Additive Manufacturing of Nitinol for Smart Personalized Medical

Devices: Current Capabilities and Challenges

Andrés Díaz Lantada

1a*

, Carlos Aguilar Vega

1b

, Rodrigo Zapata Martínez

1c

,

Mónica Echeverry Rendón

2

, Muzi Li

2

, Óscar Contreras-Almengor

2d

, Jesús Ordoño

2

,

William Solórzano-Requejo

1e

, Miroslav Vasic

3

, Juan Manuel Munoz-Guijosa

1

and Jon Molina-Aldareguia

1,2 f**

1

Department of Mechanical Engineering, ETSI Industriales, Universidad Politécnica de Madrid, Madrid, Spain

2

IMDEA Materials Institute, Tecnogetafe, Getafe, Spain

3

Center for Industrial Electronics, ETSI Industriales, Universidad Politécnica de Madrid, Madrid, Spain

Keywords: Additive Manufacturing, Shape-Memory Alloys, Smart Materials and Structures, Medical Devices.

Abstract: Shape-morphing smart medical devices constitute a current research trend and are bound to transform

healthcare thanks to the improved interactions with the human body they enable. 4D printing technologies

facilitate the development of such devices and start to provide innovative solutions like minimally invasive

surgical tools and devices, ergonomic appliances and orthoses, evolutive implants and active in vitro

biodevices, among others. Most studies so far, dealing with 4D printed biodevices, have been focused on

smart polymeric materials and structures, whose biomechanical, biochemical and biological properties cannot

always match those from shape-morphing and shape-memory alloys (SMAs). Considering several recent

synergic breakthroughs in the additive manufacturing of smart alloys, this study presents 4D printing with

SMAs for a new generation of medical devices, illustrated through case studies by our team. The more relevant

strategies under research for enhancing the performance of 4D printed NiTi are illustrated and varied foreseen

directions for achieving a sustainable and equitable impact in healthcare are discussed.

1 INTRODUCTION

Additive manufacturing technologies (AMTs) have

emerged in the last decades, as highly transformative

resources enabling freedom of design, fostering the

personalization of devices and reformulating the

world of design with original design-for-additive-

manufacturing (DfAM) methods (Lipson, 2011,

Yang, 2015 Thompson, 2016). The additive

manufacturing (AM) of lattices, porous structures,

functionally graded materials and multi-material

structures may bring to relevant benefits including

biomimetic and biomechanical design strategies for

enhanced performance through bioinspiration.

a

https://orcid.org/0000-0002-0358-9186

b

https://orcid.org/0000-0003-0291-3041

c

https://orcid.org/0000-0002-2611-7050

d

https://orcid.org/0000-0002-8166-4161

e

https://orcid.org/0000-0002-2989-9166

f

https://orcid.org/0000-0003-3508-6003

Besides, geometrical complexity can be applied

to the integration of varied functionalities, to the

minimization of components and to the elimination of

post-production operations, hence enhancing the

development lifecycle. However, in most cases, 3D

printed objects are passive elements unable to interact

with the environment in a dynamic way, as needed

quite often for biomedical applications and healthcare

products, which should often evolve according to

patients’ growing and healing processes. In general,

passive structures require the incorporation of sensors

and actuators for allowing such interactions and result

suboptimal in terms of integration, direct fabrication,

cost, weight and eco-impacts.

Lantada, A., Vega, C., Martínez, R., Rendón, M., Li, M., Contreras-Almengor, Ó., Ordoño, J., Solórzano-Requejo, W., Vasic, M., Munoz-Guijosa, J. and Molina-Aldareguia, J.

Additive Manufacturing of Nitinol for Smart Personalized Medical Devices: Current Capabilities and Challenges.

DOI: 10.5220/0012363900003657

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 17th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2024) - Volume 1, pages 123-134

ISBN: 978-989-758-688-0; ISSN: 2184-4305

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

123

For around two decades now, the AM of shape-

shifting systems or shape-morphing geometries has

been a research topic that has grown in parallel to the

progressive advances in AMTs and related usable

materials. The processing of active, multifunctional

or smart materials, capable of responding to external

stimuli, employing AMTs and rapid prototyping

processes, initiated a field that would be subsequently

referred to as “4D printing”. Synergic integration of

innovative materials, wise designs for self-assembly

or improved deployment, interlocked structures,

printable mechanisms and advanced manufacturing

technologies promoted a steady growth of 4D printing

(Tibbits, 2012, 2014, Ge, 2013, 2014).

Towards higher performance, the AM of smart

alloys has been also a topic of research for more than

a decade, although connections to 4D printed medical

devices are much more recent.

Pioneering studies dealt with the ultrasonic AM

of composites with aluminum matrices and embedded

shape memory nickel-titanium (NiTi or “nitinol”)

alloy, magnetostrictive galfenol and electroactive

PVDF phases, approaching active and self-sensing

structures (Hahnlen, 2010). Ultrasonic consolidation,

a hybrid manufacturing process that embeds fibers

into metal matrices, was also explored and led to NiTi

shape memory alloy (SMA) fibers into aluminum

(Al) matrices, mainly for structural applications

(Friel, 2011).

Regarding more adequate alloys for the

biomedical industry, the precise, efficient and

sustainable AM of highly biocompatible shape-

memory alloys from the NiTi family has been a long-

held dream that is currently at hand. Indeed, in spite

of the tricky processability of NiTi, different studies

have demonstrated that it can be additively processed,

which opens a plethora of applications (Lee, 2017). A

turning point is marked by different technologies

enabling the AM of NiTi, whose limits and potentials

have been analyzed (Van Hunbeeck, 2018).

Healthcare stands out as an extremely interesting

fields for 4D printed NiTi devices, although some

limitations still need to be addressed. Among them,

the finding of final medical applications, in which the

benefits of AMTs combined with the smartness of

NiTi can be exploited, for outperforming the current

gold standards, is also essential.

Accordingly, as presented in this study, exploring

new concepts for personalized, shape-morphing,

minimally invasive and evolutive biomedical devices

seems a very adequate strategy for taking advantage

of the mentioned benefits linked to the printability of

superelastic and shape-memory alloys.

Furthermore, unprecedented design and

manufacturing approaches, like the combined use of

both shape-memory and superelastic properties of

different kinds of NiTi, the employment of special

structures leading to NiTi metamaterials and the

creation of interwoven and interlocked NiTi

structures, to cite a few, may lead to a new generation

of 4D printed high-performance medical devices.

Considering all the above, this study analyzes the

current state, as regards the additive manufacturing of

NiTi, and the more promising approaches to obtain

4D printed nitinol medical devices. Furthermore,

different biomedical application concepts, benefiting

from DfAM methods are presented and illustrated

through printed prototypes. Main strategies for

empowering the shape-morphing performance of

these and related biodevices are also exemplified. At

the end of the paper, current limitations are described

in detail and a research roadmap is provided.

2 ADDITIVE MANUFACTURING

OF NITINOL: CURRENT STATE

2.1 Shape-Memory and Superelastic

Nitinol as Biomedical Materials

SMAs constitute a family of high-performance smart

materials capable of recovering an original shape

after being significantly deformed, just by heating

over the transformation shape temperature (shape-

memory effect). At the high temperature phase, the

deformation can be recovered just by releasing the

applied stress (superelasticity). Transformations

between the low temperature phase (martensite) and

the high temperature phase (austenite) or between

austenite and stress-induced martensite are involved.

NiTi, FeMnSi, CuZnAl and CuAlNi stand out as

polycrystalline SMAs with the previously described

transformations (Huang, 2002, De la Flor, 2005).

However, due to its special relevance, outstanding

thermomechanical properties (including shape-

memory and superelasticity) and biomedical aptitude,

our team is focusing on the enhanced AM of the

nitinol family and its application to biomedical

devices. Indeed, NiTi has been widely used in

healthcare, for instance in the cardiovascular field in

blood-contacting devices (i.e. stents, heart valves), in

orthopedics as bone substitutes and in orthodontics as

orthodontic fixators, among other applications (e.g.

otolaryngology, neurosurgery, ophthalmology,

urology, gynecology) (Auricchio, 2021).

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

124

Growing evidence suggests that NiTi alloys are

biocompatible due to the protective titanium-based

oxide layer on its surface (Elsisy, 2021). Nonetheless,

one major drawback impairing these alloys

biocompatibility is the content of Ni that can be

released from the surface into the surrounding

microenvironment and their associated toxicity

(Nasakina, 2019). Another concern that has been

associated with the use NiTi is surface-induced

thrombus formation (Gegenschatz-Schmid, 2022). In

this sense, several surface treatments have been

studied in order to improve NiTi biocompatibility.

The additive processability of NiTi may lead to a

very promising freedom of creation for highly

innovative medical devices, but necessasrily brings

also new unknowns to its biocompatibility, which

should be carefully addressed, as further discussed in

the research outline.

Regarding biomedical applicability, both

superelastic and shape-memory nitinol alloys have

their own application areas:

On the one hand, thermally activated nitinol can

be employed for the controlled deployment of a

surgical tool that may perform mechanical and

thermal ablation at the same time. Although the high

activation temperature is normally inadequate in

healthcare, composition modifications may lead to

activations at room temperature, thus opening a wider

set of applications.

On the other hand, superelastic nitinol has led to

several minimally invasive procedures based on self-

expanding surgical tools and implants. A current

research challenge is the sensitivity of these

outstanding thermomechanical properties to the

actual composition and processing conditions, as

described in sections 5.1 and 5.2.

2.2 Additive Manufacturing Strategies

for 3D/4D Printed Nitinol

Biodevices

Selective laser sintering (SLS) and selective laser

melting (SLM) or laser powder bed fusion (LPBF)

have transformed metals’ research and enabled solid

freeform fabrication with a wide set of metals and

alloys and with new design metallic materials

including high entropy and superalloys. For example,

both shape-memory and superelastic NiTi samples

have been achieved by selective laser melting

(Shayesteh Moghaddam, 2019, Obeidi, 2021). Other

laser-based processes such as laser engineering net

shaping (LENS) and laser cladding have been also

reported as options for additively processing smart

alloys (Van Hunbeeck, 2018).

To some extent, other processes like electron

beam melting (EBM), fused deposition modeling

(FDM) and wire arc additive manufacturing

(WAAM) are also applicable to the processing of

smart alloys (Van Hunbeeck, 2018), yet without the

achieved impact of PBLF. Recently, electron beam

freeform fabrication (EBF3) has been highlighted as

technology capable of mitigating some of the

common challenges involved in the selective laser

melting of NiTi, such as impurity pick-up (C, O and

N) and part size limitation (Paiotti, 2019).

Among key enabling technologies, not yet

explored for the printing of shape-memory alloys, but

with remarkable potential considering their recent

impact for extreme quality parts in high performance

materials, it is important to highlight lithography-

based methods. These lithographic techniques evolve

from the widespread digital light processing (DLP) of

photopolymers but employ slurries, in which a

polymeric matrix additively processed includes high

quantities of ceramic or metallic particles.

For instance, lithography-based ceramic

manufacturing technique (LCM) provides the most

remarkable precision and versatility in ceramic AM,

as it can process several kinds of ceramics, including

smart piezoceramics, magnetic ceramics and multi-

ceramic components (Schwentenwein, 2014). The

same principle is being applied to metallic slurries, as

an emergent process and could prove viable for the

AM of NiTi, even in the micro/nano-scale using two-

photon polymerization of metal (Vyatskikh, 2018).

2.3 Other Key Enabling Technologies

for 3D/4D Printed Nitinol

Biodevices

There are several methods by which SMAs can be

heated and activated. Among the most widely used

for this purpose are: 1) Joule, resistive heating or

direct Ohmic heating, 2) convective heating, and 3)

inductive heating (Qiu, 2001). These methods have

been validated with both conventional NiTi alloys

and with additively manufactured ones, employing

powder bed laser fusion, by our team.

Resistive heating is the most widely used heating

methodology as SMA are conductive alloys with low

resistance, but such a method is generally current-

limited to small and slim geometries. It depends on

the electrical resistivity of the SMA actuator. To cite

a biomedical example, an artificial urethral valve was

developed with NiTi wires as actuators that replace

the urinary sphincter muscles and by resistive heating

the opening and closing functions are controlled

(Chonan, 1997).

Additive Manufacturing of Nitinol for Smart Personalized Medical Devices: Current Capabilities and Challenges

125

Convective heating depends on the heat transfer

coefficient of the SMA. Convective heating using

water for rapid heating and cooling was applied to an

artificial muscle designed based on a spring bundle

actuator (Park, 2019) and to a bioinspired design of

vascular “blood vessel” that includes within a wet

SMA actuator (Mascaro, 2003). Microvascular

actuators demonstrated adequate for the convective

heating of shape-memory polymers (Díaz Lantada,

2016), which could be directly translated to SMAs,

once their high-precision 3D printing is mastered.

Induction heating seems to be a very good option

for the future of the medical field, since contactless

heating may be accomplished. With induction heating

SMA can be uniformly heated resulting in better

thermal control and higher heating rate. It depends

mostly on the magnetic permeability of the SMA, size

of the sample and applied frequency and magnetic

field intensity (Saunders, 2016). For instance,

transcutaneous induction heating was used to heat an

orthopedic shape memory implant within biological

tissue (Pfeifer, 2013, Müller, 2014). In addition,

safety studies, where stents were inducted heated,

were assessed as a potentially new method to treat

esophageal cancer (Zhou, 2009).

3 BIOMEDICAL APPLICATION

CONCEPTS FOR 3D/4D

PRINTED NITINOL

3.1 Materials

To explore the printability of NiTi and its versatility

for developing innovative medical technologies, two

powder compositions obtained by gas atomization

were acquired (Fort Wayne Metals). Mean particle

diameter was c.a. 30μm for both powders. One batch

had a composition closer to the equiatomic, for

achieving shape-memory properties, the other with

around an additional 1% of Ni to reach superelastic

properties.

3.2 Methods

Design of a collection of test probes and medical

devices concepts, such as vascular stents, heart valve

structures, surgical tools…, were carried out at UPM

employing a combination of software resources,

including: NX (Siemens PLM Solutions) for

geometrical modeling and n-Topology (nTop) for

topology/topography optimization.

Manufacturing of the different test probes and

conceptual biodevices presented in this study was

performed at IMDEA Materials Institute by laser

powder bed fusion. A Renishaw AM400 was

employed as additive manufacturing system. Final

post-processing included cleaning and electro-

polishing to achieve an adequate surface roughness,

whose impact in biocompatibility is further analyzed

in section 5.1. Overall, the process followed

recommendations from previous studies with slight

modifications due to specific software/hardware

constraints (Gan, 2021, Mani, 2022).

3.3 Innovative Concepts for 3D/4D

Printed Nitinol Biodevices

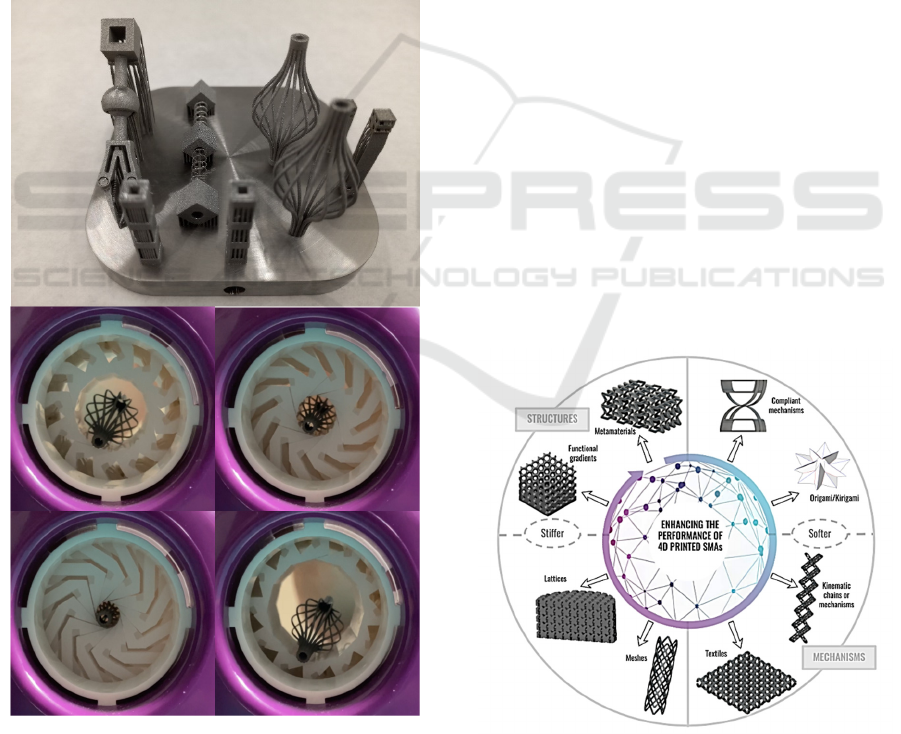

Figure 1 presents a collection of stents and heart valve

structures with systematic variations to illustrate the

viability and versatility of the additive processing of

Ni-Ti alloys.

Figure 1: Collection of stents and structures for heart valve

replacement obtained by LPBF of superelastic NiTi.

Designs: UPM, prototypes: IMDEA Materials Institute, as

in all figures presented in the study (iMPLANTS-CM

“Synergy” project from Comunidad de Madrid, Spain).

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

126

Classical manufacturing processes have led to a

very successful implementation of superelastic Ni-Ti

in medical practice, especially for self-expandable

vascular stents and valve structures. However, those

mass-produced devices do not really account for

some patients with unique morphological features. It

is precisely in this field, in which AM Ni-Ti would

prove competitive, for example for heart valve

structure with slightly elliptical cross-sections to

minimize perivalvular leakage or for Y-shaped stents

for the treatment of aneurysms.

After demonstrating the viability of obtaining the

more classical vascular devices other concepts

presented below in figure 3 and in section 4 are also

explored, such as: surgical manipulators or grippers,

functionally graded lattices as tissue engineering

scaffolds and minimally invasive kidney stone

retrieval baskets.

Figure 2: Proof-of-concept surgical actuators in NiTi.

Crimping test of a superelastic NiTi mesh conceived as

minimally invasive kidney stone retrieval basket.

4 EMPOWERING THE

SHAPE-MORPHING

PERFORMANCE

4.1 Overview of Strategies

Different principles applied to promoting the shape-

morphing behavior of shape-memory & superelastic

NiTi, are schematically presented in figure 3 and

experimentally demonstrated in the supporting videos

provided as companion for current paper. These will

be presented in the Biodevices conference and are

available for readers, on reasonable request, in case

the final publication will not share them openly. In

short, the supporting videos illustrate examples of 4D

printed actuators related to medical devices concepts

from previous section. S1 presents the successive

crimping and compliant response of a 4D printed

NiTi mesh, inspired by medical devices designed for

extracting strange bodies from inside the organism in

a minimally invasive way, such as kidney surgical

baskets and thrombectomy devices (as also presented

in figure 2). S2 presents a similar geometry to that of

S1, but 4D printed employing shape-memory NiTi

powder; the shape-memory training and recovery

processes are illustrated. S3 deals with a shape-

memory NiTi structure, counting with two structural

cubes connected by a compliant spring, which is

trained by pseudoplastic deformation and recovered

through heating. Finally, S4 and S5 present scaffolds

connected by compliant strips, respectively with

shape-memory and superelastic properties.

Figure 3: Examples of designed geometries, metamaterials,

mechanisms, textiles and other structures for empowering

the shape-memory performance of smart alloys, especially

shape-memory and superelastic NiTi.

Additive Manufacturing of Nitinol for Smart Personalized Medical Devices: Current Capabilities and Challenges

127

4.2 Biomechanical Metamaterials

Mechanical metamaterials, through designed

microstructures and solid freeform manufacturing

technologies, which are capable of defining matter in

3D, can be created with unique or exotic properties

not found in traditional synthetic materials (Kadic,

2012, Frenzel, 2017). Control over the elasticity

tensor, auxetics with negative Poisson ratio, atypical

thermal expansion coefficients and thermal

conductivity, unusual interactions with sound and

shock waves, among others, can be achieved for a

wide set of application fields (Kadic, 2019). Some

biological and biomechanical materials’ properties

can be mimicked with ad hoc designed metamaterials

and with combinations of metamaterials, lattices and

porous networks, which puts forward the interest of

these innovative geometries-structures-materials for

the development of biomedical implants. AMTs have

proven to be a fundamental booster for research in

this exciting area of metamaterials, whose properties

depend more on the actual designed microstructure

than on the characteristics of the raw materials

employed for their materialization. Interestingly,

shape-memory materials may synergize with

metamaterials’ structures to achieve enhanced shape-

morphing ability or to promote their superelastic

behavior. In consequence, investigating the

manufacturing of metamaterials employing SMAs is

proposed, as strategy for enhancing the performance

of 4D printed SMAs and devices based on them.

4.3 Origami Principles, Compliant,

Bistable & Multi-Stable Structures

Obtaining deployable structures with sufficient

stiffness in the deployed state is a very frequent

requirement in different types of applications: they

allow the transport in folded configuration of space

load-bearing structures, the minimally invasive

introduction by catheterization of medical devices

such as stents or valves, or the change of wing

geometry during the takeoff and landing of aircrafts.

Additionally, the large deflections involved in the

deployment process can be used to obtain compliant

actuators, very useful in applications such as robotic

manipulators and surgical biodevices. The energy

stored in the folding process and/or provided during

deployment can also allow high actuation forces with

very low control forces. Obtaining deployable

structures with these features and functionality

suitable for each application is based on three

fundamental considerations:

First, the design of stable structures in the

deployed state; second, the flexibility of the folding

zones; and third, the energy supply for the

deployment process. Traditionally, the physical

materialization of any of these concepts has been

subject to important restrictions, associated with the

use of plastic deformation or subtractive processes,

such as casting, folding, electrical discharge

machining or chip removal. These processes are

associated with important limitations for the

manufacture of deployable structures and compliant

actuators, both in size and geometry, being

complicated to obtain structures with characteristic

lengths less than 10

-2

m, with variable thicknesses or

morphological gradients, and usually being necessary

the assembly of different components to reach the

final system. The characteristics associated to

additive manufacturing and 4D printed components

make it possible to overcome the described

restrictions, which expands the horizons for

developing smart medical devices with

unprecedented functionalities and features. In

particular:

1) The manufacture of very small thickness features

and continuously variable thickness elements -

which allows for the tuning of the local flexural

stiffness and prevents the formation of stress

concentrators- which, in turn, facilitates:

a) Integral manufacturing of high performance

deployable structural concepts without the

need for assembly or mechanical hinges, such

as articulated, reticulated and chiral structures,

based on both flexibility and bistability, with

improved precision and repeatability.

b) The optimization of flexure hinges, and the

use of origami and auxetic geometries, that

could lead to deployable structures with

greater stiffness as well as a longer fatigue life.

2) The possibility of manufacturing along-the-

thickness morphological gradients would allow

asymmetrical sheets without the need for the use

of composite materials (Riley, 2020). Those

sheets, when cooled, would acquire bistable or

multi-stable characteristics. The same could be

achieved by using shape memory materials, which

would acquire these characteristics once the

transition temperature is reached.

3) The option of multi-material manufacturing

would allow, for example, the integration of shape

memory materials into bistable structural

concepts, giving rise to low-energy activation

actuators (Liu, 2019, Puthanveetil, 2022).

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

128

4.4 Functionally Graded Geometries

and Structures

In connection with the above, the AM of shape-

memory alloys can, not only lead to a biomimetic

performance of the developed medical devices, but

also help to reach singular smart properties like

increased shape-morphing ability, step-by-step

actuations or even quasi-autonomous responses.

Thanks to the careful design of functionally

graded geometries and structures, such features are

possible. For example, it is feasible to create

structural and functional units in the same device, to

employ topology optimization procedures to fine-

tune the compliance of different regions of the device,

and to use conformal lattice design methods to map

different unit cells of well-know properties within the

actual medical device (Feng, 2018). These methods

are already impacting the field of tissue engineering

with different alloys, ceramics and polymers, whose

additive processing and designs including

functionally graded structures lead to biomimetic

structures for repairing tissues with nonhomogeneous

density like bone. The processability of superelastic

NiTi can provide an extra design freedom and

bioinspired implants for replacing bones and bones

connected to other bones through cartilaginous joints

may be possible. The regeneration of the sternal-rib

complex and innovative spine tissue engineering

approaches can also benefit from these ongoing

research directions. Besides, functionally gradients of

porosity could even be applied to the creation of

biomimetic microvascular structures within the smart

medical devices, for enabling convective heating /

cooling from within, for enhanced control of the

activation, as already demonstrated with shape-

memory polymer concepts for surgical devices (Díaz

Lantada, 2016).

Through additive manufacturing, function and

structure become more interwoven than ever before

and multifunctional structures are achievable. The use

of smart alloys increases the number of achievable

functionalities. Thinking about the future, as

discussed in section 5.2, compliant regions for

biobots with active SMA wires or “muscles”

integrated in their structures, may lead towards smart

and living materials and structures with NiTi chassis.

Related schematic concepts and prototypes for an

innovative robotic hand (both showing a single finger

and an index-thumb couple) are presented in figure 4.

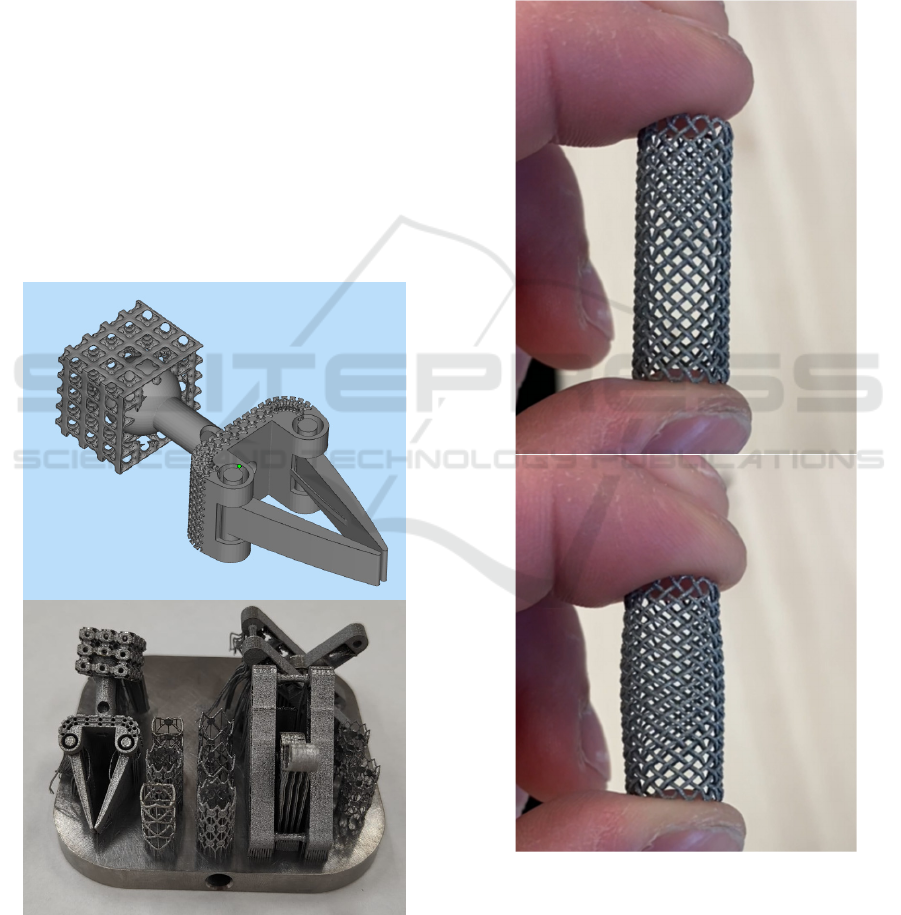

Figure 4: Innovative concepts for lightweight and smart

robotic hand: CAD models and prototypes by LPBF of

shape-memory NiTi. A single finger and an index-thumb

couple are illustrated. Both benefit from the use of

functional gradients of porosity and from the incorporation

of flexible hinges between phalanxes for enhanced

compliance and consequent actuation range.

4.5 Functionally Graded Alloys

Another way of achieving functional gradients, to

obtain design-controlled properties at every point of

a smart SMA-based biodevice, is the employment of

functional gradients of composition across the

structure. This leads to functionally graded alloys,

which combined with functionally graded geometries

and structures increase the freedom of design and

actuation of smart systems based on SMAs. The

potential creation of well-defined shape-memory and

superelastic regions in a single device, thanks to

controlling the composition of deposited NiTi powder

or the processing conditions layer-by-layer, or even

within each single layer, is of special relevance.

Pioneering examples have demonstrated that it is

possible to modify the processing conditions of

selective laser melting to obtain superelastic NiTi

without postprocessing. Arguably this effect could be

employed to spatially control the phases of NiTi

within complex printed parts. Another option may be

to resort to laser-based multiple metallic material

additive manufacturing with different compositions

of NiTi raw powders (Shayesteh Moghaddam, 2019,

Wei, 2021).

Additive Manufacturing of Nitinol for Smart Personalized Medical Devices: Current Capabilities and Challenges

129

4.6 Printed Kinematic Joints

(Mechanisms) and Textiles

An additional degree of compliance can be obtained

by printing mechanisms or textiles, for achieving

highly deformable NiTi structures, to which active

NiTi elements can be incorporated as driving

actuators. Arguable this can lead to empowering the

shape-morphing magnitude of the smart biodevices

and promote precise micromanipulation. In this way,

the traditional MEMS-related processes, applied to

the creation of NiTi surgical tools and micro-

manipulators, could be complemented with 3D/4D

printed micro-mechanisms, having the desired

number of degrees of freedom depending on the

application, and aimed at providing innovative

configurations for more versatile interactions with the

human body. The topology optimized shape-memory

NiTi actuator of figure 5, which includes a spherical

joint with 3 degrees of freedom and distal grippers

with revolute joints and shape-memory actuation,

provides an example of the achievable complexity.

Figure 5: Design and prototype of shape-memory NiTi

gripper. LPBF-printed biodevices (stents and actuarors).

Similar design principles applied to textiles can

lead to innovative NiTi meshes for implants like

stents, gastric bands and septal occluders. Surgical

devices like thrombectomy and lithoextraction

systems can also rely on SMA textiles. Interestingly,

the use of woven or knitted 3D printed meshes

importantly increases the compliance of superelastic

biodevices, as illustrated in figure 6 with a conceptual

superelastic NiTi structure mimicking an esophageal

stent.

Figure 6: Prototypes of computational-driven design of a

knitted mesh: LPBF-printed superelastic NiTi biodevices

imitating the size and features of esophageal stents. Simple

manipulation by hand illustrates the remarkable compliance

of the achieved woven structure.

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

130

5 TOWARDS THE FUTURE

5.1 Current Limitations and

Challenges

The potentials of AMTs for the personalization of

healthcare are evident and involve varied subfields,

such as patient-oriented surgical training and

planning, support to personalized surgical practice,

development of patient specific implants for soft and

hard tissues, and personalized solutions for tissue

engineering, regenerative medicine and

biofabrication. However, most experiences still are

experimental and rely on a written prescription,

which limits their incorporation to the standard

procedures at hospitals, in part due to a current lack

of standardization (and almost absent regulation

harmonization) surrounding patient-specific medical

devices obtained additively from patients’ medical

images. The incorporation of active materials, such as

shape-memory alloys, to patient-specific implants

brings new concerns, which should be analyzed and

discussed by the communities of researchers,

materials and technology developers, medical devices

manufacturers, healthcare practitioners, end users and

patients, standardization entities, regulators and

regulatory bodies. Only through the definition of

shared good practices will these medical solutions,

based on 4D printed smart alloys, deploy their

transformative potentials. The creation of specific

technical committees for standardization, the sharing

of advances through open publications and the

involvement of users in these biomedical

transformations, are among the good practices that

should be promoted.

Among technological challenges, one of the most

critical for LPBF of NiTi alloys is to identify the

optimum processing window for fabricating parts

with desirable mechanical and functional properties.

This has been widely studied in the literature. A wide

range of volumetric energy densities (VED) have

been reported in the literature by manipulating the

input laser power, scanning velocity, hatch spacing

and layer thickness to find optimal combinations,

from as low as 38 J/mm

3

(Gan, 2021) to as high as

750 J/mm

3

(Zhao, 2020). Hence, due to the high

sensitivity of NiTi SMAs and the possible hardware

and software differences in each commercial AM

system, process parameter sets generated by one

group might be rendered unusable by other

researchers (Xue, 2021). Nevertheless, a relatively

low energy density range (between 55 and 100

J/mm

3

) is commonly observed to provide the right

combination of desired properties.

Furthermore, the surface finish required by most

biomedical applications is another one of the critical

postprocessing issues that must be faced in future.

The printed parts are characterized by a rough

surface, including the presence of un-melted powder

particles left by LPBF. Surface modifications will be

thus required both to smooth the rough finish left by

LPBF and to impose the appropriate oxide layer to

optimize corrosion resistance and minimize Ni

release, which can be toxic, allergenic, and

carcinogenic depending on the amount released and

length of exposure. This is common to any

manufacturing method of nitinol implantable devices

and several reviews can be found in literature about

finishing methods, including chemical etching,

mechanical polishing, electropolishing and/or

thermal treatments (Mani, 2022). However, the

optimization of these surface treatments for LPBF

produced parts remains a challenge that must be

tackled in future.

Deepening into biocompatibility, a successful

medical device should not rely on the simple use of a

biocompatible material. The in vivo response and the

success of an implant in the body depends on multiple

variables, including aspects from the design,

composition, microstructure, surface properties, and

interaction of the material with cells and body fluids.

In addition, the applications also play a crucial role in

the material's performance. Static and dynamic

systems, for instance, consider different variables and

phenomena where mass transfer and diffusion of

elements help to compensate and equilibrate the

complete system.

SMAs are a promising tool to obtain engineered

tissue constructs and to treat tissues with complex

geometry and restricted access. However, there are

still some concerns about this topic regarding the

biological response (Wen, 2018). Among other

biomaterial properties, cell-material interactions may

be influenced by surface roughness, wettability and

chemical composition, which are well known to

determine the fate of cells. In any case, this will be

highly dependent on the cell type and the tissue to

regenerate. For instance, materials with high

roughness have been reported as suitable for inducing

osteointegration for bone implants since the surface

area to anchor the bone is more considerable, favoring

the cell adhesion. In the case of stents, roughness has

greatly influenced hemocompatibility (Wang, 2010)

or modulated endothelial and smooth muscle cell

functions (Khang, 2010), thus arising as an important

parameter to consider for the design and manufacture

of vascular stents.

Additive Manufacturing of Nitinol for Smart Personalized Medical Devices: Current Capabilities and Challenges

131

Another big challenge of 4D bioprinted structures

is their in situ delivery and activation. NiTi implants

activation or self-organization by external stimulus

without affecting the cell environment is still a big

challenge. The responsive effect of these materials to

multiple physiological signals can be modified in a

controlled way (inducing growth tissue or destroying

it, if necessary, as in the case of tumoral tissue). The

quid of the question is to identify the proper stimulus

to activate the system at the right moment, precisely,

and without causing acute side effects by affecting

multiple physiological processes (Sinha, 2020). One

promising application for these NiTi SMAs structures

is as drug delivery systems (Lukin, 2019). Through

these devices, it is possible to have precise control not

only on the spatial distribution, by the material

organization of the implant, but also on the release of

drugs or cells in a programable manner.

Among other biological-related aspects, it is

important to consider the ability to form complex

structures with multi-materials and structures that can

stimulate a stratified tissue considering the different

cell groups and specifications (Ionov, 2018). Arteries

and osteochondral regions are among the functionally

graded tissues potentially benefiting from additively

manufacturing SMAs.

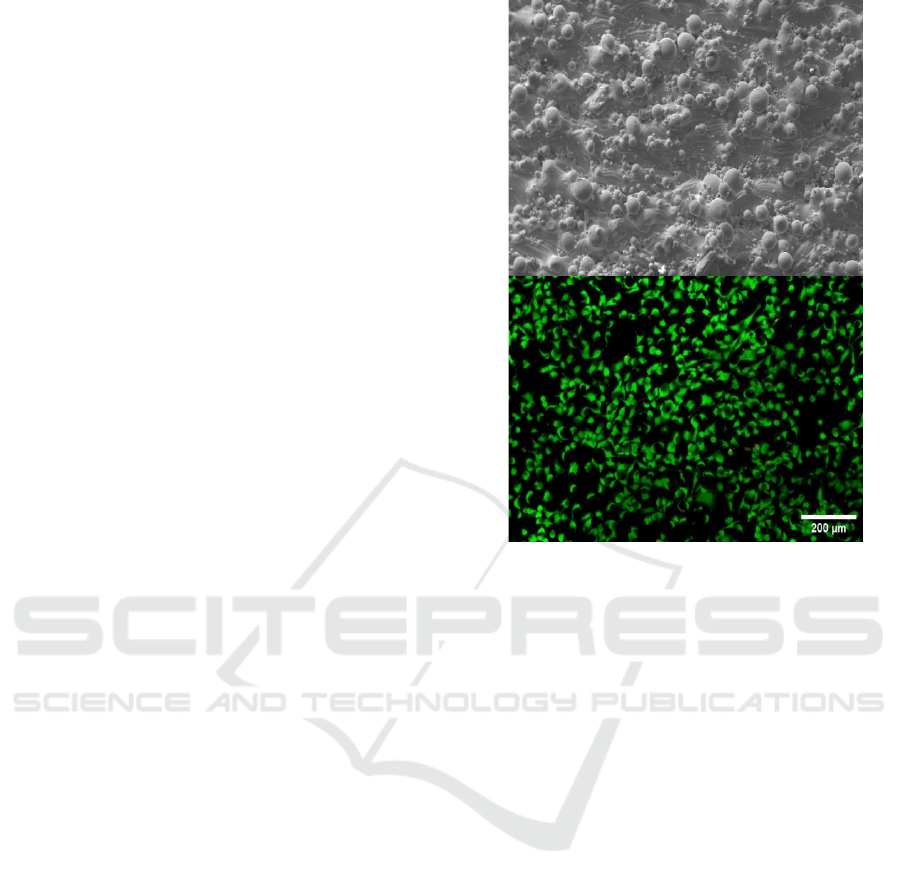

Summarizing, although preliminary results are

promising regarding the biocompatibility of

additively processed NiTi alloys for future

biomedical applications (f.e. figure 7), it is necessary

to further study several aspects, as detailed below.

5.2 Research Perspective

AMTs are continuously advancing and are expected

to lead to the processing of a wider range of NiTi

compositions and other SMAs. These combinations

may lead to high-performance devices, although their

biomedical applicability should be cautiously

analyzed, following guidelines from ISO Standard

10993.

In parallel, apart from increasing the portfolio of

additively processable alloys, other interesting

combinations between polymers and alloys, both with

shape-memory properties, should be studied for

achieving more versatile systems, capable of multiple

or stepped actuations, triggered at different

temperatures or by a variety of external stimuli, to

reach a new generation of smarter medical devices.

Among examples of the benefits of combining soft

polymeric phases with embedded SMA actuators it is

important to highlight the research by Akbari and cols

(Akbari, 2021).

Figure 7: Direct viability test, in which endothelial cells

(EA.hy926) are seeded upon a directly 3D printed surface

of NiTi (SEM image). The lower image shows live cells in

green and dead cells in red.

Together with the urgent need for internationally

accepted standards dealing with the safe and

straightforward development of high-quality

personalized medical implants, other ethical, legal

and social aspects demand careful attention for

making 4D printed SMAs truly transformative for

healthcare. Among them, healthcare technology

equity is probably the most remarkable. The key

question is: how do we accomplish that game-

changing technologies, such as high-performance

AMTs, come closer to the patients and users, in both

physical and economic terms, hence ensuring

accessible medical devices for all?

Challenging though it may be, some innovative

and inspiring equity-fostering approaches to

healthcare and production, in which additive

manufacturing technologies are key players, can be

highlighted. Do-it-yourself communities of “makers”

have already transformed several industrial fields and

their creative power, adequately canalized and

mentored to comply with internationally accepted

standards and applicable regulations, in connection

with open-source medical device initiatives, is

becoming a remarkable trend.

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

132

Thanks to open-innovation environments and to

the promotion of open-source approaches, the whole

development life-cycle can be arguably optimized

and reach to safer products by enhanced design peer-

review (De Maria, 2020). Regarding production and

supply chain issues, interconnected global networks

of additive manufacturing systems, working with

similar quality control procedures, are bound to

promote the print-on-demand of personalized

medical devices and to bring the production closer to

the point-of-care. As regards the accessibility of

expensive AM systems, strategies for making them

available to the community should be also explored.

ACKNOWLEDGEMENTS

The research presented has been supported by the

following research and innovation project:

“iMPLANTS-CM”, from the “Convocatoria 2020 de

ayudas para la realización de proyectos sinérgicos de

I+D en nuevas y emergentes áreas científicas en la

frontera de la ciencia y de naturaleza interdisciplinar”

funded by Comunidad Autónoma de Madrid

(reference: Y2020/BIO-6756).

REFERENCES

H. Lipson, “The Shape of Things to Come: Frontiers in

Additive Manufacturing,” 2011.

S. Yang and Y. F. Zhao, “Additive manufacturing-enabled

design theory and methodology: a critical review,” The

International Journal of Advanced Manufacturing

Technology, vol. 80, no. 1–4, pp. 327–342, Sep. 2015.

M. K. Thompson et al., “Design for Additive

Manufacturing: Trends, opportunities, considerations,

and constraints,” CIRP Annals, vol. 65, no. 2, pp. 737–

760, 2016.

S. Tibbits, “Design to Self-Assembly,” Architectural

Design, vol. 82, no. 2, pp. 68–73, Mar. 2012.

S. Tibbits and K. Cheung, “Programmable materials for

architectural assembly and automation,” Assembly

Automation, vol. 32, no. 3, pp. 216–225, Jul. 2012.

Q. Ge, H. J. Qi, and M. L. Dunn, “Active materials by four-

dimension printing,” Appl Phys Lett, vol. 103, no. 13,

p. 131901, Sep. 2013.

Q. Ge, C. K. Dunn, H. J. Qi, and M. L. Dunn, “Active

origami by 4D printing,” Smart Mater Struct, vol. 23,

no. 9, p. 094007, Sep. 2014.

R. Hahnlen and M. J. Dapino, “Active metal-matrix

composites with embedded smart materials by

ultrasonic additive manufacturing,” Mar. 2010, p.

76450O.

R. J. Friel, “Investigating the effect of ultrasonic

consolidation on shape memory alloy fibres,” 2011.

A. Y. Lee, J. An, and C. K. Chua, “Two-Way 4D Printing:

A Review on the Reversibility of 3D-Printed Shape

Memory Materials,” Engineering, vol. 3, no. 5, pp.

663–674, Oct. 2017.

J. Van Humbeeck, “Additive Manufacturing of Shape

Memory Alloys,” Shape Memory and Superelasticity,

vol. 4, no. 2, pp. 309–312, Jun. 2018.

W. Huang, “On the selection of shape memory alloys for

actuators,” Mater Des, vol. 23, no. 1, pp. 11–19, Feb.

2002.

S. de la Flor, “Simulación numérica y correlación

experimental de las propiedades mecánicas en las

aleaciones con memoria de forma.,” Tesis, Universitat

Politècnica de Catalunya, Barcelona, 2005.

F. Auricchio, E. Boatti, M. Conti, and S. Marconi, “SMA

biomedical applications,” in Shape Memory Alloy

Engineering, Elsevier, 2021, pp. 627–658.

M. Elsisy, M. Shayan, Y. Chen, B. W. Tillman, C. Go, and

Y. Chun, “Assessment of mechanical and

biocompatible performance of ultra-large nitinol

endovascular devices fabricated via a low-energy laser

joining process,” J Biomater Appl, vol. 36, no. 2, pp.

332–345, Aug. 2021.

Nasakina, Sudarchikova, Sergienko, Konushkin, and

Sevost’yanov, “Ion Release and Surface

Characterization of Nanostructured Nitinol during

Long-Term Testing,” Nanomaterials, vol. 9, no. 11, p.

1569, Nov. 2019.

K. Gegenschatz-Schmid et al., “Reduced thrombogenicity

of surface-treated Nitinol implants steered by altered

protein adsorption,” Acta Biomater, vol. 137, pp. 331–

345, Jan. 2022.

M. A. Obeidi et al., “Laser beam powder bed fusion of

nitinol shape memory alloy (SMA),” Journal of

Materials Research and Technology, vol. 14, pp. 2554–

2570, Sep. 2021.

N. Shayesteh Moghaddam et al., “Achieving superelasticity

in additively manufactured NiTi in compression

without post-process heat treatment,” Sci Rep, vol. 9,

no. 1, p. 41, Dec. 2019.

R. Paiotti Marcondes Guimaraes, F. Pixner, G. Trimmel,

and S. T. Amancio-Filho, “4-D Printing of NiTi Shape

Memory Alloys,” Sep. 2019. Accessed: Sep. 14, 2022.

M. Schwentenwein, P. Schneider, and J. Homa,

“Lithography-Based Ceramic Manufacturing: A Novel

Technique for Additive Manufacturing of High-

Performance Ceramics,” Oct. 2014, pp. 60–64.

A. Vyatskikh, S. Delalande, A. Kudo, X. Zhang, C. M.

Portela, and J. R. Greer, “Additive manufacturing of 3D

nano-architected metals,” Nat Commun, vol. 9, no. 1, p.

593, Dec. 2018.

J. Qiu, J. Tani, D. Osanai, Y. Urushiyama, and D.

Lewinnek, “High-speed response of SMA actuators,”

International Journal of Applied Electromagnetics and

Mechanics, vol. 12, no. 1–2, pp. 87–100, Feb. 2001.

S. Chonan et al., “Development of an artificial urethral

valve using SMA actuators,” Smart Mater Struct, vol.

6, no. 4, p. 004, Aug. 1997.

C. H. Park, K. J. Choi, and Y. S. Son, “Shape Memory

Alloy-Based Spring Bundle Actuator Controlled by

Additive Manufacturing of Nitinol for Smart Personalized Medical Devices: Current Capabilities and Challenges

133

Water Temperature,” IEEE/ASME Transactions on

Mechatronics, vol. 24, no. 4, pp. 1798–1807, Aug.

2019.

S. A. Mascaro and H. Harry Asada, “Wet Shape Memory

Alloy Actuators for Active Vasculated Robotic Flesh”.

A. Díaz Lantada, A. De Blas Romero, and E. C. Tanarro,

“Micro-vascular shape-memory polymer actuators with

complex geometries obtained by laser

stereolithography,” Smart Mater Struct, vol. 25, no. 6,

p. 065018, Jun. 2016.

R. Pfeifer et al., “Noninvasive induction implant heating:

An approach for contactless altering of mechanical

properties of shape memory implants,” Med Eng Phys,

vol. 35, no. 1, pp. 54–62, Jan. 2013.

C. W. Müller et al., “Transcutaneous electromagnetic

induction heating of an intramedullary nickel–titanium

shape memory implant,” Int Orthop, vol. 38, no. 12, pp.

2551–2557, Dec. 2014.

J. Zhou et al., “Hyperthermia by a nitinol stent in an

alternating magnetic field: Safety and feasibility in

rabbit esophageal cancer,” Progress in Natural Science,

vol. 19, no. 12, pp. 1713–1719, Dec. 2009.

R. N. Saunders, J. G. Boyd, D. J. Hartl, J. K. Brown, F. T.

Calkins, and D. C. Lagoudas, “A validated model for

induction heating of shape memory alloy actuators,”

Smart Mater Struct, vol. 25, no. 4, p. 045022, Apr.

2016.

M. Kadic, T. Bückmann, N. Stenger, M. Thiel, and M.

Wegener, “On the practicability of pentamode

mechanical metamaterials,” Appl Phys Lett, vol. 100,

no. 19, p. 191901, May 2012.

T. Frenzel, M. Kadic, and M. Wegener, “Three-

dimensional mechanical metamaterials with a twist,”

Science (1979), vol. 358, no. 6366, pp. 1072–1074,

2017.

M. Kadic, G. W. Milton, M. van Hecke, and M. Wegener,

“3D metamaterials,” Nature Reviews Physics, vol. 1,

no. 3, pp. 198–210, Mar. 2019.

K. S. Riley, K. J. Ang, K. A. Martin, W. K. Chan, J. A.

Faber, and A. F. Arrieta, “Encoding multiple permanent

shapes in 3D printed structures,” Mater Des, vol. 194,

p. 108888, Sep. 2020.

Y. Liu et al., “Synergistic effect enhanced shape recovery

behavior of metal-4D printed shape memory polymer

hybrid composites,” Compos B Eng, vol. 179, p.

107536, Dec. 2019.

S. Puthanveetil, W. C. Liu, K. S. Riley, A. F. Arrieta, and

H. le Ferrand, “Programmable multistability for 3D

printed reinforced multifunctional composites with

reversible shape change,” Compos Sci Technol, vol.

217, p. 109097, Jan. 2022.

J. Feng, J. Fu, Z. Lin, C. Shang, and B. Li, “A review of the

design methods of complex topology structures for 3D

printing”, doi: 10.1186/s42492-018-0004-3.

A. Díaz Lantada, A. De, B. Romero, and E. C. Tanarro,

“Micro-vascular shape-memory polymer actuators with

complex geometries obtained by laser

stereolithography,” 2016, doi: 10.1088/0964-

1726/25/6/065018.

N. Shayesteh Moghaddam et al., “Achieving superelasticity

in additively manufactured NiTi in compression

without post-process heat treatment,” Sci Rep, vol. 9,

no. 1, p. 41, Dec. 2019.

C. Wei, Z. Zhang, D. Cheng, Z. Sun, M. Zhu, and L. Li,

“An overview of laser-based multiple metallic material

additive manufacturing: from macro- to micro-scales,”

International Journal of Extreme Manufacturing, vol. 3,

no. 1, p. 012003, Jan. 2021.

J. Gan et al., “Effect of laser energy density on the evolution

of Ni4Ti3 precipitate and property of NiTi shape

memory alloys prepared by selective laser melting,” J

Alloys Compd, vol. 869, p. 159338, Jul. 2021.

C. Zhao, H. Liang, S. Luo, J. Yang, and Z. Wang, “The

effect of energy input on reaction, phase transition and

shape memory effect of NiTi alloy by selective laser

melting,” J Alloys Compd, vol. 817, p. 153288, Mar.

2020.

L. Xue et al., “Controlling martensitic transformation

characteristics in defect-free NiTi shape memory alloys

fabricated using laser powder bed fusion and a process

optimization framework,” Acta Mater, vol. 215, p.

117017, Aug. 2021.

G. Mani, D. Porter, K. Grove, S. Collins, A. Ornberg, and

R. Shulfer, “Surface finishing of Nitinol for implantable

medical devices: A review,” J Biomed Mater Res B

Appl Biomater, Jun. 2022.

C. Wen et al., “Mechanical behaviors and biomedical

applications of shape memory materials: A review,”

AIMS Mater Sci, vol. 5, no. 4, pp. 559–590, 2018.

B. L. Wang, L. Li, and Y. F. Zheng, “In vitro cytotoxicity

and hemocompatibility studies of Ti-Nb, Ti-Nb-Zr and

Ti-Nb-Hf biomedical shape memory alloys,”

Biomedical Materials, vol. 5, no. 4, p. 044102, Aug.

2010.

J. Lu, D. Khang, and T. J. Webster, “Greater endothelial

cell responses on submicron and nanometer rough

titanium surfaces,” J Biomed Mater Res A, vol. 9999A,

p. NA-NA, 2010.

S. K. Sinha, “Additive manufacturing (AM) of medical

devices and scaffolds for tissue engineering based on

3D and 4D printing,” in 3D and 4D Printing of Polymer

Nanocomposite Materials, Elsevier, 2020, pp. 119-160.

I. Lukin et al., “Can 4D bioprinting revolutionize drug

development?,” Expert Opin Drug Discov, vol. 14, no.

10, pp. 953–956, Oct. 2019.

L. Ionov, “4D Biofabrication: Materials, Methods, and

Applications,” Adv Healthc Mater, vol. 7, no. 17, p.

1800412, Sep. 2018.

S. Akbari, A. H. Sakhaei, S. Panjwani, K. Kowsari, and Q.

Ge, “Shape memory alloy based 3D printed composite

actuators with variable stiffness and large reversible

deformation,” Sens Actuators A Phys, vol. 321, p.

112598, Apr. 2021.

C. de Maria, L. di Pietro, A. Ravizza, A. D. Lantada, and A.

D. Ahluwalia, “Open-source medical devices:

Healthcare solutions for low-, middle-, and high-

resource settings,” Clinical Engineering Handbook,

Second Edition, pp. 7–14, Jan. 2020.

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

134