An Open-Source Approach to OT Asset Management in Industrial

Environments

Luca Pöhler

a

, Marko Schuba

b

, Tim Höner

c

, Sacha Hack

d

and Georg Neugebauer

e

Department of Electrical Engineering and Computer Science, FH Aachen University of Applied Sciences,

Eupener Str. 70, 52066 Aachen, Germany

Keywords: OT, ICS, OT Security, Risk Management, Asset Management, Asset Discovery, Asset Inventory.

Abstract: The need for compliance and the growing number of IT security threats force many companies to improve

their level of IT security. At the same time, new legal regulations and the trend to interconnect IT with

automation environments (operational technology, OT) lead to the situation that IT security and OT security

need to be approached at the same time. However, OT differs from IT in several aspects and many well-

established IT security procedures cannot simply be copied to OT networks. As in IT the first step to establish

an acceptable security level for OT is to perform a proper risk assessment. Available tools that support OT

asset management are either expensive or they do not provide the functionality needed. In the context of this

paper a new open-source approach to OT asset management is presented. The tool that was developed to

collect OT assets considers the specific characteristics of OT devices, the sensitivity of production

environments, and the typically rudimentary starting situation of many real-world machine operators while

being free of charge at the same time.

1 INTRODUCTION

The global cybersecurity threat situation continues to

stay critical (Crowdstrike, 2023). Operational

technology (OT) environments are becoming

increasingly attractive to threat actors. The German

Federal Office for Information Security 2022 annual

report on the state of IT security in Germany shows

that attacks affecting OT are becoming more

common. Examples include the state-sponsored

attack on the power grid in Ukraine, the collateral

damage caused by an attack on a satellite service

controlling German wind turbines, rendering 5,800

turbines inaccessible, or the cyberattack on German

oil traders (BSI, 2022, p.49 f).

To mitigate the risks of industrial plants and

increase their resilience, it is necessary to approach

the topic of OT security in a structured manner. The

basis of a functioning information security

management system - also in OT - is always a

systematic risk management. This in turn requires

knowledge of all IT and OT assets. In the field, asset

a

https://orcid.org/0009-0007-5648-0559

b

https://orcid.org/0000-0002-3302-3060

c

https://orcid.org/0009-0006-0224-6292

management is still suboptimal and has high potential

for improvement in both IT and OT. Especially in the

OT environment, the knowledge of own OT assets is

often poor. If at all, OT assets are inventoried in Excel

files, a tedious, unreliable and expensive method of

asset management.

The purpose of this paper is to present an open-

source tool that can significantly improve asset

management for OT in many organizations. The goal

is to create an extensible, free and open-source tool

that considers OT-specific characteristics and

delivers similarly good results as commercial tools.

2 BACKGROUND

2.1 Operational Technology

Operational technology includes programmable

systems and devices that interact with the physical

environment. OT devices can detect changes in this

environment or can trigger changes to it (NIST, 2023).

d

https://orcid.org/0000-0001-6624-0486

e

https://orcid.org/0009-0008-0927-2324

128

Pöhler, L., Schuba, M., Höner, T., Hack, S. and Neugebauer, G.

An Open-Source Approach to OT Asset Management in Industrial Environments.

DOI: 10.5220/0012362200003648

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 10th International Conference on Information Systems Security and Privacy (ICISSP 2024), pages 128-136

ISBN: 978-989-758-683-5; ISSN: 2184-4356

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

Besides the application area of industrial plants -

here OT systems are often referred to as Industrial

Control Systems (ICS) - OT is also used in other

areas, e.g., building automation or in vehicles. Even

though the focus of this paper is on industrial plants,

the term OT will continue to be used instead of ICS

because the results can in principle be extended to

other OT application areas.

2.2 OT Systems and Devices

OT systems and devices are often based on

proprietary hardware and software and come from a

multitude of manufacturers, including sensors and

actuators, programmable logic controllers (PLC),

supervisory control and data acquisition systems

(SCADA), manufacturing execution systems (MES),

or enterprise resource planning (ERP) systems (IEC

62441-1, 2013; Sauer et al., 2019).

Other typical devices in the OT area are Human

Machine Interfaces (HMI) and Engineering

Workstations (EWS).

2.2.1 OT and Related Protocols

In contrast to the private or office IT area, where

TCP/IP is mostly used via Ethernet or WLAN, there

are many different protocols in the OT area. Two

prominent examples are Modbus and Profinet.

The Modbus serial protocol is now an open and

very widely used protocol (Schneider Electric, 2022).

Modbus is available in several variants, one of which

is Modbus TCP (Transmission Control Protocol), that

can transmit Modbus data units over the standard

Internet protocols TCP and IP (Internet Protocol).

The Process Field Network (Profinet) protocol is

the successor to the older Profibus protocol and is

based on Ethernet TCP/IP (PI, 2023). Industrial

Ethernet, as implemented by Profinet, has become the

standard technology for automation systems and will

replace the fieldbus implementations over time.

Due to the increasing implementation of OT

protocols via TCP/IP, underlying protocols of classic

IT are also becoming relevant, in particular Ethernet

and the Address Resolution Protocol (ARP) (RFC

826, 1982).

2.3 OT Asset Management

In principle, it is essential in today's world to know

which components are in use. Sensible risk

management, for example, is only possible if you

know exactly which systems you have and which

software they use (Kassa, 2017), i.e. the security of IT

or OT correlates with the knowledge of the assets.

2.3.1 Asset Management Process

Asset management is a continuous process that is

more than just inventory. The process starts with the

identification of the asset and the inclusion of this

asset in the data management. To do this, the

organization must first determine which systems are

relevant. Once the asset is included, its information

must be permanently maintained, checked and

possibly updated. This means the information must be

kept up to date, and possible changes, for example

new threats, must be reacted to. Here, various

processes come into play that, depending on the

definition, belong to asset management or work

closely together with it.

A well-known model for the life cycle of IT assets

is the so-called IMAC model. In full, this is also

referred to as IMAC/R/D (Bluhm, 2020). IMAC

stands for Install, Move, Add and Change, with

Remove and Dispose being added in the complete

model, describing phases, or processes, that an asset

usually passes throughout its life cycle.

In addition, there are processes that are either part

of the asset management system, or at least closely

linked to it.

Patch management is responsible for checking the

version status of all installed software and identifying

possible updates.

Closely related to patch management is

vulnerability management. This monitors system

vulnerabilities and categorizes them based on their

impact and the likelihood that they will occur. If a

vulnerability has a major impact on an organization

and is also very likely to occur, it should be

considered critical and should be dealt with as quickly

as possible.

2.3.2 Reasons for OT Asset Management

The reason for the now fundamental importance of

OT asset management is partly due to the fact that OT

security has found its way into legislation.

In Germany, for example, there are requirements

for OT asset management that can be derived directly

from the IT-Sicherheitsgesetz 2.0 (IT Security Act

2.0; BSI, 2020) or the Maschinenverordnung

(Machinery Ordinance; BMJ, 2021). At the European

level, similar requirements follow from the Cyber

Resilience Act (EU, 2023). In the USA, there are

NIST recommendations on the same topic (NIST,

2023).

In general, asset management in OT must consider

the specific characteristics of OT (cf. NIST, 2023).

An Open-Source Approach to OT Asset Management in Industrial Environments

129

While automated asset management tools are

obviously efficient and avoid human error,

organizations should consider how the tool collects

information and whether the collection method (e.g.,

active scanning) may have a negative impact on their

OT systems. If problems are expected here, NIST

recommends that the organization consider manual

processes to maintain current inventory.

3 STATE OF THE ART

The topic of OT asset management is a very practical

one, which is why the state of the art includes work

from the field of applied research as well as

commercial solutions. The latter usually require

licenses that need to be bought. In a few cases, free

but limited demo version are available, however,

those are not very useful in real use cases. In addition,

not all information for the commercial tools is

publicly available, so the accessible statements of the

manufacturers must be relied upon.

3.1 Research on OT Asset Management

OT asset management is not a new topic. As early as

2005, ABB Switzerland Ltd. dealt with the "IT Asset

Management of Industrial Automation" (Gelle,

2005). However, this was not a general solution to the

problem, but a proprietary solution for ABB's own

automation system 800xA. Similar solutions can be

found from many manufacturers in the industrial

sector. However, since very few integrators or

operators of plants exclusively use a (single) product

(variant) of a single manufacturer, these solutions are

often not useable.

Other works like "A literature survey on asset

management in electrical power [transmission and

distribution] system" (Khuntia, 2016) or

"Development of a concept for OT asset management

in the production environment" (Koch, 2021) deal

with the theoretical basics of asset management in

OT. These are by no means to be neglected, but in

practice they do not provide the necessary

opportunity for a company to set up an asset

management system.

Many projects such as "OT-asset CMDB

Solutions" (Koskelo, 2020) look for the best solution

for a specific purpose at an enterprise. This is

certainly a good approach for the organization

concerned, but not a transferable solution. As a result

of the project, an asset management software is

selected that is not free of charge.

3.2 Existing OT Asset Management

Tools

Many existing solutions for OT asset management

charge licensing fees. Some of these tools claim to

have been developed specifically for OT. In the

following sections, we will briefly introduce some of

the tools. Interestingly, the promised functions are

mostly the same.

The company Langner Communications GmbH

from Norderstedt, Germany offers an asset

management system especially for OT. It is neither

freeware, nor an open-source solution. Langner

promises that their tool OT-BASE "makes

automation engineers, cybersecurity experts and

maintenance staff more efficient" (Langner, 2023).

Verve Industrial Protection of Chicago, USA

claims its Verve product provides the deepest,

broadest and most efficient asset inventory

management solution for OT (Verve, 2023). In doing

so, Verve promises a particular depth of information

retrieval about assets.

Industrial Defender from Foxborough, USA

offers another software for asset and risk management

(Industrial Defender, 2023).

Other fee-based asset management systems

developed specifically for OT are:

Asset Guardian (Asset Guardian, 2023)

Claroty (Claroty, 2023)

Dragos (Dragos, 2023)

Microsoft Defender for IoT (Microsoft, 2023)

Nozomi (Nozomi Networks, 2023)

PAS Cyber Integrity (PAS, 2023)

Another asset management system is Snipe-IT

(Grokability, 2023). Although it does not advertise

that it is OT-compatible, it is open-source and at least

the basic version is available free of charge. The tool

does not offer asset recognition but would

theoretically be extensible since it is open-source. It

is very complex and offers many options that go more

in the direction of commercial management. In the

context of the project, it was therefore decided against

Snipe-IT.

4 REQUIREMENTS FOR AN

OPEN-SOURCE OT ASSET

MANAGEMENT TOOL

As already mentioned, the development of the tool

focused on practical applicability. Therefore, a case

study was first conducted at a real company before

ICISSP 2024 - 10th International Conference on Information Systems Security and Privacy

130

the actual requirements analysis was implemented.

4.1 Case Study

To assess the current state of OT asset management

in the industry, an interview was conducted with a

German business. The company, which is

anonymized here, has a history of more than a

hundred years, tenths of thousands of employees, its

headquarters in Germany and hundreds of locations

worldwide. The enterprise manufactures equipment

itself in the role of an integrator and is in turn an

operator of equipment.

Due to the size of the enterprise, the asset

management is organized in a distributed manner.

Various systems and tools are used for this.

For manufacturing, i.e. OT, the company

currently has no system for asset management.

Machines, PLCs or sensors are managed using Excel

lists or PDF files. There are also no strict protocols or

processes to ensure that the data is up-to-date and

complete. The responsibility to maintain the lists is

entirely up to the employees. The industrial facilities

are highly segmented and separated from the

environment by an air gap. This separation is relied

upon to minimize the risk of a successful attack on the

OT.

However, the topic of asset management is

becoming increasingly important for the company. It

was affected by the Log4shell vulnerability in the

Java library Log4j (IBM, 2021) and had to manually

query which departments were affected. Currently,

several OT asset management tools are being

evaluated, but no tool had yet been found that could

fully meet the requirements. The main complaint is

the inadequate detection of assets. Even tools that

promise automatic detection of the devices would

only recognize about 50-60%. Often IT asset

management systems would also sell themselves as

OT-compatible, but due to lack of experience would

encounter problems mainly with network

segmentation. Another quality feature would be the

ability to import existing Excel lists into the new

system.

4.2 Requirements and Goals

Due to the poor experience of the case study company

with commercial OT asset management solutions and

because no suitable open-source software was

available, it was decided to develop a new asset

management software. The goal was not to compete

in scope and performance with paid software such as

OT-Base (see 3.2). Rather it should be shown that it

is possible to build a good free tool within a short

development time, which offers especially smaller

companies the chance to improve their OT asset

management. But also, for larger companies, like the

one described in the case study, the development of

an own OT asset management system can be an

attractive option, because off-the-shelf solutions

often need adaptations to the specific requirements.

Before implementation, a complete set of

requirements was specified in collaboration with the

case study enterprise and a company from the OT

security sector. Through extensive interviews,

requirements for the software could be derived in

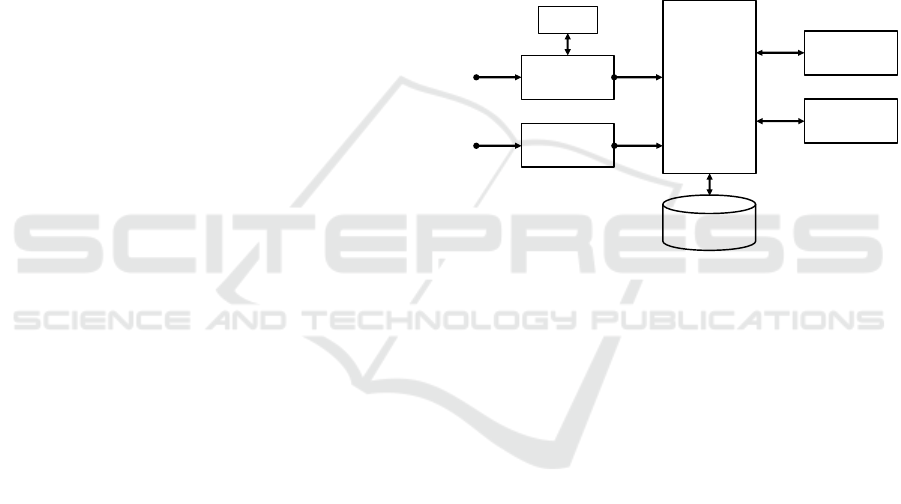

detail. The following figure 1 shows the conceptual

structure of the application, which is explained in

more detail in the following sections.

Figure 1: Conceptual structure of the application.

The specified requirements are only roughly

outlined within the scope of this paper:

Costs and licensing: the program to be created

should be free of charge and available as open-

source software.

Use of inventory data: since the company

already has data in the form of Excel files, it

should be possible to continue using these. For

this purpose, an Excel or CSV import is to be

implemented. An export to standard formats

such as Excel or pdf should be possible as well.

Database connection: the asset information

should be persistently stored in a database.

Asset availability: this is one of the most

critical requirements. The processes or

operations of the industrial plant must not be

disturbed or interrupted by the tool. Since an

active network scan always carries the risk of

triggering disturbances, the execution of the

asset detection requires a certain sensitivity as

well as knowledge about the plant on the part

of the executing employee. The operator should

therefore be able to select from various

intensity levels (profiles) for the detection.

Program

UI/Website

Export

(xlsx, pdf…)

Network

scans

Import

(csv, xlsx)

Profile

Database

An Open-Source Approach to OT Asset Management in Industrial Environments

131

Usability: the tool should be easy to use and

require little training.

Extensibility: the tool should be easy to extend

or adapt to new requirements and conditions.

No need for expensive hardware scanners: the

tool should also be able to work across the

segmentation boundaries of the networks

without having to install additional hardware.

5 IMPLEMENTATION OF THE

OPEN-SOURCE OT ASSET

MANAGEMENT TOOLS

The software was implemented as a web app. The

asset discovery function was implemented via a

Python "network discovery" script that uses the

Netdiscover (Kali, 2023a), Nmap (Nmap.org, 2023a),

and Crackmapexec (Kali, 2023b) scanning programs

for different intensity profiles. This Python script can

also be run without the web app and returns a CSV

file that can then be read into the webapp or could

potentially be further processed in other programs. By

developing additional Python modules, the

recognition of the program can thus be extended as

desired.

5.1 Web App

The website provides the user interface for asset

management. It currently consists of the following

components: dashboard, table view and detail view.

There is also a login and an admin portal, but these

are not described further.

The dashboard provides an overview of the

existing assets and the possibility to edit or delete

them. In addition, the user can import or export data,

or start a scan.

The table view provides an overview and

management of the assets. All existing assets are

displayed in a table. By means of a plug-in,

functionalities are added to the table on client side.

Automatically imported assets are colored differently

from those added via CSV/Excel import. This allows

for manual checks to confirm the correctness of the

data. After verification the coloring can be removed.

For each object in the database (device, software,

product, supplier) there is an editable detail view on

all information about the objects.

5.2 Network Discovery Module

The module currently includes two functions that are

used for asset detection via network: General

Network Scan and Siemens S7 Scan. The module can

be executed individually and can therefore be used

independently of the web application. For example,

one could just run the network discovery Python

script on a mini computer in different network

segments, and then add the resulting data to the asset

management via CSV import.

5.2.1 General Network Scan

This function implements the main functionality of

this module. It is divided into five different levels

(profiles) that perform different scans. These levels

are used to fulfill the requirement that the processes

of the industrial plant must not be influenced. The

user must assess for himself which level is

appropriate for the device to be scanned. In addition

to the IP range and the level, the user can also select

a timeout, after which a scan should stop.

Level 0 - Very Cautious: This level is based on a

passive ARP scan. If a network node searches for the

MAC address of another node, it sends an ARP

request via broadcast to the entire network. This

request contains the IP and MAC address of the node

as well as the IP address of the node being searched

for. Since the message is sent to everyone, it is

possible to receive it, for example with the command

line program Netdiscover (Kali, 2023a), and thus

obtain the information mentioned. Consequently,

Netdiscover has now found a MAC address for each

specified IP address, if available. This MAC address

can be evaluated automatically. For this purpose, both

Netdiscover and Nmap use tables which contain a

mapping of the first part of the address to the

respective manufacturer of the device. This type of

scan is the safest of the methods implemented here,

since it does neither generate nor affect any network

data. It can therefore be used in fragile and highly

available production environments. The disadvantage

is that one must rely on ARP requests from the nodes

and these also contain only little information. If a

system does not send a request, it will not be detected.

Note also, that the scan duration needs to be specified

as the test has no natural end.

Level 1 – Cautious: To solve the problem of not

being able to detect inactive devices, there is an

option to perform an active ARP scan. This is the

default setting of Netdiscover. The ARP scan

automatically terminates as soon as it has queried all

IP addresses in the specified range. Unlike level 0,

Netdiscover now actively sends ARP requests to the

specified IP address ranges. This guarantees that all

ICISSP 2024 - 10th International Conference on Information Systems Security and Privacy

132

nodes supporting ARP are discovered, but also brings

risks. New frames are generated which could

theoretically lead to failures. In reality, however, the

active ARP scan is still mostly safe to use, since ARP

as such works on the data link layer and therefore has

little influence on applications located in higher

layers. In addition, ARP request frames are

comparatively small.

To ensure that no systems are overlooked, the

active ARP scan is used as the basis in each of the

following stages.

Level 2 – Medium: To find out more about the

software and firmware used on the OT devices, an

Nmap scan, more precisely a TCP SYN scan, is

performed in level 2 in addition to the ARP scans. The

scan is based on the SYN, ACK and RST protocol

flags of the TCP handshake that is performed to

establish a TCP connection. The server responds to a

client's SYN request to a specific TCP port with the

SYN and ACK flags being set if the port is open, and

with the RST flag set if the port is closed. To the

SYN/ACK response from the server, the client would

normally respond with an ACK, and then begin TCP

communication. However, Nmap sends an RST in

response, so no connection is established. This means

that this scan is relatively unobtrusive and harmless

and can be performed quickly. It is also less likely to

be blocked by firewalls compared to other scanning

methods. However, if too many connection attempts

are made in too short a time, the TCP SYN scan may

be detected by a firewall or intrusion detection

system, but this can be circumvented by configurable

delays between scan packets. The result of the TCP

SYN scan is a list of running hosts, and the ports open

on them. Since standard ports are often used for

certain services, Nmap offers a suggestion for a found

service based on a database of open ports, but this

suggestion may not always be correct. It should be

noted that when implementing level 2, only the 100

most frequently used ports are scanned to keep the

load low.

Level 3 – OS: To obtain even more information about

the running services and the operating system of the

devices, level 3 extends the TCP SYN scan to the 100

most frequent ports with the service and version

detection (command option -sV) and the operating

system detection of Nmap (option -O) being

activated. Nmap sends packets to the services behind

the ports found to draw conclusions about the type

and version of the service based on the response. At

this point at the latest, the availability of an industrial

system is at risk, since direct addressing of ports can

lead to jerks, dropouts or even the crash of the

devices. Especially with older devices, port scans can

trigger uncontrolled behavior, for example if the

machine simply processes all incoming data without

checking. Operating system detection works similarly

and requires at least one open port to work and

multiple open ports for a more accurate result. Testing

in the experimental environment found that operating

system detection worked poorly to not at all on

Windows systems. Therefore, an additional

Crackmapexec scan was implemented specifically for

Windows systems. This scan is used by penetration

testers to exploit Windows systems but is used in this

context for the detection of Windows operating

systems only (Kali, 2023b).

Level 4 - Full Port Scan: Since level 3 is not able to

detect all services on a system (only the 100 most

common ports are scanned), level 4 extends the scan

to all 65,535 ports. Both OS and version detection are

enabled via options, as well as time-wise aggressive

scanning.

5.2.2 Siemens S7 Scan

The second function is based on the s7-info.nse script

developed for Nmap (Nmap.org, 2023b). This script

collects information about Siemens S7 controllers via

a specified port. Siemens uses port 102 by default, so

this is also used in the script. The function is intended

to scan individual systems that are suspected to

contain a PLC and should not be applied carelessly to

the entire production environment. Therefore, a best

practice should be to first identify potential S7

systems, e.g., by using a level 1 or 2 general network

scan. After that the Siemens S7 scan can be used to

collect detailed information on devices suspected to

come from Siemens.

6 TEST OF THE OPEN-SOURCE

OT ASSET MANAGEMENT

TOOL

The OT asset management tool was tested at the case

study enterprise as part of a proof of concept (PoC).

It was compared directly with a solution from well-

known manufacturers in industrial IT, which at the

point of test was still under development. The purpose

of testing the PoC was to find out whether - from

enterprise perspective - a solution developed in-house

based on open-source software could be an alternative

to a paid asset management system.

An Open-Source Approach to OT Asset Management in Industrial Environments

133

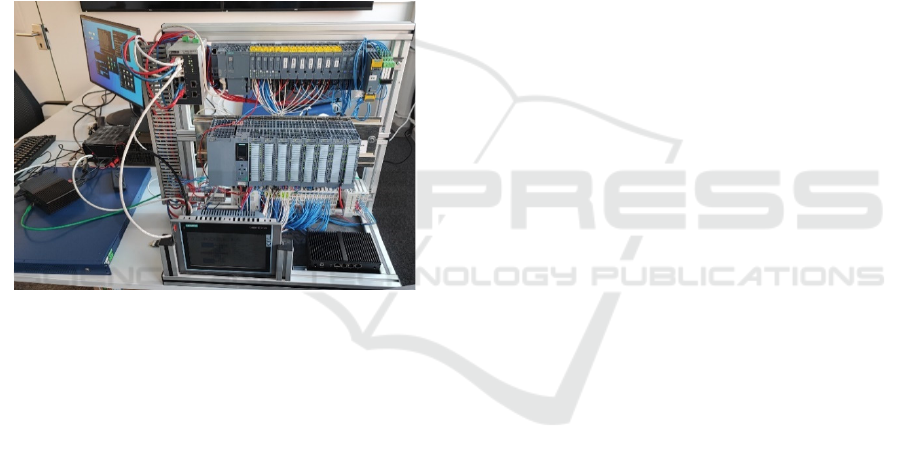

6.1 Test Setup

A test environment consisting of various industrial

devices was set up, including the following devices:

Windows XP laptop

Dell server

Siemens SIMATIC S7-400 with a SIMATIC

NET CP Industrial Ethernet Module

Siemens SIMATIC S7-mEC

Siemens SIMATIC S7-1500

Siemens SIMATIC ET200SP

Siemens SIMATIC HMI Touch

WAGO 750-8206

WAGO 750-375

Commercial tool HW

Own tool on mini PC

Managed switch

The majority of devices can be seen in figure 2.

Figure 2: Subset of PoC setup at case study user site.

6.2 Test Execution and Results

6.2.1 ARP Scan

The test was started with the passive ARP scan (level

0). This worked in the test environment, but only

delivered a few assets in the short test time (30

seconds), as expected.

The active ARP scan (level 1), on the other hand,

was able to provide a complete overview of the

devices that could be reached in the network. The

mapping table provided information about the

manufacturers of the devices. According to the

company's contact persons, the ARP scan alone is

helpful, as it provides information about which

devices are available and which may still be missing

from the data storage.

6.2.2 S7 Scan

The ARP scan and address mapping identified some

of the systems as Siemens devices. Therefore, the

tests continued with S7 scans for the respective

devices.

The first scans were performed on the two older

Siemens controllers (S7-400, S7-mEC). The

SIMATIC S7-mEC had the port 102 closed. This port

is normally open on all Siemens controllers and

cannot be closed by the user. The S7-info.nse script

could not find out any further information for this

embedded device. On the S7-400 port 102 was open,

but the S7 scan could not get any information about

the PLC either. After consulting with the company's

colleagues, this was most likely due to the fact that

this PLC uses a non-native extension module for

Ethernet, which leads to slight changes in

communication compared to a normal Siemens PLC

with an integrated Ethernet port. Adjustments to the

s7-info.nse script might overcome this limitation, but

this effort was not made, as both devices are more

than 20 years old, and the company only has a small

number of them left, which allows manual

management, particularly, as those devices hardly

receive any updates. Only the IP address, the MAC

address and thus the manufacturer, as well as the open

ports could be found out for the two tested devices.

The comparison tool from the well-known

manufacturer also could not find out anything else

than the MAC and IP addresses for these two devices.

Additionally, it provided the state of the devices

(online or offline).

The two newer Siemens PLCs could be scanned

successfully by means of the S7 scan as well as by the

alternative tool. This provided information about the

type of device, including serial number and firmware

version. Via the serial numbers, all data about the

hardware in use could also be obtained online.

7 CONCLUSIONS

The goal of the project was to improve OT security in

industrial environments through simplified OT asset

management. For this purpose, a case study with a

real enterprise was performed, which led to a set of

OT asset management requirements. As the search for

suitable, free and open-source solution was

unsuccessful, it was decided to implement a new asset

management software due to dissatisfaction with

existing commercial solutions. The tool was

implemented as a proof of concept and then tested in

a test environment of the company.

The test results were promising, also in

comparison with a tool from a device manufacturer.

All in all, the new tool could provide small companies

ICISSP 2024 - 10th International Conference on Information Systems Security and Privacy

134

with a cost-effective OT asset management solution.

Also, large companies could benefit from the

flexibility and extensibility of the solution.

REFERENCES

Asset Guardian (2023). We protect the integrity of

Industrial Automation and Control Systems software,

[Online], Available: https://www.assetguardian.com/,

[24 Oct 2023].

Bluhm, P. (2020). IMAC/R/D – IT-Lifecycle-Management,

[Online], Available: https://www.i-doit.com/en/blog/

imac-r-d-it-lifecycle-management/, [24 Oct 2023].

BMJ (2021). Neunte Verordnung zum

Produktsicherheitsgesetz (Maschinenverordnung) (9.

ProdSV) (Ninth Ordinance to the Product Safety Act

(Machinery Ordinance)), [Online], Available:

https://www.gesetze-im-

internet.de/gsgv_9/BJNR070410993.html, [24 Oct

2023].

BSI (2022). Die Lage der IT-Sicherheit in Deutschland

2022 (The state of IT security in Germany 2022),

[Online], Available: https://www.bsi.bund.de/Shared

Docs/Downloads/DE/BSI/Publikationen/Lageberichte/

Lagebericht2022.pdf?__blob=publicationFile&v=6 [2

4 Oct 2023].

BSI (2020). Konkretisierung der Anforderungen an die

gemäß § 8a Absatz 1 BSIG umzusetzenden

Maßnahmen (Specification of the requirements for the

measures to be implemented in accordance with Section

8a (1) BSIG), [Online], Available:

https://www.bsi.bund.de/SharedDocs/Downloads/DE/

BSI/KRITIS/Konkretisierung_Anforderungen_Massna

hmen_KRITIS.pdf?__blob=publicationFile&v=3 /, [24

Oct 2023].

Claroty (2023). Asset Management for Industrial

Environments, [Online], Available: https://claroty.

com/industrial-cybersecurity/asset-management, [24

Oct 2023].

Crowdstrike (2023). 2023 Global Threat Report, [Online],

Available: https://www.crowdstrike.com/global-threat-

report/ [24 Oct 2023].

Dragos (2023). Visualize, Detect, & Respond to ICS/OT

Cybersecurity Threats, [Online], Available: https://

www.dragos.com/platform/, [24 Oct 2023].

EU (2023). EU Cyber Resilience Act, [Online], Available:

https://digital-strategy.ec.europa.eu/en/policies/cyber-

resilience-act, [24 Oct 2023].

Gelle, E., Koch, T.E., Sager, P. (2005). IT asset

management of industrial automation systems, in: 12th

IEEE International Conference and Workshops on the

Engineering of Computer-Based Systems (ECBS’05).

Grokability (2023). Snipe-IT Open Source IT Asset

Management. [Online], Available: https://snipeitapp.

com/, [24 Oct 2023].

IBM (2021). What is Log4Shell?, [Online], Available:

https://www.ibm.com/topics/log4shell, [24 Oct 2023].

IEC 62264-1:2013 (2013). Enterprise-control system

integration - Part 1: Models and terminology,

International Organization for Standardization (ISO).

Industrial Defender 82023). OT Asset Management for

Critical Infrastructure, [Online], Available:

https://www.industrialdefender.com/solutions/ot-asset-

management, [24 Oct 2023].

Kali (2023a). Netdiscover, [Online], Available:

https://www.kali.org/tools/netdiscover/, [24 Oct 2023].

Kali (2023b) Crackmapexec, [Online], Available:

https://www.kali.org/tools/crackmapexec/, [24 Oct

2023].

Kassa, S.G. (2017). IT Asset Valuation, Risk Assessment

and Control Implementation Model, [Online],

Available: https://www.isaca.org/resources/isaca-

journal/issues/2017/volume-3/it-asset-valuation-risk-

assessment-and-control-implementation-model/, [24

Oct 2023].

Khuntia, S.R., Rueda, J.L., Bouwman, S., Meijden, M.

(2016). A literature survey on asset management in

electrical power [transmission and distribution]

system, in: International Transactions on Electrical

Energy Systems 26(10).

Koch C.E. (2021). Entwicklung eines Konzepts für das OT-

Asset Management im Produktionsumfeld

(Development of a concept for OT asset management in

the production environment), Bachelor Thesis at Duale

Hochschule Baden-Württemberg Heidenheim,

Germany.

Koskelo, M. (2021). OT-asset CMDB Solutions, Bachelor

Thesis at Metropolia University of Applied Sciences,

Metropolia, Finland.

Langner (2023). OTbase - If you don’t have OTbase, you

don’t have an OT asset inventory, [Online], Available:

https://www.langner.com/, [24 Oct 2023].

Microsoft (2023). Microsoft Defender for IoT, [Online],

Available: https://www.microsoft.com/en-

us/security/business/endpoint-security/microsoft-

defender-iot, [24 Oct 2023].

NIST (2023), Special Publication 800-82 Revision 3, Guide

to Operational Technology (OT) Security, [Online],

Available: https://csrc.nist.gov/pubs/sp/800/82/r3/final,

[24 Oct 2023].

Nmap.org (2023a). Nmap, [Online], Available:

https://nmap.org/, [24 Oct 2023].

Nmap.org (2023b). s7-info NSE script - Nmap Scripting

Engine documentation, [Online], Available:

https://nmap.org/nsedoc/scripts/s7-info.html, [24 Oct

2023].

Nozomi Networks (2023). Automate Your OT Asset

Inventory Management, [Online], Available:

https://www.nozominetworks.com/solutions/iot-ot-

asset-inventory-management, [24 Oct 2023].

PAS (2023). OT Inventory & Configuration Management,

[Online], Available: https://pas.com/products-and-

services/solutions/ot-inventory-configuration-

management, [24 Oct 2023].

PI (2023). PROFINET - the leading Industrial Ethernet

Standard, [Online], Available: https://www.profibus.

com/technology/profinet/, [24 Oct 2023].

An Open-Source Approach to OT Asset Management in Industrial Environments

135

RFC 826 (1982). An Ethernet Address Resolution Protocol.

Sauer, F., Niedermaier, M., Kießling, S., Merli, D. (2019).

LICSTER - A Low-cost ICS Security Testbed for

Education and Research, 6th International Symposium

for ICS & SCADA Cyber Security Research 2019

(ICS-CSR 2019).

Schneider Electric (2022). What is Modbus and How does

it work?, [Online], Available: https://www.se.com/

us/en/faqs/FA168406/, [24 Oct 2023].

Verve (2023). Verve for OT/ICS Asset Inventory, [Online],

Available: https://verveindustrial.com/verve-security

center/asset-inventory/, [24 Oct 2023].

ICISSP 2024 - 10th International Conference on Information Systems Security and Privacy

136