacturing process,

collected using OptiMold from Synthesites (Zhang &

Pantelelis, 2011). The temperature was controlled at

114

o

C but fluctuated randomly throughout each

experiment due to process noise. 25 sets of 19-

minute-long runs were provided for this investigation

(labelled A1-A25). Figure 1 shows the pictures of the

product and the mould.

(a)

(b)

Figure 1: Product (a) and mould (b) for the reactive polymer

composite moulding process.

The degree of cure (DOC) was determined using

Eq(1) (Zhang & Pantelelis, 2011). The value of α

max

was calculated for each data set using Eq(2), where

R

max,O

represents the maximum resistance achieved

by any of the 25 experiments (4.05x10

6

MΩ on

experiment A6). This is considered universal (A1-

A25) as each composite part is assumed to be the

same shape and size. However, R

min

was taken on a

case-by-case basis as due to the confidential nature of

the experimental setup, it is assumed that the resin

and the curative have not interacted before the

experiment begins.

ICAART 2024 - 16th International Conference on Agents and Artificial Intelligence

616

𝛼

log

𝑅

log𝑅

,

log𝑅

,

log𝑅

,

𝛼

,

,

𝑖1,…,25

(1)

𝛼

,

log𝑅

,

log

𝑅

,

, 𝑖 1, … ,25 (2)

where α

E

is the experimental DOC, α

max

is the

maximum DOC, R is resistance (MΩ), and i is

experiment number.

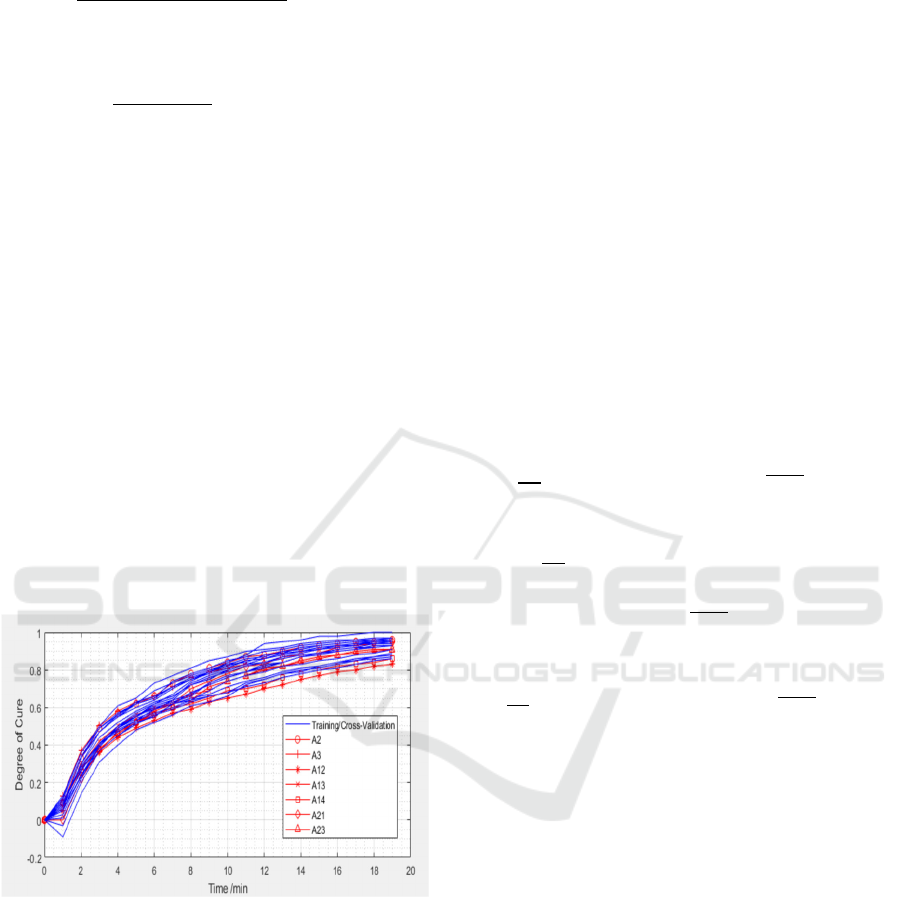

Each model development process consisted of

fitting and testing. The experimental data was divided

into two groups: 70% for fitting and 30% for testing.

This was the ratio used in (Zhang & Pantelelis, 2011)

when building their NN from a similarly sized dataset

using degree of cure data, resulting in an accurate

model. The fitting data was used to define the model

parameters (i.e. kinetics constants or node weights)

where the experimental DOC data was available to

the model. The testing data set was used to test the

model to get an indication of how the model will

perform when it is applied to the real life cure process,

i.e. testing performance as opposed to “recall” (Lee et

al., 2002). 7 runs (~30%) were selected at random for

use in the testing stage. These were: A2, A3, A12,

A13, A14, A21 and A23, and Figure 2 shows how the

spread of fitting and testing data compares.

Figure 2: Degree of cure in training and testing data.

For the NN and HNN models, the fitting group

was further divided again into training and cross

validation groups. The training group is used to define

several combinations of node weights that model the

input/output relationship adequately. These

candidates are then exposed to the cross-validation set

which allows the most accurate model to be chosen

from the candidates. This is not to be confused with

testing, as the output data is still available to the

model, and the candidate selected will carry any

biases present in the cross-validation data (Demuth &

Beale, 2004).

2.2 Mechanistic Modelling

A mechanistic model was identified to act as the

mechanistic component of the hybrid neural network

(HNN) model, but also to be used for comparison

purposes to the HNN model to test model

performance. To identify the best mechanistic model,

three types of semi-empirical models were identified

and tested to compare their respective accuracy and

precision. The three mechanistic models are shown in

Eq(3) to Eq(5) and are labelled as Models 1 to 3.

These are the semi-empirical models presented by

(Karkanas et al., 1996) that apply to the majority of

different matrix-phase curing processes, and versions

of these models are used by Joshi et al. (1999) and Du

et al. (2004).

Model 1:

dα

d𝑡

𝑘

1𝛼

,𝑘

𝐴

,

𝑒

,

(3)

Model 2:

dα

d𝑡

𝑘

𝑘

𝛼

1𝛼

,

𝑘

𝐴

,

𝑒

,

(4)

Model 3:

dα

d𝑡

𝑘

𝛼

1𝛼

,𝑘

𝐴

,

𝑒

,

(5)

In the above equations, k

1

and k

2

are reaction rate

constants (min

-1

), m and n are reaction orders, A

0

is

the nominal Arrhenius pre-exponential factor (min

-1

),

E

A

is the nominal activation energy (J.mol

-1

), and R is

the universal gas constant (J.mol

-1

.K

-1

).

The model parameters in these equations are

obtained by fitting the training dataset. This was

carried out by using the FMINCON function from the

MATLAB Optimisation Toolbox. This is a non-linear

optimisation algorithm that locates points of zero

gradient in the objective function based on several

inputs. For larger optimisation problems, a Hessian is

used, and for small/medium size problems a

Sequential Quadratic Programming method is used to

find the optimum (Novac et al., 2009). While

FMINCON finds only local minima (therefore the

output objective function is dependent on the initial

guess values) and genetic algorithms have been found

to be more accurate optimisers. The fitted

mechanistic models were then applied to the testing

dataset with the results given in Table 1. It can be seen

Hybrid Mechanistic Neural Network Modelling of the Degree of Cure of Polymer Composite

617

that Model 3 was identified to be the most accurate

mechanistic model having the lowest SAE (sum of

absolute errors) and SSE (sum of squared errors).

Model 3 is used in the development of HNN model.

Table 1: Identified model parameters and performance on

the testing data.

Model 1 Model 2 Model 3

A

0,1

9.997×10

4

9.928×10

4

9.996×10

4

A

0,2

- 9.997×10

4

-

E

A,1

4.297×10

4

5.334×10

4

4.900×10

4

E

A,2

- 4.164×10

4

-

m - 0.2119 0.2033

n 1.0893 1.3787 1.3728

SAE 6.695 6.658 6.636

SSE 0.527 0.521 0.520

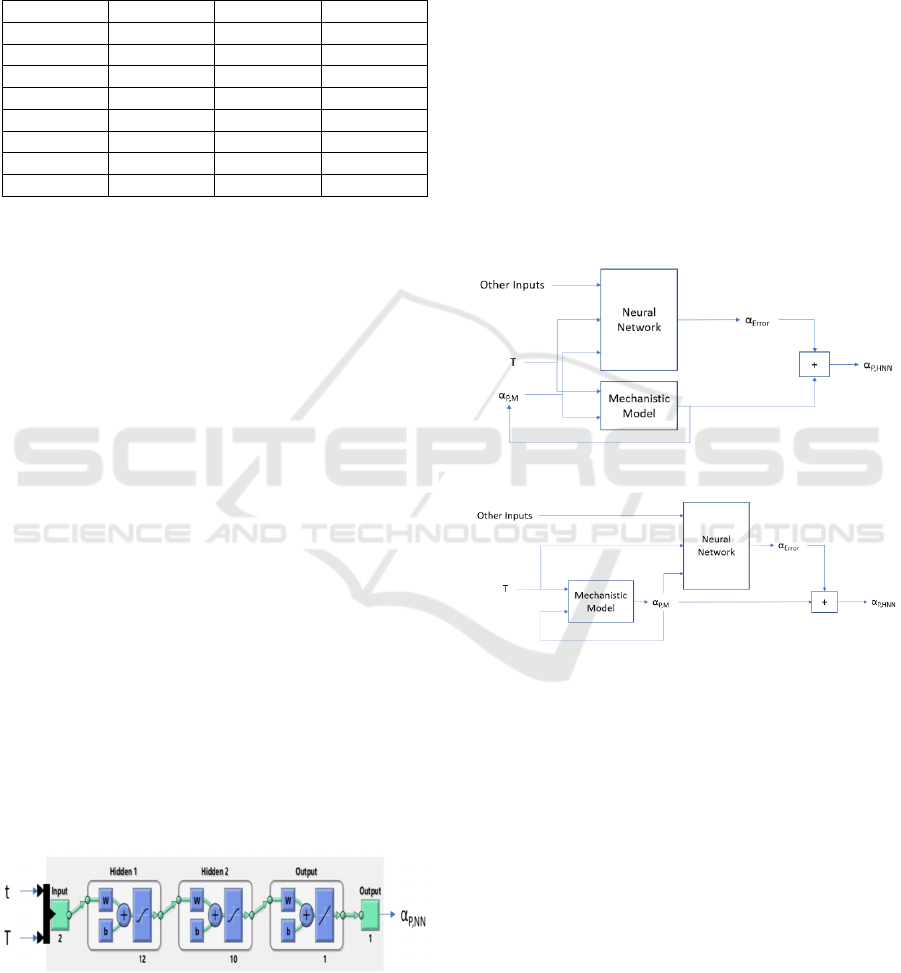

2.3 Neural Network Modelling

A neural network model was developed for the

purpose of comparison with the hybrid model. The

model inputs are curing temperature (T) and curing

time (t). A two hidden layer feedforward neural

network is developed. The fitting data were further

portioned to training data (75%) and validation data

(25%). The number of hidden neurons were

determined by considering a range of hidden neurons

and the one giving the best performance on the

validation data is considered to have the appropriate

network structure. For building the NN model and the

NN part of the HNN model, the MATLAB Deep

Learning Toolbox was employed. This allows the

user to specify the architecture of different inbuilt

neural network systems. The neural network that was

used for this investigation was the feedforward neural

network as shown in Figure 3. The feedforward

neural network architecture is simple and does not

require time delays or for the neural network to be

recurrent which allows greater control for the user

and for a greater number of network types to be

investigated. The final selected NN model is shown

in Figure 3, where the numbers of hidden neurons

were determined through cross-validation using the

validation data.

Figure 3: NN model structure.

3 HYBRID MODEL

3.1 Model Structure

The hybrid neural network is shown in Figure 4. The

neural network model was trained to model the error,

α

Error,

between the mechanistic model and the

experimental value for α calculated using Eq(1) and

Eq(2). This does not exactly follow the explicit

parallel form of the hybrid created by (Lee et al.,

2022) as their hybrid relied on inputs for the

mechanistic model and the neural network being the

same with no series characteristics. The model setup

following this mantra is shown in Figure 4, however

initial modelling studies found greater accuracy using

the output of the mechanistic model as the input for

the neural network. Hence, the model shown in

Figure 5 was preferred over Figure 4.

Figure 4: Hybrid model with the parallel scheme.

Figure 5: Hybrid model with the combination of series and

parallel schemes.

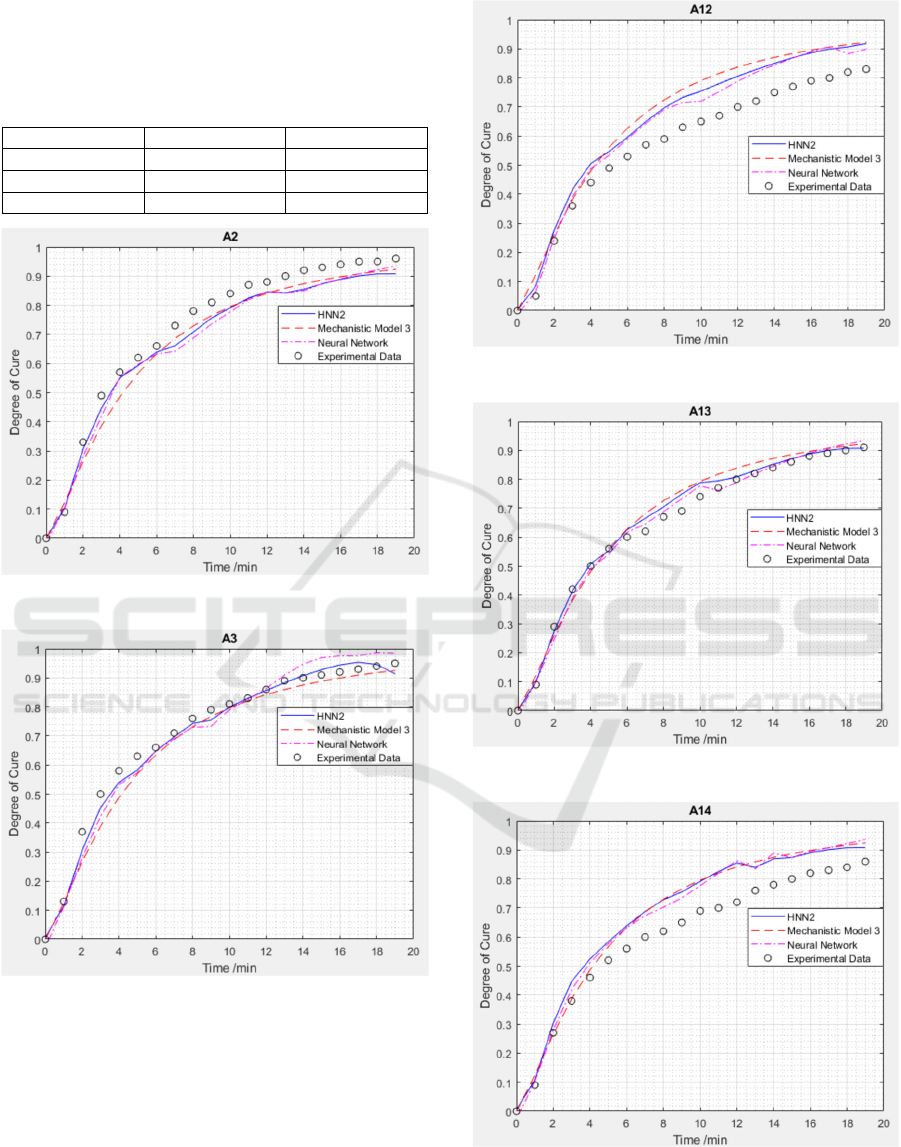

3.2 Model Performance

Table 2 shows the performance of the mechanistic

model, NN model, and HNN model on the testing

data. It can be seen from Table 2 that the mechanistic

model gives the worst performance. This could be due

to that the three considered mechanistic models do

not fully represent the reaction kinetics of the reactive

polymer curing process. The NN model gives better

performance than the mechanistic model in this case.

This could be due to the excellent capability of NN in

representing nonlinear functions. The HNN model

integrating a mechanistic model and an NN model

gives the best performance. In terms of SAE, the

HNN model is 7.7% more accurate than the NN

ICAART 2024 - 16th International Conference on Agents and Artificial Intelligence

618

model and 17.1% more accurate than the mechanistic

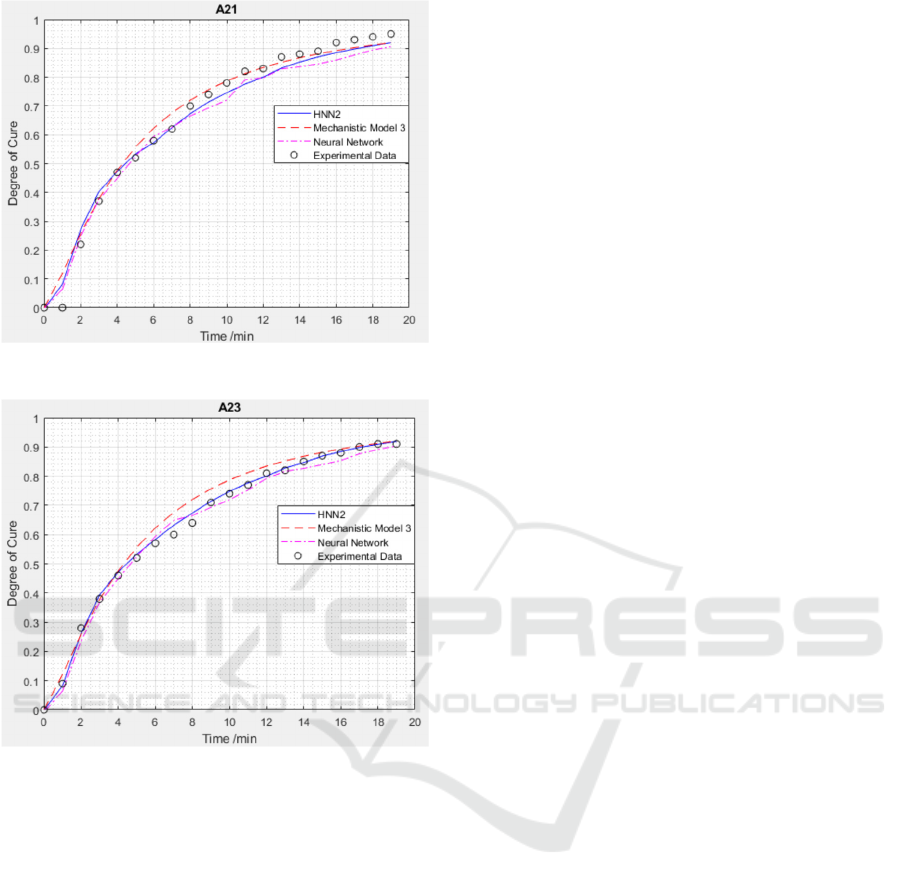

model. Figures 6 to 12 show the predications of the

three models on the testing batches.

Table 2: Model performance on the testing data.

Models SSE SAE

Mechanistic 0.5197 6.6356

NN 0.3806 5.9606

HNN 0.3741 5.5011

Figure 6: Model predictions on the test batch A2.

Figure 7: Model predictions on the test batch A3.

Figure 8: Model predictions on the test batch A12.

Figure 9: Model predictions on the test batch A13.

Figure 10: Model predictions on the test batch A14.

Hybrid Mechanistic Neural Network Modelling of the Degree of Cure of Polymer Composite

619

Figure 11: Model predictions on the test batch A21.

Figure 12: Model predictions on the test batch A23.

4 CONCLUSIONS

Hybrid mechanistic/neural network models for the

curing of FRPCs are developed in this paper. The

obtained results have shown that the hybrid model

with the combination of series and parallel schemes

gives the best performance and it can provide 7.7%

better accuracy than the NN model and 17.1% more

accurate than the mechanistic model in terms of sum

of absolute errors, using only curing temperature and

curing time as model inputs. An important factor for

increasing the accuracy of the HNN was found to be

high data-diversity in the cross-validation training

group, as well as mechanistic-component accuracy.

When the mechanistic model is improved, and the

fitting data set is large and diverse enough, the HNN

can achieve further improved prediction

performance.

REFERENCES

Ahmad, F., Abbassi, F., Ul-Islam, M., Jacquemin, F., &

Hong, J. W. (2021). Enhanced impact-resistance of

aeronautical quasi-isotropic composite plates through

diffused water molecules in epoxy. Scientific Reports,

11(1775), pp. 1-13.

Blanco, B., Angeles Corcuera, M., Riccardi, C. &

Mondragon, I. (2005). Mechanistic kinetic model of an

epoxy resin cured with a mixture of amines of different

functionalities. Polymer, 46(1), pp. 7989-8000.

Demuth, H. & Beale, M. (2004). Neural Network Toolbox

User's Guide. 4 ed. Natick: The MathWorks, Inc.

Du, S., Guo, Z. S., Zhang, B. & Wu, Z. (2004). Cure

kinetics of epoxy resin used for advanced composites.

Polymer International, 53(1), pp. 1343-1347.

Friedrich, K. & Almajid, A. A. (2013). Manufacturing

aspects of advanced polymer composites for

automotive applications. Applied Composite Materials,

20(1), pp. 107-128.

Grand View Research, (2019). Body Armor Market Size,

Share & Trends Analysis Report By Level, By

Application (Law Enforcement Protection, Defense),

By Material, By Product By Type, By Product By Style,

By Region, And Segment Forecasts, 2019-2025, s.l

Halley, P. J. & Mackay, M. E. (1996). Chemorheology of

thermosets - an overview. Polymer Engineering and

Science, 36(5), pp. 593-609.

Hara, O. (1990). Curing agents for epoxy resin. Three Bond

Technical News, 20 12, pp. 1-10.

Joshi, S. C., Liu, X. L. & Lam, Y. C. (1999). A numerical

approach to the modeling of polymer curing in fibre-

reinforced composites. Composites Science and

Technology, 59(1), pp. 1003-1013.

Karkanas, P. I., Partridge, I. K. & Attwood, D. (1996).

Modelling the cure of a commercial epoxy resin for

applications in resin transfer moulding. Polymer

International, 41(1), pp. 183-191.

Kondyurin, A., Komar, L. A. & Svistkov, A. L. (2012).

Combinatory model of curing process in epoxy

composite. Composites: Part B, 43(1), pp. 616-620.

Lee, C. W. & Price, B. P. (1996). Modeling of epoxy cure

reaction rate by neural network. Proceedings of the 28th

International SAMPE Technical Conference,

November 4-7, 1996, Seattle, WA, USA.

Lee, D. S., Jeon, C. O., Park, J. M. & Chang, K. S. (2002).

Hybrid neural network modeling of a full-scale

industrial wastewater treatment process. Biotechnology

and Bioengineering, 78(6), pp. 670-682.

Liu, Y. N., Yuan, C., Liu, C., Pan, J. & Dong, Q. (2019).

Study on the resin infusion process based on automated

fiber placement fabricated dry fiber preform. Scientific

Reports, 9(7440), pp. 1-11.

Novac, M., Vladu, E., Novac, O. & Gordan, M. (2009).

Aspects regarding the optimization of the induction

heating process using fmincon, minimax functions and

simple genetic algorithm. Journal of Electronics and

Electrical Engineering, 2(2), pp. 64-69.

Pendhari, S. S., Kant, T. & Desai, Y. M. (2008).

Application of polymer composites in civil

ICAART 2024 - 16th International Conference on Agents and Artificial Intelligence

620

construction: A general review. Composite Structures,

84(1), pp. 114-124.

Riccardi, C., Fraga, F., Dupuy, J. & Williams, R. (2001).

Cure kinetics of diglycidylether of bisphenol A-

ethylenediamine revisited using a mechanistic model.

Journal of Applied Polymer Science, 82(1), pp. 2319-

2325.

Smallman, R. E. & Bishop, R. J. (1999). Fibre-reinforced

composite materials. In: Modern Physical Metallurgy

and Materials Engineering. Oxford: Butterworth-

Heinemann, pp. 361- 375.

Soutis, C. (2005). Fibre reinforced composites in aircraft

construction. Progress in Aerospace Sciences, 41(2),

pp. 143-151.

Su, H. B., Fan, L. T. & Schlup, J. R. (1998). Monitoring the

process of curing of epoxy/graphite fiber composites

with a recurrent neural network as a soft sensor.

Engineering Applications of Artificial Intelligence,

11(1), pp. 293-306.

Taj, S., Munawar, M. A. & Khan, S. (2007). Natura fiber-

reinforced polymer composites. Proceedings of the

Pakistan Academy of Science, 44(2), pp. 129-144.

Tian, Y., Zhang, J. & Morris, J. (2001). Modeling and

optimal control of a batch polymerization reactor using

a hybrid stacked recurrent neural network model.

Industrial & Engineering Chemical Research, 40(28),

pp. 4525-4535.

Zhang, J. & Pantelelis, N. G. (2011). Modelling and control

of reactive polymer composite moulding using

bootstrap aggregated neural network models. Chemical

Product and Process Engineering, 6(2), pp. 1-18.

Hybrid Mechanistic Neural Network Modelling of the Degree of Cure of Polymer Composite

621