Deep Learning Model to Predict the Ripeness of Oil Palm Fruit

Isis Bonet

1a

, Mario Gongora

2b

, Fernando Acevedo

3

and Ivan Ochoa

4c

1

Universidad EIA, Envigado, Colombia

2

Institute of Artificial Intelligence, School of Computer Science and Informatics, De Montfort University, U.K.

3

Soluciones Integrales TIC Group S.A.S.

4

UNIPALMA de Los Llanos S.A, Meta, Colombia

Keywords: Fruit Ripeness Classification, Oil Palm, YOLO.

Abstract: This study explores the application of deep learning, specifically the YOLOv8 model, for predicting the

ripeness of oil palm fruit bunch through digital images. Recognizing the economic importance of oil palm

cultivation, precise maturity assessment is crucial for optimizing harvesting decisions and overall productivity.

Traditional methods relying on visual inspections and manual sampling are labor-intensive and subjective.

Leveraging deep learning techniques, the study aims to automate maturity classification, addressing

limitations of prior methodologies. The YOLOv8 model exhibits promising metrics, achieving high precision

and recall values. Practical applications include deployment in production areas and real-time field scenarios,

enhancing overall production processes. Despite excellent metric results, the model shows potential for further

improvement with additional training data. The research highlights the effectiveness of YOLOv8 in

automating the ripeness classification oil palm fruit bunches, contributing to sustainable cultivation practices

in diverse agricultural settings.

1 INTRODUCTION

Colombia stands as the largest producer of oil palm

(Elaeis guineensis) in the Americas and ranks fourth

globally, annually yielding millions of tons

(Fedepalmas, 2019). The economic and social

significance of this cultivation has spurred interest in

sustainable development models. Within the global

vegetable oil market, oil palm holds a pivotal role,

serving as a primary source for industries such as

food, cosmetics, and biofuels. The economic

importance has led to a heightened focus on

optimizing cultivation practices to meet the growing

demand (Corley & Tinker, 2015).

A critical aspect of the cultivation process is the

precise assessment of oil palm fruit bunch maturity,

influencing harvesting decisions and overall

productivity. The quality of palm oil is deeply

intertwined with the ripeness of the fruit. It's ideal for

the fruit to reach an exact level of ripeness, steering

clear of both being excessively green or overly ripe

a

https://orcid.org/0000-0002-3031-2334

b

https://orcid.org/0000-0002-7135-2092

c

https://orcid.org/0000-0003-1651-3831

extremes. When the fruit is immature, it lacks

sufficient oil content, and when overly ripe, it

detaches too easily, leading to significant oil loss as

the fruits separate from the bunches. The

classification of the fruits is closely tied to how easily

they detach from the bunch and a certain color

change, ultimately dependent on individual

experience and visual assessment.

Traditional methods relying on visual inspections,

manual sampling, and expert judgment are labor-

intensive, time-consuming, and subjective,

potentially introducing inaccuracies. Classifying the

fruits is closely associated with how easily they

detach from the bunch and a certain change in color,

which ultimately relies on individual experience and

visual assessment. Many studies have been

conducted, some related to computer vision attempts

based on color. Others have used sensors, which also

did not provide great outcomes, partly because there

are different palm varieties that alter the shape of

bunch and fruits (Lai et al., 2023).

1068

Bonet, I., Gongora, M., Acevedo, F. and Ochoa, I.

Deep Learning Model to Predict the Ripeness of Oil Palm Fruit.

DOI: 10.5220/0012434600003636

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 16th International Conference on Agents and Artificial Intelligence (ICAART 2024) - Volume 3, pages 1068-1075

ISBN: 978-989-758-680-4; ISSN: 2184-433X

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

The advent of deep learning, particularly

convolutional neural networks (CNN), offers a

transformative avenue to automate complex visual

tasks, including image classification. The application

of deep learning techniques to agricultural processes,

such as maturity assessment, has shown promising

results in enhancing accuracy and efficiency

(Mohanty et al., 2016).

One of the major challenges in conducting

predictive work regarding the ripeness of oil palm

fruit bunches lies in acquiring appropriate images for

fruit maturity detection. Typically, fruits are

segregated, and images are captured either when they

are on the ground or while still on the tree (Suharjito

et al., 2023).

There are two critical moments requiring fruit

maturity classification: 1) while the fruit is still on the

tree to determine the optimal harvesting time and 2)

when it's within the production area before oil

extraction. However, it's uncommon to find work or

images of fruits during this latter stage, despite it

being arguably the most crucial. Large companies

usually have fruit suppliers, and accurately

classifying incoming fruit is essential. Additionally,

for a final evaluation of one's own fruits, determining

their maturity is crucial.

In fruit unloading zones, there are often inclined

ramps or reception platforms where fruits are

transported from trucks to the oil extraction area.

During transit on these ramps, fruit bunches are

typically not well-separated and may stack on top of

one another. Our aim is precisely to develop a model

capable of classifying fruit at this stage of the process.

Hence, this work's primary objective is to establish a

database using images captured specifically on these

loading ramps.

In response to the limitations of traditional

methods and building upon promising prior deep

learning research, this study aims to harness deep

learning for oil palm fruit bunch maturity

classification. Primary objectives include developing

a robust deep learning model capable of accurately

distinguishing between different maturity stages,

utilizing images to capture dynamic changes in fruit

bunches over time. To achieve these goals, images at

various maturity states will be annotated, and

YOLOv8 will be employed for maturity detection.

This study seeks to provide technological

advancement, enhancing maturity assessment

accuracy, and contributing to sustainable practices in

oil palm cultivation.

2 RELATED WORKS

The use of video data for crop monitoring has

emerged as a valuable tool in precision agriculture.

Video-based approaches provide a dynamic

understanding of crop growth and maturation

processes over time. Successfully applied in various

crops such as grapes (Kangune et al., 2019; Zhao et

al., 2023) and wheat (Virlet et al., 2016), this

methodology showcases its potential to capture

temporal changes in oil palm fruit bunches.

Recent research has made significant strides in the

maturity classification of oil palm fruit, leveraging

advanced technologies. Many studies rely on non-

invasive methods, predominantly visual-based,

avoiding direct contact with the fruit. Some authors

employ computer vision and machine learning

systems, extracting color features or other image

characteristics using methods like support vector

machine (SVM) (Septiarini et al., 2019) and artificial

neural networks (ANN). For example, Septiarini A. et

al. (2021) use different machine learning algorithms

as Naïve Bayes, SVM and ANN. Others utilize

Raman spectroscopy, as demonstrated by Raj T. et al.

(2021) employing Raman signal features as input for

KNN. Considering the importance of segmentation in

traditional machine learning and/or computer vision

methods, some authors have focused on this aspect

(Septiarini et al., 2020).

The integration of deep learning techniques into

agriculture has gained ground, offering innovative

solutions to various challenges, including crop

monitoring, disease detection, and yield prediction.

Deep learning models, particularly Convolutional

Neural Networks (CNN), have shown remarkable

success in image-based tasks, providing a foundation

for their application in maturity classification. Recent

works, including the use of convolutional neural

networks capable of classifying oil palm fruit through

knowledge transfer, for example, Suharjito et al.,

(2021), compare various CNN models, such as

MobileNetV1, MobileNetV2, NASNet Mobile, and

EfficientNetB0, with transfer learning (Suharjito et

al., 2021). On the other hand, models such as YOLO

show promising results when it comes to classifying

multiple fruits in a single image with internal

segmentation. Authors using the YOLO model have

employed various versions, ranging from YOLOv3

(Mohd Basir Selvam et al., 2021) to YOLOv5

(Mansour et al., 2022). Some authors have even

compared YOLO with other CNN models (Junior &

Suharjito, 2023; Mansour et al., 2022).

However, effective classification models depend

on a robust database, emphasizing the fundamental

Deep Learning Model to Predict the Ripeness of Oil Palm Fruit

1069

role of correct data labeling. Selecting the number of

maturity grades to classify and building a high-quality

database are key to model performance. Some authors

have dedicated efforts to label databases for this

purpose. Divergence exists in the number of maturity

classes used by different authors, ranging from 2

(ripe, unripe)(Saleh & Liansitim, 2020) to 6 (unripe,

under ripe, ripe, over-ripe, empty, abnormal)

(Suharjito et al., 2023). Up to 7 classes have even

been used, attempting to differentiate all possible

options (Herman et al., 2020). But if having few

classes can be detrimental, as it may not cover all

maturity options or attempt to group many different

types of maturity into one class, having too many can

also be problematic. It is challenging to have images

for all maturity styles or types of fruits because some

use the abnormal class, which is for when the fruit has

issues. The truth is that distinguishing different

patterns would be ideal whenever we have a sufficient

amount of data for each class.

Another important aspect when classifying oil

palm fruits is the timing of classification. As

mentioned earlier, there are two critical moments:

when they are on the tree ready to be harvested and

when they are in the production stage to determine

how they were collected. Both stages are

significant—the first for efficient harvesting. The

second is crucial for quality control of the harvest.

While this stage may not seem directly related to

harvesting, it does ensure control over the quality of

the process and allows evaluation of other suppliers a

company might have. Depending on the production

area, this can become quite complex; classifying fruit

by fruit is impractical due to inclined surfaces in

production areas, causing the fruits to be closely

packed rather than completely separated.

Most articles that have developed models to

predict the ripeness of oil palm fruit have done so with

individual bunches or completely separated from

each other, for example, on the ground (Junior &

Suharjito, 2023; Mansour et al., 2022; Saleh &

Liansitim, 2020; Suharjito et al., 2023). This isn't

typical in a production area as it's challenging to

separate cluster by cluster to classify them all. This

work aims to classify the fruits in the final production

stage where they pass through an inclined ramp

before oil extraction.

These collective efforts highlight diverse

approaches and methodologies to enhance the

accuracy of oil palm fruit maturity classification,

forming a basis for understanding the challenges in

maturity assessment. The demonstrated potential of

deep learning in recent works contributes to the

context of the proposed research on oil palm fruit

bunch maturity classification. In our case, we propose

three classes to avoid noise between closely related

classes, considering their significance for workers in

the oil palm industry. The database will be built using

images of fruits from a video taken on an inclined

ramp in the production area. Furthermore, given the

capabilities demonstrated by previous versions of the

YOLO model in other works, we will use the latest

version of this model.

3 DATA AND METHODS

3.1 Methodology

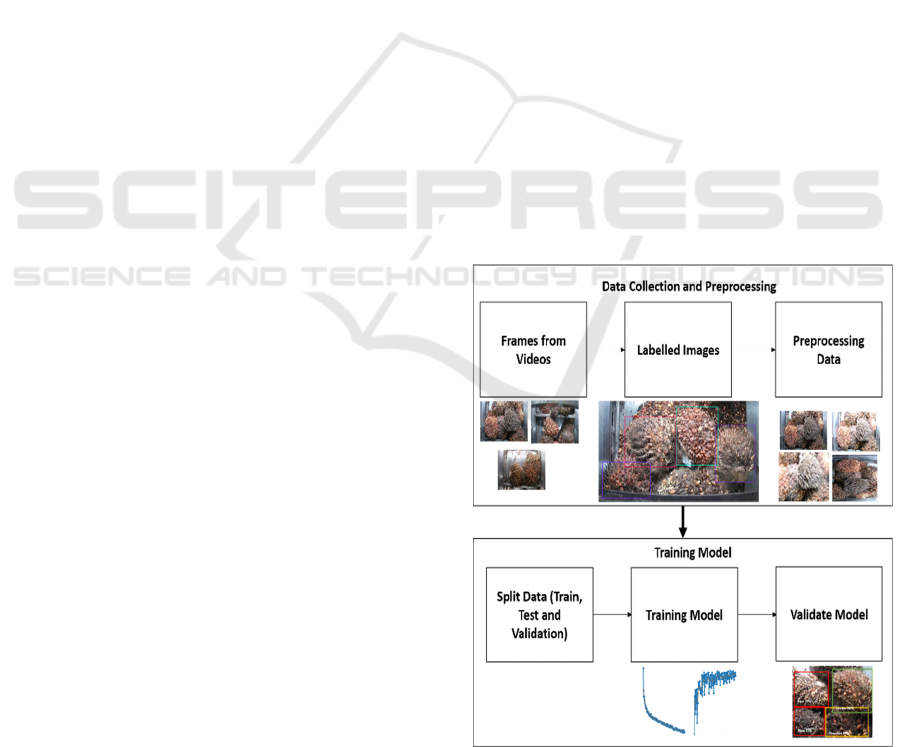

The methodology followed is shown in Figure 1

below. First, data collection is performed from videos

by capturing frames. The images are labeled,

selecting the bunch based on their ripeness.

Afterward, the data is preprocessed, meaning it is

resized to the same dimensions and augmented.

Following all the data preprocessing, the model

training takes place, involving tasks such as splitting

the data into training, testing, and validation sets,

training the model over several epochs, and validating

it. The data set was divided into percentages: 85%

training, 10% testing, and 5% validation.

Next, the steps of this methodology are described

in more detail.

Figure 1: Methodology.

ICAART 2024 - 16th International Conference on Agents and Artificial Intelligence

1070

3.2 Data Collection and Preprocessing

The data were extracted from videos and

meticulously labeled by experts. To label the oil palm

fruit bunches, different ripening stages were

considered. Based on the available data and aiming

for practicality in maturity prediction, only 3 maturity

stages were utilized from the 4 classic types shown in

Figure 2. In this figure, a) represents the unripe stage,

crucial as the fruit isn’t yet ready and might not be

useful for oil production due to low oil content. The

mature stage, depicted in b), is considered ideal as it

allows for the extraction of the highest oil yield

without losses. Stage c) indicates overripeness,

leading to losses as the fruits easily detach from the

bunch and might remain unused. Lastly, stage d)

represents the fruit being beyond overripe, continuing

its deterioration and entering a state considered rotten

or spoiled. Despite its significance, due to limited

available data, this latter stage was not individually

considered; instead, it was merged with the previous

stage. Therefore, stages c) and d) were labeled as

overripe. Finally, the fruit bunches were labeled as

unripe, ripe, and overripe.

Two types of palms were considered: Elaeis

guineensis and hybrids OxG (E. oleifera x E.

guineensis). Roboflow software facilitated image

labeling, yielding 65 images from the videos (see

Figure 3 for one example of the images). Within these

images, fruit bunch were annotated, resulting in 390

labeled bunch: 65 unripe, 203 ripe, and 122 overripe.

Figure 2: Example of ripeness level of oil palm fruit bunch.

One of the first things to consider is the difficulty

of the images. As can be seen, for example, in the

figure 3, there are many fruits grouped together,

which can be challenging to identify. This is precisely

one of the issues with the YOLO model, identifying

objects that may be overlapped. The photos were

taken on a loading ramp in the production area, so the

bunch may shift, and sometimes they can be on top of

each other or too close. Even due to the detachment

of fruits from the bunch, there may be some bunch of

loose fruits that resemble bunches.

Figure 3: Example of image taken from the video.

Before training, image pre-processing was

conducted. Initially, the image size was adjusted to

640x640 pixels. Various data augmentation processes

were then applied, including flipping, rotating,

cropping, saturating, adjusting brightness, and

exposure alterations. The applied data augmentation

processes are as follows:

Flip: Horizontal, Vertical

90° Rotate: Clockwise, Counter-Clockwise,

Upside Down

Crop: 0% Minimum Zoom, 20% Maximum

Zoom

Rotation: Between -15° and +15°

Shear: ±15° Horizontal, ±15° Vertical

Saturation: Between -15% and +15%

Brightness: Between -15% and +15%

Exposure: Between -15% and +15%

The data augmentation process was performed

during training, obtaining 165 images to train the

model, significantly increasing the data per classes:

156 immature, 642 mature, and 309 overripe.

3.3 YOLOv8 Model

In this study, we employed the YOLOv8 model for

object detection, the latest version to date in the You

Only Look Once (YOLO) series. Developed by

Deep Learning Model to Predict the Ripeness of Oil Palm Fruit

1071

Ultralytics, this model is renowned for its real-time

capabilities (Jocher et al., 2023).

The architecture is based on a CNN. It utilizes a

simple CNN to predict bounding boxes and class

probabilities in a single pass. YOLOv8 is a multiscale

model, employing three scale-detection layers. This

model is at the forefront of real-time object detection,

providing a balance between accuracy and speed,

making it a valuable tool for various applications.

Our utilization of YOLOv8 involved fine-tuning

on labelled datasets, including pre-processing steps

such as resizing images to 640x640 pixels.

3.4 Metrics

Object detection involves not only the classification

of an object but also the classification of several

objects. In each case, it is necessary to evaluate

whether the detection position is correct.

To assess the performance of the YOLOv8 model

for object detection, various metrics are employed to

evaluate accuracy and efficiency. These metrics

provide information about the model's ability to

accurately identify objects within an image.

3.4.1 Intersection over Union (IoU)

Intersection over Union (IoU) is a metric used to

evaluate the overlap between the predicted bounding

box and the ground truth bounding box. It is

calculated by dividing the area of overlap between the

two boxes by the area of their union. IoU provides a

measure of how well the predicted box aligns with the

actual object location.

𝐼𝑂𝑈

𝐴

𝑟𝑒𝑎 𝑜𝑓 𝐼𝑛𝑡𝑒𝑟𝑠𝑒𝑐𝑡𝑖𝑜𝑛

𝐴

𝑟𝑒𝑎 𝑜

𝑓

𝑈𝑛𝑖𝑜𝑛

(1)

3.4.2 Precision and Recall

Precision and recall are fundamental metrics

quantifying the model's accuracy in correctly

identifying positive instances (precision) and

capturing all relevant instances (recall).

3.4.3 Mean Average Precision (mAP)

One key metric is the mean Average Precision (AP),

measuring the average accuracy across different

object classes. Where (AP) is calculated as the area

under the precision-recall curve. This metric is crucial

for understanding the overall effectiveness of the

YOLOv8 model in various scenarios.

This metric is often calculated under an IoU

threshold. For example, mAP50 calculates the mean

of AP at an IoU threshold of 0.5, considering only

predictions with IoU greater than or equal to 0.5. This

metric is useful when flexibility in bounding box

matching is needed. On the other hand, mAP50-95 is

the mean of AP at different IoU thresholds from 0.5

to 0.95, calculated at 0.05 intervals. These two

metrics provide information about the model's ability

to accurately detect objects at different levels of

overlap between predicted bounding boxes and

ground truth.

4 RESULTS AND DISCUSION

In this study, the YOLOv8 model was employed to

train the previously described dataset. The advantage

of using a model like this is the ability to detect fruit

bunches in images without the need for prior

segmentation. This contributes to a faster model. The

model was trained using transfer learning for 300

epochs with a batch size of 16.

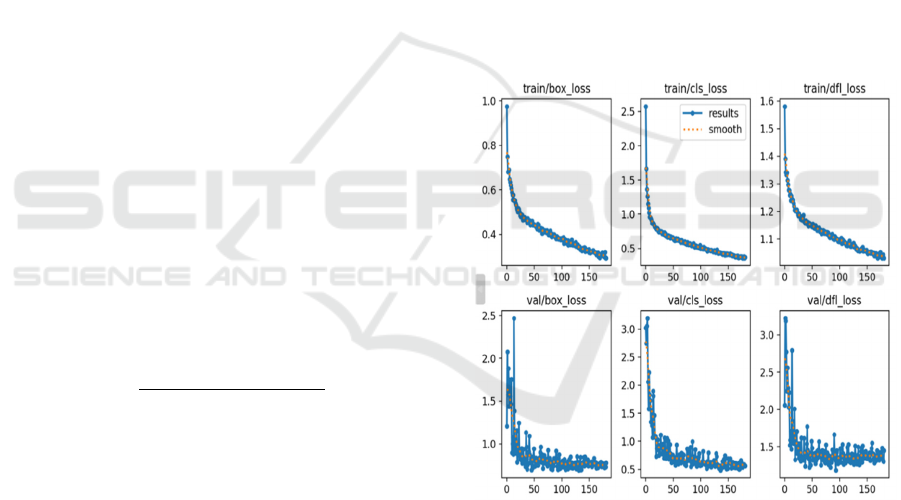

Figure 4: Training loss graphs of the model.

Figure 4 illustrates the training loss graphs. In the

figure, graphs related to three losses that play a

significant role in the performance of a YOLO model

can be observed: loss related to bounding box

regression (box_loss), loss associated with

classification accuracy (cls_loss), and distribution

focal loss (dfl_loss). The box_loss measures the

accuracy of predicted bounding boxes around objects,

indicating the alignment between predicted and actual

object boundaries. Meanwhile, cls_loss evaluates the

precision of object classification, reflecting the

model's ability to correctly identify object classes.

ICAART 2024 - 16th International Conference on Agents and Artificial Intelligence

1072

Lastly, dfl_loss is a variant that aids in mitigating

class imbalance and challenging examples during

model training, thereby enhancing its capability to

handle varied classes and complex instances. The first

row contains three graphs related to losses, showing

a clear trend of decreasing loss, indicating that more

training epochs could have been performed. The

subsequent three graphs are about the validation

losses. The limited number of validation images

results in somewhat unstable loss despite a decrease

at the same level. This instability may be attributed to

the scarcity of validation data.

Figure 5: Training metrics graphs of the model.

Figure 5 shows the graphs that represent precision

and recall, achieving values of 96.5% and 95%,

respectively. Finally, mAP50 and mAP50-95 graphs,

crucial for measuring model precision, reached

significant values of 98% for mAP50 and 80% for

mAP50-95. The validation resulted in an mAP of

94.3%.

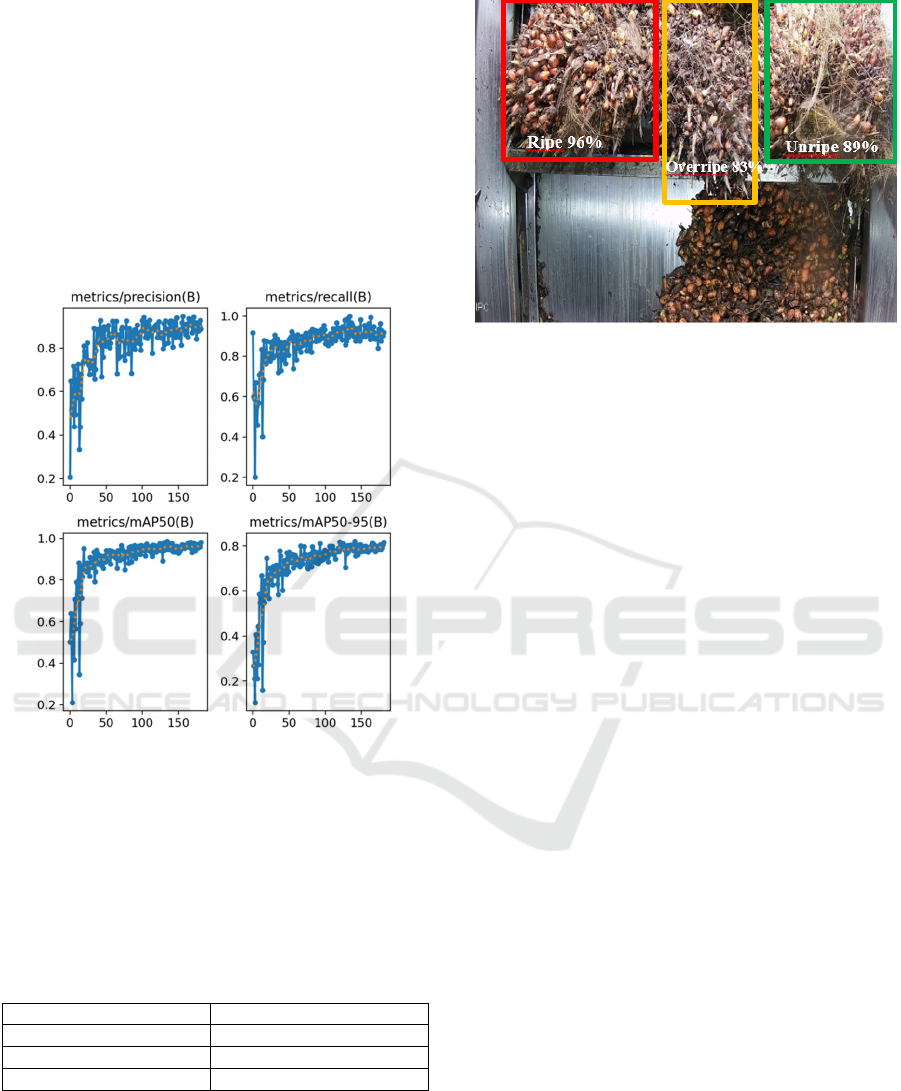

Table 1: Average precision by class.

Class Precision

Unri

p

e 92

Ripe 85

Overripe 93

Table 1 displays the precision results for each

class in the validation set. It can be observed that the

intermediate class, 'mature,' has the lowest precision,

while 'green' and 'overripe' exhibit the highest

precision.

Figure 6: Image classify by the model.

As depicted in Figure 6, the model adeptly

identifies fruits in all three classes. It can be seen in

the figure that the model also provides a percentage

of the classification of the identified object, which can

also be a factor in the prediction, selecting only

objects with a specific threshold. Such a model holds

great utility for camera deployment in production

areas, where photos are taken on a conveyor where

fruits pass before being taken to tanks for oil

extraction. Although this marks the final production

stage, it is crucial for evaluating the overall

production process. Additionally, the model could be

applied in the field, using a smartphone camera to

classify fruits in real-time, assisting fruit pickers in

harvesting at the right moment of ripeness.

Despite achieving excellent metric results, the

model shows promise for even better performance

with additional training data.

Consideration could be given to adding another

class for empty or rotten bunch. A detailed analysis

revealed challenges, especially in classifying overripe

bunch, indicating the need for a nuanced approach.

Although overripe bunch tend to lose many fruits,

they are not necessarily empty or semi-empty,

introducing another level of complexity, but the

quantity of such instances was insufficient to

establish a separate class in this study.

Figure 7 shows how the model makes a mistake in

classifying the bunch at the bottom right as overripe

when it is actually ripe. It can be seen that this specific

bunch has lost fruits, but despite that, it is not

overripe. Perhaps the loss of fruits was due to the

transportation process in production and not the

maturity state. These can become classic errors and

are challenging to detect even by some experts.

However, increasing the quantity of images in the

data is believed to significantly aid in improving

distinctions like this.

Deep Learning Model to Predict the Ripeness of Oil Palm Fruit

1073

Figure 7: Image classify by the model, with wrong

identification.

5 CONCLUSIONS

The research presented in the article leverages the

YOLOv8 model for identifying the maturity of fruit

bunches through digital images, demonstrating its

application in production scenarios and considering it

a promising tool for fruit harvesting. Several key

observations can be extracted:

• The study focuses on classifying fruits as ripe or

overripe, highlighting the model's ability to

discern different stages of fruit maturity, being

more accurate in the unripe and ripe stages.

• Deep learning, particularly YOLO variants,

proves effective in various fruit detection

scenarios, capable of identifying objects in

images with multiple items without the need for

prior segmentation.

• The analyzed models exhibit real-time

capabilities, with applications in complex

orchard scenarios, contributing to timely fruit

classification and harvest decisions.

• Experimental results, especially with the YOLO

v8 model, emphasize its robustness in addressing

variations in lighting and unstructured grape

growth environments.

• In conclusion, the research underscores the

versatility and effectiveness of YOLOv8 and

related models in the detection, classification,

and identification of the maturity of oil palm fruit

bunches in diverse agricultural settings.

• For future work, it is recommended to split the

overripe class into two, adding the empty or

rotten bunch class to learn different patterns

more effectively and increase the quantity of

images.

• Another recommendation for future work is to

utilize different types of photos, capturing fruit

bunches not only on the loading ramp but also

while on the tree. This approach would provide

broader coverage for the final application's

usability.

ACKNOWLEDGEMENTS

This piece of research is a part of the project which

has received funds from The Royal Academy of

Engineering under the Award Distinguished

International Associates (DIA).

Furthermore, we want to thank Unipalma S.A.S

for letting us access their facilities and for all support

provided to carry out our project.

REFERENCES

Corley, H., & Tinker, P. (2015). The oil palm. Wiley Online

Library. https://doi.org/10.1002/9781118953297

Fedepalmas. (2019, December). The Oil Palm Agribusiness

in Colombia.

Herman, H., Susanto, A., Cenggoro, T. W., Suharjito, S., &

Pardamean, B. (2020). Oil Palm Fruit Image Ripeness

Classification with Computer Vision using Deep

Learning and Visual Attention. In Journal of

Telecommunication, Electronic and Computer

Engineering (JTEC) (Vol. 12, Issue 2, pp. 21–27).

https://jtec.utem.edu.my/jtec/article/view/5543

Jocher, G., Chaurasia, A., & Qiu, J. (2023). Ultralytics

YOLOv8. https://github.com/ultralytics/ultralytics

Junior, F. A., & Suharjito. (2023). Video based oil palm

ripeness detection model using deep learning. Heliyon,

9(1), e13036. https://doi.org/10.1016/J.HELIYON.

2023.E13036

Kangune, K., Kulkarni, V., & Kosamkar, P. (2019). Grapes

Ripeness Estimation using Convolutional Neural

network and Support Vector Machine. 2019 Global

Conference for Advancement in Technology (GCAT),

1–5. https://doi.org/10.1109/GCAT47503.2019.

8978341

Lai, J. W., Ramli, H. R., Ismail, L. I., & Wan Hasan, W. Z.

(2023). Oil Palm Fresh Fruit Bunch Ripeness Detection

Methods: A Systematic Review. Agriculture 2023, Vol.

13, Page 156, 13(1), 156.

https://doi.org/10.3390/AGRICULTURE13010156

Mansour, M. Y. M. A., Dambul, K. D., & Choo, K. Y.

(2022). Object Detection Algorithms for Ripeness

Classification of Oil Palm Fresh Fruit Bunch.

International Journal of Technology, 13(6), 1326–

1335. https://doi.org/10.14716/IJTECH.V13I6.5932

Mohanty, S. P., Hughes, D. P., & Salathé, M. (2016). Using

Deep Learning for Image-Based Plant Disease

ICAART 2024 - 16th International Conference on Agents and Artificial Intelligence

1074

Detection. Frontiers in Plant Science, 7, 1419.

https://doi.org/10.3389/fpls.2016.01419

Mohd Basir Selvam, N. A., Ahmad, Z., & Mohtar, I. A.

(2021). Real Time Ripe Palm Oil Bunch Detection

using YOLO V3 Algorithm. 19th IEEE Student

Conference on Research and Development: Sustainable

Engineering and Technology towards Industry

Revolution, SCOReD 2021, 323–328.

https://doi.org/10.1109/SCORED53546.2021.9652752

Raj, T., Hashim, F. H., Huddin, A. B., Hussain, A., Ibrahim,

M. F., & Abdul, P. M. (2021). Classification of oil palm

fresh fruit maturity based on carotene content from

Raman spectra. Scientific Reports 2021 11:1, 11(1), 1–

11. https://doi.org/10.1038/s41598-021-97857-5

Saleh, A., & Liansitim, E. (2020). Palm oil classification

using deep learning. Science in Information Technology

Letters, 1(1), 1–8. https://doi.org/10.31763/sitech.

v1i1.1

Septiarini, A., Hamdani, H., Hatta, H. R., & Anwar, K.

(2020). Automatic image segmentation of oil palm

fruits by applying the contour-based approach. Scientia

Horticulturae, 261, 108939. https://doi.org/10.1016/J.

SCIENTA.2019.108939

Septiarini, A., Hamdani, H., Hatta, H. R., & Kasim, A. A.

(2019). Image-based processing for ripeness

classification of oil palm fruit. 2019 5th International

Conference on Science in Information Technology

(ICSITech), 23–26. https://doi.org/10.1109/

ICSITech46713.2019.8987575

Septiarini, A., Sunyoto, A., Hamdani, H., Kasim, A. A.,

Utaminingrum, F., & Hatta, H. R. (2021). Machine

vision for the maturity classification of oil palm fresh

fruit bunches based on color and texture features.

Scientia Horticulturae, 286, 110245. https://doi.org/10.

1016/J.SCIENTA.2021.110245

Suharjito, Elwirehardja, G. N., & Prayoga, J. S. (2021). Oil

palm fresh fruit bunch ripeness classification on mobile

devices using deep learning approaches. Computers

and Electronics in Agriculture, 188, 106359.

https://doi.org/10.1016/J.COMPAG.2021.106359

Suharjito, Junior, F. A., Koeswandy, Y. P., Debi,

Nurhayati, P. W., Asrol, M., & Marimin. (2023).

Annotated Datasets of Oil Palm Fruit Bunch Piles for

Ripeness Grading Using Deep Learning. Scientific

Data, 10(1), 72. https://doi.org/10.1038/s41597-023-

01958-x

Virlet, N., Sabermanesh, K., Sadeghi-Tehran, P., &

Hawkesford, M. J. (2016). Field Scanalyzer: An

automated robotic field phenotyping platform for

detailed crop monitoring. Functional Plant Biology :

FPB, 44(1), 143–153. https://doi.org/10.1071/FP16163

Zhao, J., Hu, Q., Li, B., Xie, Y., Lu, H., & Xu, S. (2023).

Research on an Improved Non-Destructive Detection

Method for the Soluble Solids Content in Bunch-

Harvested Grapes Based on Deep Learning and

Hyperspectral Imaging. Applied Sciences,

13(11).

https://doi.org/10.3390/app13116776.

Deep Learning Model to Predict the Ripeness of Oil Palm Fruit

1075