Deep Transfer Learning for Installed Base Life-Cycle Evolution Forecast

Emna Turki

1,3 a

, Oualid Jouini

1 b

, Ziad Jemai

2 c

and Robert Heidsieck

3

1

Laboratoire Genie Industriel, Centrale Sup

´

elec, Universit

´

e Paris-Saclay, 3 rue Joliot-Curie, 91190 Gif-sur-Yvette, France

2

Laboratoire OASIS,

´

Ecole Nationale d’Ing

´

enieurs de Tunis, Universit

´

e Tunis El Manar, BP37, 1002 Tunis, Tunisia

3

General Electric Healthcare, 283 Rue de la Mini

`

ere, 78530 Buc, France

Keywords:

Healthcare Industry, Closed Loop Supply Chain, Transfer Learning, Deep Learning, Installed Base Forecast.

Abstract:

In Healthcare industry, companies are reducing their environmental impact by implementing a closed loop

supply chain (CLSC) in which products can be de-installed and bought back for reconditioning or parts reuse.

In this supply chain, it is necessary to implement the appropriate strategies to ensure a sustainable parts man-

agement system knowing that the installed base (IB) evolution and the products design changes are highly

impacting factors. Since strategic CLSC decisions are taken early in the part and/or product life-cycles, usu-

ally there is not enough data to predict the IB information. Therefore, We build a Deep Transfer learning

framework to forecast the products IB evolution from the beginning to the end-of-life (EOL) using data of dif-

ferent generations from the same product family. We provide a use case from a Healthcare company showing

the performance of different deep learning models on a long horizon.

1 INTRODUCTION

In Healthcare industry, optimizing spare parts con-

sumption and production is crucial to establish a

circular economic strategy and to attain the carbon

emissions neutrality by the year 2050 (European-

Commission, 2020). Companies are changing their

approaches to be more environmental friendly and are

working on different levels of their supply chains to

reduce their impact. Typically, they employ a closed-

loop supply chain (CLSC) in which there is more

profit to the company and to the environment.

In a CLSC, a product-service system (PSS) is im-

plemented, which means that products are delivered

along with different types of services. Companies

design a products’ return scheme, provide mainte-

nance service contracts, and have more interactions

with the customers to fulfil their needs and reduce

their environmental impact during the product use

phase (Mont, 2002).

Spare parts consumption is mainly governed by

installed base (IB) information like the number of

products in use, their location, and their ages. There-

fore, predicting the IB information evolution from the

a

https://orcid.org/0000-0002-7002-7722

b

https://orcid.org/0000-0002-9498-165X

c

https://orcid.org/0000-0001-7679-9670

beginning of life to the end-of-life (EOL) is neces-

sary for long-term spare parts demand forecasting.

Existing methods in the literature focusing on the IB

prediction use experts knowledge, statistical methods,

Consumer/market research and the handled data is

usually from pre-sales or from other products histori-

cal sales (Machuca et al., 2014). These methods per-

form poorly when there is not enough historical data,

especially for new products. It is also important to

acknowledge that the products sales depend on their

types, their use, and in the case of healthcare industry,

the location of the customer.

In this paper, we build a model to predict the IB

information of Healthcare products during different

phases of their life-cycles. We provide a Transfer

Deep learning framework trained on data from previ-

ous generations of the same product family installed

in the same region. We compare four deep learning

models namely RNN, LSTM, a combination of RNN

and LSTM, and GRU. We show that GRU and RNN

are the better performing models on the used data.

2 LITERATURE REVIEW

In this section, we study the IB information forecast

methods and the use of machine learning and deep

learning models for this aim.

398

Turki, E., Jouini, O., Jemai, Z. and Heidsieck, R.

Deep Transfer Learning for Installed Base Life-Cycle Evolution Forecast.

DOI: 10.5220/0012467500003639

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 13th International Conference on Operations Research and Enterprise Systems (ICORES 2024), pages 398-402

ISBN: 978-989-758-681-1; ISSN: 2184-4372

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

When predicting the installed base evolution, we

assume that it will change over time. It increases dur-

ing the product’s growth phase, reaches a peak dur-

ing the maturity phase, and decreases during the EOL

phase (Van der Auweraer et al., 2019). The forecast

model should capture the pattern of the installed base

in different life-cycle stages. Hu and Li (2023) em-

ploys Bayesian netwrok (BN) to predict products de-

mand. The authors conduct numerical experiments on

six data-sets and compare the BN to ARIMA method

and PSO algorithm to show that the method provides a

good prediction for products demand. Machine learn-

ing models were in recent years used to predict the

IB sales. These models can detect the correlation be-

tween the IB information and the non-linear trends in

consumption. In this vein, (Bandara et al., 2019) ex-

ploits the non-linear patterns of product sales in an

e-commerce using a Long-Short-Term model to gen-

erate sales forecast. (Salinas et al., 2020) proposes

DeepAR, a model based on an auto-regressive recur-

rent neural network model to calculate time series

future probability distribution. Smyl (2020) proposes

a hybrid method that exploits exponential smoothing

and neural networks for time series forecasting. How-

ever, these models do not address the issue of missing

data for new products.

A similar domain to the products IB evolution pre-

diction with the lack of historical data, is new prod-

ucts sales forecast. This is a complex problem since

the predictions can be very far from the reality. In

practice, decision makers use previous products in-

formation on which they base their strategic moves.

For new products that are very different from the

past ones, the risk of great error is particularly high

(Thomas et al., 2007). This is a subject that has been

widely addressed in the literature. In this case, usu-

ally there is not enough data to provide prediction

and forecasters have either very little historical in-

formation or none. Therefore, they need to rely on

other types of information. Four types of prediction

models can be implemented to forecast new prod-

ucts sales namely judgmental forecast using experts

knowledge, Consumer/market research, cause/effect

models, time-series and explanatory models, and Ar-

tificial intelligence (Machuca et al., 2014). (Ching-

Chin et al., 2010) designed a procedure called NFSP

for this purpose using similar product sales, pre-sales

data and/or product classification information. The

authors suggest employing the best model among

classic forecast methods like Moving Average (MA)

and Exponential Smoothing, and Heuristic methods

like Sales Index (SI), Taylor Series (TS), and Diffu-

sion Model (DF). Baardman et al. (2017) Proposes a

model for clustering other products and fitting linear

regression with LASSO regularization to these clus-

ters simultaneously to predict new products in the

same cluster. Other regression analysis techniques

like Nonlinear regression and Logistic regression are

also used (Thomas et al., 2007). The use of machine

learning methods in this research area is limited as

machine learning models require a big set of data to

be accurate. To deal with the lack of historical data

problem, (Karb et al., 2020) used a Transfer learning

approach from similar products in the food industry

using a neural network.

A variety of studies have addressed the problem

of new product sales. These works use pre-sales data,

market research, or other product history. In the con-

text of our research, there is numerous products for

which the IB can be very different depending on their

type or family and on their location. Therefore, we

propose an approach based on Transfer learning to

predict the IB information during a product life-cycle.

We start by a classification of the products according

to their family or usage and their location. Our contri-

bution to the literature is in the use of transfer learning

to study the patterns of previous product generations

and to provide a long horizon forecast for different

IB information of the targeted product in Healthcare

industry. We evaluate different deep learning mod-

els and discuss their performance on a use case from

GEHealthCare.

3 PROPOSED APPROACH

In this section, we present a novel forecasting ap-

proach to predict the products IB information. Firstly,

we provide an overview of the method and then we

show more details of its composing elements. We

start by collecting data and creating features that de-

scribe the IB. We use Transfer learning with four deep

learning models namely Long-Short-Term Memory

(LSTM), simple Recurrent Neural Networks (RNN),

Gated Recurrent Unists (GRU), a combination of

RNN and LSTM. Then, we compare between these

models on a use case from GEHealthCare.

3.1 Data Collection and Features

Engineering

We collect data of products IB from the same fam-

ily and the same region. This first classification of

products is important since the products installation,

the customers needs, the regulations, and the collected

data are different from one region to another and from

one product family to another. The purpose is to study

the historical IB patterns for the past generations of a

Deep Transfer Learning for Installed Base Life-Cycle Evolution Forecast

399

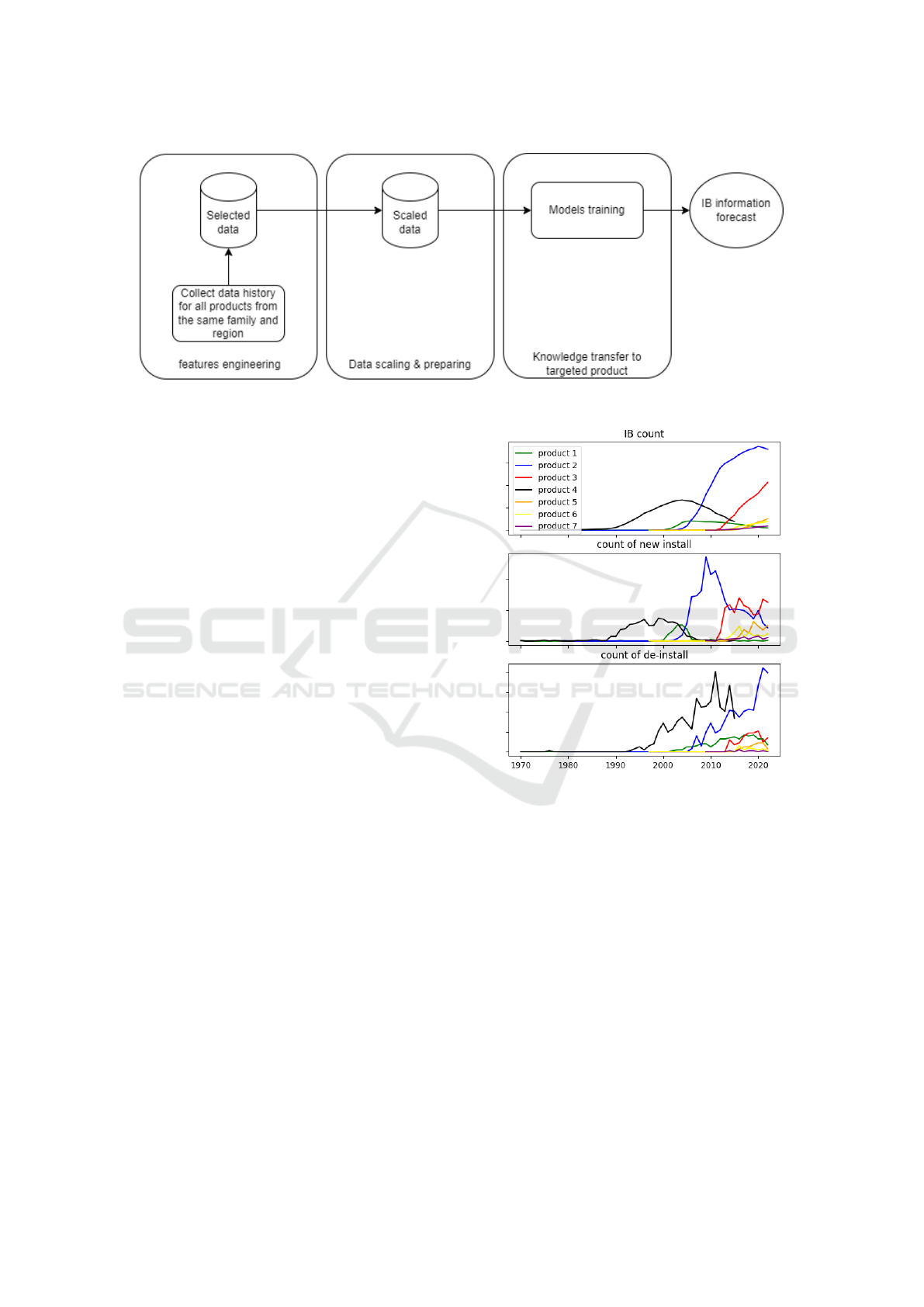

Figure 1: Deep Transfer learning Framework.

product family or type to predict the IB evolution for

the newest generation. The collected data contains

snapshots of the IB status updated each week starting

from the first installed product of the oldest genera-

tion up until the latest one. We use it to create features

that can help us model the IB evolution over the years.

The created features are the IB count, the average IB

age, and the new installations count.

3.2 Deep Transfer Learning Framework

We build a Deep Transfer learning framework to pre-

dict the selected IB information. The framework is

illustrated in Figure 1. The first step is Features engi-

neering where we collect historical data for all prod-

ucts. Then, a classification is applied based on the

product family and the region where these products

are installed. The second step is Data scaling and

preparing. In this step, we clean the selected data by

removing noise, standardizing data, and imputing the

missing values using the Multivariate Imputation by

Chained Equations (MICE) algorithm. In the follow-

ing step, we build a time-series Transfer Deep learn-

ing model for each feature. We train the models on

data for all products from the same family and re-

gion as the targeted product. Then, we transfer the

learnt knowledge to predict the features evolution on

the targeted product from the beginning to the end of

its life-cycle.

4 GE HealthCare USE CASE

In this section, we show results from numerical exper-

iments on a product in GE HealthCare. We have cho-

sen to work with a family of products that had mul-

tiple changes in products generations over the years.

In Figure 2, we show the IB count, the new installa-

tions count, and the de-installations count of the stud-

Figure 2: Products IB evoluion.

ied products. We observe that the IB count for each

of them is impacted by the installations at the begin-

ning of its life and the de-installation at the EOL. In

this industry, it becomes more complex to predict the

IB information at the EOL since de-installed products

can be re-injected into the IB in a different region and

at a different customer.

4.1 Features Engineering

The data we collect is a collection of IB status screen-

shots updated on a weekly basis from each product

generation’s beginning of life. Therefore, we need

to build informative features of the IB namely the IB

count, IB average age, and the Count of new prod-

ucts install. Every product generation has its own life-

cycle evolution characteristics namely the maximum

ICORES 2024 - 13th International Conference on Operations Research and Enterprise Systems

400

count of products, the life-cycle period, the growth

and the decline speed, and the maturity period length.

The IB count is a result of the new installs of products

and products de-installs. However, we need to con-

sider the fact that some de-installed products will also

be installed later as a refurbished product. That will

make the product life longer and can have an impact

on our predictions.

4.2 Results and Discussion

The training data is consisted of information of six

other product generations. The models evaluation is

conducted one of the newest generations. The prod-

uct life-cycle is in the growth phase. Looking at its

growth compared to the other generations in Figure 2,

it has the highest installation speed and count.

We test the proposed framework using four deep

learning models namely RNN, LSTM, GRU, and a

combination of RNN and LSTM. We use the root

mean squared error and the mean absolute error as

evaluation metrics. We provide the results in Table 1.

Using the RMSE, we see that RNN outperforms the

other models for the IB count prediction, while GRU

has the best results for the IB average age and the new

installations count prediction. Meanwhile, using the

MAE, the RNN outperforms the tested models when

predicting the new installations.

Table 1: Models results for the IB information forecast.

Model RMSE MAE

Information IB count IB Avg age New install IB count IB Avg age New install

LSTM 113.5 1.8 29.4 89.65 1.44 19.16

RNN 79.45 1.88 27.2 42.18 1.45 13.89

RNN-LSTM 97.9 1.8 27.3 66.5 1.42 16.11

GRU 94.5 1.7 25.88 58.5 1.33 15.42

The model evaluation is conducted on an out of

sample data-set. We observe a very close shape to the

actual evolution of the IB features. The model is able

to predict the growth as well as the decrease in the

average age and the number of new installations.

Figures 3 to 5 illustrate the features evolution pre-

diction vs their actual evolution with yearly steps. The

models testing is applied on ’product 2’. We observe

a close prediction to the actual values. Using this ap-

proach, we are able to predict not only the growth,

but also the peak and the decline of an installed base

information.

5 CONCLUSION &

PERSPECTIVE

In this paper, we provided a framework for installed

base information prediction on a long horizon in

Figure 3: Products IB count prediction.

Figure 4: Products IB new install prediction.

Figure 5: Products IB average age prediction.

Healthcare industry using products classification in-

formation. We employed and compared between deep

learning models like RNN, LSTM, a combination of

both, and GRU to learn the patterns of previous gener-

ations from the same product type in the same region.

We showed that RNN outperforms the other models

for the IB count prediction. We also concluded that,

in our use case, the GRU model outperforms the oth-

ers on the IB average age prediction. This prediction

can be used to provide recommendations for decision

makers in the Healthcare industry. It can also be used

in other industries where the IB is highly impacted

by the products families’ significant differences and

the location of the customers. This work can be im-

proved by using other machine learning models and

more data.

Deep Transfer Learning for Installed Base Life-Cycle Evolution Forecast

401

REFERENCES

Baardman, L., Levin, I., Perakis, G., and Singhvi, D.

(2017). Leveraging comparables for new product sales

forecasting. Available at SSRN 3086237.

Bandara, K., Shi, P., Bergmeir, C., Hewamalage, H., Tran,

Q., and Seaman, B. (2019). Sales demand fore-

cast in e-commerce using a long short-term mem-

ory neural network methodology. In Neural Infor-

mation Processing: 26th International Conference,

ICONIP 2019, Sydney, NSW, Australia, December 12–

15, 2019, Proceedings, Part III 26, pages 462–474.

Springer.

Ching-Chin, C., Ieng, A. I. K., Ling-Ling, W., and Ling-

Chieh, K. (2010). Designing a decision-support sys-

tem for new product sales forecasting. Expert Systems

with applications, 37(2):1654–1665.

European-Commission (2020). The commission calls for a

climate neutral europe by 2050*. brussels: Press re-

lease, 28 november 2018.

Hu, S. and Li, K. (2023). Bayesian network demand-

forecasting model based on modified particle swarm

optimization. Applied Sciences, 13(18):10088.

Karb, T., K

¨

uhl, N., Hirt, R., and Glivici-Cotruta, V.

(2020). A network-based transfer learning approach

to improve sales forecasting of new products. arXiv

preprint arXiv:2005.06978.

Machuca, M. M., Sainz, M., and Costa, C. M. (2014). A

review of forecasting models for new products. Intan-

gible capital, 10(1):1–25.

Mont, O. K. (2002). Clarifying the concept of product–

service system. Journal of cleaner production,

10(3):237–245.

Salinas, D., Flunkert, V., Gasthaus, J., and Januschowski, T.

(2020). Deepar: Probabilistic forecasting with autore-

gressive recurrent networks. International Journal of

Forecasting, 36(3):1181–1191.

Smyl, S. (2020). A hybrid method of exponential smoothing

and recurrent neural networks for time series forecast-

ing. International Journal of Forecasting, 36(1):75–

85.

Thomas, J. W. et al. (2007). New product sales forecasting.

10th Annual Marketing Research.

Van der Auweraer, S., Boute, R. N., and Syntetos, A. A.

(2019). Forecasting spare part demand with installed

base information: A review. International Journal of

Forecasting, 35(1):181–196.

ICORES 2024 - 13th International Conference on Operations Research and Enterprise Systems

402