Bioinspired Design and Manufacturing Strategies for next

Generation Medical Implants: Trends and Challenges

Andrés Díaz Lantada

a*

, Adrián Martínez Cendrero, Francisco Franco Martínez

b

,

Rodrigo Zapata Martínez

c

, Carlos Aguilar Vega

d

, William Solórzano-Requejo

e

and Alejandro De Blas De Miguel

Department of Mechanical Engineering, ETSI Industriales, Universidad Politécnica de Madrid, Madrid, Spain

Keywords: Bioinspiration & Biomimetics, Medical Devices, Engineering Design, Additive Manufacturing.

Abstract: Bioinspired design and manufacturing strategies are enabling radical innovations in healthcare and medical

devices. The complex, functionally graded, fractal, multifunctional geometries and structures of nature are

inspiring for conceiving highly transformative biomedical engineering solutions, but highly challenging to

replicate. Decades (if not centuries) of research, together with a convergent collection of recently developed

and emergent software and hardware resources, empower our biomimetic design and manufacturing abilities

and render truly bioinspired solutions feasible. Such convergence is analyzed in this study and connected with

the engineering of next generation implants, characterized for their life-like features or even with quasi-living

behaviors. Synergic design and manufacturing technologies with remarkable impact in implants innovation,

tissue engineering, biofabrication and engineered living materials are presented and illustrated by means of

different case studies. Current research trends and challenges are discussed.

1 INTRODUCTION

The complex geometries of nature (Mandelbrot,

1983, Place, 2009), characterized by functionally

graded structures, hierarchical features, multi-

material extracellular matrices, dynamic tissues and

living cells within, lead to highly precious features

from an engineering point of view. Indeed, natural

living entities stand out for being remarkably

lightweight, self-regulated, stimuli-responsive (or

even smart), eco-efficient and truly multifunctional,

which inspires designers (Benyus, 2002).

Achieving some of the mentioned characteristics

has been a long-held dream for many scientists and

technology developers and has made of biomimetics

a fruitful area of study (Bar-Cohen, 2006). The

impact of bioinspiration in healthcare is outstanding

and has led to the birth of research fields like tissue

engineering, biofabrication and, more recently,

engineered living materials (ELMs).

a

https://orcid.org/0000-0002-0358-9186

b

https://orcid.org/0000-0002-7894-7478

c

https://orcid.org/0000-0002-2611-7050

d

https://orcid.org/0000-0003-0291-3041

e

https://orcid.org/0000-0002-2989-9166

In our experience, traditional implants usually

lack carefully conceived biomimetic design features.

Besides, they do not frequently benefit from recent

and ongoing advances in the computational

modelling of complex-shaped objects and fractal,

hierarchical or multi-scale geometries. Seldom are

they manufactured as patient-specific or personalized

medical solutions, as mass-production is currently the

industrial standard. In consequence, the potential

benefits of employing additive manufacturing

technologies (AMTs), also known as solid freeform

fabrication resources, are frequently discarded.

The limited personalization and the shortage of

biomimetic design strategies lead to suboptimal

implants in terms of biomechanical performance. All

kinds of articular implants, acting like thick bulk

metallic nails anchored to the remaining bone, suffer

from dramatic stress shielding phenomena due to the

mechanical mismatches between employed alloys

and bones.

42

Lantada, A., Cendrero, A., Martínez, F., Martínez, R., Vega, C., Solórzano-Requejo, W. and Blas De Miguel, A.

Bioinspired Design and Manufacturing Strategies for next Generation Medical Implants: Trends and Challenges.

DOI: 10.5220/0012363800003657

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 17th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2024) - Volume 1, pages 42-53

ISBN: 978-989-758-688-0; ISSN: 2184-4305

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

The compact structures employed for state-of-the-

art implants have nothing to do with the porous,

vascularized, functionally graded and multi-material

tissues present in bones and joints. Compliant

regions, such as those involving cartilage or

transitions between bones and ligaments or bones and

tendons are extremely complex to repair with mono-

material mass production techniques. In the

cardiovascular and neurological fields, it is common

to find stiff metallic implants interacting with very

soft tissues, which also generates undesired

biomechanical mismatches (Liverani, 2021). In

general, the bulk properties of synthetic materials

cannot match the combination of strength and

flexibility from natural ones. Derived synthetic

structures for potential biomedical implants are either

too stiff or lacking in strength.

Consequently, alternative biomimetic design and

manufacturing technologies are required for

modulating the stiffness of biomedical materials

usable for creating implants, without dramatically

affecting their strength and durability. This has been

a matter for research in the tissue engineering field for

more than two decades now and has been also

addressed, more recently, by the development and

application of biofabrication techniques. Important

advances have been achieved in terms of biomimetic

solutions, but their clinical impact is still very limited.

Next generation medical implants should be

conceived and developed according to new strategies

taking benefit of advanced design and manufacturing

technologies for enhanced biomimetics. In many

ways, these technologies transcend the classical

Bauhaus principle of “form follows function” (Droste,

2019), enabling a new engineering design paradigm.

In this reformulated approach, geometry, structure,

material and function are bound together, become

integral aspects of the same entity, thanks to the

freeform design input and the use of special

manufacturing resources that allow for a precise

definition of matter in three or even four dimensions.

Accordingly, the classical frontiers between

geometry, structure, material and function dissolve,

exactly as in natural living entities, which is also

pursued for next generation implants.

The following section presents some of the most

relevant bioinspired design features for next

generation implants. Subsequently, different design

strategies are presented, and synergic families of

manufacturing technologies discussed through use

cases. These involve AMTs, micro- and nano-

manufacturing resources, robotic technologies and

emergent synthetic biology related techniques.

2 DESIRED FEATURES FOR

“NEXT-GEN” IMPLANTS

2.1 Lightweight and Compliant

Natural materials and structures are consequence of

multi-objective optimizations achieved through

evolution and responses to environmental cues. The

structure of large bones in mammals, with the typical

external cortical region, inner trabecular core and

curvature (Bertram, 1988), are optimized for a

combination of bending and dynamic loads varying in

direction and constitute examples of lightweight

structures. In birds, skeletons have gone through

continuous adaptations to minimize the metabolic

cost of flight (Dumont, 2010). At the same time,

vertebrates count with different means for rendering

their bodies and biological structures compliant for a

better interaction with the external environment.

Kinematic chains of bones connected through

ligaments, like the spine and extremities, or the

cushion-like features of cartilage contribute to such

compliance. However, the medical device industry

has traditionally relied on highly stiff materials, like

steel or titanium alloys, and used mainly 100%

compact structures. These lack the desired

lightweight properties and compliance that biological

structures exhibit. Hence, innovative design and

manufacturing approaches are needed.

2.2 Functionally Graded

Biological structures also stand out for their usual

functional gradients of properties. The already

mentioned cortical-trabecular structure of bone is an

example of density, stiffness and strength gradients,

which also renders bone multifunctional by enabling

vascularization. Entheses, connective tissues between

tendon or ligament and bone, modulate stiffness

through functionally graded structures and by

combining different fibres, arrangements of extra-

cellular matrices and cells. Functional gradients of

properties are also found in synthetic biomechanical

replacements and are normally achieved by wise

geometrical designs, combinations of materials or

through functional coatings (Leong, 2008, Phillips,

2008). However, in order to perfectly mimic the

functionally gradients of biological materials and

structures, additional research is required. Taking

mechanobiology into account (Boccaccio, 2016,

Perier-Metz, 2022) constitutes a relevant design trend

for improved results.

Bioinspired Design and Manufacturing Strategies for next Generation Medical Implants: Trends and Challenges

43

2.3 Multi-Scale and Multi-Material

Essential functional gradients are also achieved in

nature thanks to the hierarchical, multi-scale or fractal

geometry that characterizes living tissues, organs and

systems. Our cells decode and transcribe DNA, our

lungs perform gas exchange, and our fingers play an

electric guitar or a piano thanks to the hierarchical

organization of our body. Nevertheless, multi-scale

features are not so common in classical medical

implants, apart from their increasingly frequent

hierarchical surfaces that lead to enhanced biological

interactions. These features indicate an interesting

path for bioinspired implant development.

At the same time, composites are very common in

biological structures. In the case of the human body,

ceramics and polymers co-exist in bones, whose

ceramic structure is interpenetrated by a polymeric

vascular network, and joints, with their osteochondral

transitions, to mention a couple of examples. Multi-

material articular prostheses, with ultra-high

molecular weight polyethylene capsules in between

metallic components, are common but their structures

and radical transitions not yet truly biomimetic.

2.4 Multifunctional and Smart

Functional gradients, combinations of constructive

building blocks and hierarchical structures render

biological systems multifunctional and smart, in the

sense of adequately responding or adapting to

external stimuli. Tissues perform several functions at

the same time: structural support, thermal stability,

energetic management, self-sensing, information

processing, acting, among others. These features are

seldom found in biomechanical replacements like

prostheses or orthoses. In fact, biological multi-

scaling and multifunctionality allows both for “plenty

of room at the bottom” (Feynman, 1959) and for

“plenty of room right here” (Bongard, 2023).

2.5 Dynamic and Living

Possibly the most challenging bioinspired properties

for next generation or “next-gen” implants are the

dynamism and liveness of biological entities. The

self-healing properties of biological structures, based

on extremely complex surveillance and repair

strategies; the natural mechanisms of growth and

biodegradation, which would be fundamental for

paediatric biomedical prostheses; the reconfigurable

and shape-morphing nature of several organs, to cite

a few, feature dynamism and liveliness. Still, they

prove extremely challenging to replicate.

3 BIOINSPIRED DEVELOPMENT

STRATEGIES

3.1 Lattices, Meshes and Woven

Structures

Straightforward combinations of computer-aided

design operations can rapidly lead to biomimetic

geometrical complexity built upon simple geometries

like cylindric trusses, square-section bars, spheric

pores, among others. Extrusions, lofts along splines,

Boolean and matrix-based design tools let us achieve

lattices, meshes and woven structures that imitate the

porous and compliant structures of several tissues. In

many cases, these geometries can be employed as

load bearing scaffolds for tissue repair, which have

set the foundations of tissue engineering and

biofabrication (Hutmacher, 2000, Harley, 2021). The

scaffolds, being porous, should allow for three-

dimensional cell culture, access to nutrients in vitro,

elimination of debris and vascularization in vivo. In

general, meshes and woven structures may be usable

for soft tissue repair, while lattices, depending on the

properties of raw materials employed, may lead to

advanced multipurpose implants.

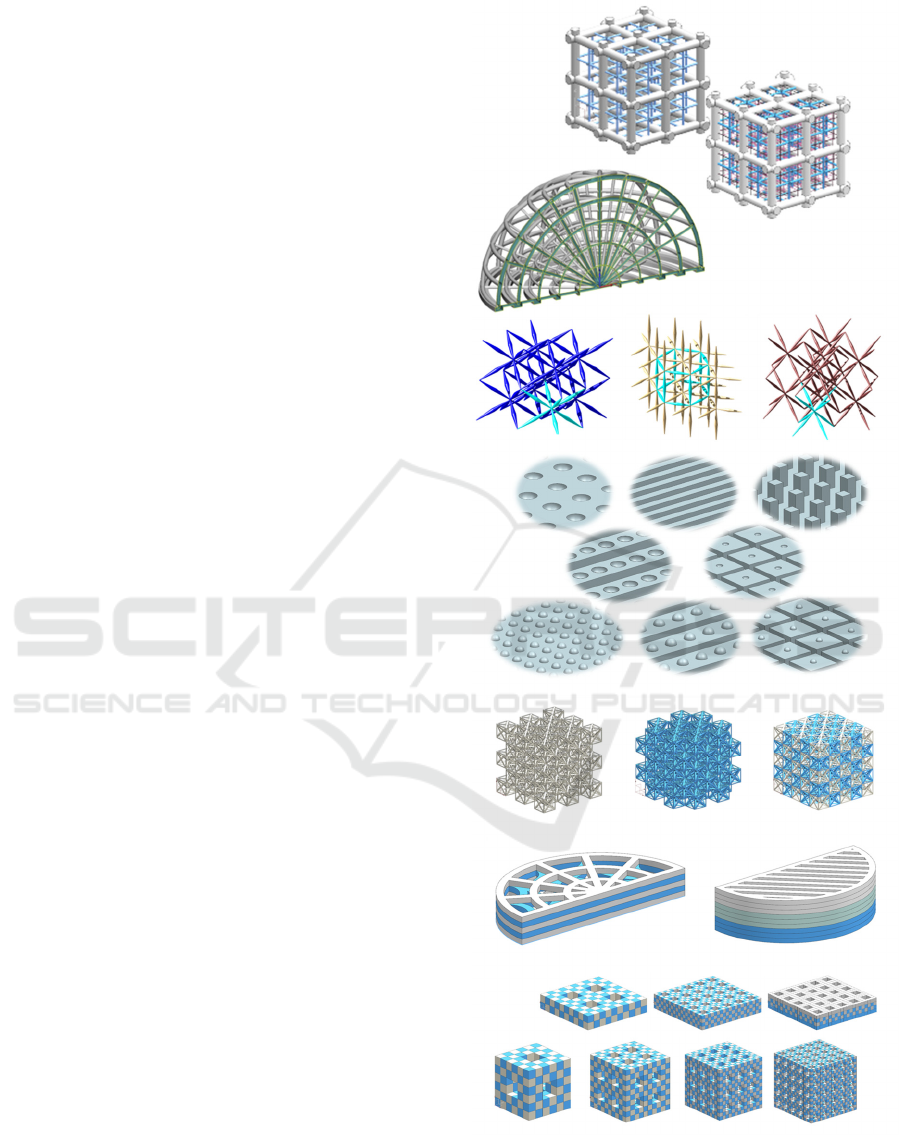

3.2 FGMs and Hierarchical Structures

Despite the benefits of quasi-periodic repetitions for

easily designing biomedical constructs with some

biomimetic features, in many cases an additional

level of complexity involving hierarchical and

functionally graded materials (FGMs) can lead to

enhanced biomechanical and biological performance.

Progressively, along the last decade, CAD modelling

resources have been complemented with specific

modules or with dedicated packages aimed at

performing very relevant design operations from a

biomimetic point of view. Nowadays, topology

optimization resources, conformal lattice design

tools, algorithmic CAD modelling software, to cite

some options, enable the generation of networks and

porous structures within computational models, the

application of lattices to desired working volumes and

the use of recursive approaches to reach multi-scale

hierarchical structures. These are already making a

remarkable impact in biomedical implants innovation

(Wang, 2016). In parallel, classical CAD modelling

and methodical procedures can also lead to multi-

scale features. Some examples of lattices and meshes

with functional gradients and hierarchical structures

are shown in figure 1 to illustrate the already

achievable geometrical complexity.

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

44

3.3 Metamaterials and Metasurfaces

The unconventional properties of biological materials

(stress-stiffening behaviours, unusual Poisson ratios,

stimuli-responsive abilities…) are challenging to

replicate with traditional materials. Metamaterials

and metasurfaces, thanks to their microstructures

being designed on purpose to achieve very unique

structural properties or surface interactions, constitute

an emergent path for creating biomimetic biodevices.

Their properties depend on their CAD-modelled

designed features more than on the raw materials

employed, which is remarkable. The advent of high-

performance AMTs is enabling their conceptual

application to healthcare (Zadpoor, 2019, 2020).

3.4 Composites, Digital Materials and

Voxelated Matter

Composite materials are also being reinvented by

computational design and manufacturing means,

which has led to concepts like digital materials and

voxelated matter (Bader, 2018, Skylar-Scott, 2019),

in which both structure and chemical composition are

precisely defined in 3D or 4D. Consequently, relevant

opportunities arise for biomedical implants better

imitating the composite and intricate structures and

compositions of living tissues.

3.5 Smart Materials and Structures

Smart materials and structures contribute to the final

biomimetic performance through enhanced multi-

functionality. In fact, smart, stimuli-responsive or

multi-functional materials incorporated to advanced

implants, may act as transducers for enabling self-

sensing and acting abilities. The possibility of

processing many of these families, such as shape-

memory polymers and alloys, piezoelectric materials,

electroactive polymers…, using solid freeform

fabrication technologies is bound to make their

incorporation to biodevices quite direct (Gardan,

2019).

3.6 Engineered Living Materials

Probably the ultimate degree of biomimicry may only

be achieved by resorting to biohybrid solutions, in

which synthetic materials, biological extracellular

matrices and living cells synergize, as in the case of

tissue engineering scaffolds, biofabricated constructs

and emergent engineered living materials (ELMs)

(Nguyen, 2018, Srubar III, 2020, Díaz Lantada,

2022).

Figure 1: Examples of CAD models showcasing different

bioinspired design strategies: multi-material and multi-

scale lattices, functionally graded structures, mechanical

metamaterials, microtextured biointerfaces, interwoven and

layered materials and voxelated matter.

Bioinspired Design and Manufacturing Strategies for next Generation Medical Implants: Trends and Challenges

45

4 ADVANCED COMPUTATIONAL

RESOURCES

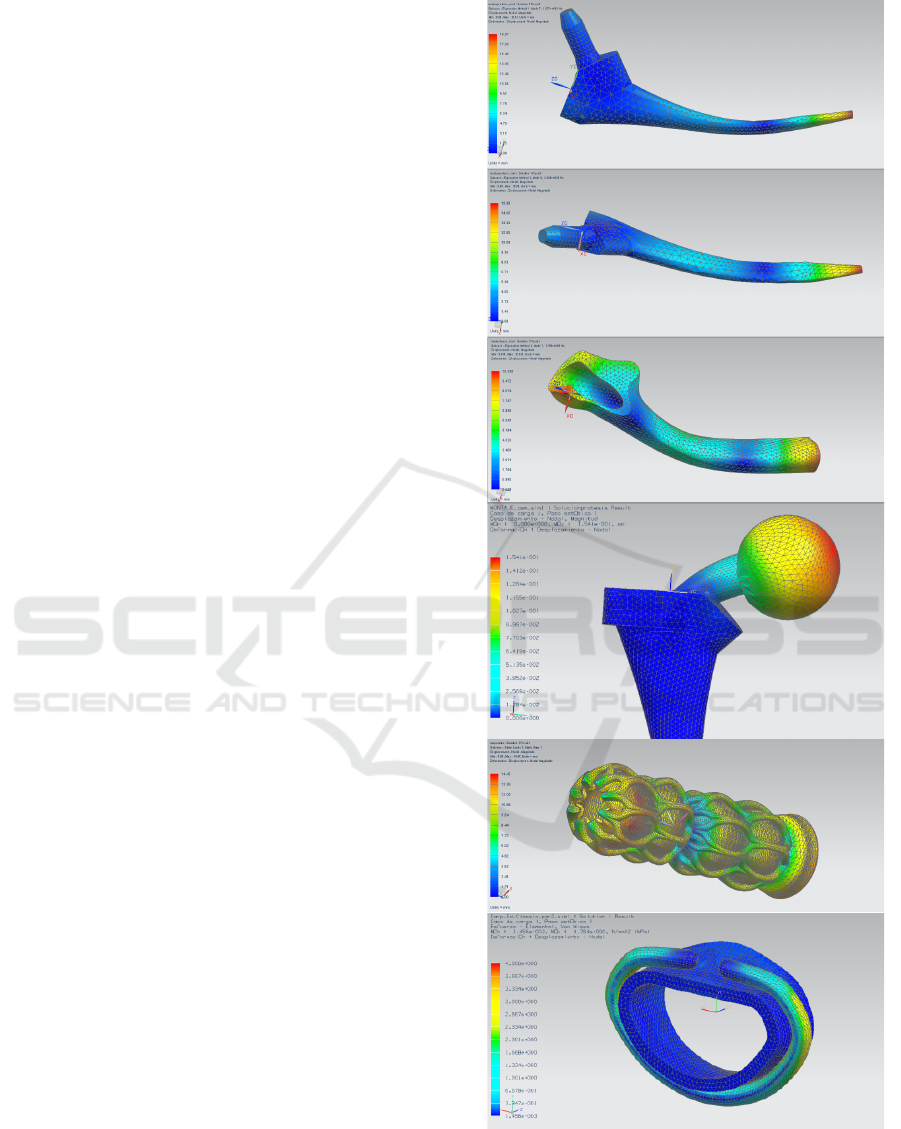

4.1 CAD Modelling and Simulations

The bioinspired development strategies from section

3, as regards advanced computational resources for

design purposes, are illustrated in this section and

exemplified through different examples connected to

the design, simulation and optimization of different

biomedical implants. To start with, CAD modelling

supported by simulations constitutes the statu quo for

designing and optimizing engineering components.

Geometries from implants can be designed, even in

personalized ways using input from patients’ medical

images, and their biomechanical performance

evaluated by simulations. Figure 2 presents examples

of the finite element method applied to assessing and

validating in silico different designs, before eventual

in vitro or ex vivo trials. These have been performed

with NX (Siemens PLM Solutions) as computational

modelling software. In fact, in silico methods (i.e.

simulations, digital twins…) are becoming more and

more relevant as an alternative to in vivo testing, even

for certification purposes, in a clear alignment with

the 3Rs principles (Tannenbaum, 2015).

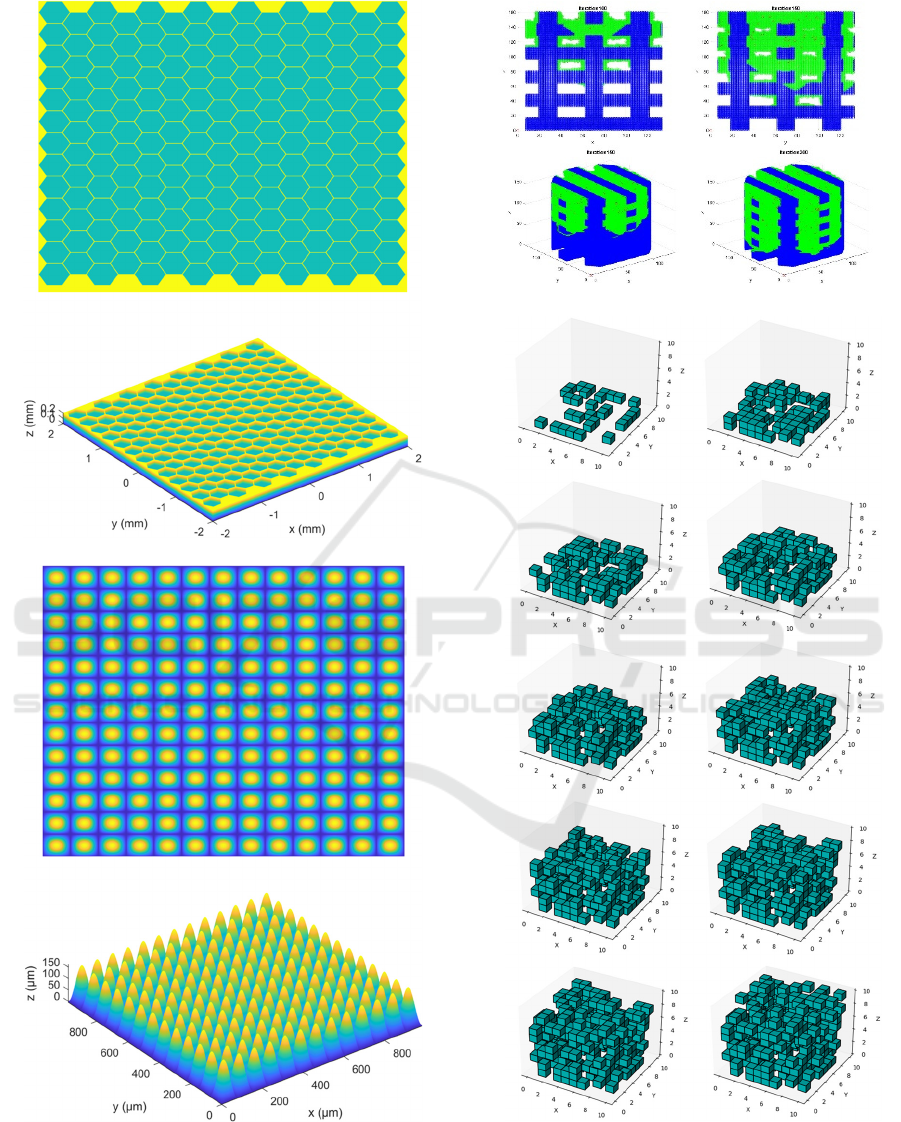

4.2 Topology and Topography

Optimization

For an increased degree of biomimicry, the porous

intricate networks that conform human tissues and

their functional surface topographies should be taken

into account. To this end, topology and topography

optimization resources, such as n-Topology and 3D

Coat, are a right choice. For instance, n-Topology (n-

Top) is applied to obtain the functionally graded and

bioinspired porous scaffolds designs of figure 3.

4.3 Math-Based Designs and

Algorithmic CAD

In a complementary way, math-based designs and

algorithmic CAD modelling are also usable for

achieving lattices, meshes, woven structures, textures

and metamaterials with biomimetic features. These

methods also apply to rapidly modifying parametric

designs for personalization purposes. By means of

example, figure 3 includes the algorithmic design of

a woven mesh for a stent-like device, while figure 4

presents the math-based design of innovative

biointerfaces (Franco Martínez, 2023).

Figure 2: FEM simulations upon CAD models (adapted

from Díaz Lantada, 2013): study of resonances in hip

prosthesis and femur, biomechanical performance of hip

replacement, interactions between transcatheter stent,

annuloplasty ring and surrounding tissues.

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

46

Figure 3: Topology optimized and functionally graded

tissue engineering scaffolds (upper images). Algorithmic

design of woven meshes for stent-like medical devices with

improved mechanical compliance (lower images).

4.4 Agents Based Modelling and

AI-Based Approaches

The hierarchical fractal features of the extracellular

matrices, the presence of living entities in biological

structures and their particular responses to a myriad

of environmental cues lead to irregular and random

features, which are almost impossible to imitate with

classical design software. To account for these

particular characteristics, the employment of agents-

based modelling -in which cells, pixels or voxels

iteratively and autonomously evolve in a sort of

“game of life”- adequately integrated with CAD

modelling and artificial intelligence (AI) methods,

can be an interesting solution (Von Neumann, 1966,

Gardner, 1970).

As an example, figure 5a presents the cellular

automata-based modelling (Matlab, The Mathworks

Inc.) of cells colonizing a 3D scaffolding structure, an

approach that can be applied with some modifications

to the modelling of porous networks and biomimetic

structures for biomedical devices (Díaz Lantada,

2023). Through this approach, it is possible to model

the influence of cell-material interactions and predict

aspects related to cellular colonization of scaffolds,

vascularization within porous implants, eventual

biodegradation of the implanted structures, among

other issues relevant for predicting the long-term

biocompatibility and understanding the interactions

between the abiotic structures and the living cells.

Another case study is presented in Figure 5b,

which illustrates the automated design of a porous

scaffolding structure employing cellular automata. It

has been programmed using Python and interactions

1 to 10 are presented. Initial seeds, iteration by

iteration, thanks to the defined growth rules, lead to a

voxelated structure. Different biomimetic properties

like porosity, functional gradients of stiffness,

eventual outer textures… can be achieved by minor

modifications of the growth rules.

A relevant aspect of these agents-based methods

is their adequacy for mimicking the randomness of

nature and their applicability to designing self-similar

fractured fractal geometries common in nature. Once

connected to artificial intelligence methods, which

are capable of screening biomechanical properties

and biointerfaces performance from the design stage

(Bermejillo Barrera 2021, Díaz Lantada, 2020),

automated design and optimization procedures can be

implemented.

Bioinspired Design and Manufacturing Strategies for next Generation Medical Implants: Trends and Challenges

47

a)

b)

Figure 4: a-b) Math-based design of micro- and nano-

textured biointerfaces for special cellular interactions

(adapted from Franco Martínez, 2023). Top and isometric

views. a) Hexagonal-based texture and b) lotus flower

leave-like pattern.

a)

b)

Figure 5: a) Cellular automata modelling of cells colonizing

scaffolds, (adapted from: Díaz Lantada, 2023). b)

Automated design of porous scaffolding structure

employing cellular automata: iterations 1 to 10.

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

48

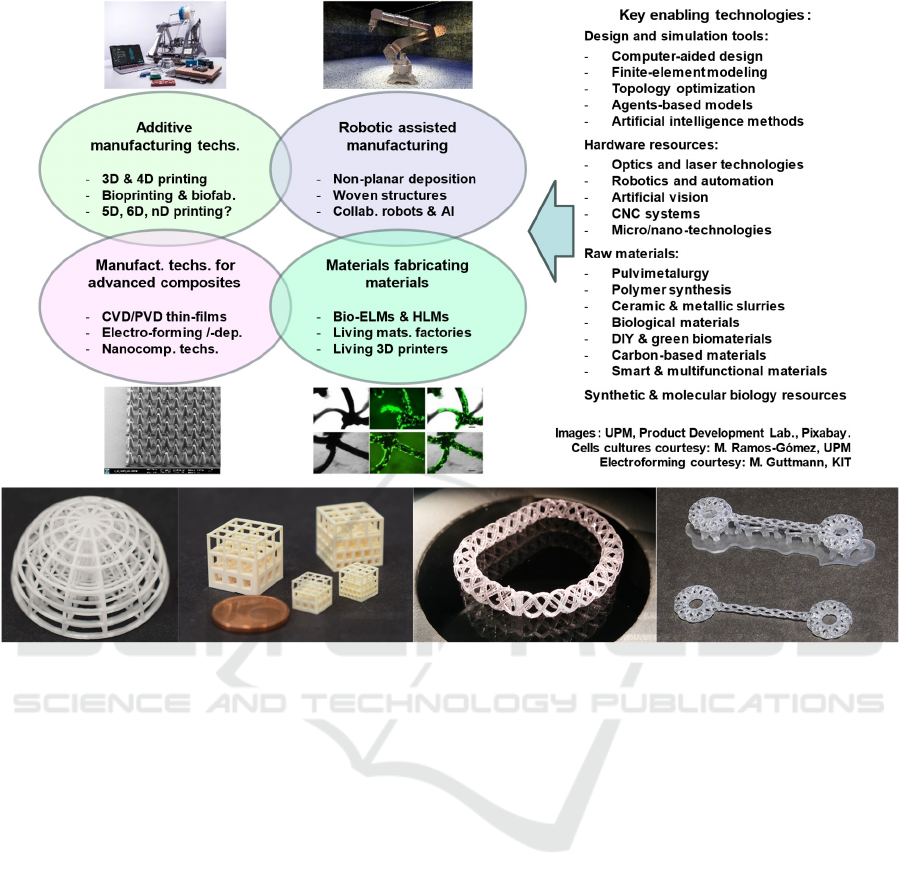

5 ADVANCED

MANUFACTURING

RESOURCES

5.1 Additive Manufacturing

Technologies

The degree of geometrical complexity achieved with

advanced computational resources can only be

materialized thanks to the advent of some special

families of manufacturing technologies analyzed in

this section and schematically illustrated in figure 6.

Among these advanced resources, additive

manufacturing technologies, most of them invented

during the 1980s and 1990s, and importantly

improved in terms of resolution, precision and

processable materials along the first two decades of

the 21

st

Century, stand out for the freedom of creation

they enable. Indeed, AMTs (a.k.a. 3D printing

technologies) usually work on a layer-by-layer

fashion, depositing or changing the physical/chemical

state of the raw materials being processed, employing

written lines, pixels or voxels as building blocks. In a

way, material, structure and product are being created

at the same time, which leads on many occasions to

an integration of functions through geometrical

complexity. The additive approach enables the

creation of meshes, lattices, porous structures,

interwoven geometries, metamaterials, common in

nature, but impossible or very challenging to achieve

with traditional methods. An additional benefit of

AMTs is the autonomous processing directly from the

computational models.

From the very beginning, AMTs were applied to

the biomedical field. At first, they were used for

creating surgical training and planning models, and as

a complement to medical diagnostic technologies, but

progressively also for the direct fabrication of

orthoses and prostheses (Díaz Lantada, 2012).

Nevertheless, the expansion of their materials

portfolio, especially the increasing possibility of

manufacturing with a wide set of biomedical

materials including polymers, metals and ceramics,

has recently led to very relevant transformations in

the medical industry. Among them, the increase of

personalized implants is a clear industrial trend.

Furthermore, AMTs have helped to set the

foundations of biomedical research fields like tissue

engineering and biofabrication, which are radically

reformulating the therapeutic strategies for

biomechanical tissue repair and regeneration

(Hutmacher, 2000, Harley, 2021).

5.2 Robotic-Assisted Manufacturing

Progresses in robotics synergize with AMTs and

contribute to healthcare innovation. 5-axis, 6-axis, 7-

axis robots, with the possibility of moving along the

x, y, z axes and performing additional movements,

like roll, pitch and yaw, and of being mounted upon

linear paths in production facilities, may outperform

AMTs in some aspects. The use of robots for freeform

fabrication by deposition of material, taking

inspiration from 3D printing, has led to the concepts

of “5D-, 6D-, 7D-printing”, depending on the number

of axes employed (Haleem, 2019, Vasiliadis, 2022).

Biomedical applications are indeed being explored,

especially in fields like tissue engineering and

biofabrication, in which non-planar deposition paths

may be biomechanically remarkable compared to

those achievable by 3D printing.

5.3 Manufacturing of Advanced

Micro/Nano-Composites

Micro and nanomanufacturing technologies, such as

chemical and physical vapour deposition, UV-photo-

lithography, electrochemical deposition, to cite a few,

synergize with the aforementioned technologies in

the quest for enhanced implants. As advanced, most

tissues have a functionally graded and composite

nature, for which the synthetic creation of graded,

multi-layered and composite materials and structures

is fundamental. Functionalized biomaterials that can

be additively processed to achieve micro/nano-

composites and the use of multi-material printing

technologies creating voxelated composites are also

becoming relevant for smart implants (Velu, 2019).

5.4 Synthetic Biology, Tissue

Engineering, Biofabrication

Last but not least, methods from synthetic biology,

tissue engineering and biofabrication enable the

processing of living cells and their employment,

together with biomaterials, as building blocks for

highly innovative healthcare products. Scaffolds with

cells are advanced medicinal products, not just

medical devices, and enter the realm of engineered

living materials (ELMs) (Srubar III, 2020, Díaz

Lantada, 2022). The boundaries of biomimicry are

hence expanded and may even lead to living

biomaterials as biomaterials factories (Niemeyer,

2018, Nguyen, 2018).

Bioinspired Design and Manufacturing Strategies for next Generation Medical Implants: Trends and Challenges

49

a) b) c) d)

Figure 6: Schematic representation of synergic families of advanced manufacturing technologies enabling the engineering of

biomimetic biodevices: additive manufacturing technologies, robotic assisted manufacturing, technologies for advanced

composites and micro-/nano-composites and resources derived from synthetic biology. Key enabling technologies and raw

materials for these families of advanced manufacturing technologies are also presented. Illustrative examples of achievable

complexity include prototypes of: b) functionally graded tissue engineering ceramic scaffolds (courtesy of Lithoz GmbH,

Tomax project), c) concepts for annuloplasty reconstruction and d) tendon repair lattices (UPM, Product Development Lab).

6 APPLICATION CASES

6.1 Bioinspired Hip Prosthesis

Two conceptual application cases are presented in

this section to illustrate synergies between varied

design strategies aiming at enhanced biomimicry.

First, a bioinspired hip prothesis stem is designed,

as schematically shown in figure 7. The design stands

out for combining: 1) a biomechanical short structure

for minimizing stress-shielding; 2) a topology

optimization for achieving a graded network that

mimics the trabecular and cortical regions; and 3) a

selective application of bioinspired biointerfaces to

different regions, in which osseointegration and

vascularization should be selectively promoted.

6.2 Bioinspired Vascular Stent

Second, a bioinspired vascular stent is designed, as

illustrated in figure 8. Its compliant mesh is surface

functionalized by means of two microtextures. The

external one is aimed at the improved interaction with

the endothelial cells by using a pattern that imitates

the extracellular matrix of the blood vessels. The

internal biointerface is conceived for simultaneously

promoting blood flow and minimizing blood clotting

by employing a bioinspired shark skin design.

In both cases, materialization of the presented

designs would rely on ultra high-performance AMTs

capable of processing the adequate biomedical

materials with the desired precision, which is still a

current challenge, as happens with in vitro validation.

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

50

Figure 7: Multifunctional topography optimization of a

short stem hip prosthesis. a) Biomechanically optimized

short stem for femoral implantation. The conceptual design

counts with different biointerfaces defined from the design

stage according to desired biological features. b) Topology

and topography-optimized solution. c-e) Topography

optimization with textures mimicking the shark skin in

regions where different flow orientations would be desired.

d) Bone-like surface topography for enhanced

osseointegration and increased primary stability.

Figure 8: Innovative design for vascular stent with

bioinspired surface topographies. The design process

includes: a) Creation of unit cell. b) Application of

topography optimizations. c) Design of basic ring. d)

Replication towards complete stent. e) Detailed inner

texture imitating shark skin for enhanced hemodynamics. f)

Detailed external texture in contact with arterial wall for

improved adhesion and long-term stability of the stent

(avoiding slippery and preventing migration).

Bioinspired Design and Manufacturing Strategies for next Generation Medical Implants: Trends and Challenges

51

7 CONCLUSIONS

The geometrical and material complexity of living

biological structures has been traditionally extremely

challenging to imitate, which used to derive in

suboptimal biomedical devices and implants, whose

biomechanical behavior and biological interaction

properties were not truly biomimetic.

Fortunately, bioinspired development strategies

and advanced computational and manufacturing

resources, as explained and exemplified in this study,

are already synergizing in a highly stimulating way to

solve the riddles of natural materials and biological

structures. The quest for next generation bioinspired

implants is just starting and requires integrative

research efforts from as many fields as possible.

Towards the future, further expanding the

biomaterials portfolio of advanced manufacturing

technologies and exploring new ways of jointly

processing biomaterials and living entities like cells

and bacteria, in clear alignment with the nascent field

of engineered living materials, can contribute to

bringing biomimicry a step beyond.

In addition, if the implants of the future may rely

on biohybrid solutions, there is a need for updated

regulations and standards. In the European Union, to

take an example, implants and tissue engineering

scaffolds without cells are usually Class III medical

devices, according to the Medical Device Regulation

2017/745, while scaffolds with cells are still

considered advanced therapy medicinal products

according to regulation 1394/2007. Further efforts in

regulation and standardization harmonization are

needed in this continuously evolving field.

Arguably, through expanded bioinspired and

biomimetic development strategies and technological

capabilities the biomedical implants of the future will

importantly outperform the state-of-the-art and,

hopefully, become the perfect solutions for users’

biological structures needing repair or regeneration.

ACKNOWLEDGEMENTS

The research presented has been supported by the

following research and innovation projects:

“iMPLANTS-CM”, from the “Convocatoria 2020 de

ayudas para la realización de proyectos sinérgicos de

I+D” funded by Comunidad Autónoma de Madrid

(reference: Y2020/BIO-6756). “INKplant” funded

by the European Union’s Horizon 2020 Research and

Innovation Programme under grant agreement No.

953134.

REFERENCES

Bader, C. et al. (2018) ‘Making data matter: Voxel printing

for the digital fabrication of data across scales and

domains’, Science Advances, 4(5), p. eaas8652.

Bar-Cohen, Y. (2006) ‘Biomimetics--using nature to

inspire human innovation’, Bioinspiration &

Biomimetics, 1(1), pp. 1–12.

Benyus, J.M. (2002) ‘Biomimicry: innovation inspired by

nature’, Harper Perennial, Harper Collins, New York,

USA.

Bermejillo Barrera, M.D., Franco-Martínez, F., Díaz

Lantada, A. (2021) ‘Artificial Intelligence Aided

Design of Tissue Engineering Scaffolds Employing

Virtual Tomography and 3D Convolutional Neural

Networks’. Materials, 14(18), 5278.

Bertram, J.E. and Biewener, A.A. (1988) ‘Bone curvature:

sacrificing strength for load predictability?’, Journal of

Theoretical Biology, 131(1), pp. 75–92.

Boccaccio, A. et al. (2016) ‘Geometry Design Optimization

of Functionally Graded Scaffolds for Bone Tissue

Engineering: A Mechanobiological Approach’, PLOS

ONE, 11(1), p. e0146935.

Bongard, J. and Levin, M. (2023) ‘There’s Plenty of Room

Right Here: Biological Systems as Evolved,

Overloaded, Multi-Scale Machines’, Biomimetics,

8(1), p. 110.

Dumont, E.R. (2010) ‘Bone density and the lightweight

skeletons of birds’, Proceedings of the Royal Society B:

Biological Sciences, 277(1691), pp. 2193–2198.

Díaz Lantada, A. (ed.) (2013) Handbook on Advanced

Design and Manufacturing Technologies for

Biomedical Devices. Boston, MA: Springer US.

Díaz Lantada, A., Franco-Martínez, F., Hengsbach, S.,

Rupp, F., Thelen, R., Bade, K. (2020) Artificial

Intelligence Aided Design of Microtextured Surfaces:

Application to Controlling Wettability. Nanomaterials,

10(11), 2287.

Díaz Lantada, A., Korvink, J.G. and Islam, M. (2022)

‘Taxonomy for engineered living materials’, Cell

Reports Physical Science, 3(4), p. 100807.

Díaz Lantada, A. and Morgado, P.L. (2012) ‘Rapid

Prototyping for Biomedical Engineering: Current

Capabilities and Challenges’, Annual Review of

Biomedical Engineering, 14(1), pp. 73–96.

Díaz Lantada, A., Sánchez, M.U. and Fernández, D.F.

(2023) ‘In silico Tissue Engineering and Cancer

Treatment Using Cellular Automata and Hybrid

Cellular Automata-Finite Element Models’, in. 16th

International Conference on Biomedical Electronics

and Devices, pp. 56–63.

Droste, M. (2019) ‘Bauhaus 1919-1933. Updated Edition’.

Taschen, commemorative edition for the 100th

anniversary of Bauhaus.

Feynman, R.P. (1959) ‘Plenty of Room at the Bottom’.

Lecture at the annual American Physical Society

meeting at Caltech.

Franco Martínez, F. (2022) ‘Artificial intelligence aided

design of microstructured surfaces for tribology and

BIODEVICES 2024 - 17th International Conference on Biomedical Electronics and Devices

52

biointerfaces engineering’, PhD thesis, Universidad

Politécnica de Madrid.

Gardan, J. (2019) ‘Smart materials in additive

manufacturing: state of the art and trends’, Virtual and

Physical Prototyping, 14(1), pp. 1–18.

Gardner, M. (no date) ‘Conway’s Game of Life: Scientific

American, October 1970’, Scientific American, 223,

pp. 120–123.

Haleem, A., Javaid, M. and Vaishya, R. (2019) ‘5D printing

and its expected applications in Orthopaedics’, Journal

of Clinical Orthopaedics and Trauma, 10(4), pp. 809–

810.

Harley, W.S. et al. (2021) ‘Advances in biofabrication

techniques toward functional bioprinted heterogeneous

engineered tissues: A comprehensive review’,

Bioprinting, 23, p. e00147.

Hutmacher, D.W. (2000) ‘Scaffolds in tissue engineering

bone and cartilage’, Biomaterials, 21(24), pp. 2529–

2543.

Leong, K.F. et al. (2008) ‘Engineering functionally graded

tissue engineering scaffolds’, Journal of the Mechanical

Behavior of Biomedical Materials, 1(2), pp. 140–152.

Liverani, E., Rogati, G., Pagani, S., Brogini, S., Fortunato,

A. and Caravaggi, P. (2021) ‘Mechanical interaction

between additive-manufactured metal lattice structures

and bone in compression: implications for stress

shielding of orthopaedic implants’, Journal of the

Mechanical Behavior of Biomedical Materials, 121,

104608.

Mandelbrot, B.B. (1983) The Fractal Geometry of Nature.

Henry Holt and Company.

Neumann, J.V. and Burks, A.W. (1966) Theory of Self-

Reproducing Automata. USA: University of Illinois

Press.

Nguyen, P.Q. et al. (2018) ‘Engineered Living Materials:

Prospects and Challenges for Using Biological Systems

to Direct the Assembly of Smart Materials’, Advanced

Materials (Deerfield Beach, Fla.), 30(19), p. e1704847.

Niemeyer, C.M. et al. (2018) ‘White Paper on the

Biologization of Materials Research’. Preprints.

Perier-Metz, C., Duda, G.N. and Checa, S. (2022) ‘A

mechanobiological computer optimization framework

to design scaffolds to enhance bone regeneration’,

Frontiers in Bioengineering and Biotechnology, 10.

Phillips, J.E. et al. (2008) ‘Engineering graded tissue

interfaces’, Proceedings of the National Academy of

Sciences, 105(34), pp. 12170–12175.

Place, E.S., Evans, N.D. and Stevens, M.M. (2009)

‘Complexity in biomaterials for tissue engineering’,

Nature Materials, 8(6), pp. 457–470.

Skylar-Scott, M.A. et al. (2019) ‘Voxelated soft matter via

multimaterial multinozzle 3D printing’, Nature,

575(7782), pp. 330–335.

Srubar III, W.V. (2020) ‘Engineered living materials:

taxonomies and emerging trends’, Trends in

Biotechnology, 39(6), pp. 574-583.

Tannenbaum, J. and Bennett, B.T. (2015) ‘Russell and

Burch’s 3Rs Then and Now: The Need for Clarity in

Definition and Purpose’, Journal of the American

Association for Laboratory Animal Science, 54(2).

Vasiliadis, A.V., Koukoulias, N. and Katakalos, K. (2022)

‘From Three-Dimensional (3D)- to 6D-Printing

Technology in Orthopedics: Science Fiction or

Scientific Reality?’, Journal of Functional

Biomaterials, 13(3), p. 101.

Velu, R. et al. (2019) ‘A Comprehensive Review on Bio-

Nanomaterials for Medical Implants and Feasibility

Studies on Fabrication of Such Implants by Additive

Manufacturing Technique’, Materials, 13(1), p. 92.

Wang, X. et al. (2016) ‘Topological design and additive

manufacturing of porous metals for bone scaffolds and

orthopaedic implants: A review’, Biomaterials, 83, pp.

127–141.

Zadpoor, A.A. (2019) ‘Mechanical performance of

additively manufactured meta-biomaterials’, Acta

Biomaterialia, 85, pp. 41–59.

Zadpoor, A.A. (2020) ‘Meta-biomaterials’, Biomaterials

Science, 8(1), pp. 18–38.

Bioinspired Design and Manufacturing Strategies for next Generation Medical Implants: Trends and Challenges

53