Sustainable Printed Electrodes for Energy Harvesting from Urine to

Power IoT Sensor Nodes in Smart Diapers

Muhammad Tanweer

1 a

, Raimo Sepponen

2

, I. Oguz Tanzer

1

and Kari Halonen

1

1

Department of Electronics and Nanoengineering, Aalto University, Espoo 02150, Finland

2

Department of Automation and Electrical Engineering, Aalto University, Espoo 02150, Finland

fi

Keywords:

Energy Harvesting, Green Electronics, IoT Sensors, Printed Electronics, Self-Powered, Smart Diaper,

Wearable Biomedical Devices.

Abstract:

The expansion of Internet of Things (IoT) devices is rapidly increasing across various aspects of life, notably

in wearable healthcare. With billions of already deployed IoT sensor nodes, this figure is anticipated to

escalate into the hundreds of billions in coming years. One of the most significant challenges is how

to economically power these devices by adopting sustainable and environment-friendly solutions as the

conventional power sources are inadequate to meet the demands of this vast IoT ecosystem. In recent years,

innovative approaches have emerged to design energy-optimized electronic systems, opening a pathway for

applications based on energy harvesting. In this study, a novel energy harvesting solution is proposed by

developing sustainable and disposable harvesting electrodes, leveraging the capabilities of printed electronics

technology. These electrodes are engineered to harvest energy from human urine, a readily available resource,

to power the energy-efficient wearable IoT sensor nodes of smart diapers. A comprehensive characterization

of these harvesting electrodes is conducted using pseudo-urine as an electrolyte within a controlled laboratory

environment. The results demonstrate great promise for the development of self-powered IoT sensor nodes of

smart diapers, with the capacity for overnight operations lasting up to 12 hours.

1 INTRODUCTION

Energy harvesting from saltwater, for example, salt

concentration gradient in seawater, has been a topic

of interest since the 1970s. Despite its potential,

it has historically received limited attention due to

its comparative limitations against more promising

energy sources (Muhthassim et al., 2018). However,

with advancements in integrated circuit technology,

the development of power-efficient circuits and

systems that operate at micro- and nano-watt scales

has emerged. This technological progress has

paved the way for energy harvesting from ambient

surroundings on a microscale, enabling the powering

of IoT devices.

Zinc-carbon-based dry batteries with manganese

dioxide and ammonium chloride electrolytes have

been available commercially for more than 150 years

(Kordesch and Taucher-Mautner, 2009; Linden and

Reddy, 2001). A market growth trend is expected

for zinc-carbon batteries because of their sustainable

a

https://orcid.org/0000-0001-7425-2452

and environment-friendly nature as compared to other

competitors (Reports, 2022). However, the wide

use of ammonium chloride as an electrolyte in dry

batteries still poses challenges of being hazardous for

humans (NJ-Gov, 2016; Pelner, 1956) and harmful to

aquatic life (Rani et al., 1998).

Typical human urine contains sodium, chloride,

and potassium electrolytes along with more than

150 different constituents as studied by investigators

at National Aeronautics and Space Administration

(NASA) (Putnam et al., 1971). The specific

conductivity of sodium chloride solution (1.3

k℧cm

2

/mol) is close to the specific conductivity of

ammonium chloride solution (1.5 k℧cm

2

/mol) of the

same concentration at room temperature (Murtom

¨

aki

et al., 2018). The presence of these electrolytes in

urine makes it suitable to be used as an electrolyte

for harvesting electrodes printed with materials like

zinc-carbon to harness chemical energy from urine.

In this study, a novel energy-harvesting approach is

proposed involving the design and development of

zinc-carbon-based flexible electrodes using printed

electronics technology to harvest chemical energy

Tanweer, M., Sepponen, R., Tanzer, I. and Halonen, K.

Sustainable Printed Electrodes for Energy Harvesting from Urine to Power IoT Sensor Nodes in Smart Diapers.

DOI: 10.5220/0012424100003657

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 17th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2024) - Volume 1, pages 65-70

ISBN: 978-989-758-688-0; ISSN: 2184-4305

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

65

from urine in diapers. The electrodes are printed

directly onto the diaper back-sheets, aiming to

offer a sustainable, environmentally friendly, and

cost-effective disposable solution. This innovation

intends to eliminate the need for batteries, which are

not only hazardous but also challenging to recycle.

The primary objective is to harvest the chemical

energy to supply power to the energy-optimized

circuits of IoT sensor nodes and integrate the printed

harvesting electrode seamlessly into smart diapers.

The materials used to develop the printed

harvesting electrodes, the preparation of pseudo

urine, the experimental setup, and the various

measurement scenarios are discussed in section 2 of

this article. Section 3 includes a discussion of the

obtained measurement results with the help of plots.

Finally, section 4 concludes the work by discussing

the findings and limitations along with the potential

prospects of the research.

2 MATERIALS AND METHODS

The rolled sheets and printable inks of zinc and

carbon materials are used to develop the electrodes to

harvest chemical energy from indigenously developed

pseudo-urine. The design and development of

electrodes, formulation of pseudo-urine, and

the details of measurement setup for various

measurements are discussed in the following

subsections.

2.1 Energy Harvesting Mechanism

Off-the-shelf flexible rolled sheets of carbon

material and zinc metal are used initially to develop

the harvesting electrodes for the preliminary

measurements to establish the proof-of-concept. A

sheet of pure conductive carbon holding a thickness

of 0.1 mm (Fly Fiber, 2022) is used to develop the

cathode having a size of 7 cm x 7 cm. The anode

of the same size is developed with an off-the-shelf

flexible rolled sheet of 99.99% pure zinc metal

(Tools Store, 2022) with a thickness of 0.2 mm. Both

electrodes have a surface area of 98 cm

2

each with

49 cm

2

on either side of the electrode. The electrical

connections for the carbon cathode are implemented

using a small patch of copper tape with conductive

adhesive (3M, StPaul, Minnesota, USA) and for the

zinc anode by directly soldering the copper wire to

the sheet surface.

The printed harvesting electrodes of 7 cm x 7 cm

size are developed using zinc and carbon inks on the

inner side of the diaper back sheet. The Figure. 1(a)

Figure 1: Printed electrode design for energy harvesting;

(a) carbon ink cathode, (b) zinc ink anode over the current

collector layer of carbon ink.

depicts the cross-section of the cathode electrode with

printed carbon ink on the single side of the diaper

back sheet and 1(b) shows the cross-section of the

anode with printed zinc ink on top of the carbon-based

current collector layer.

2.1.1 Fabrication of Printed Electrodes

The cathode (reducing electrode) with the same

geometry as described in Figure 1 is fabricated

by deposition and curing of electrically conductive

carbon ink (Saral Carbon 700A, by Saralon GmbH).

Consecutive two layers of carbon ink with a

sheet resistance of 30 Ω/□/25 µm are deposited

sequentially and each layer is thermally dried in a

95 °C preheated oven (ProtoFlow E, by LPKF Laser

& Electronics) at 100 °C for 10 minutes. The

electrical connections are implemented using a small

patch of copper tape with conductive adhesive (3M,

StPaul, Minnesota, USA) on the dried carbon ink

layer. The water-resistant tape is employed to make

the connections waterproof, preventing short circuits.

The anode (oxidizing electrode) is fabricated by

depositing and curing the electrically resistive zinc

ink (Saral Zinc 700, by Saralon GmbH). Consecutive

two layers of Zinc ink with a thickness of 100

microns are deposited sequentially and each layer is

thermally dried in a 95 °C preheated oven (ProtoFlow

E, by LPKF Laser & Electronics) at 100 °C for 10

minutes. Two consecutive layers of carbon ink are

printed as a current collector under the zinc layer as

Figure 2: Fabricated flexible harvesting electrodes on diaper

back sheets; (a) carbon ink cathode, (b) zinc ink anode.

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

66

shown in Figure 1(b) because of the low conductive

properties of zinc ink. The finished version of the

printed cathode and anode are shown in Figure 2.

2.1.2 Pseudo-Urine as Electrolyte

The pseudo-urine is used as an electrolyte to

replace the hazardous electrolyte ammonium chloride

(NH

4

Cl) which is used in commercial zinc-carbon

dry batteries. The reference concentration of sodium

electrolytes in human urine exhibits a range of 80

to 240 mmol/l and the concentration of chloride

electrolytes has a range of 85 to 260 mmol/l for

adults, as reported by the Laboratory of Helsinki

University Hospital and FimLabs of Finland (HUS,

2023; FimLab, 2023). In this study, the chemical

composition of pseudo-urine is formulated at Aalto

University labs using sodium chloride (NaCl) at

an electrolyte concentration of 220 mmol/l. The

designed concentration falls within the referenced

concentrations for sodium and chloride electrolytes

in the human urine. It is noteworthy that a one-mole

solution of NaCl consists of a molar mass of 23 g/mol

for sodium and 35.5 g/mol for chloride, as outlined in

a reference source (Lide, 2009).

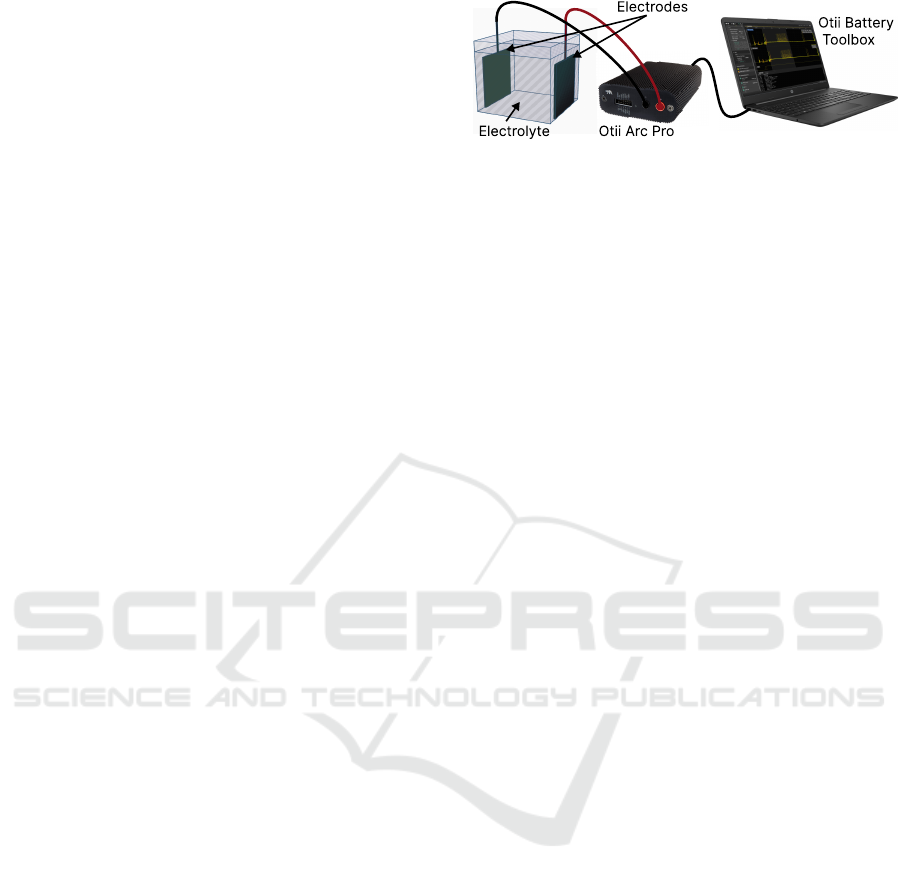

2.2 Measurement Setup

A galvanic cell is established as a vertical container,

holding the pseudo-urine of one liter as electrolyte.

The harvesting electrodes are deployed on the inner

side of the container in a parallel orientation. The

salt bridge of pseudo-urine connects the oxidation

and reduction reactions of these half cells. Figure 3

depicts the established measurement setup to evaluate

the harvested energy. Various measurement scenarios

are employed to analyze the harvested voltage level

and amount of energy from pseudo-urine. The

multimeter (73 III, Fluke) is used to measure

the open circuit voltages (OCV) of the developed

galvanic cell. A direct current (DC) energy

analyzer and power profiler instrument Otii Arc Pro

(Qoitech AB, Sweden) is employed with Otii Battery

Toolbox (Qoitech AB, Sweden) to characterize the

zinc-carbon flexible electrodes for energy harvesting

from pseudo-urine as an electrolyte.

In the first measurement scenario, the rolled

sheet-based zinc-carbon harvesting electrodes with

a surface area of 98 cm

2

are deployed in the

galvanic cell with an inter-electrode distance of 7

cm. The pseudo-urine-based electrolyte is poured

inside the cell and the immersed depth of electrodes

is increased by 1 cm in each measurement hence

increasing the immersed electrode area by 14 cm

2

for each measurement to analyze the effect of the

Figure 3: Measurement setup to harvest energy from

pseudo-urine.

variations in the partially immersed electrode area

on harvested energy. The voltage level and the

amount of harvested energy are analyzed to emulate

the frequent urination events when the electrodes are

partially immersed in small urine quantities inside

diapers. The second measurement scenario uses

fully immersed zinc-carbon electrodes in a one-liter

pseudo-urine electrolyte of the galvanic cell and the

inter-electrode distance is varied from 5 mm to 30 mm

with an increment of 5 mm for each measurement.

In the third measurement scenario, the printed

zinc-carbon flexible electrodes are fully immersed

in one liter of pseudo-urine electrolyte of the

galvanic cell in parallel orientation at a distance

of 7 cm to evaluate the change in voltages and

current flow when a constant power of 800 uW is

continuously withdrawn. The fourth measurement

scenario evaluates the intermittent energy harvesting

sessions every 30 minutes where the same printed

zinc-carbon electrodes are fully immersed in the

pseudo-urine electrolyte of a galvanic cell for 11

hours to understand the possibility of powering the

IoT sensor node overnight to perform measurements

for multiple urination events inside the same diaper.

3 RESULTS AND DISCUSSION

In the evaluation measurements, the OCV level of

1032 mV is measured for the developed single

galvanic cell and 2060 mV when the two galvanic

cells are connected in series. The harvested voltage

level of the single galvanic cell, with fully immersed

electrodes, drops to 875 mV when connected to

a constant power load of 100 uW and further

drops to 831 mV when the load is increased to

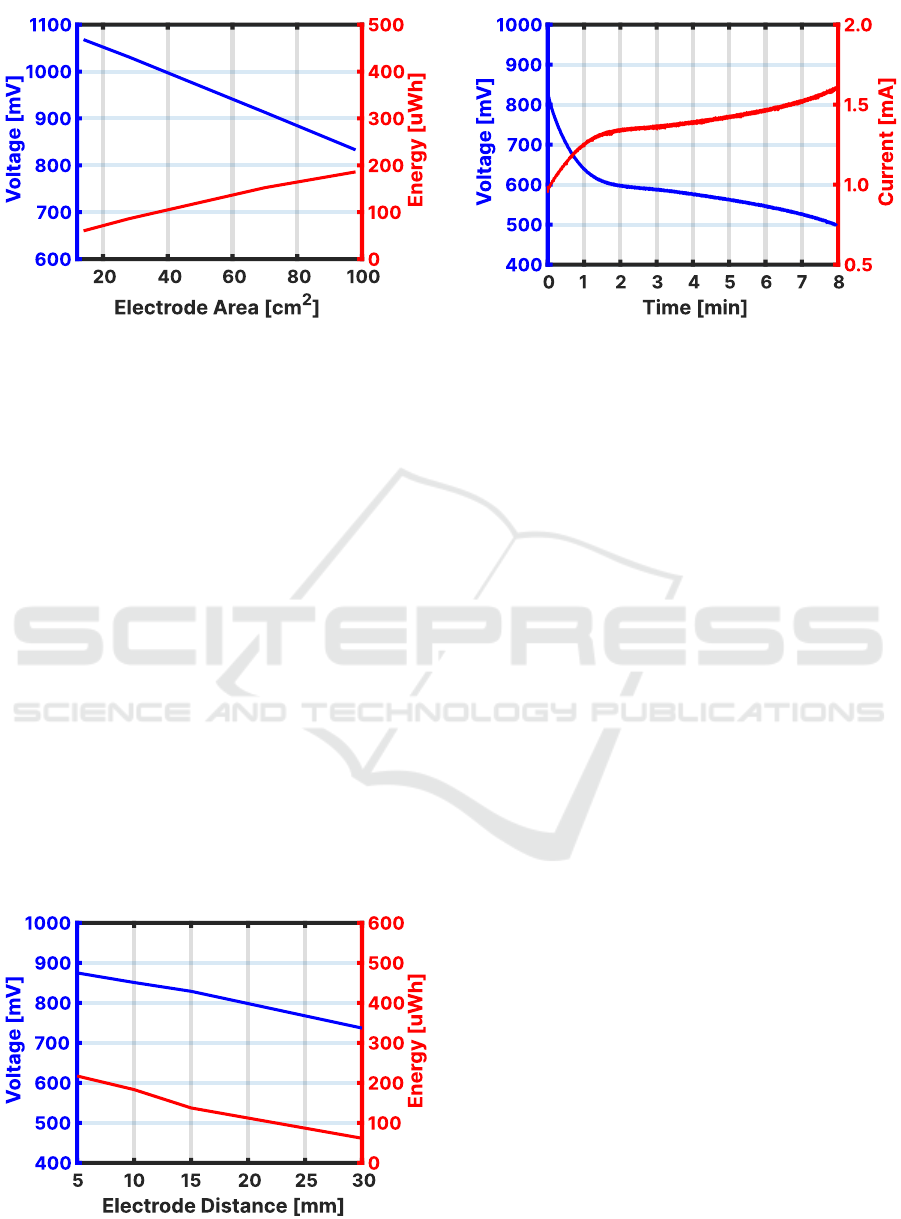

800 uW. The effect of variation in the immersed

electrode area out of the total area on the amount of

harvested energy from the first measurement scenario

is depicted in Figure 4. It is observed that the amount

of harvested energy is linearly proportional to the

immersed surface area of the harvesting electrode

with a variation of 1.9 uWh/cm

2

to 4.3 uWh/cm

2

when the percentage of the immersed surface area

of the single electrode increases from 14% to 100%.

Sustainable Printed Electrodes for Energy Harvesting from Urine to Power IoT Sensor Nodes in Smart Diapers

67

Figure 4: The effect of surface area on the harvested energy

and voltages.

Another interesting observation is that the voltage

level gets as high as 1068 mV when the percentage

of the submerged surface area is reduced to 14% and

the galvanic cell is connected to a constant power load

of 100 uW.

The effect of variations in the inter-electrode

distance on the amount of harvested energy is

analyzed in the second measurement scenario.

The galvanic cell with fully immersed zinc-carbon

electrodes in the pseudo-urine electrolyte is loaded

with 100 uW for the initial 10 seconds. The load

is increased to 500 uW power afterward and the

harvested energy is recorded until the voltage level

drops to 500 mV, the lower threshold of Otii Battery

Toolbox (Qoitech AB, Sweden). The measurement

is repeated by increasing the inter-electrode distance

by 5 mm for each measurement using the same

electrodes and electrolyte. The results of harvested

energy and starting voltage levels with inter-electrode

distance variations are presented in Figure 5. It

is observed that the amount of harvested energy

reduces linearly with an increase in the inter-electrode

Figure 5: The effect of inter-electrode distance on the

harvested energy and voltages.

Figure 6: The output voltage and output current response of

printed harvesting electrodes.

distance and drops 25% when the distance is doubled.

The non-linearity at the inter-electrode distance of 15

mm is observed due to measurement errors because

each measurement was taken only once. The starting

voltage level of the galvanic cell has also seen a drop

of 130 mV because the redox process deteriorates

the surface of the harvesting electrodes over the

harvesting time period (Singh et al., 2021).

The third measurement scenario involves the

utilization of printed zinc-carbon electrodes on the

inner side of the diaper back sheet having 50% surface

area (49 cm

2

) compared to sheet-based electrodes.

The printed electrodes are fully immersed in the

one-liter pseudo-urine electrolyte and connected to

the constant power load of 800 uW. The trend of

voltage level and current flow is observed over time

until the voltage level drops to 500 mV. The voltage

and current response of the printed zinc-carbon

electrodes is depicted in Figure 6. It is observed

that the single cell of single-side printed zinc-carbon

electrodes is capable of supporting output current

flow up to 1.6 mA.

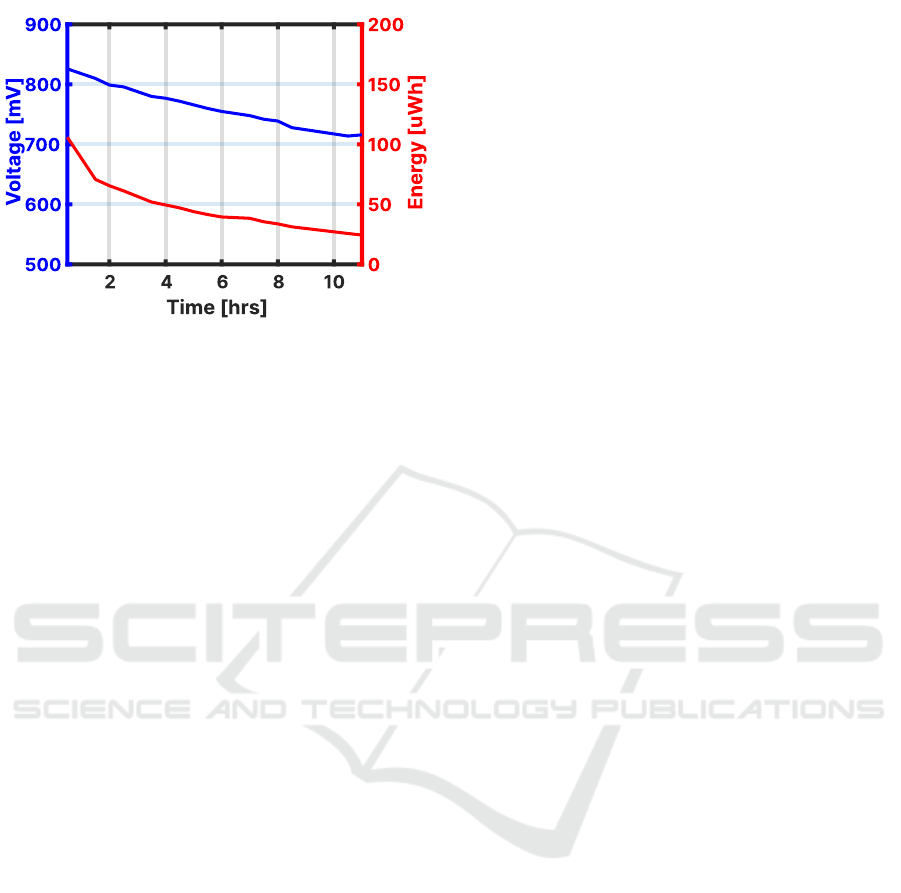

The same setup of printed zinc-carbon electrodes

from the previous measurement scenario is further

used in the fourth measurement scenario to evaluate

the performance of harvesting electrodes when fully

immersed in the same electrolyte for a longer period.

A fixed power amount of 800 uW is withdrawn in

each harvest session until the voltage level reduces to

500mV and the session is repeated every 30 minutes

for up to 11 hours. The results of the harvested

energy and the starting voltage level of the single

galvanic cell are shown in Figure 7. It is observed

that the starting voltage level and the amount of the

harvested energy from the same electrodes in the

same electrolyte drop linearly for each subsequent

harvesting session. It is evident that even after

11 hours the printed zinc-carbon electrodes are still

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

68

Figure 7: The harvested energy and voltages of the printed

electrode over a longer time in the electrolyte.

capable of providing 25% of the energy amount from

the first harvesting session. The total drop in single

cell starting voltage level is measured as low as 110

mV after 22 harvesting sessions.

The proposed novel chemical energy harvesting

solution using printed zinc-carbon electrodes in

a pseudo-urine electrolyte has yielded promising

results. These electrodes may be adopted with a

power-optimized on-chip system for smart diapers

as developed by (Tanweer et al., 2023b) interfaced

with printed coplanar capacitive sensors developed

by (Tanweer et al., 2023c) to detect wet diapers and

quantify voided volumes in diapers.

The harvested energy from the proposed printed

harvesting electrodes is sufficient to power on-chip

circuits fundamental for most of the front-end sensor

interface electronics such as 0.39–3.56 µW wide

dynamic range universal multi-sensor interface circuit

by (Moayer et al., 2020) and 462 nW 2-axis gesture

sensor interface based on capacitively controlled ring

oscillators (Pulkkinen et al., 2017). It can also power

energy-optimized wireless communication blocks of

the IoT sensor nodes such as a low-power wireless

transceiver with a 67 nW differential pulse-position

modulation (DPPM) transmitter (Pulkkinen et al.,

2020). The on-chip sensor-end electronics can also

be combined with the low-power DPPM transmitter

to develop a self-powered IoT sensor node for smart

diapers running on harvested energy from urine

with sustainable and economical printed harvesting

electrodes.

4 CONCLUSIONS

This research introduces an innovative approach to

creating printed electrodes that can harvest energy

from pseudo-urine, offering a sustainable solution for

powering IoT sensors in smart diapers. The study

explores the potential of using urine as a renewable

energy source to operate these sensors and interfaces,

emphasizing the importance of eco-friendly practices

in the development of wearable technology. By

utilizing zinc and carbon materials, these electrodes

are printed directly onto the back sheets of diapers,

a process that aligns well with current diaper

manufacturing techniques. The primary focus of the

research is to test the effectiveness of these disposable

zinc-carbon electrodes in generating power from

urine. This breakthrough presents for the first time

a significant step towards developing smart diaper

sensors that operate overnight without the need for

traditional batteries, promoting sustainability and

energy efficiency.

In the future, an on-chip power management

unit might be incorporated with the single cell

of proposed flexible printed harvesting electrodes

to harness energy from urine and to ensure the

continuous supply of regulated voltage to the on-chip

front-end sensor interface circuits, control systems,

and communication interfaces of an IoT sensor node

developed for smart diapers. The changes in the

level of generated voltages from printed harvesting

electrodes might also be further studied to provide

an additional parameter together with measurement

data from the printed coplanar capacitive sensors

for reliable and precise quantification of the voided

volume inside the diaper which is otherwise affected

by body weight on the wet diaper as discussed by

(Tanweer et al., 2023a).

ACKNOWLEDGEMENTS

Technical assistance towards the printed harvester

electrodes from Mr. Muhammad Qaisar Nadeem is

gratefully acknowledged. The authors would also like

to thank Dipesh C. Monga, Aalto University, Finland

for his valuable review and comments.

REFERENCES

FimLab (2023). dU-Kloridi (2077 dU-Cl ) — vshp.fi. https:

//www.vshp.fi/medserv/klkemi/fi/ohjekirja/2077.htm.

[Accessed 02-11-2023].

Fly Fiber (2022). Fly-Fiber 10 Stück

High Pure Flexible Graphite Sheet Folien

Graphite Film Conductive Graphitpapier

250x200x0.1 mm : Amazon.de: Küche,

Haushalt & Wohnen — amazon.de.

h t t p s : / / w w w. a m a z o n . d e / d p / B 0 8 3 L X K 9 G 6.

[Accessed 06-11-2023].

Sustainable Printed Electrodes for Energy Harvesting from Urine to Power IoT Sensor Nodes in Smart Diapers

69

HUS (2023). HUSLAB - Natrium, vuorokausivirtsasta —

huslab.fi. https://huslab.fi/ohjekirja/2376.html.

[Accessed 02-11-2023].

Kordesch, K. and Taucher-Mautner, W. (2009). Primary

batteries – aqueous systems — leclanch

´

e and

zinc–carbon. In Garche, J., editor, Encyclopedia

of Electrochemical Power Sources, pages 43–54.

Elsevier, Amsterdam.

Lide, D. R., editor (2009). CRC handbook of chemistry and

physics, 90th edition. CRC Press, Boca Raton, FL, 90

edition.

Linden, D. and Reddy, T. (2001). Handbook of batteries.

Handbook Series. McGraw-Hill Professional, New

York, NY, 3 edition.

Moayer, M. M., Salomaa, J., and Halonen, K. A. I. (2020).

A 0.39–3.56-µW Wide-Dynamic-Range Universal

Multi-Sensor Interface Circuit. IEEE Sensors Journal,

20(20):12262–12273.

Muhthassim, B., Thian, X. K., and Hasan, K. N. M.

(2018). Energy harvesting from salinity gradient. IOP

Conference Series: Earth and Environmental Science,

140:012045.

Murtom

¨

aki, L., Kallio, T., Lahtinen, R., and Ikonen, M.

(2018). Fundamental electrochemistry: An interactive

e-book with quizzes in mycourses learning platform.

NJ-Gov (2016). nj.gov. https://www.nj.gov/health/eoh/rtkw

eb/documents/fs/0013.pdf. [Accessed 02-11-2023].

Pelner, L. (1956). TOXIC EFFECTS OF AMMONIUM

CHLORIDE. Journal of the American Medical

Association, 162(1):63.

Pulkkinen, M., Haapala, T., Salomaa, J., and Halonen, K.

(2020). Low-power wireless transceiver with 67-nW

differential pulse-position modulation transmitter.

IEEE Transactions on Circuits and Systems I: Regular

Papers, 67(12):5468–5481.

Pulkkinen, M., Salomaa, J., Moayer, M. M., Haapala,

T., and Halonen, K. (2017). 462-nW 2-axis gesture

sensor interface based on capacitively controlled ring

oscillators. In 2017 IEEE International Symposium on

Circuits and Systems (ISCAS). IEEE.

Putnam, D., Company-West, M. D. A., Center, L. R.,

Aeronautics, U. S. N., and Administration, S. (1971).

Composition and Concentrative Properties of Human

Urine. NASA contractor report. National Aeronautics

and Space Administration.

Rani, E. F., Elumalai, M., and Balasubramanian, M. P.

(1998). Water, Air, and Soil Pollution, 104(1/2):1–8.

Reports, W. M. (2022). Global Zinc Carbon

Battery Market – Market Reports

World — marketreportsworld.com. h t t p s :

//www.marketreportsworld.com/global- zinc- c

ar b o n- b at te r y- m ar ke t- 2 10 62 60 4. [Accessed

31-10-2023].

Singh, A. K., Pahlevaninezhad, M., Yasri, N., and Roberts,

E. P. L. (2021). Degradation of carbon electrodes in

the all-vanadium redox flow battery. ChemSusChem,

14(9):2100–2111.

Tanweer, M., Gillan, L., Sepponen, R., Tanzer, I. O.,

and Halonen, K. A. (2023a). Evaluation of printed

coplanar capacitive sensors for reliable quantification

of fluids in adult diaper. In MEDICON & CMBEBIH

2023. Springer International Publishing.

Tanweer, M., Monga, D. C., Gillan, L., Sepponen, R.,

Tanzer, I. O., and Halonen, K. A. (2023b). Smart

diaper with printed capacitive sensors and integrated

front-end to monitor voided fluid volume. IEEE

Sensors Journal [submitted 2023].

Tanweer, M., Sepponen, R., Tanzer, I. O., and Halonen,

K. A. (2023c). Development of capacitive sensors

to detect and quantify fluids in the adult diaper.

In Bio-inspired Information and Communications

Technologies, pages 237–245. Springer Nature

Switzerland.

Tools Store, T. L. o. (2022). 5 Stück

reines Zinkblech, hohe Reinheit 99,99

für wissenschaftliches Labor, 140 x

140 x 0,2 mm. : Amazon.de: Gewerbe,

Industrie & Wissenschaft — amazon.de.

https://www.amazon.de/dp/B096SDJS9K. [Accessed

06-11-2023].

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

70