Anomaly Detection and Localization for Images of Running Paper Web

in Paper Manufacturing

Afshin Dini

1,∗ a

, Marja Mett

¨

anen

2,† b

and Esa Rahtu

1,∗ c

1

Unit of Computing Sciences, Tampere University, Tampere, Finland

2

Procemex Oy Ltd, Jyv

¨

askyl

¨

a, Finland

∗

fi fi

†

marja.mettanen@procemex.com

Keywords:

Anomaly Detection, Anomaly Localization, Running Paper Web Defects, Paper Manufacturing.

Abstract:

We introduce a new method based on convolutional autoencoders to detect and locate paper web anomalies

that can cause web breaks during the paper production process. In this approach, we pre-process the images,

captured by two high-speed cameras located at the opposite sides of the running paper web at a paper machine,

in several steps to remove noises and separate the paper web areas from the background. After designing

and training a convolutional autoencoder with non-anomalous samples, a novel anomaly score and map are

defined to find and locate web irregularities based on an edge detector and a reconstruction error, defined

by the combination of absolute error and Structural Similarity Index Measure between the reconstructed and

the original images, in each test sample. By assessing the proposed approach on the images taken from a

real paper machine, we discover that this method can detect paper defects properly and, therefore it has the

potential to improve machine functionality and even to prevent certain types of web breaks, which reduces the

machine downtime, paper losses, maintenance costs, and energy consumption, i.e., increases the performance

and efficiency of paper machinery.

1 INTRODUCTION

Anomalies, also known as outliers, refer to the sam-

ples that differ significantly from the normal patterns

of the majority of data (Yang et al., 2021). Anomaly

detection involves the process of finding anomalous

samples within a dataset, while anomaly localization

refers to the techniques of specifying the defective

area within an anomalous sample (Pang et al., 2021).

Anomaly detection has a wide range of applica-

tions across various industries, such as manufactur-

ing and quality control (Rippel and Merhof, 2023),

cybersecurity (Alabadi and Celik, 2020), and health

monitoring (Fernando et al., 2021). In this work, we

mainly focus on the visual application of anomaly

detection in manufacturing products, specifically for

identifying defects in images taken from running pa-

per webs, which helps to predict and prevent web

breaks that may happen when dirt or tear appears on

the rapidly running paper web.

Generally, paper machines are designed for con-

tinuous operations and will only be shut down for

a

https://orcid.org/0000-0001-6234-3322

b

https://orcid.org/0000-0002-3863-0484

c

https://orcid.org/0000-0001-8767-0864

Figure 1: Detecting and locating anomalies in paper images

taken from the front and back cameras installed in a paper

machine. (a) Original image, (b) Cropped region of inter-

est (RoI) including the paper web area, (c) prominent area

detected by the edge detector, (d) Final anomaly map, (e)

Anomalies highlighted on the top of the original RoI.

predetermined maintenance periods that may take ap-

proximately three weeks annually. In this regard,

unexpected stops, caused mainly by accidental web

breaks, require equipment cleaning and additional

maintenance periods, which not only increase ma-

chine downtime, paper losses, energy consumption,

678

Dini, A., Mettänen, M. and Rahtu, E.

Anomaly Detection and Localization for Images of Running Paper Web in Paper Manufacturing.

DOI: 10.5220/0012406200003660

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 19th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2024) - Volume 2: VISAPP, pages

678-685

ISBN: 978-989-758-679-8; ISSN: 2184-4321

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

and maintenance expenses but also reduce the prod-

uct quality and efficiency of the machine (Dias et al.,

2021). Due to these reasons, many companies try to

monitor the running webs to detect and analyze the

reasons for probable breaks in paper machines.

Many methods have been developed attempting to

estimate paper web break sensitivity by using fuzzy

logics (Ahola and Juuso, 2006), calculating paper

break sensitivity (Bonissone and Goebel, 2002), or

using classification approaches on the equipment’s

status (Sorsa et al., 1992). However, these algorithms

only focus on detecting potential web break sensitiv-

ity indicators and cannot identify the root cause of

the break. Moreover, none of them has tried to de-

tect web anomalies from paper images as developing

a high-performance visual detection method for this

application is a challenging task due to some inherent

complexities of the problem, such as rarity, unpre-

dictability, unknownness, and variety of web irregu-

larities, the existence of large noises, and the quality

and availability of labeled data (Liu et al., 2023).

The main difficulty of visual anomaly detection

in paper production lines is the varying image qual-

ity caused by light conditions, camera instability, en-

vironmental contaminants, and the high-speed nature

of the process (Sorsa et al., 1992). Producing paper

from pulps generates dust, debris, and contaminants

(Haile et al., 2021) that affect the quality of images

and create noises in the images by reflecting the light.

Moreover, due to the narrow space and limited possi-

bilities to attach the cameras to the desired positions

around the paper machine, some machine instruments

irrelevant to the paper web may appear in the images,

which makes defect detection more challenging. Be-

sides, various light conditions change the contrasts of

images, and the high-speed nature of the process may

also create some vibration and motion blur in the web

area, resulting in poor quality of the available images,

as is shown in Fig.1.

On the other hand, irregularities rarely occur dur-

ing the normal paper production process, making

it impractical to gather labeled anomalous samples

(Pang et al., 2021) for training a supervised method

(Rippel and Merhof, 2023) in reality. Moreover, the

locations, sizes, and types of anomalies are unknown

and unpredictable (Chandola et al., 2009), making the

detection process even more difficult.

To deal with the abovementioned complexities,

we present an efficient method based on an autoen-

coder (Tsai and Jen, 2021) with an edge-based atten-

tion mechanism to detect web anomalies from paper

images. The model is trained in such a way that it

can decode normal images properly from the encoded

space while the anomalies cannot be recreated appro-

priately from the latent space, as a result of which the

web defects will appear in the reconstruction error.

To detect and locate abnormalities, a new anomaly

score and map are defined based on the combination

of Structural Similarity Index Measure (SSIM) (Has-

san and Bhagvati, 2012) and the absolute error (L1)

between the reconstructed and original images. More-

over, in order to reduce the false detection alarms

mainly resulting from the imperfect reconstruction

of the moving machine parts and irregular illumina-

tion conditions inside the region of interest, we apply

edge-based attention to focus on defects that occur in

prominent areas, specifically on paper edges.

It is shown in section 3 that our approach is the

first method that properly adapts a visual anomaly de-

tection technique for detecting irregularities in paper

images that can cause web breaks in paper machines.

By assessing our method on the images taken from a

real paper machine, section 4, we demonstrate that not

only can this method detect subtle and large anoma-

lies properly in a noisy imaging environment, but also

it reduces the false detection rate which is very im-

portant in real applications as too high false detection

rate practically drives the operators to deem the alarm

system unreliable and to turn it off.

2 RELATED WORK

Although a few methods, developed mainly based on

fuzzy logics (Ahola and Juuso, 2006) and calculating

paper sensitivity (Bonissone and Goebel, 2002), at-

tempt to detect web breaks in paper machines, there is

still room for further improvement due to the inherent

complexities of this problem. Since this paper is the

first one in the literature that attempts to apply com-

puter vision techniques to paper images to detect and

locate defects that can lead to web breaks, we intro-

duce state-of-the-art anomaly detection methods (Liu

et al., 2023) in this section that might apply to this

problem and discuss their advantages and limitations.

Many semi-supervised approaches (Pang et al.,

2021), varying from autoencoders to self-supervised

approaches and one-class classifiers that only utilize

normal samples for training purposes, have been de-

veloped to deal with anomaly detection and localiza-

tion in visual applications. Autoencoders (AEs) (Tsai

and Jen, 2021), the most common and simplest meth-

ods, are designed to reconstruct an image from a la-

tent space in such a way that only normal patterns

will be reconstructed properly while the defective ar-

eas will be missed, as a result of which the difference

between the original and reconstructed samples can

be used to detect anomalies. Many variants of au-

Anomaly Detection and Localization for Images of Running Paper Web in Paper Manufacturing

679

Figure 2: Sample images from paper machine demonstrat-

ing Region of Interest (RoI), anomalies, dirty background,

and the existence of other elements. (left) Front camera,

(right) Back camera.

toencoders with different types of topologies and loss

functions (Bergmann et al., 2018; Bionda et al., 2022)

are developed to detect visual anomalies.

Convolutional autoencoders (CAE) (Tsai and Jen,

2021) are the simplest forms of autoencoders that uti-

lize several convolutional layers in their architecture.

On the other hand, variational autoencoders (VAEs)

(An and Cho, 2015) employ the distribution of latent

space to increase the accuracy. In these methods, it

is assumed that the latent space adheres to a specific

probability distribution, commonly a Gaussian distri-

bution. This distribution is used to create a regular-

ization error alongside the reconstruction error to en-

courage the latent space to follow the Gaussian dis-

tribution, enhancing the model’s efficiency. Although

autoencoders are simple in structure and can detect

large defects properly, they face problems in detecting

small anomalies, specifically in the presence of large

noises (Liu et al., 2023), which limits their usage in

paper anomaly detection problems.

On the other hand, self-supervised approaches

such as TPSAD (Dini and Rahtu, 2022) and CutPaste

(Li et al., 2021) attempt to train a model with normal

samples and simulated irregularities generated from

a pre-defined proxy, which gives a better representa-

tion of the images for detecting irregularities. Most of

these methods utilize a pre-trained model as the back-

bone structure and then fine-tune it based on the nor-

mal and simulated samples. Although these methods

are able to detect small and large defects accurately,

they are sensitive to noises (Dini and Rahtu, 2022)

in such a way that even small noises in the images

increase the false detection rate significantly. More-

over, simulating anomalies on the small area of the

paper web is a big challenge in these methods as the

web area represents only a small portion of the entire

image compared to the background, Fig. 2.

One-class classifier methods such as (Dini and

Rahtu, 2023) and PSVDD (Yi and Yoon, 2020) are

other types of semi-supervised approaches that at-

tempt to establish a decision boundary in the feature

space of normal images and identify anomalous sam-

ples by recognizing those that fall outside this bound-

ary. Some of these methods, like PSVDD (Yi and

Yoon, 2020), divide the image into patches and at-

tempt to find irregular patches, while others, such

as (Dini and Rahtu, 2023), detect outliers based on

the overall representation of images. Although these

methods are effective at detecting subtle defects, they

face scalability issues as the dimension of the related

feature space increases (Pang et al., 2021) in addition

to the fact that noises can affect their performance

significantly. Moreover, analyzing patches separately

for finding defects requires more computational re-

sources in the training and testing phases, which lim-

its the usage of these methods in real-time processes.

3 METHOD

3.1 Overview

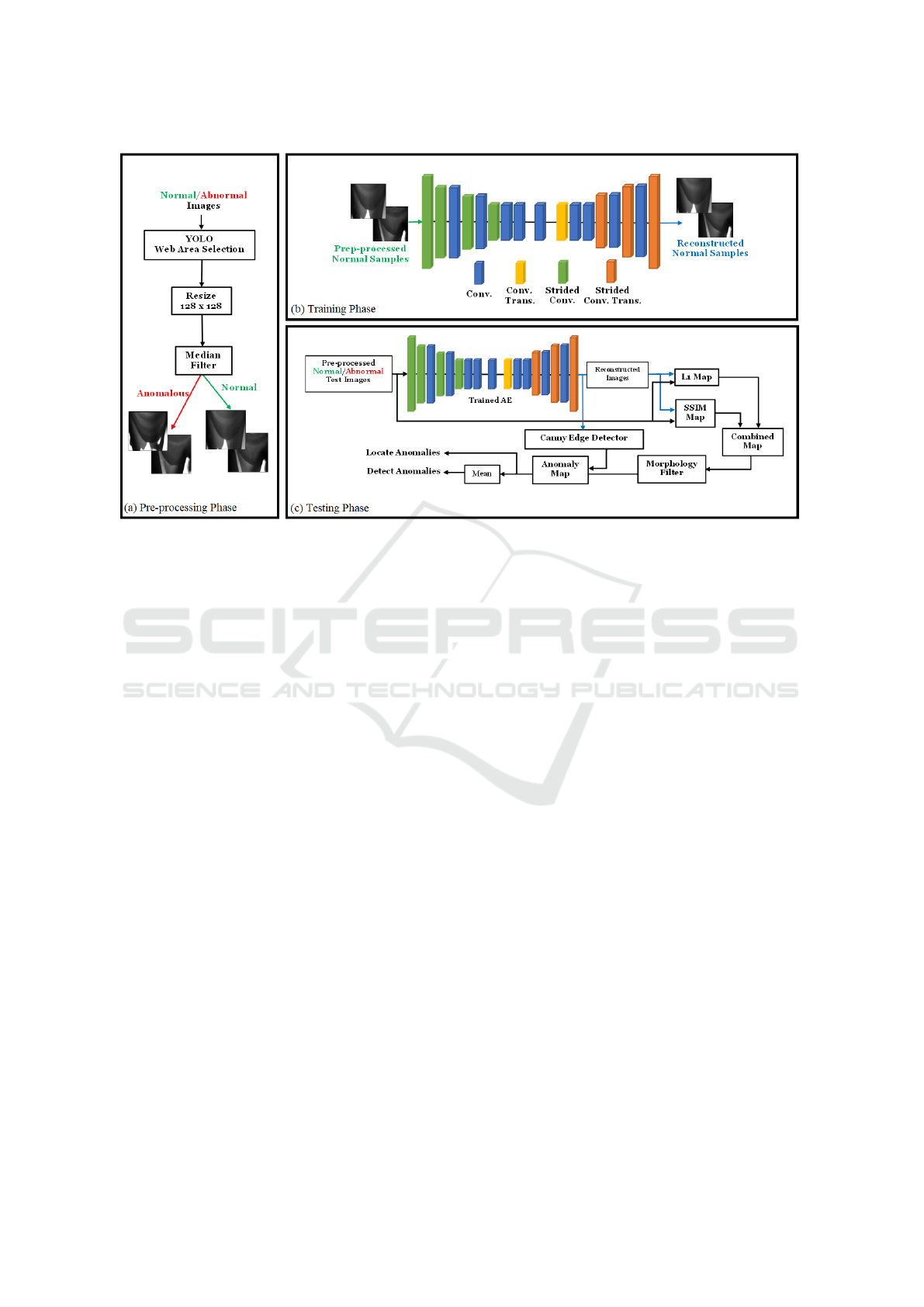

The proposed anomaly detection approach consists of

three main phases: pre-processing, training, and test-

ing. The pre-processing phase is responsible for filter-

ing, cropping, and resizing the train and test images in

such a way that the final model is more robust against

the noises and varying imaging conditions.

The convolutional autoencoder learns the normal

patterns of the webs in the second phase since only

normal images are used in the training process. In

other words, in the case of web defects in the test sam-

ples, the model replaces them with normal patterns as

it only has the information of normality.

In the testing phase and with the help of SSIM and

L1 errors, post-processing filters, and an edge detec-

tor, an anomaly map is created for each test sample.

The anomaly map indicates the exact locations of web

defects in the test image, and the average value of the

map expresses the level of abnormality of the image.

It is good to mention that the edge detector plays a

significant role in reducing false detection alarms as

it filters out the large parts of the noise in the recon-

struction error map. The model architecture of the

proposed method is described in detail in Fig. 3.

3.2 Pre-Processing Procedures

Pre-processing step plays an important role in increas-

ing the accuracy of the proposed method. Finding pa-

per web anomalies from original images is a challeng-

ing task as they contain many irrelevant elements, and

the web areas represent only a small portion of the en-

tire images, Fig. 2. To address these complexities, the

VISAPP 2024 - 19th International Conference on Computer Vision Theory and Applications

680

Figure 3: Overview and model architecture of the proposed method for anomaly detection and localization in paper images.

(a) Pre-processing steps to specify web areas with YOLO (Adarsh et al., 2020) and filter noises with median filter, (b) Training

the autoencoder model. (c) Testing phase to detect and locate defects with the help of edge detector.

YOLO (Adarsh et al., 2020) model is applied to the

images to detect the web areas as the region of interest

(RoI) to be utilized in the training phase. Specifically,

the RoI in our application contains the paper web area

and excludes large parts of the background. These re-

gions of interest are resized to 128 × 128 to have the

same size.

Due to the light reflection from dust and debris

generated in the normal paper production process,

white areas with different sizes appear in the images,

which might be considered anomalies in the testing

phase. To circumvent that, a median filter is utilized

to filter small and medium noises. It is obvious from

the images shown in Fig. 3(a) and more clearly in Fig.

5 that the web area and anomalies remain intact after

filtering while the noises are filtered properly.

3.3 Model Architecture and Training

In the autoencoder-based methods, selecting a suit-

able model architecture is crucial and has a signifi-

cant impact on the method’s performance (Liu et al.,

2023). An appropriate model should be able to cap-

ture semantic and detailed information to accurately

recreate non-anomalous areas while avoiding defects.

In deep autoencoders with large bottlenecks, the

model can reconstruct both normal and abnormal ar-

eas simultaneously, often leading to difficulties in de-

tecting anomalies due to small reconstruction errors

in the anomalous areas. Very shallow models may

struggle to properly reconstruct even normal images,

which can result in normal samples being falsely con-

sidered anomalies. Finding the right balance in the

model architecture and bottleneck size is crucial to

detect anomalies accurately without compromising

reconstruction capabilities (Tsai and Jen, 2021).

To design a proper model, an encoder with 8 con-

volutional layers is utilized to encode images to a la-

tent space, and then a decoder with 8 layers is used

to reconstruct the image from the latent space as is

shown in Fig. 3(b). We find out that using a combina-

tion of convolutional and convolutional transpose lay-

ers allows the decoder to give a better reconstruction

image compared to using only convolutional trans-

pose layers. The proposed model learns the normal

patterns of web areas as it is trained with normal im-

ages while using the SSIM loss function as follows:

L

SSIM

=

N

∑

i=1

(1 − SSIM(x

i

, D(E(x

i

)))) (1)

where x

i

∈ X

N

is a training image and X

N

is the set of

normal samples used in the training phase. E(x

i

) rep-

resents the encoded space of the training sample x

i

,

while D(E(x

i

)) represents the related reconstructed

image. SSIM(x

i

, D(E(x

i

))) calculates the structural

similarity between the original and reconstructed im-

ages according to (Hassan and Bhagvati, 2012).

Anomaly Detection and Localization for Images of Running Paper Web in Paper Manufacturing

681

3.4 Web Anomalies Detection and

Localization

To detect abnormal samples, it is essential to assign a

numerical value, known as an anomaly score, to each

data sample. By establishing an appropriate thresh-

old on these scores, we can distinguish defective sam-

ples. Likewise, an anomaly map can be generated

by attributing anomaly scores to individual pixels in

an image, aiding in the identification of irregularities

present in the corresponding abnormal samples.

To identify and locate web defects in the testing

phase, each test sample is fetched into the trained

model, and then the L1 and SSIM maps are created

based on the difference between the original and re-

constructed images. After setting a threshold on these

maps and combining them together, a morphology fil-

ter is applied to remove the salty noises in the maps.

To reduce the false detection alarms generated

from large noises, dirty backgrounds, and the exis-

tence of irrelevant elements, the edges of the paper

web in each test image are found by the Canny edge

detector (Canny, 1986), and then the overlaps be-

tween the filtered map and the web edges are used

to create the final anomaly map. The average values

of anomaly maps are thresholded to detect anomalous

samples, and the related anomaly map represents the

exact location of web anomalies. The testing phase is

shown in Fig. 3(c) in detail.

4 EXPERIMENT

4.1 Dataset

To evaluate the performance of our method on

a real-world application, we gather high-resolution

grayscale images from two high-speed cameras in-

stalled on the front and back sides of a roller of a paper

machine. The training dataset contains only normal

samples for training the autoencoder, while the testing

dataset contains a few images with anomalies in addi-

tion to the normal ones, as is shown in Tab. 1. Images

from the front camera have 2040 × 1020 resolution

while images from the back camera are 764 × 540.

Table 1: Number of samples in the test and train datasets

for the front and back cameras installed in a paper machine.

Group

Train Dataset Test Dataset

Normal Normal Anomaly

Front Cam. 5000 1318 19

Back Cam. 5970 1100 35

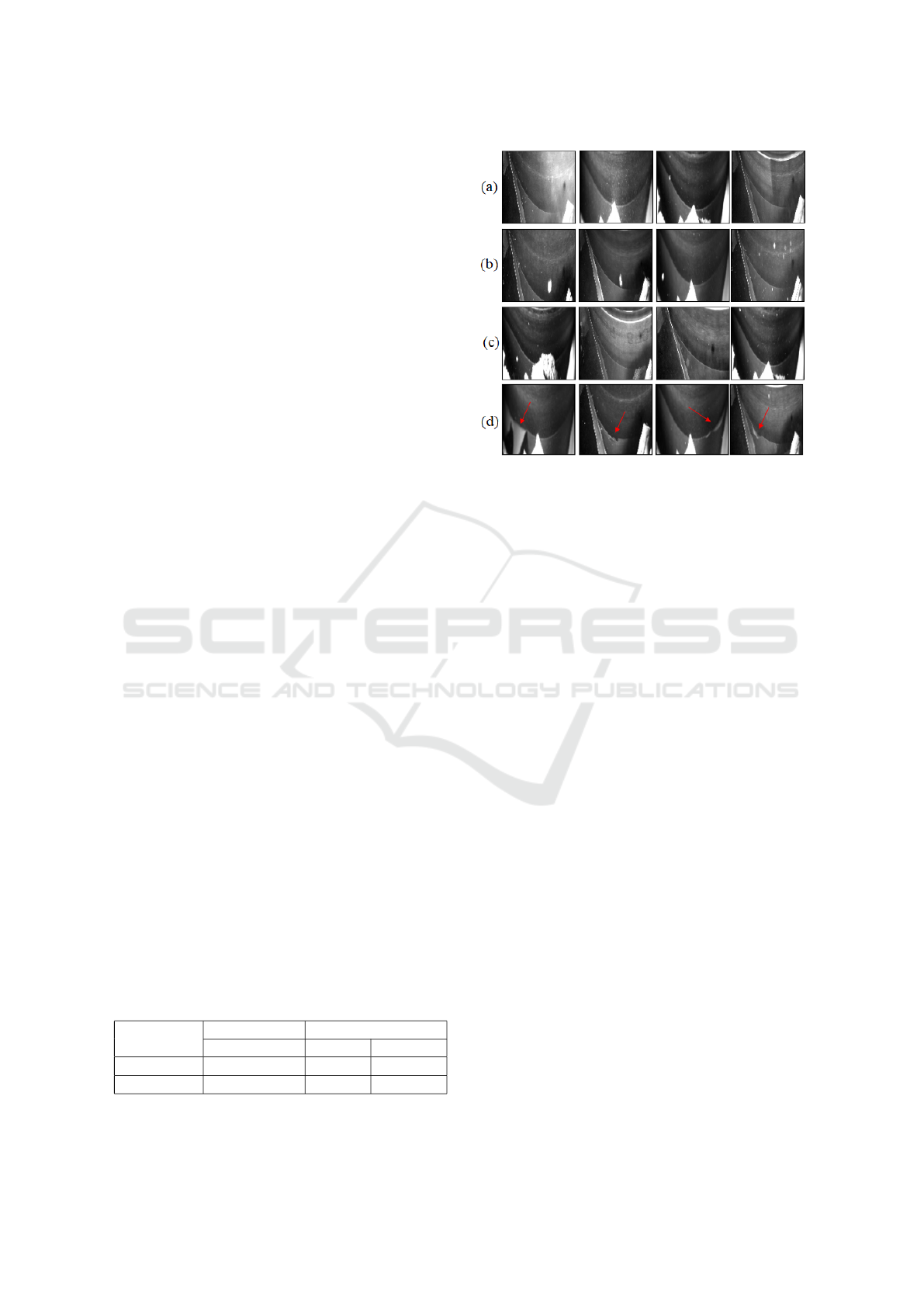

Figure 4: Samples variety and web defect detection chal-

lenges. (a) Normal images with various qualities and con-

trasts, (b) Normal samples with noises originating from

light reflection from particles in the air, (c) Normal images

containing various types of irrelevant elements and texts, (d)

Anomalous images with various defect sizes and locations.

This dataset contains various images that repre-

sent the challenges of detecting paper web anomalies,

mentioned in section 1, which makes it a suitable can-

didate to assess the performance and generalizability

of the proposed method. Due to the harsh conditions

at the paper production line, the images of this dataset

have various qualities, Fig. 4(a), contain small and

large noises, Fig. 4(b), and consist of multiple objects

and uneven background that changes from image to

image because the cylinder is rotating, Fig. 4(c). On

the other hand, the web defects have various sizes,

shapes, and contrasts that represent the unpredictabil-

ity property of the anomalies properly, Fig. 4(d).

4.2 Metrics

To present our results, we calculated the accuracy,

false positive rate (FPR), and false negative rate

(FNR) for each camera dataset based on the best

threshold and compared the results of our method

with the recent anomaly detection approaches.

It is important to mention that accuracy alone

might not be a proper metric to evaluate the perfor-

mance of a defect detector as anomaly detection can

be considered an imbalanced classification problem

in which the number of anomalous samples is signifi-

cantly less than the number of normal samples, result-

ing in the fact that a detector that detects all samples

as normal ones will end up in high accuracy. How-

ever, it is still a useful metric as one can understand

the difference between the method that cannot label

VISAPP 2024 - 19th International Conference on Computer Vision Theory and Applications

682

the normal or anomalous samples properly and the

one that is able to do so at first glance. On the other

hand, the false positive and negative rates are proper

metrics to describe the ability of the method to detect

anomalous samples while avoiding false detections.

4.3 Implementation Details

To detect paper web anomalies, two separate autoen-

coders are trained with the images gathered from each

camera. These models are optimized with the pre-

processed normal samples, filtered with a median fil-

ter of size 9, and resized to 128 × 128. The Adam

optimizer with a learning rate of 0.0002 and decay of

0.00001 is used for updating the model parameters for

200 epochs, considering SSIM as the loss function.

To create the anomaly map, the SSIM map with

the kernel size of 5 (for the front camera) and 7 (for

the back camera) are combined with the L1 map and

then filtered with a 4 × 4 morphology filter to remove

the salty noises. The overlap of the resulting map with

the prominent edge areas, detected by the edge-based

detector, defines the final anomaly map.

4.4 Results

We evaluated our approach on the above-mentioned

real dataset and calculated the accuracy, false positive

rate, and false negative rate for each camera dataset

to demonstrate the ability of the proposed method

while dealing with the paper web defect detection

challenges. As there are no similar computer vision

methods in the literature for detecting web anoma-

lies from paper images to which we can compare the

performance of our method, we also run a few im-

age anomaly detection methods on the dataset, such

as a self-supervised method TPSAD (Dini and Rahtu,

2022), a patch-wise one-class classifier method (Dini

and Rahtu, 2023), a variational autoencoder (An and

Cho, 2015), and convolutional encoders with various

loss functions (Bergmann et al., 2018; Tsai and Jen,

2021) and compare the results in Tab. 2.

In general, our expectation is that our method ac-

curately detects defects without mistakenly identify-

ing anomalies in normal images or missing anoma-

lous samples, resulting in high accuracy and low false

positive and negative rates. It is important to men-

tion that reducing the false positive rate is an impor-

tant issue in our application as the cameras installed

in paper machines are high-speed cameras, operating

around 50-100 FPS, that take a lot of images from the

high-speed running paper web during the production

process. In this regard, even a small reduction in false

positive rate can improve the usability of the defect

alarming system considerably, considering the huge

number of images taken daily in real applications.

In terms of accuracy, it can be deducted from Tab.

2 that our approach has better accuracy than other

methods, implying the fact that most normal samples

are labeled properly, as well as some of the abnormal

samples, with different shapes, contrasts, and sizes of

anomalies. By comparing the accuracy of different

methods in Tab. 2, one can conclude that TPSAD and

patch-wise methods are not able to label normal sam-

ples properly, considering the fact that their accura-

cies are low. By analyzing the results, we find out

that many normal samples are detected as abnormal

ones mistakenly by the Patch-wise OCC and TPSAD

methods due to the existence of noises in the images.

Moreover, by comparing the false positive rates in

Tab. 2, we find out that our approach has the smallest

FPR amongst all the compared methods. This can be

considered as one of the prominent achievements in

our work, as it indicates that our method can properly

reduce the false alarms that might be caused by the

noisy environment in our application.

By comparing the false negative rates of the pro-

posed method with other approaches, we discover that

VAE (An and Cho, 2015), CAE (Tsai and Jen, 2021),

and the one-class classifier (Dini and Rahtu, 2023)

Table 2: Comparison of our approach with the recent methods, CAE (SSIM) (Bergmann et al., 2018), CAE(SSIM, L1) (Tsai

and Jen, 2021), VAE (An and Cho, 2015), TPSAD (Dini and Rahtu, 2022), and Patch-wise One-Class Classifer (Dini and

Rahtu, 2023) results in paper web defect detection using accuracy, FPR, and FNR metrics.

Group

Back Camera Front Camera

Acc (%) FPR (%) FNR (%) Acc (%) FPR (%) FNR (%)

CAE(SSIM) (Bergmann et al., 2018) 98.23 0.45 40.0 98.65 0.38 68.43

CAE(SSIM,L1) (Tsai and Jen, 2021) 98.67 0.81 17.15 98.57 0.75 47.37

VAE (An and Cho, 2015) 96.03 3.7 11.5 95.43 4.09 36.85

TPSAD (Dini and Rahtu, 2022) 70.83 28.72 42.85 69.25 30.27 63.15

Patch OCC (Dini and Rahtu, 2023) 56.2 45 5.7 60.80 39.22 36.84

Ours 99.91 0.09 2.85 99.1 0.22 47.38

Anomaly Detection and Localization for Images of Running Paper Web in Paper Manufacturing

683

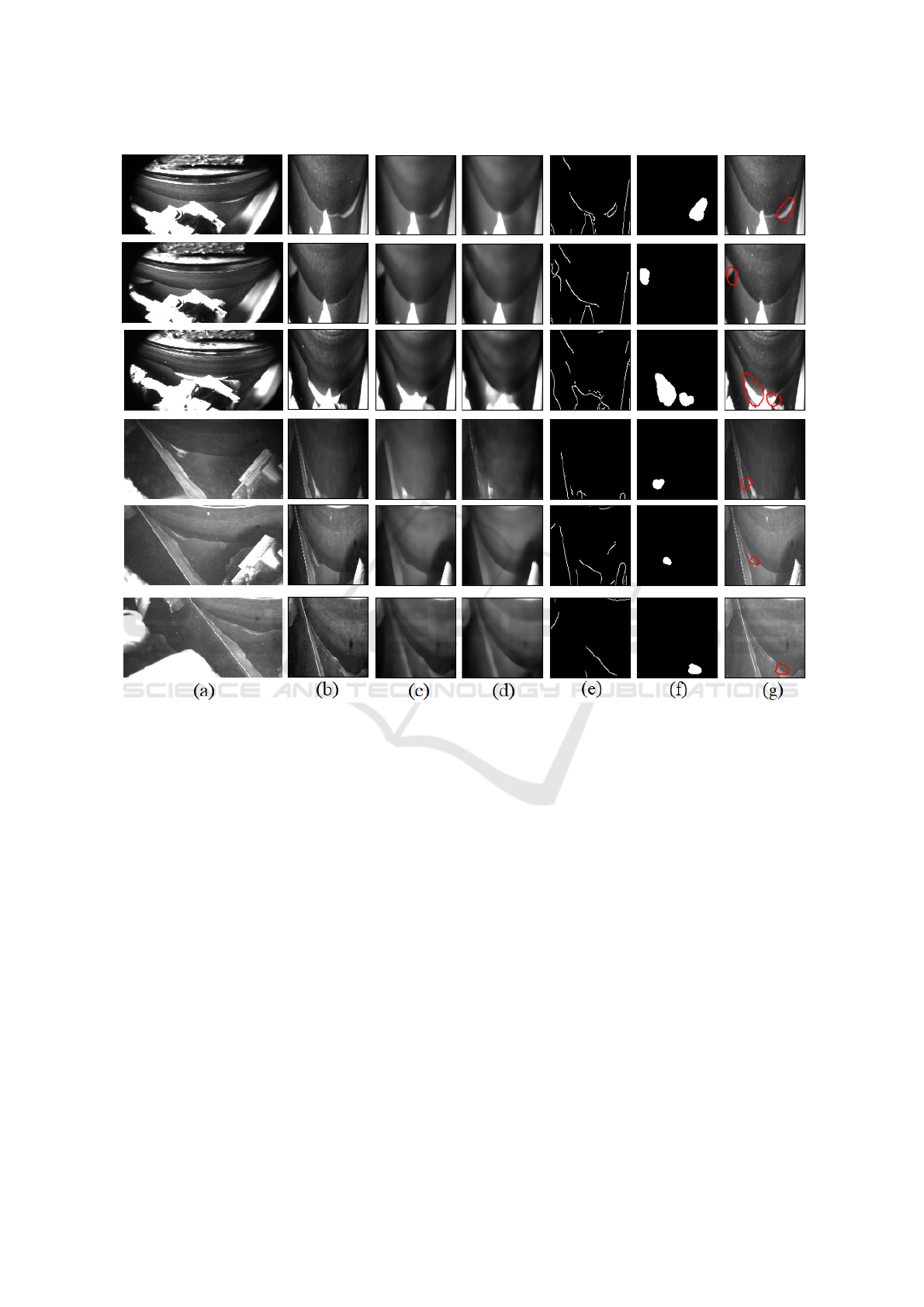

Figure 5: Visualization of paper web anomaly detection and localization using the proposed method, first three rows are

images from the back camera, and the last three rows are from the front camera. (a) Original camera frames, (b) Cropped RoI

resized to 128 × 128, (c) Filtered by median filter, (d) Reconstructed images by the trained autoencoder, (e) Prominent areas

detected by the edge attention technique, (f) Final anomaly map, (g) Located anomalies highlighted on top of the original RoI.

have lower false negative rate than our method in one

of the two camera datasets, meaning that a smaller

amount of defects are missed. However, they have

significantly larger false detection rates which limits

their usage in real applications. In other words, since

these methods are sensitive to noise, quality of im-

ages, and changing contrast in the images, they do

not show proper results in our application. Some of

the detected defects are shown in Fig. 5 indicating

the fact that our approach not only can deal with the

unknownness, unpredictability, and rarity complexi-

ties of the anomalies but also locates the web defects

properly with the help of the anomaly map.

By comparing the first three and last rows of Tab.

2, the benefits of integrating an edge detector within

our method become more evident. This integration

leads to a significant reduction in the false positive

rate by effectively filtering out the defects that occur

only in the prominent areas of the image.

It is also good to mention that our approach has

proper generalizability, according to which it can be

used in different paper machines with minimum ef-

fort. Since most of the paper production lines re-

semble each other in terms of process, structure, and

devices, one can use our three-step approach to pre-

process images, fine-tune the autoencoder, and detect

paper defects by defining a proper anomaly map with

the help of an edge detector although there might be

minor differences in the position of cameras, viewing

angles, and contrast from one machine to another one.

5 CONCLUSION

The proposed method, developed based on the convo-

lutional autoencoders for detecting and locating web

VISAPP 2024 - 19th International Conference on Computer Vision Theory and Applications

684

defects on the prominent areas of paper images de-

tected by an edge detector, is the first technique in the

literature that aims to utilize visual anomaly detection

approaches in paper applications. Through the evalu-

ation of our method on the paper images, we demon-

strate that the proposed method not only has the su-

perior ability to detect and locate different types of

unknown anomalies but also can properly deal with

the inherent complexities of the paper web defect de-

tection problem such as the effects of large and small

noises, as well as the presence of irrelevant objects

and dirty backgrounds. Showing high accuracy, low

false detection rate and low false negative rate makes

our approach a suitable candidate for detecting paper

irregularities in real-world applications.

REFERENCES

Adarsh, P., Rathi, P., and Kumar, M. (2020). Yolo v3-tiny:

Object detection and recognition using one stage im-

proved model. In 2020 6th international conference

on advanced computing and communication systems

(ICACCS), pages 687–694. IEEE.

Ahola, T. and Juuso, E. (2006). Paper web break sensi-

tivity monitoring in modern paper machines. In Pro-

ceedings of the 11th International Conference, IPMU

2006, Information Processing and Management of

Uncertainty in Knowledge-based Systems, 2006, Les

Cordeliers, Paris, volume 1, pages 518–525.

Alabadi, M. and Celik, Y. (2020). Anomaly detection for

cyber-security based on convolution neural network :

A survey. In 2020 International Congress on Human-

Computer Interaction, Optimization and Robotic Ap-

plications (HORA), pages 1–14.

An, J. and Cho, S. (2015). Variational autoencoder based

anomaly detection using reconstruction probability.

Bergmann, P., L

¨

owe, S., Fauser, M., Sattlegger, D., and Ste-

ger, C. (2018). Improving unsupervised defect seg-

mentation by applying structural similarity to autoen-

coders. arXiv preprint arXiv:1807.02011.

Bionda, A., Frittoli, L., and Boracchi, G. (2022). Deep au-

toencoders for anomaly detection in textured images

using cw-ssim. In International Conference on Image

Analysis and Processing, pages 669–680. Springer.

Bonissone, P. P. and Goebel, K. (2002). When will it

break? a hybrid soft computing model to predict time-

to-break margins in paper machines. In Applications

and Science of Neural Networks, and Fuzzy Systems,

volume 4787, pages 53–64. SPIE.

Canny, J. (1986). A computational approach to edge de-

tection. IEEE Transactions on pattern analysis and

machine intelligence, (6):679–698.

Chandola, V., Banerjee, A., and Kumar, V. (2009).

Anomaly detection: A survey. ACM computing sur-

veys (CSUR), 41(3):1–58.

Dias, M., Lourenc¸o, N., Silva, C., and Moniz, S. (2021).

The break point: A machine learning approach to web

breaks in paper mills. In Congress of APDIO, the Por-

tuguese Operational Research Society, pages 73–85.

Dini, A. and Rahtu, E. (2022). Tpsad: Learning to detect

and localize anomalies with thin plate spline transfor-

mation. 2022 26th International Conference on Pat-

tern Recognition (ICPR), pages 4744–4750.

Dini, A. and Rahtu, E. (2023). Visual anomaly detec-

tion and localization with a patch-wise transformer

and convolutional model. In International Joint Con-

ference on Computer Vision, Imaging and Computer

Graphics Theory and Applications. SCITEPRESS.

Fernando, T., Gammulle, H., Denman, S., Sridharan, S.,

and Fookes, C. (2021). Deep learning for medical

anomaly detection–a survey. ACM Computing Sur-

veys (CSUR), 54(7):1–37.

Haile, A., Gelebo, G. G., Tesfaye, T., Mengie, W., Mebrate,

M. A., Abuhay, A., and Limeneh, D. Y. (2021). Pulp

and paper mill wastes: utilizations and prospects for

high value-added biomaterials. Bioresources and Bio-

processing, 8:1–22.

Hassan, M. and Bhagvati, C. (2012). Structural similarity

measure for color images. International Journal of

Computer Applications, 43(14):7–12.

Li, C.-L., Sohn, K., Yoon, J., and Pfister, T. (2021). Cut-

paste: Self-supervised learning for anomaly detection

and localization. In Proceedings of the IEEE/CVF

conference on computer vision and pattern recogni-

tion, pages 9664–9674.

Liu, J., Xie, G., Wang, J., Li, S., Wang, C., Zheng, F., and

Jin, Y. (2023). Deep industrial image anomaly detec-

tion: A survey. arXiv preprint arXiv:2301.11514, 2.

Pang, G., Shen, C., Cao, L., and Hengel, A. V. D. (2021).

Deep learning for anomaly detection: A review. ACM

computing surveys (CSUR), 54(2):1–38.

Rippel, O. and Merhof, D. (2023). Anomaly detection for

automated visual inspection: A review. Bildverar-

beitung in der Automation: Ausgew

¨

ahlte Beitr

¨

age des

Jahreskolloquiums BVAu 2022, pages 1–13.

Sorsa, T., Koivo, H., and Korhonen, R. (1992). Application

of neural networks in the detection of breaks in a paper

machine. IFAC Proceedings Volumes, 25(4):219–224.

Tsai, D.-M. and Jen, P.-H. (2021). Autoencoder-based

anomaly detection for surface defect inspection. Ad-

vanced Engineering Informatics, 48:101272.

Yang, J., Xu, R., Qi, Z., and Shi, Y. (2021). Visual

anomaly detection for images: A survey. arXiv

preprint arXiv:2109.13157.

Yi, J. and Yoon, S. (2020). Patch svdd: Patch-level svdd for

anomaly detection and segmentation. In Proceedings

of the Asian conference on computer vision.

Anomaly Detection and Localization for Images of Running Paper Web in Paper Manufacturing

685