Action Duration Generalization for Exact Multi-Agent Collective

Construction

Martin Rame

ˇ

s

a

and Pavel Surynek

b

Faculty of Information Technology, Czech Technical University, Th

´

akurova 9, 160 00 Prague 6, Czech Republic

fi

Keywords:

Multi-Agent Construction, Multi-Agent Planning, Mixed Integer Linear Programming.

Abstract:

This paper addresses exact approaches to multi-agent collective construction problem which tasks a group

of cooperative agents to build a given structure in a blocksworld under the gravity constraint. We propose

a generalization of the existing exact model based on mixed integer linear programming by accommodating

varying agent action durations. We refer to the model as a fraction-time model. The introduction of action

durations enables one to create a more realistic model for various domains. It provides a significant reduction

of plan execution duration at the cost of increased computational time, which rises steeply the closer the model

gets to the exact real-world action duration. We also propose a makespan estimation function for the fraction-

time model. This can be used to estimate the construction time reduction size for cost-benefit analysis. The

fraction-time model and the makespan estimation function have been evaluated in a series of experiments

using a set of benchmark structures. The results show a significant reduction of plan execution duration for

non-constant duration actions due to decreasing synchronization overhead at the end of each action. According

to the results, the makespan estimation function provides a reasonably accurate estimate of the makespan.

1 INTRODUCTION

The multi-agent collective construction (MACC)

problem tasks a group of cooperative agents to build

a given structure in a blocksworld. Agents can pick

up, move, and place blocks, which are used as the

only building material for a three-dimensional struc-

ture. Both blocks and agents are moving under the

condition of gravity. The problem aims to determine

a collision-free plan for the agent movement, which

would perform the construction task while minimiz-

ing the execution time (makespan) and the sum of du-

rations the agents spend on the grid (sum-of-costs).

Previously, such problems were solved heuristi-

cally with no proof of optimality. Recently, a new

branch of research emerged, aiming to study optimal

MACC problem solutions. This paper aims to fur-

ther this research by generalizing the currently best

optimal model – MILP model by (Lam et al., 2020)

– further referred to as the constant-time model. The

generalization, further referred to as the fraction-time

model, allows agent actions to differ in duration to

better map real-world multi-agent systems.

a

https://orcid.org/0009-0000-3301-6269

b

https://orcid.org/0000-0001-7200-0542

(a) ”Termes robot 01” by Forgemind ArchiMedia is licensed

under CC BY 2.0 (Forgemind ArchiMedia, 2014).

(b) Visualization of the world state in the MACC problem.

Figure 1: Example of the TERMES system and its MACC

representation. Three robotic agents are building a long

stair structure. The middle agent is performing a deliver-

block action.

718

Rameš, M. and Surynek, P.

Action Duration Generalization for Exact Multi-Agent Collective Construction.

DOI: 10.5220/0012385600003636

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 16th International Conference on Agents and Artificial Intelligence (ICAART 2024) - Volume 3, pages 718-725

ISBN: 978-989-758-680-4; ISSN: 2184-433X

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

The constant-time model (Lam et al., 2020) ex-

actly optimizes the MACC plan to achieve minimum

makespan and sum-of-costs as primary and secondary

optimization criteria, respectively, assuming all ac-

tions to have the same duration. This is not the case in

real life and the robots are forced to wait for the end of

the longest action. This includes the TERMES robots

(Petersen et al., 2011), which inspired the constant-

time model. Notably, the difference between average

block pick-up time (15s) and placement time (24s),

measured in (Petersen et al., 2011), is 46%. The paper

also shows that agents carrying a block or moving on

unstructured terrain (i.e. gravel, grass) move slower.

To better utilize the information about mean ac-

tion durations, we propose the fraction-time model.

The model will accept a structure height map along

with action durations as input and provide a MACC

plan as output. We modify the constant-time model

to include the action durations. The modification is

non-trivial, as the generalized model needs to prevent

mid-action agent collisions and maintain the network

flow substructure of the base model to remain compu-

tationally viable. We demonstrate the improvement of

plan execution duration on three instances with three

non-constant action durations, including TERMES

durations. We provide two makespan lower bounds,

one based on fraction-time model relaxation and one

based on the fraction-time model with a less detailed

action duration assignment, which can also be used to

get the makespan upper bound. To solve the fraction-

time MILP model, we use the state-of-the-art solver

Gurobi (Gurobi Optimization, LLC, 2023).

2 RELATED WORK

The MACC problem is part of a wider research

branch, which studies various forms of collaborative

construction. These forms include, for instance, self-

assembly, where the agents themselves act as build-

ing blocks, once they reach their destination (Piranda

and Bourgeois, 2018; Romanishin et al., 2013). An-

other uses quadrotors to assemble the structure from

beams and columns (Barros dos Santos et al., 2018).

Robotic arms with connectors on both sides are pro-

posed by (Jenett and Cheung, 2017) to build and move

atop lightweight lattice structures like an inchworm.

All these approaches focus on robots with unique

capabilities and limitations, requiring dedicated algo-

rithms. We focus on the TERMES, a termite-inspired

multi-agent system by (Petersen et al., 2011). The

TERMES robots can pick up, carry, and place similar-

sized blocks. Each robot can carry at most one block,

and climb the difference of one block. The robots

can build complex structures based on simple sen-

sor feedback and high-level instructions – move for-

ward by one block, turn 90° left, turn 90° right, pick

up the block in front of the robot, and deliver a car-

ried block at a position in front of the robot (Petersen

et al., 2011). The MACC discretizes the movement

of the TERMES robot and makes the problem par-

tially hardware-independent by limiting the robots to

the above high-level actions. Image 1 shows the TER-

MES robots and their MACC representation.

Currently, there are only two models that can solve

the MACC makespan-optimally (Lam et al., 2020) – a

mixed integer linear programming (MILP) model and

a constraint programming model. The results of both

models in the paper match on finished instances, with

the MILP model being much faster to compute. Both

models assume a constant action duration.

There are also multiple heuristic/sub-optimal ap-

proaches to the MACC problem. The Compiler for

Scalable Construction by the TERMES Robot Col-

lective heuristically minimizes the number of agents,

who pass through the construction site (Deng et al.,

2019). Another approach presents an algorithm mini-

mizing the number of pick-up and deliver actions, per-

forming dynamic programming on a spanning tree to

find paths for a TERMES robot (Cai et al., 2016).

There are also two approaches, which utilize a

solver/planner but sacrifice the optimal solution to

gain order-of-magnitude better computation speed

(Srinivasan et al., 2023; Singh et al., 2023). Both

compare their solution to the constant-time model.

3 THE FRACTION-TIME MODEL

To allow more precise modeling of non-constant ac-

tion durations of real-world robots, we propose the

fraction-time model. The model replaces the timestep

t of each action by t

s

and t

e

, which denote the timestep

of action start (inclusive) and action end (exclusive),

respectively. This notation mirrors non-preemptive

scheduling notation, where the action is executed

within a time interval [t

s

,t

e

).

We use the non-standard notation of (Lam et al.,

2020). For set U of tuples (u

1

,u

2

,. .. , u

n

) with length

n ∈ Z

+

notation U

u

1

,u

2

,...,u

n

is short for {(u

′

1

,u

′

2

,. .. ,

u

′

n

) : u

′

1

= u

1

∧ u

′

2

= u

2

∧ ··· ∧ u

′

n

= u

n

}. Let ∗ be a

wildcard symbol matching any value at its position in

the tuple (i.e. U

∗,u

2

,...,u

n

is short for {(u

′

1

,u

′

2

,. .. , u

′

n

) :

u

′

2

= u

2

∧ ··· ∧ u

′

n

= u

n

} and U

u

1

,u

2

,∗,...,∗

is short for

{(u

′

1

,u

′

2

,. .. , u

′

n

) : u

′

1

= u

1

∧ u

′

2

= u

2

}).

Let

b

a be shorthand for {0,. . . , a − 1},a ∈ Z

+

. Let

(X,Y) be the size of the building area and (Z − 1)

be the height of the target structure in blocks, the ex-

Action Duration Generalization for Exact Multi-Agent Collective Construction

719

tra layer allows travel on top of the structure. Let

C =

b

X ×

b

Y ×

b

Z be the set of all positions within the

grid, P =

b

X ×

b

Y is the projection of C into the first two

dimensions, B = {(x,0,0) : x ∈

b

X} ∪ {(x,Y − 1,0) :

x ∈

b

X} ∪ {(0,y, 0) : y ∈

b

Y } ∪ {(X − 1,y, 0) : y ∈

b

Y } is

the set of border cells at the perimeter of the building

area. Let z

(x,y)

be the target height of the block column

at position (x,y). Let C

′

= C ∪ {(S, S, S),(E,E,E)}

be a set of all agent-accessible positions – including

two special positions (S,S,S),(E, E, E), which sym-

bolize the start and the end position outside the grid.

Let K = {M, P, D} be a set of agent action type dis-

tinguishers – M for move action (used for “entry”,

“leave”, “move block”, “move empty” and “wait” ac-

tion types), P for “pick up” action type and D for

“deliver” action type. Let N

(x,y)

= {(x − 1,y),(x +

1,y), (x,y − 1),(x,y + 1)} ∩ P be the set of neigh-

bor positions of (x,y) and T =

b

T be the planning

horizon of T timesteps. The actions are tuples i =

(t

s

,t

e

,x,y,z,c,k, x

′

,y

′

,z

′

), which consist of values:

• start time t

s

∈ Z

+

(inclusive)

• end time t

e

= t

s

+ d,d ∈ Z

+

(exclusive), where d

is the action duration

• start position (x, y,z) ∈ C ∪{(S,S,S)}

• indicator c ∈ {0,1} if agent carries a block

• action type distinguisher k ∈ K

• end position (x

′

,y

′

,z

′

) ∈ C ∪ {(E,E,E)}

– position of affected block for pick up and de-

liver actions (agent stays at the same position)

– marks agent position at the end of the action for

other action types

Let duration d

i

of action i = (t

s

,t

e

,. .. ) be d

i

= t

e

−t

s

.

Let f

d

: Z

+

×C

′

×{0,1} ×K × C

′

−→ Z

+

be a func-

tion of action duration, based on the rest of action tu-

ple – that is t

s

, (x,y,z), c, k and (x

′

,y

′

,z

′

) respectively.

Let A = {entry, leave,move block, move empty,

deliver,pick up, wait} be the set of all action types.

• Q

entry

= {(t

s

,S,S, S, c, M, x,y,z) : t

s

∈

[

T − 3 ∧ c ∈

{0,1} ∧ (x,y, z) ∈ B}

• Q

move empty

= {(t

s

,x,y,z,0,M,x

′

,y

′

,z

′

) : t

s

∈

{1,. .. , T − 3} ∧ (x,y, z) ∈ C ∧ (x

′

,y

′

) ∈

N

(x,y)

∧ |z

′

− z| ≤ 1}

• Q

move block

= {(t

s

,x,y,z,1,M,x

′

,y

′

,z

′

) : t

s

∈

{1,. .. , T − 3} ∧ (x,y, z) ∈ C ∧ (x

′

,y

′

) ∈

N

(x,y)

∧ |z

′

− z| ≤ 1}

• Q

wait

= {(t

s

,x,y,z,c,M,x,y, z) : t

s

∈ {1,. . . , T −

3} ∧ c ∈ {0,1} ∧ (x,y, z) ∈ C }

• Q

leave

= {(t

s

,x,y, z, c, M, E, E, E) : t

s

∈ {2,...,T −

2} ∧ c ∈ {0,1} ∧ (x,y, z) ∈ B}

• Q

pick up

= {(t

s

,x,y,z,0,P,x

′

,y

′

,z) : t

s

∈ {1,...,T −

3} ∧ (x,y) ∈ P ∧ (x

′

,y

′

) ∈ N

(x,y)

∧ z ∈

[

Z − 1}

• Q

deliver

= {(t

s

,x,y, z, 1, D, x

′

,y

′

,z) : t

s

∈ {1, . . . , T −

3} ∧ (x,y) ∈ P ∧ (x

′

,y

′

) ∈ N

(x,y)

∧ z ∈

[

Z − 1}

Let Q =

S

a∈A

Q

a

. Let f

q

: Z

+

×C

′

×{0,1}×K ×

C

′

−→ Q

+

be a function, which assigns each action a

duration f

q

(t

s

,. .. , z

′

),(t

s

,. .. , z

′

) ∈ Q . If not specified

otherwise, the f

q

function must be part of the model

input. Let m be the least common multiple of de-

nominators in { f

q

(t

s

,. .. , z

′

) : ∀(t

s

,. .. , z

′

) ∈ Q }. Then,

unless otherwise specified, the f

d

function is de-

fined as f

d

(t

s

,. .. , z

′

) = m f

q

(t

s

,. .. , z

′

),∀(t

s

,. .. , z

′

) ∈

Q . Let us introduce the following simplifying nota-

tion – let f

d

(v) = f

d

(t

s

,. .. , z

′

),∀v = (t

s

,. .. , z

′

) ∈ Q .

Let us define a set of all actions for each action

type a ∈ A as R

a

= {(t

s

,t

e

,x,y,z,c,k, x

′

,y

′

,z

′

) : v =

(t

s

,x,y,z,c,k, x

′

,y

′

,z

′

) ∈ Q

a

∧t

e

= t

s

+ f

d

(v)}.

The proposed model has seven disjoint sets of

agent action types, which in union give the new set

of agent actions. Agent action types are derived from

six different action subsets in the original model:

Set R

entry

of “entry” type actions features all ac-

tions, where the agent enters from the starting posi-

tion outside the grid to a border cell. The agent might

carry a block when it enters. This action type is the

only source of new blocks for the construction site.

The set of agent actions, where the agent moves to

the neighbor grid position is divided into two action

types – “move block” and “move empty” for moving

to the neighbor position while carrying / not carry-

ing a block, respectively. This distinction is made for

cases where the carried block requires the agent to

move slower. Set R

move empty

is for “move empty”,

set R

move

block

is for “move block” action type. Both

action types can be implemented on TERMES robots

as a combination of turn and move-forward actions.

Action type “wait” with action set R

wait

has a du-

ration of T

wait

= 1 timestep, chosen because the mini-

mum wait-time of agents is generally not limited. Ac-

tion type “leave” is for agents leaving the grid from a

border cell (going to the end position (E,E, E)). The

associated action set is R

leave

. The agents can carry

a block when leaving the grid, the only way to re-

move blocks from the construction site. Set R

pick up

of “pick up” type actions features all actions, where

the agent picks up a block from a neighbor position.

Set of “deliver” type actions R

deliver

features all ac-

tions, where the agent delivers a block to a neighbor

position. Let the set of all actions be R =

S

a∈A

R

a

.

Let H be a set of block-actions. Block-action is

a tuple (t, x,y,z,z

′

) ∈ H , where (x, y,z) ∈ C ∧ z

′

∈

{z − 1, z, z + 1} ∩

b

Z ∧ t ∈

b

T . All block-actions last

one timestep, meaning that only action start time t

ICAART 2024 - 16th International Conference on Agents and Artificial Intelligence

720

is required. Indicators r

i

∈ {0,1},i ∈ R and h

i

∈

{0,1}, i ∈ H decide, which action is part of the plan.

For instance, r

j

= 1, j = (5,7,1,2,0,1,D,2,2,0) ∈ R

in the solution indicates that an agent at timestep 5

delivers block to position (2,2,0) ∈ C while standing

at (1,2, 0) ∈ C . The action is finished by timestep 7.

The objective function 1 minimizes the sum-of-

costs (the sum of timesteps each robot spends on the

grid). The proposed model counts the “entry”-type

action timesteps into the objective function, because

the agent is considered to partially be on the grid,

when the action starts (blocking the border cell as part

of the action exclusion zone).

The exclusion zones are proposed as a measure to

avoid agent collisions. Each exclusion zone is cre-

ated at the start of an action, removed at the end

of the same action and grants the agent performing

the action exclusive access to start- and end-position

columns, if the position is within grid. The exclusive

access does not allow the remaining agents to perform

actions, which start or end within the exclusion zone.

min(

∑

i∈R

r

i

d

i

) (1)

h

t,x,y,z,z

= 1,∀t ∈

b

T , (x, y,z) ∈ B (2)

h

0,x,y,0,0

= 1,∀(x, y) ∈ P (3)

h

T −1,x,y,z

(x,y)

,z

(x,y)

= 1,∀(x, y) ∈ P (4)

∑

i∈H

t,x,y,∗,z

h

i

=

∑

i∈H

t+1,x,y,z,∗

h

i

, ∀t ∈

[

T − 1, (x, y,z) ∈ C (5)

∑

i∈H

t,x,y,∗,∗

h

i

= 1,∀t ∈

b

T , (x, y) ∈ P (6)

Constraints 2 – 6 are the same as in the origi-

nal MILP model. Constraint 2 forbids placement of

blocks at border cells, constraint 3 starts the world

devoid of blocks, constraint 4 ensures that the target

structure is finished at the end of construction, con-

straint 5 flows the column height from one timestep

to the next and constraint 6 forces every position to

have one height.

∑

i∈R

∗,t,

∗,∗,∗,

0,M,

x,y,z

r

i

+

∑

i∈R

∗,t,

x,y,z,

1,D,

∗,∗,∗

r

i

=

∑

i∈R

t,∗,

x,y,z,

0,M,

∗,∗,∗

r

i

+

∑

i∈R

t,∗,

x,y,z,

0,P,

∗,∗,∗

r

i

,∀t ∈

b

T , (x, y,z) ∈ C (7)

∑

i∈R

∗,t,

∗,∗,∗,

1,M,

x,y,z

r

i

+

∑

i∈R

∗,t,

x,y,z,

0,P,

∗,∗,∗

r

i

=

∑

i∈R

t,∗,

x,y,z,

1,M,

∗,∗,∗

r

i

+

∑

i∈R

t,∗,

x,y,z,

1,D,

∗,∗,∗

r

i

,∀t ∈

b

T , (x, y,z) ∈ C (8)

Constraints 7 and 8 flow the agents from one ac-

tion to the next. Semi-closed interval of action exe-

cution [t

s

,t

e

) is exploited for a seamless transition be-

tween actions. Similarly to the base model, constraint

7 flows agents without block and ensures that the

number of agents ending their action without block at

position (x,y,z) at timestep t is the same as the num-

ber of agents without block starting their action at the

same position and in the same timestep. Constraint 8

does the equivalent for agents carrying a block.

∑

i∈R

t

s

,t

e

,

x,y,∗,

∗,∗,

∗,∗,∗

t

s

≤t<t

e

r

i

+

∑

i∈R

t

s

,t

e

,

∗,∗,∗,

∗,∗,

x,y,∗

t

s

≤t<t

e

r

i

−

∑

i∈R

t

s

,t

e

,

x,y,∗,

∗,∗,

x,y,∗

t

s

≤t<t

e

r

i

≤ 1,∀t ∈

b

T , (x, y) ∈ P (9)

Constraint 9 addresses vertex collision of agents

during action execution. Since the only requirement

for the agent is to perform the action a between t

s

and t

e

, the exact position of the agent is unknown and

both start and end position are made into the exclu-

sion zone, where no other action can take place (for

timesteps within interval [t

s

,t

e

)). To avoid agents re-

moving blocks under moving agents, the constraint

makes the whole block column at position (x, y) of

both the start and end of the action an exclusion zone.

Separate constraint to prevent edge collisions (like in

the base model) is no longer necessary, as two actions

can no longer share vertices while executing simulta-

neously, due to the exclusion zones.

∑

i∈R

t

s

,t

e

,∗,∗,∗,∗,∗,∗,∗,∗

:t

s

≤t<t

e

r

i

≤ A,∀t ∈ T (10)

Constraint 10 limits the number of agents on the

grid to at most A ∈ Z

+

, given as part of model input.

∑

i∈H

t,x,y,z,∗

h

i

≥

∑

i∈R

t

s

,t

e

,x,y,z,∗,∗,∗,∗,∗

:t

s

≤t<t

e

r

i

, ∀t ∈

b

T , (x, y,z) ∈ C (11)

h

t,x,y,z+1,z

=

∑

i∈R

∗,t+1,∗,∗,∗,0,P,x,y,z

r

i

,

∀t ∈

[

T − 1, (x, y) ∈ P ,z ∈

[

Z − 1 (12)

h

t,x,y,z,z+1

=

∑

i∈R

∗,t+1,∗,∗,∗,1,D,x,y,z

r

i

,

∀t ∈

[

T − 1, (x, y) ∈ P ,z ∈

[

Z − 1 (13)

h

i

∈ {0,1}, ∀i ∈ H (14)

r

i

∈ {0,1}, ∀i ∈ R (15)

Constraint 11 forces agents to always stand on

the highest block in the column. Constraints 12 and

13 govern decreases and increases in block column

height, respectively. Constraint 12 ties every decrease

by one block to pick up action. Constraint 13 ties in-

crease by one block to deliver action. Constraints 14

and 15 specify the variable domains.

Action Duration Generalization for Exact Multi-Agent Collective Construction

721

The model is used to exactly optimize makespan

and sum-of-costs, the primary and secondary opti-

mization criteria, respectively. Optimization of the

makespan is done by starting at the minimum possible

value (estimated by a lower bound function described

below) and sequentially increasing the makespan by

one timestep until a solution is found.

We expect that the most often used f

d

assignment

will give each action-type a fixed duration (i.e. all

actions in Q

deliver

will have the duration T

deliver

, the

“pick up” actions will have the duration T

pick up

etc. –

see equation 16). Namely, in the case of the TERMES

robots, the first two action type durations would be

T

deliver

= 3 and T

pick up

= 2. The times assume one

timestep is 10 s and are from (Petersen et al., 2011),

where the block pick-up time is measured to be 15± 5

s and the block delivery time 24 ± 5 s. The rest of the

action type durations are derived similarly, the full list

is in table 1 in column “TERMES”.

f

d

(v) =

(

T

a

if v ∈ Q

a

,a ∈ A

1 otherwise.

(16)

4 MAKESPAN ESTIMATION,

UPPER AND LOWER BOUND

Due to the generalization, the fraction-time model is

expected to be more computationally demanding than

the base model, when the action durations are not con-

stant. To allow for an informed decision, whether

the use of a fraction-time model is required, a lower

bound, heuristic estimate, and upper bound of the

fraction-time model makespan are presented.

A lower bound is computed using the relaxed

problem MACC

r

. MACC

r

relaxes the requirement

for the maximum number of agents (allowing an un-

limited number of agents), the constraint of agent

collisions (allowing multiple agents to stand on one

block), exclusion zone constraint (allowing agents

to place blocks under other agents) and constraints

limiting changes of agent vertical position (allowing

agents to stay on top of a column, while it is be-

ing built and place blocks to the neighbor column

at the same time). The only optimization criterion

for MACC

r

is makespan. MACC

r

has a trivial so-

lution – for each column in the building area add the

number of agents equal to the column height and as-

sign them to the column, starting at the border po-

sition closest to the column. For all agents – enter

at the assigned starting position with a block, move

to the assigned column (simultaneously), and one by

one place the held block at the top of the assigned

column. Once all agents assigned to a column place

their blocks, move all those agents to the starting bor-

der cell and leave the building area. The makespan of

MACC

r

is the lower bound of fraction-time MACC

(because MACC

r

is the relaxation of MACC). Let

T

r

be the optimum makespan of MACC

r

. Let s

(x,y)

be the minimum L

1

distance from a border cell to

N

(x,y)

(a neighbor of (x, y)). Let d

min

a

= min

i∈R

a

d

i

,a ∈

A be the minimum duration of action type a. Let

d

min

move

= min{d

min

move block

,d

min

move empty

}. Let T

(x,y)

=

d

min

entry

+ s

(x,y)

d

min

move

+ z

(x,y)

d

min

deliver

+ s

(x,y)

d

min

move

+ d

min

leave

be the duration of the described action sequence for

building the column at (x,y) (z

(x,y)

is the desired

height of the column). Then l

r

= max{T

(x,y)

| ∀(x, y) ∈

P ∧z

(x,y)

> 0} ≤ T

r

is a MACC lower bound (building

of each column is independent in MACC

r

, due to the

relaxations, l

r

is equal to the longest duration T

(x,y)

).

A simple mission duration improvement func-

tion is proposed to assist in cost-benefit analysis and

makespan estimation for more precise action dura-

tion mapping of the fraction-time model. Let d

avg

a

=

(

∑

i∈R

a

d

i

)/|R

a

|,a ∈ A. Let α =

∑

a∈A

d

avg

a

/|A| be

the estimation of the relative makespan increase. Let

T

b

be the makespan computed by the fraction-time

model where all actions last one timestep. The es-

timated makespan of the fraction-time model with a

more detailed action duration mapping is defined as

T

h

= max(l

r

,min(u

f

,⌈αT

b

⌉)), where u

f

is an upper

bound defined later in the chapter.

Finally, the fraction-time model can be used for

its own makespan estimation. Let r

i

, R , T and d

i

for the fraction-time model with less precise action

duration mapping be marked as r

′

i

, R

′

, T

′

and d

′

i

, re-

spectively. Since the more precise mapping of action

durations makes the model more computationally de-

manding, a model with less precise mapping – defined

as max

i∈R

′

a

d

′

i

≤ min

i∈R

a

d

i

,∀a ∈ A – can be used for

estimating the makespan of the more computation-

ally demanding task. In this regard, the model with

d

′

i

= 1,∀i ∈ R

′

is especially interesting, as constant

action durations should provide the smallest runtime

of the fraction-time model for given height-map. Let

l

f

= T

′

be a lower bound gained using fraction-time

model with less precise action duration mapping.

Let u

f

be an upper bound, defined as the execution

duration of a plan by the fraction-time model with

less precise action duration mapping, where the ac-

tions use durations of the more precise mapping and

the agents wait at the beginning of each timestep until

all actions that were supposed to end at that timestep

are performed. This waiting strategy can also be used

when executing the plan on real hardware. When

d

′

i

= 1,∀i ∈ R

′

, u

f

is defined by equation 17.

Let u

c

= T

′

∗ max

v∈Q

f

d

(v) be a naive upper

bound, where T

′

is the makespan of fraction-time

ICAART 2024 - 16th International Conference on Agents and Artificial Intelligence

722

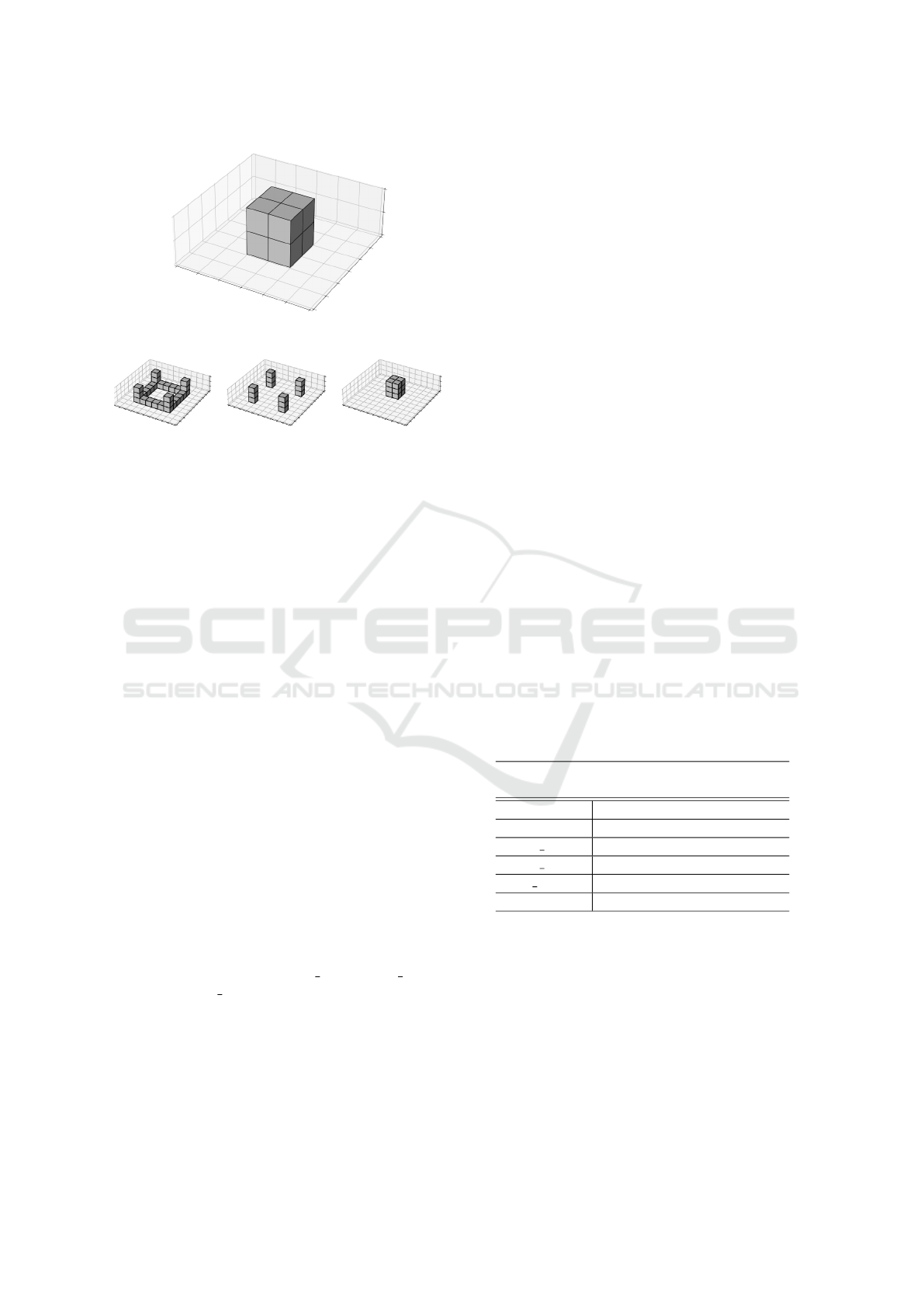

Figure 2: Instance used for makespan estimation precision

measurement.

Figure 3: Three different instances used in experiments.

model with d

′

i

= 1, ∀i ∈ R

′

. In practice, we mul-

tiply the makespan of unit-action-duration fraction-

time model with the duration of the longest action.

u

f

0

= 0

u

f

n

= u

f

n−1

+ max

(t

s

,t

e

,x,...,z

′

)

∈R

′

n−1,∗,...,∗

f

d

(u

f

n−1

,x,...,z

′

),

(17)

5 EXPERIMENTS

The first experiment aims to demonstrate construction

time reduction for non-constant action durations. It

is performed with the Gurobi 10.0.3 solver (Gurobi

Optimization, LLC, 2023), limited to 32 threads on a

3 GHz Intel Skylake processor with 16 physical cores

and hyper-threading, along with 132 GB of RAM.

For evaluation, we translate the fraction-time

model to Python Gurobi API, which we use to de-

scribe the objective function 1 and all the constraints

(2 – 15). The resulting translation requires a known

makespan and optimizes only the sum-of-costs. To

optimize makespan, we add an outer loop, iterating

over makespans starting at lower bound l

r

and in-

creasing by 1 until a solution (construction plan) is

found. The input for the Python program is speci-

fied as a 2-dimensional height-map of the structure,

durations for enter, leave, move block, move empty,

deliver and pick up action types. The output of the

model is a set of indicators r

i

and h

i

, which action tu-

ples were used. Each action tuple contains a start and

an end position, which is used to assign the actions to

agents and compile an action sequence for each agent.

We experiment with three structures shown in fig-

ure 3. These instances represent a subset of instances

from (Lam et al., 2020) that have the lowest solver

computation time, with part of the area without blocks

around the third structure removed to reduce access

time for the agents. The fraction-time model is used

to compute plans for the construction of each struc-

ture instance. Four action duration sets (i.e. sets of ac-

tion durations) are used for each structure – the action

durations can be seen in table 1. The maximum num-

ber of agents is 50 for instances 1 and 2; 20 for the

third instance (due to the smaller construction area).

The table 2 shows the results of the first experi-

ment, measuring solver runtime, solution makespan,

and sum-of-costs for each instance–action-type-set

duo. The construction plans are saved as well, the 1-

timestep plan is used for u

f

and u

c

upper bound com-

putation (result in parentheses next to makespan). The

u

f

and u

c

values are very similar, showing that in most

cases, the more easily computed u

c

value is sufficient.

The makespan values show a decrease in construction

duration in comparison with the wait-action padded

plan by u

f

. The construction duration decreases on

average by approximately 19% for 1-2 timestep, 6%

for 1-2-3 timestep, and 9% for TERMES timestep.

The table also contains the average value and sam-

pling variance of the runtime, showing a steep growth

in computational complexity. The results suggest an

exponential increase of computation time in regards

to makespan, which was also observed in a similar

model by (Srinivasan et al., 2023). This is likely

caused by linear dependency between the number of

MILP variables (r

i

and h

i

) and model makespan (also

noted by (Srinivasan et al., 2023)) and a general MILP

problem being NP-hard (Bulut and Ralphs, 2021).

Table 1: Action type durations for used action duration sets.

Action duration sets

Action 1 1-2 1-2-3 TERMES

enter 1 2 3 3

leave 1 1 2 3

move block 1 1 3 3

move empty 1 1 1 2

pick up 1 2 3 2

deliver 1 2 3 3

The second experiment aims to evaluate the ef-

fects of varying action durations on the makespan es-

timation accuracy of T

h

. For this purpose, all action

types, but T

wait

, are assigned durations T

a

∈ {1,2,3} =

β,∀a ∈ A \ {wait} and all combinations of those du-

rations are measured (requiring |β|

|A|−1

= 729 con-

struction plans to be computed). T

wait

is left as 1, as

the minimum robot wait time is not limited. We select

a 2 × 2 × 2 cube target structure (figure 2) due to the

high number of required measurements.

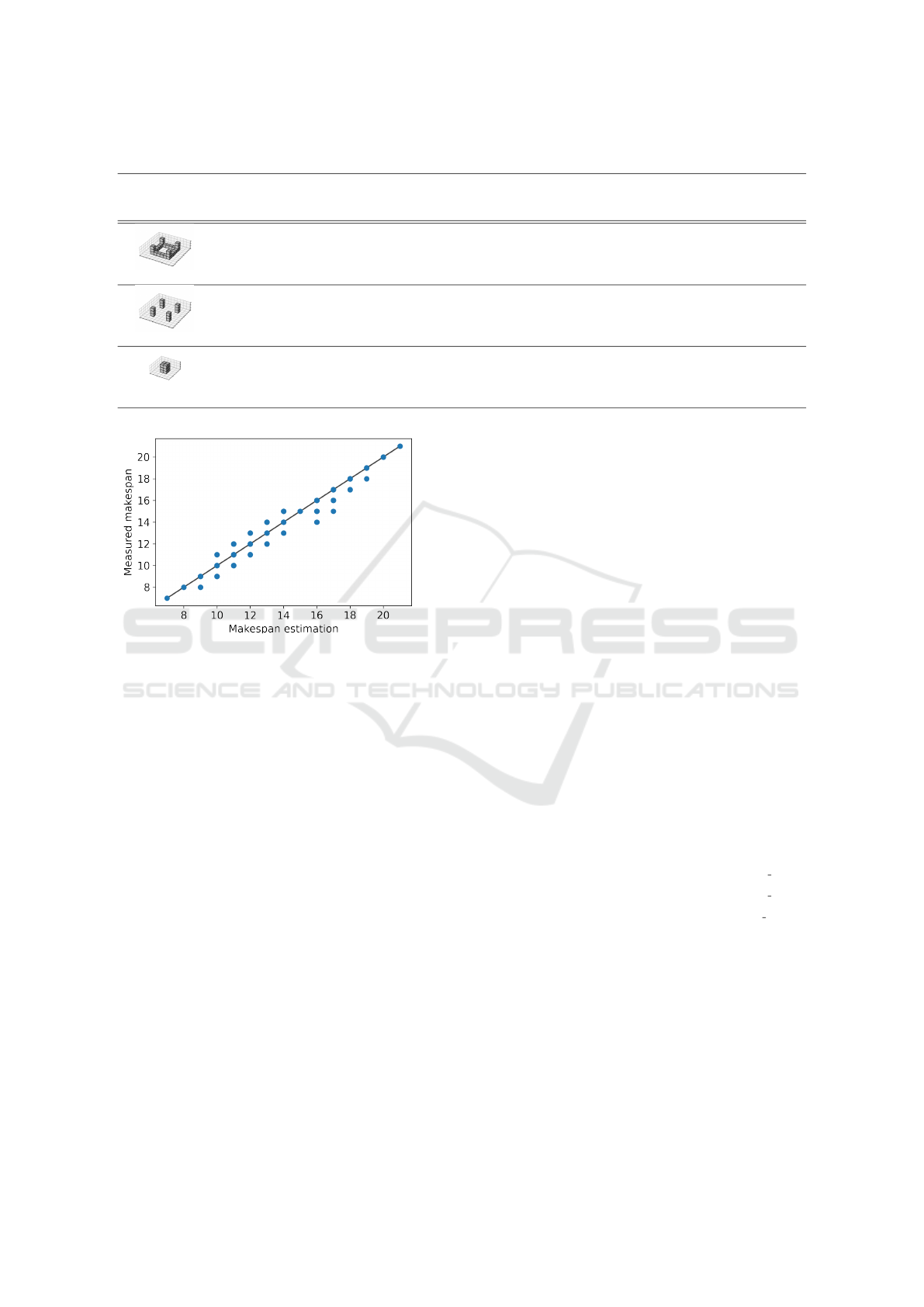

The results in figure 4 show that T

h

both can

Action Duration Generalization for Exact Multi-Agent Collective Construction

723

Table 2: Experimental results.

Instance Action duration set Run-time Run-time Makespan Makespan Sum-of-costs Robots

mean [s] sampling lower with (u

f

;u

c

variance [s

2

] bound upper bound)

1

1-timestep 26.75 1.41 6 11 (11; 11) 232 32, 33, 34, 37

1-2-timestep 355.33 95.16 10 17 (21; 22) 316 32, 33

1-2-3-timestep 426.32 28.48 15 30 (32; 33) 576 32

TERMES-timestep 322.73 9.19 18 30 (33; 33) 648 32, 33, 34

2

1-timestep 24.10 1.05 6 11 (11; 11) 196 32

1-2-timestep 58.88 0.93 10 17 (21; 22) 284 32

1-2-3-timestep 287.24 15.76 15 30 (32; 33) 508 32

TERMES-timestep 264.28 2.83 18 30 (33; 33) 548 32

3

1-timestep 239.21 47.98 6 14 (14; 14) 142 16, 17

1-2-timestep 303.92 43.62 10 21 (27; 28) 213 17

1-2-3-timestep 3807.62 414.87 15 37 (41; 42) 352 17

TERMES-timestep 6152.27 1132.99 18 38 (41; 42) 398 16, 17

Figure 4: Scatter plot of makespanheuristic relation.

under- and over-estimate the actual makespan value.

The root mean square error (RMSE) of T

h

is 0.655,

with minimum estimation error absolute value, rela-

tive to makespan, being 0 and maximum 0.143. The

error stems from the simplicity of T

h

– it depends only

on the action type duration mean and makespan of the

generalized model with unit action durations. It does

not take into account the usage of the action types.

The last test aims to show another beneficial ac-

tion duration set for the fraction-time model. The

real TERMES use marine foam blocks with indenta-

tions/protrusions and neodymium magnets to ensure

block alignment and stability (Petersen et al., 2011).

The resulting block columns are stable enough that

the agents do not need to adapt their movement speed

to their height on the structure – at least at the scales

used in the paper. For TERMES-like multiagent sys-

tems with less stability, the fraction-time model al-

lows to adjust the agent movement speed according

to the vertical position of the agent. This is shown on

a task with action durations given by the equation 18,

ensuring that the action durations grow linearly with

the vertical position of the robot at the action’s end

(except the wait action, where the robot stays still).

The experiment measures 10 run-times with ac-

tion durations f

d

h

(referred to as “Unstable columns”

in the results) on the instance 1. Makespan, sum-

of-costs and run-time are compared with results for

“TERMES-timestep” action duration set of instance

1. The “TERMES-timestep” results are called “Base”

in the results table 3. The makespan of unstable

columns task has increased by 40%, the sum-of-

costs by 7.4%, relative to the base. The increase

of makespan was expected, due to f

d

h

consisting of

TERMES-timestep f

d

with an added positive linear

component. The interesting result is the small 7.4%

increase in sum-of-costs in relation to the 40% rel-

ative increase in makespan. This indicates a lower

agent utilization in case of the unstable columns task.

The run-time increased with the makespan. How-

ever, it is still notably lower than runtime of in-

stance 3 with TERMES-timestep in table 2, which has

makespan 38. This indicates, that while run-time is

greatly dependent on makespan, the remaining task-

dependent constraints, such as the structure height

map and the agent count, also affect the computa-

tional complexity to a relatively large degree.

f

d

h

(v) =

3 if v ∈ Q

entry

∪ Q

leave

2 + z

′

if v = (.. . , z

′

) ∈ Q

move empty

3 + z

′

if v = (.. . , z

′

) ∈ Q

move block

2 + 2z

′

if v = (.. . , z

′

) ∈ Q

pick up

3 + 2z

′

if v = (.. . , z

′

) ∈ Q

deliver

1 otherwise.

(18)

6 CONCLUSION

A new branch of the multi-agent construction has re-

cently emerged – exact optimization of the problem.

The current state-of-the-art exact approach provides

solutions with optimal makespan and sum-of-costs

ICAART 2024 - 16th International Conference on Agents and Artificial Intelligence

724

Table 3: Comparison of TERMES task solution where

movement and block manipulation speed depends on agent

height (unstable columns) with task solution, where move-

ment speed is independent of the agent height (base).

TERMES Base Unstable columns

Makespan 30 42

Sum-of-costs 648 696

Mean run-time [s] 322.73 3837.64

but assumes all agent high-level actions to have the

same duration. This is not the case in the real world.

For instance, the mean duration of block manipulation

actions of the TERMES robot differs by 46%.

This has motivated us to generalize the current

state-of-the-art exact MILP model (Lam et al., 2020)

into the fraction-time model with action durations

specified as part of the model input. The generaliza-

tion is non-trivial – upholding the agent collision con-

straint has necessitated the redefinition of agent colli-

sion using exclusion zones while keeping the model

computationally viable required the preservation of

the two network flow structures within the model. We

test the generalized model on various action durations

(including TERMES), studying its behavior. The ex-

periment shows a 9% decrease in construction dura-

tion (makespan vs u

f

upper bound, which can provide

a non-optimal plan) for the TERMES robots. Other

action duration sets also show similar results.

The second experiment analyses the heuristic

makespan estimation function T

h

and its behavior

with different action duration sets. The experiment

uses toy instance – 2 × 2 × 2 cube and showcases the

spread of estimated makespan values in comparison

with the real ones. The RMSE of the T

h

is 0.665, mak-

ing it a viable source of information for cost-benefit

analysis when considering a more computationally

demanding action duration mapping. The last exper-

iment showcases the ability of the model to adjust to

agents moving slower at greater heights. The opti-

mal solutions show a notably lower relative utiliza-

tion of the agents in comparison with a non-height-

dependent action duration assignment.

While the model is computationally demanding,

it can provide reference solutions for both existing

and future heuristic models. These solutions can be

used to estimate the heuristic model efficiency and

as long-term targets for models optimizing makespan

(i.e. construction duration).

ACKNOWLEDGEMENTS

This work has been supported by the project number

22-31346S of the Czech Science Foundation GA

ˇ

CR

and by the CTU project SGS23/210/OHK3/3T/18.

An extended version of this paper is available at

(Rame

ˇ

s and Surynek, 2023).

REFERENCES

Barros dos Santos, S. R., Givigi, S., Nascimento, C. L., Fer-

nandes, J. M., Buonocore, L., and de Almeida Neto,

A. (2018). Iterative decentralized planning for col-

lective construction tasks with quadrotors. Journal of

Intelligent & Robotic Systems, 90(1):217–234.

Bulut, A. and Ralphs, T. K. (2021). On the complexity of

inverse mixed integer linear optimization. SIAM Jour-

nal on Optimization, 31(4):3014–3043.

Cai, T., Zhang, D. Y., Kumar, T. S., Koenig, S., and Aya-

nian, N. (2016). Local search on trees and a frame-

work for automated construction using multiple iden-

tical robots. In Proceedings of the 2016 International

Conference on Autonomous Agents & Multiagent Sys-

tems, pages 1301–1302.

Deng, Y., Hua, Y., Napp, N., and Petersen, K. (2019).

A compiler for scalable construction by the termes

robot collective. Robotics and Autonomous Systems,

121:103240.

Forgemind ArchiMedia (2014). Termes robot 01.

Gurobi Optimization, LLC (2023). Gurobi Optimizer Ref-

erence Manual.

Jenett, B. and Cheung, K. (2017). Bill-e: Robotic plat-

form for locomotion and manipulation of lightweight

space structures. In 25th AIAA/AHS Adaptive Struc-

tures Conference, page 1876.

Lam, E., Stuckey, P., Koenig, S., and Kumar, T. (2020). Ex-

act approaches to the multi-agent collective construc-

tion problem. In Simonis, H., editor, Principles and

Practice of Constraint Programming, Lecture Notes

in Computer Science, pages 743–758. Springer. In-

ternational Conference on Principles and Practice of

Constraint Programming 2020, CP2020 ; Conference

date: 07-09-2020 Through 11-09-2020.

Petersen, K. H., Nagpal, R., and Werfel, J. K. (2011).

Termes: An autonomous robotic system for three-

dimensional collective construction. Robotics: sci-

ence and systems VII.

Piranda, B. and Bourgeois, J. (2018). Geometrical

Study of a Quasi-spherical Module for Building Pro-

grammable Matter, pages 387–400. Springer Interna-

tional Publishing, Cham.

Rame

ˇ

s, M. and Surynek, P. (2023). Action duration gener-

alization for exact multi-agent collective construction.

arXiv.org. https://arxiv.org/abs/2312.13485.

Romanishin, J. W., Gilpin, K., and Rus, D. (2013). M-

blocks: Momentum-driven, magnetic modular robots.

In 2013 IEEE/RSJ International Conference on Intel-

ligent Robots and Systems, pages 4288–4295.

Singh, S., Gutow, G., Srinivasan, A. K., Vundurthy, B., and

Choset, H. (2023). Hierarchical propositional logic

planning for multi-agent collective construction. In

Construction Robotics Workshop.

Srinivasan, A. K., Singh, S., Gutow, G., Choset, H., and

Vundurthy, B. (2023). Multi-agent collective con-

struction using 3d decomposition.

Action Duration Generalization for Exact Multi-Agent Collective Construction

725