Classification of Towels in a Robotic Workcell Using Deep Neural

Networks

Jens Møller Rossen

1

, Patrick Søgaard Terp

1

, Norbert Kr

¨

uger

1 a

, Laus Skovg

˚

ard Bigum

2

and Tudor Morar

2

1

Maersk Mc-Kinney Moller Institute (MMMI), University of Southern Denmark (SDU),

Campusvej, Odense, Denmark

2

Inwatec, Odense, Denmark

Keywords:

Image Classification, AI, Deep Neural Networks, Towels, Laundry Industry.

Abstract:

The industrial laundry industry is becoming increasingly more automated. Inwatec, a company specializing

in this field, is developing a new robot (BLIZZ) to automate the process of grasping individual clean towels

from a pile, and hand them over to an external folding machine. However, to ensure that towels are folded

consistently, information about the type and faces of the towels is required. This paper presents a proof of

concept for a towel type and towel face classification system integrated in BLIZZ. These two classification

problems are solved by means of a Deep Neural Network (DNN).

The performance of the proposed DNN on each of the two classification problems is presented, along with

the performance of it solving both classification problems at the same time. It is concluded that the proposed

network achieves classification accuracies of 94.48%, 97.71% and 98.52% on the face classification problem

for three different towel types with non-identical faces. On the type classification problem, it achieves an

accuracy of 99.10% on the full dataset. Additionally, it is concluded that the system achieves an accuracy of

96.96% when simultaneously classifying the type and face of a towel on the full dataset.

1 INTRODUCTION

Industrial laundries use many different processes

when handling garments, e.g. washing, sorting and

folding. Some of these processes have been auto-

mated, however others are still mainly manually pro-

cessed. One such process is the feeding of towels to

folding machines. While towel folding machines have

been around for some time, automating the feeding of

these machines still poses problems.

The problem itself is complex, since towels are

non-rigid objects which requires complicated auto-

matic manipulation. Furthermore, obtaining informa-

tion about the type of towel being fed to the folding

machine is critical, since the folding processes for dif-

ferent towel types may differ from one another de-

pending on towel size, material and appearance (col-

ors, patterns, logos). In particular, obtaining informa-

tion about the appearance of towel types is critical to

ensure consistent folding. This is because differences

a

https://orcid.org/0000-0002-3931-116X

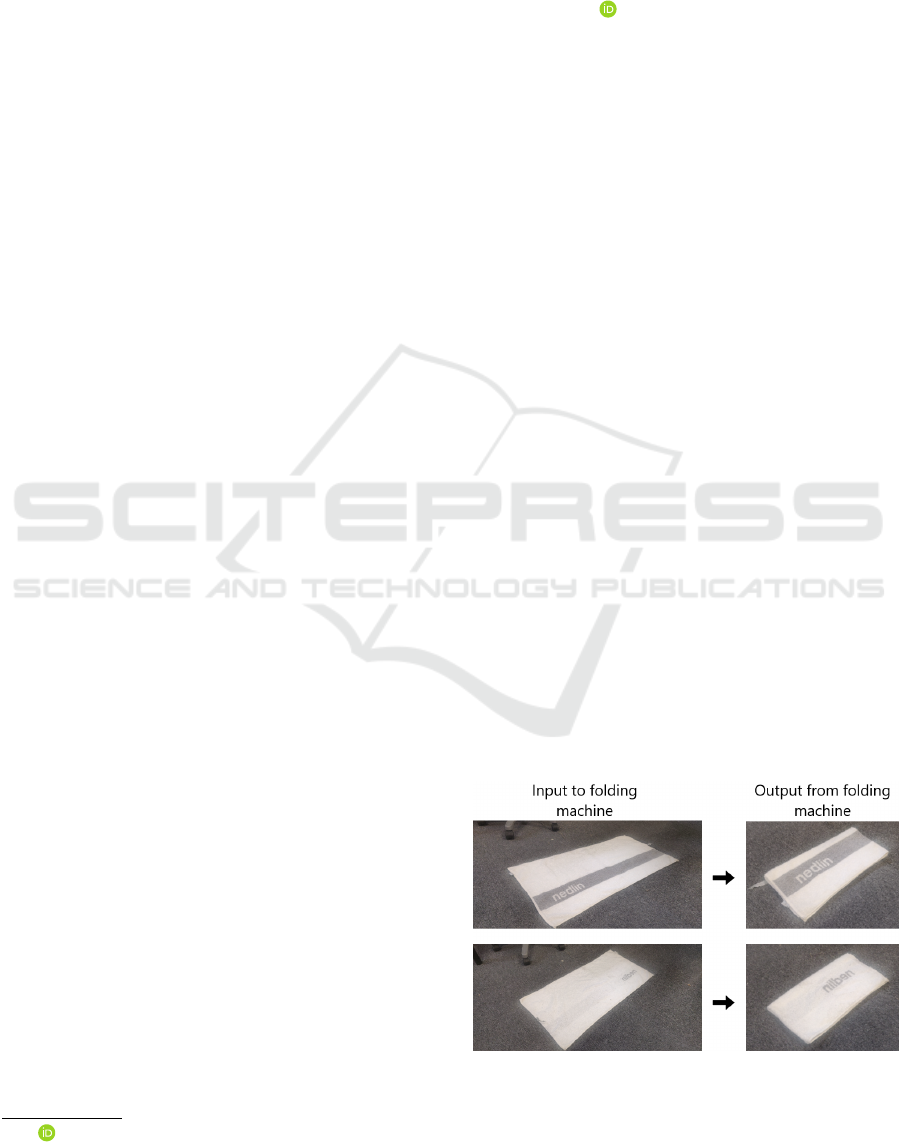

in the appearance of the two faces of a towel causes

different configurations after folding, as is illustrated

in figure 1.

There already exists some robots that can au-

tomate the feeding of towels to folding machines

(Sewts, 2023), however these robots lack the ability

Figure 1: Illustration of how the result of the folding process

of one type of towel is affected by which face of the towel is

facing up on the conveyor when fed to the folding machine.

Rossen, J., Terp, P., Krüger, N., Bigum, L. and Morar, T.

Classification of Towels in a Robotic Workcell Using Deep Neural Networks.

DOI: 10.5220/0012297500003660

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 19th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2024) - Volume 2: VISAPP, pages

309-316

ISBN: 978-989-758-679-8; ISSN: 2184-4321

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

309

Figure 2: Illustration of how BLIZZ processes towels such that it can feed them to a folding machine. The illustrated process

is divided into three steps. A descriptive text is found above each of the three steps.

to estimate the type and face of the towels they pro-

cess which limits their functionality.

Likewise, the company Inwatec (Inwatec, 2023a)

is developing a new robot named BLIZZ to solve this

problem. It separates a towel from a pile of towels

containing multiple different types, and subsequently

feeds it to a folding machine. A simplified version of

how it achieves this is illustrated in figure 2. How-

ever, like the aforementioned robots, it too cannot ef-

fectively determine what type of towel it is currently

processing. This is referred to as the type classifica-

tion problem. Furthermore, it cannot determine which

face is the front and which is the back of a towel type,

in the case that the two faces are different. This is

referred to as the face classification problem.

In this work, we extend the functionality of

BLIZZ through a computer vision based approach,

such that it can solve both the type and face classifi-

cation problems. The approach is split into two parts:

1) Designing a pipeline for collecting, processing

and labeling images of towels.

2) Developing a DNN architecture that can classify

the type of towel BLIZZ is currently processing,

and — in case that the faces of the towel are dif-

ferent — classify which face of the towel is the

front and which is the back.

2 STATE OF THE ART

Working with image classification typically involves

both processing of images and designing, training and

testing an AI network. Therefore, approaches in these

two fields will be presented focusing on the problem

of segmentation and classification of towels.

2.1 Image Processing

In the context of this paper, the processing of images

concerns segmenting the towel from the rest of the

image, i.e. the background. This process is generally

known as image segmentation and is split into two

main categories (Yu et al., 2023): Those that utilize

classical segmentation methods and those that utilize

Deep Learning (DL).

In (Maitin-Shepard et al., 2010), a classical seg-

mentation method is used in a robot developed to fold

towels. Images from two cameras are used to find

corresponding depth-discontinuities along a towels

edges after picking it up, thus allowing computation

of grasping points. A foreground-background seg-

mentation method is used to segment the towel, uti-

lizing generated high precision background images.

In (Paulauskaite-Taraseviciene et al., 2022), a so-

lution is presented to extract dimensions of garments

like the size. They utilize the U-Net Convolutional

Neural Network (CNN) architecture (Ronneberger

et al., 2015) as a backbone to generate the masks used

for segmentation.

Inwatec currently utilizes a classical foreground-

background segmentation in BLIZZ similar to

(Maitin-Shepard et al., 2010) to segment the towel

from the background in multiple stages of towel pro-

cessing. In this paper, a similar algorithm is used, but

additional steps has been added.

2.2 Image Classification

For the problem of image classification, different

learning methods have been applied. Since 2010

DNNs have become particularly popular for use in

image classification problems, with the CNN archi-

tecture being especially efficient.

VISAPP 2024 - 19th International Conference on Computer Vision Theory and Applications

310

A CNN is used in (Gabas et al., 2016) to deter-

mine which of five possible classes a garment belongs

to, which uses multiple depth images of the garment

taken from different angles. The algorithm was tested

on a dataset consisting of 4272 depth images. They

used this dataset to train their own CNN network ar-

chitecture. An average classification rate of 83% was

achieved when classifying garments using only a sin-

gle depth image, which increased to 92% when con-

sidering all images.

Inwatec currently utilize DNNs in their robots to

solve image classification problems. In a master the-

sis written in collaboration with Inwatec (Lyngbye

and Jakobsgaard, 2021), different CNN backbones

were tested in combination with a custom fully con-

nected top layer to classify different types of garments

being separated by Inwatecs THOR robot garment

separator (Inwatec, 2023b). The thesis achieved a

classification accuracy of 97% on a dataset consisting

of 17 different classes using ResNet (He et al., 2015)

as a CNN backbone.

3 METHODS

This section presents the methods that have been de-

veloped to classify the type and face of towels pro-

cessed by BLIZZ. The methods are split into two sec-

tions. The first section presents the designed image

collection and processing pipeline, while the second

section presents the developed DNN architecture used

for image classification.

3.1 Image Collection and Processing

To extract as much information as possible from a

towel, it is desired to obtain two images, one of each

face of the towel. To facilitate this, two stereo cam-

eras (Intel D435) were installed in BLIZZ. Images of

faces of a towel must be taken before BLIZZ has fin-

ished processing the towel, such that it can utilize the

classifications output by the image classifier to manip-

ulate the towel correctly. This, along with hardware

constraints, meant that it was not possible obtain com-

plete images of both faces of towels. Instead, it was

only possible to obtain two images, each one covering

most of one face of the towel. An example of images

captured by the two cameras can be seen in figure 3.

In order for the image classifier to achieve the

highest possible classification accuracy, it is desired

to remove the parts in both images in figure 3 that are

not a part of the towel. This is done in a three stage

process, which is shown in figure 4, where it is ap-

plied to the image shown in figure 3a.

(a) From ’Corner’ camera.

(b) From ’Rear’ camera.

Figure 3: Example of two captured images of a towel. Res-

olution of images is 1920 by 1080 pixels.

The first stage involves cropping the image ac-

cording to a Region Of Interest (ROI), which is based

on physical constraints of BLIZZ and size constraints

of towels. The results of this stage are shown in the

image in figure 4a.

The second stage involves segmenting the towel

from the background in the image shown in figure 4a.

This process is shown in figures 5a, 5b and 5c, with

the result shown in figure 4b. The segmentation is

performed by utilizing the depth image from the cam-

era, where each pixel in the depth image contains the

(a) Stage I.

(b) Stage II.

(c) Stage III.

Figure 4: The results of each of the three stages in the image

processing, applied to the image in figure 3a.

Classification of Towels in a Robotic Workcell Using Deep Neural Networks

311

z-component of the Euclidian distance from the cam-

era sensor to the object located at the pixel. An abso-

lute difference is computed between the depth value

at a given pixel and the depth value at the correspond-

ing pixel in the background image, i.e., a depth im-

age without a towel present. This absolute difference

is computed for all pixels in the depth image, where

each of the differences greater than a specified thresh-

old is determined to belong to the towel, which yields

a binary mask that is shown in figure 5a. To eliminate

noise in the binary mask, only the largest contour is

retained, which is shown in figure 5b. The edge of

this contour is visualized as a red line in figure 5c.

(a) Initial segmentation mask.

(b) After size filtration.

(c) After applying Sobel gradients.

(d) Calculated cropping lines.

Figure 5: Figures providing a detailed view of the process

of towel segmentation (stage II) and cropping of the seg-

mented image (stage III) as shown in figure 4.

Improving this segmentation is achieved by us-

ing Sobel gradients (Dawson-Howe, 2014). For each

point in the contour, a line is fit to set of points. This

set includes the point itself, along with the five pre-

ceding and proceeding contour points. Sobel gradi-

ents are then calculated along the normal of this line

for a predefined length. The point is then moved to

the position of the pixel that contains the highest So-

bel gradient, since this is theorized to be be the actual

edge of the towel. The final contour can be seen in

figure 5c, represented by the green line.

The third stage involves cropping the segmented

image shown in figure 4b to the smallest bound-

ing box that encompasses the towel. The lines that

are used for cropping are shown in figure 5d, with

the result of the cropping being shown in figure 4c.

The cropping is performed using three cropping lines,

which are calculated by two different methods. The

first method computes two of the cropping lines us-

ing the image shown in figure 4b. The first of these

is a vertical line, which is goes through the non-

zero pixel(s) with the highest x-value, while the sec-

ond line is horizontal, and goes through the non-zero

pixel(s) with the highest y-value. These cropping

lines are visualized as the blue and red lines in fig-

ure 5d, respectively. The second method, which re-

moves the gripper, also uses the image shown in figure

4b and is based on the position of the linear actuator

grasping the towel. This method utilizes an estimated

encoder to image mapping to calculate the cropping

line visualised as a green line in figure 5d. All three

of these cropping lines are then simultaneously ap-

plied to the image shown in figure 4b, which yields

the image shown in figure 4c.

After images from both cameras, as shown in fig-

ure 3, have been segmented and cropped in the three

stages process illustrated in figure 4, they must be

further processed before they are usable to the im-

age classifier. This involves scaling the images to

500 × 500 pixels before concatenating them along the

horizontal axis. This yields an image as shown in fig-

ure 6.

Figure 6: Example of an image of a towel after processing

is finished. The towel in the image is of the type ’Nedlin’,

and is labelled as ’NedlinFront’.

VISAPP 2024 - 19th International Conference on Computer Vision Theory and Applications

312

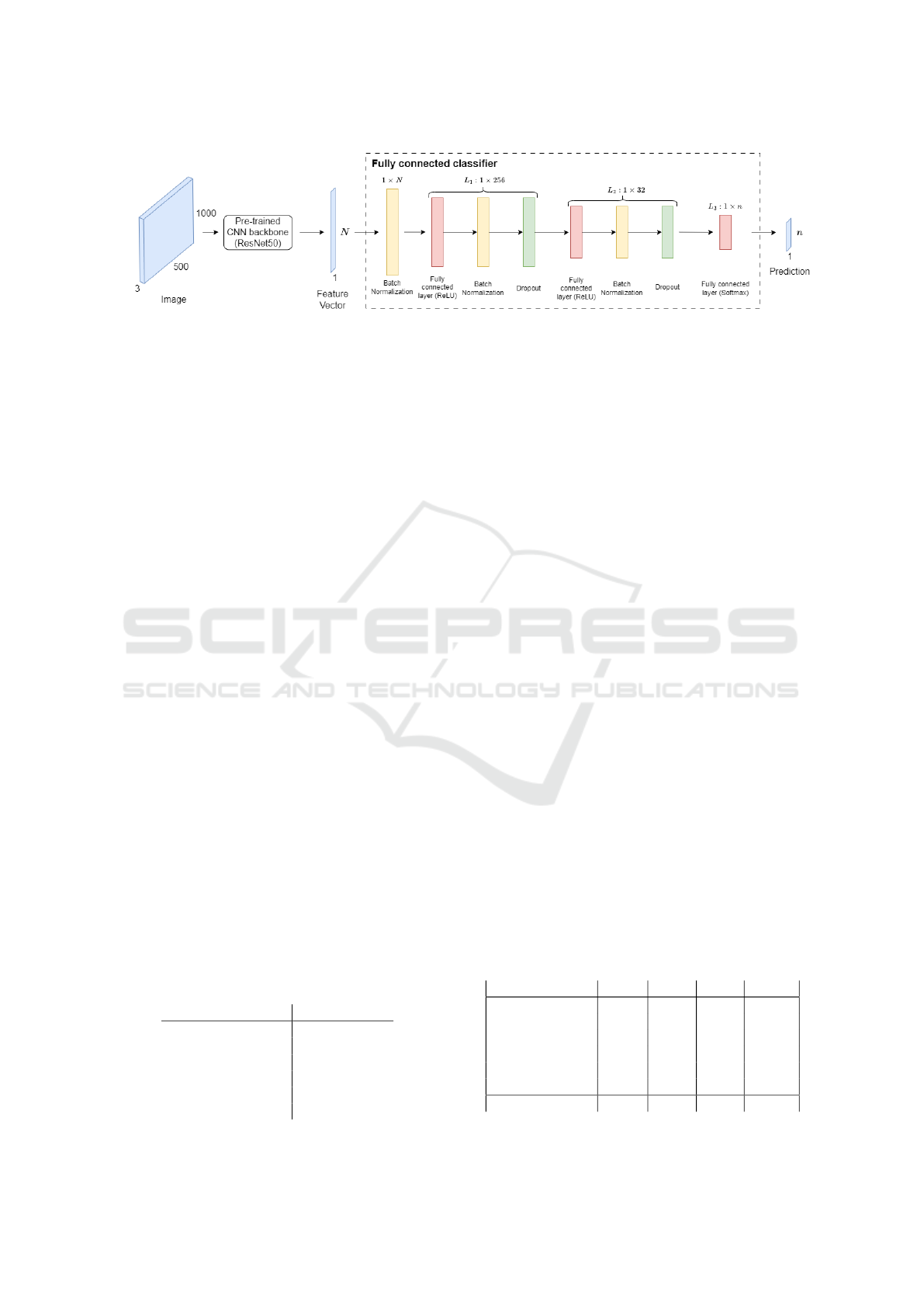

Figure 7: Architecture of the proposed network.

3.2 Image Classifier

The proposed image classifier utilizes the concept of

CNNs based on the ResNet50 architecture (He et al.,

2015) trained on the ImageNet dataset (Stanford Vi-

sion Lab, 2023) where the classifying layer is sub-

stituted with a custom Fully Connected (FC) classi-

fier. This approach is common when designing CNN

networks, and is generally known as transfer learning

(Goodfellow et al., 2016). The particular architecture

was chosen, since it proved the most effective in re-

lated work (Lyngbye and Jakobsgaard, 2021).

The reason for using an existing CNN is that they

are trained on large datasets which in theory makes

them good general feature extractors. Choosing the

ResNet50 architecture was based on previous work in

(Lyngbye and Jakobsgaard, 2021) as presented in the

state of the art section, where different CNN back-

bones were tested on a similar image classification

problem.

The architecture of the proposed image classifier

is illustrated in figure 7. It takes a three channel

500 × 1000 pixel color image of a towel as an in-

put, as shown in figure 6. This image must be in

the BGR-format and be normalized to the ImageNet

dataset, since the ResNet50 architecture is trained on

this dataset. This is done by converting images to

the BGR-format and zero centering each of the color

channels of the image with respect to the ImageNet

dataset (Tensorflow, 2023).

The image is then processed by the ResNet50 ar-

chitecture, whose output features are flattened to a

feature vector of length 1 × N, where N is dependent

Table 1: CNN image classifier hyperparameters & optimal

values.

Hyperparameter Optimal value

Image dimension 500 × 1000

Learning rate 1 · 10

−4

Batch size 32

Dropout rate 0.5

FC classifier layers 2

Layer neurons 256, 32

on the input dimensions of images. This feature vec-

tor is then passed to the custom FC classifier, which

consists of two layers, L

1

, L

2

that contain 256 and 32

neurons, respectively. Additionally, each layer ap-

plies Batch Normalization (Ioffe and Szegedy, 2015)

and Dropout (Srivastava et al., 2014) to the outputs

of the fully connected layer respectively. This cus-

tom fully connected classifier yields a 1 × n vector

containing the probabilities of the image belonging to

each of the n classes in the dataset.

Apart from the data itself, the performance of the

proposed image classifier is influenced by the value

of the hyperparameters of the network. The hyper-

parameters seen in table 1 yield optimal performance

of the image classifier. They have been determined

experimentally by keeping all hyperparameter values

constant, except the one being tested, and then train-

ing networks for 20 epochs on a subset of the full

dataset using ten fold cross-validation.

4 DATASET

A dataset totalling 24120 images of six different types

of towels, of which three have non-identical faces,

has been collected. Illustrations of the different towel

types are given in figure 8. An overview is given in ta-

ble 2 where each row contains information about each

of the towel types. In each row, it can be seen how

many of the images have been labelled as ’Front’ or

’Back’ in their respective columns, in the case that the

towel type has non-identical faces. If not, the ’I’ col-

Table 2: Overview of the collected dataset and its contents.

Types Front Back I Total

’Nedlin’ 1623 1750 - 3373

’BathTowel’ 3342 3326 - 6568

’Rentex’ 1673 1768 - 3441

’VDK’ - - 6520 6520

’GrayStriped’ - - 1176 1176

’YellowStriped’ - - 1074 1074

Sum 6638 6844 8770 22152

Classification of Towels in a Robotic Workcell Using Deep Neural Networks

313

umn shows how many images of that type is in the

dataset. The ’Total’ column shows how many images

of a given towel type is in the dataset. The reason why

the number of towels classified as ’Front’ and ’Back’

is not equal, is due to the stochastic nature of how

towels are grasped by BLIZZ, where the probability

for BLIZZ to pick up a towel which must be labeled

’Front’ is equal to the probability to pick up a towel

which must be labeled ’Back’.

Images are always given two labels. The first la-

bel, referred to as the type label, is related to what

type of towel is present in the image. The second la-

bel, referred to as the face label, relates to the face

(a) ’NedlinFront’ (b) ’NedlinBack’

(c) ’BathTowelFront’ (d) ’BathTowelBack’

(e) ’RentexFront’ (f) ’RentexBack’

(g) ’VDK’ (h) ’GrayStriped’

(i) ’YellowStriped’

Figure 8: Illustrations of the six different towel types of

which the collected dataset in table 2 is comprised.

visible in the left-half side of the part of the image

captured by the ’Corner’ camera (See figure 3a). In

case of the image shown in figure 6, it is given the

type label ’Nedlin’, since the observed type matches

the images displayed in figures 8a and 8b. Addition-

ally, it is given the face label ’Front’, since the face

observed in the left-half side of the part of the image

captured by the ’Corner’ camera fits the image dis-

played in figure 8a.

5 RESULTS

Classification of the type of a towel is a multi-class

classification problem, since there exists more than

two different types of towels in the dataset presented

in section 4. On the other hand, the face classification

problem is inherently a binary classification problem,

since towels of the same type whose faces are non-

identical in the dataset have exactly two faces.

The proposed network has been trained and tested

on both classification problems separately. The full

dataset is used to test the type classification prob-

lem, thus containing n = 6 different classes. For the

face classification problem, the proposed network was

trained and tested on three different datasets. Each

of these datasets contains all images of only a sin-

gle towel type whose faces are non-identical. This

means that the proposed network was tested on three

different datasets, each containing all images of the

towel types ’Nedlin’, ’BathTowel’and ’Rentex’ re-

spectively, and each dataset having n = 2 classes.

All networks presented in this section have been

trained, validated and tested, using an 80/10/10 split

for 100 epochs, and the hyperparameters presented in

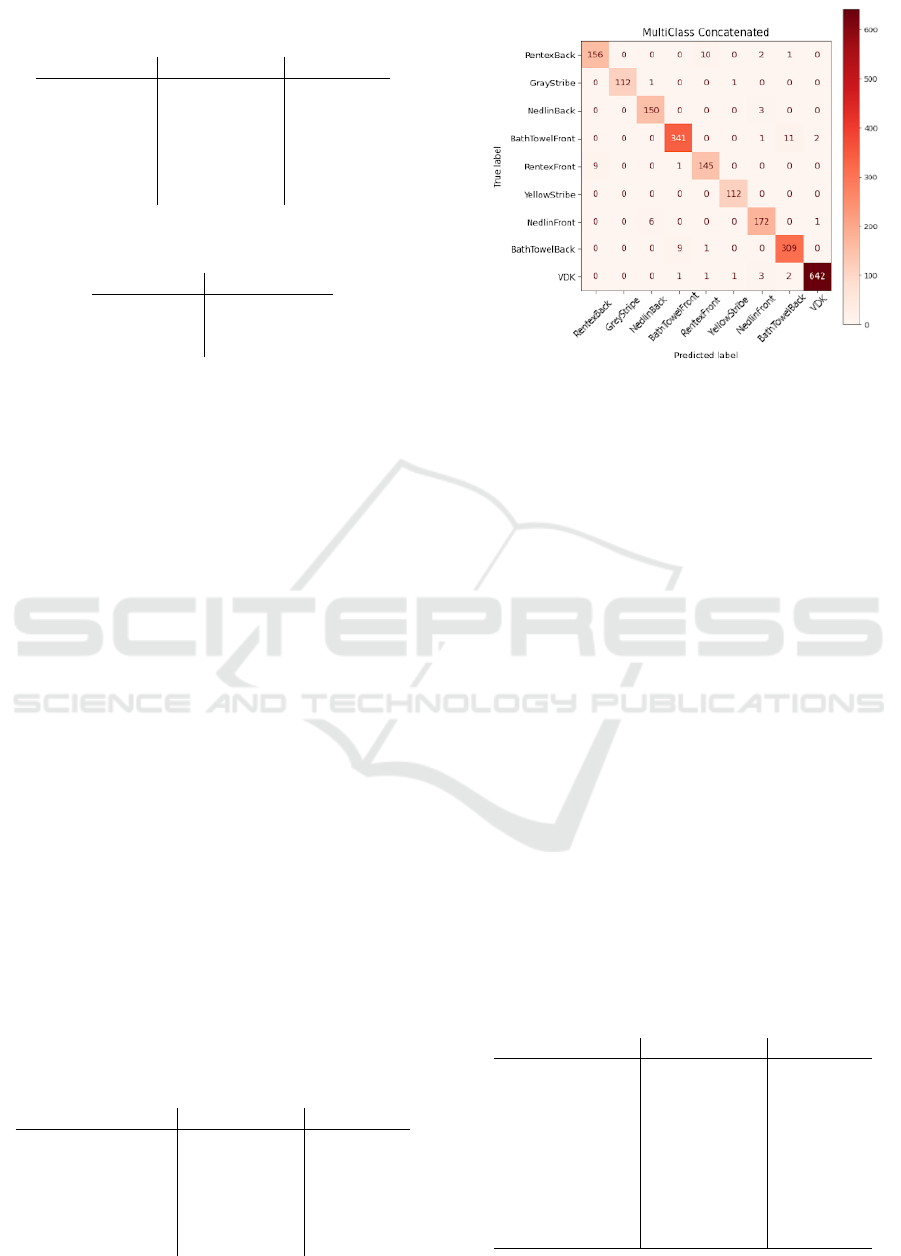

Figure 9: Confusion matrix for the network trained to clas-

sify types of towels. Network accuracy: 99.10%.

VISAPP 2024 - 19th International Conference on Computer Vision Theory and Applications

314

Table 3: Precision and recall values for the network trained

to classify types of towels.

Towel Type Precision [%] Recall [%]

YellowStripe 100 100

BathTowel 98.64 99.24

Nedlin 99.40 98.52

Rentex 99.71 99.71

GreyStripe 100 100

VDK 98.77 98.62

Table 4: Accuracies of the networks trained to classify

towel faces.

Towel Type Accuracy [%]

BathTowel 97.71

Nedlin 98.52

Rentex 94.48

section 3.2. The categorical cross entropy function

has been used to calculate the loss, with the exception

of the network trained to solve the face classification

problem, where the binary cross entropy loss function

has been used instead. Furthermore, the Adam opti-

mizer is used during training (Kingma and Ba, 2017).

The confusion matrix of the network trained to

solve the type classification problem is shown in fig-

ure 9, from which the network accuracy is calculated

to be 99.10%, while the precision and recall of the

network on the individual types of towels is shown

in table 3. The accuracy, precision and recall metrics

have been calculated using the information found in

(Evidently AI, 2023). Similarly, the accuracies for the

network trained to solve the face classification prob-

lem on the three different datasets is shown in table 4,

while the precision and recall for each towel type and

face combination is shown in table 5.

A single network has also been trained on the full

dataset presented in table 2 to solve both classification

problems, meaning that it can determine both the type

and face given an image of a towel. This is achieved

by combining the type and face attributes of towels

into a total of n = 9 classes for the classifier to choose

from. For example, a towel whose faces are non-

identical would create two new classes, e.g. ’Nedlin-

Front’ and ’NedlinBack’. Meanwhile, a towel whose

faces are identical would create only one class, e.g.

’VDK’. The performance of this network is shown in

Table 5: Precision and recall values for the networks trained

to classify towel faces.

Towel Face Precision [%] Recall [%]

BathTowel - Front 97.00 98.48

BathTowel - Back 98.45 96.95

Nedlin - Front 98.01 98.67

Nedlin - Back 98.92 98.40

Rentex - Front 94.41 94.94

Rentex - Back 94.55 93.98

Figure 10: Confusion matrix for the network trained to clas-

sify both types and faces of towels. Network accuracy:

96.96%.

the confusion matrix in figure 10, while the precision

and recall of each of the classes are shown in table 6.

6 DISCUSSION

When examining tables 4 and 5, it can be seen the

the network trained to solve the face classification

problem on a dataset consisting only of towels of the

’Rentex’ type performs significantly worse than the

two other tested networks. This is believed to be

caused by a difference in the appearance of the towel,

since the central logo on the ’Rentex’ towel type (fig-

ures 8e and 8f) is more easily obscured on images than

the off-center logo on the ’Nedlin’ towel type (figures

8a and 8b), thus increasing the difficulty for the net-

work to classify correctly. Additionally, this assump-

tion is supported when comparing the ’Rentex’ and

’BathTowel’ towel types. Although the ’BathTowel’

towel type dataset contains substantially more images

than the ’Rentex’ towel type dataset, its characteristic

feature runs along the entire edge of the towel (fig-

Table 6: Precision values for the network trained to classify

both towel types and faces.

Dataset class Precision [%] Recall [%]

RentexBack 94.55 92.31

RentexFront 92.36 93.55

NedlinBack 95.54 98.04

NedlinFront 95.03 96.09

BathTowelBack 95.67 96.87

BathTowelFront 97.15 96.06

GreyStripe 100 98.25

YellowStripe 98.25 100

VDK 99.53 98.77

Classification of Towels in a Robotic Workcell Using Deep Neural Networks

315

ures 8c and 8d), thus almost guaranteeing that it will

be visible when images are taken of that towel type.

As can be seen in the overview of the dataset in

table 2 as well as in the confusion matrices in sec-

tion 5 (figures 9 and 10), the dataset is imbalanced,

with some classes containing more images than oth-

ers. This is caused by the availability of towels dur-

ing data collection, i.e. there were more towels avail-

able for some towel types than others, as well as the

data collection process being automatic. It has been

attempted to minimize the effects of an imbalanced

dataset by matching the distribution of the full dataset

when splitting it into training, validation and testsets.

As seen in results of the network trained on the full

dataset to solve the type classification problem (ta-

ble 3), the imbalance doesn’t seem to be a problem,

since classes with a relatively large amount of data

(’VDK’) achieve comparable metrics to classes with

relatively small amounts of data (’GreyStriped’, ’Yel-

lowStriped’).

7 CONCLUSION

In conclusion, this paper presents a proof of concept

which is capable of capturing and processing images

of towels being processed by Inwatecs BLIZZ using

two mounted depth cameras. Furthermore, a CNN

network has been developed, which classifies both the

type and face of towels. This proof of concept can be

used by BLIZZ to improve its functionality, enabling

it to deliver towels to folding machines more consis-

tently, while also improving its versatility.

A dataset consisting of six different types of towel,

of which three have non-identical faces and total-

ing 22152 images has been collected and labelled.

The developed image classification network has been

trained and tested on this dataset, resulting in an ac-

curacy of 99.10% when it is trained to solve only the

type classification problem. Likewise, the proposed

network trained to solve only the face classification

problem achieves an accuracy of 94.48%, 97.71% and

98.52% on three different datasets consisting of im-

ages of just the ’Rentex’, ’BathTowel’ and ’Nedlin’

towel types, respectively. Comparatively, when the

proposed network is trained to solve both classifica-

tion problems, it achieves an accuracy of 96.96%.

REFERENCES

Dawson-Howe, K. (2014). A Practical Introduction to

Computer Vision with OpenCV. Wiley Publishing, 1st

edition.

Evidently AI (2023). Accuracy, precision, and recall in

multi-class classification. https://www.evidentlyai.

com/classification-metrics/multi-class-metrics. Ac-

cessed: 18-09-2023.

Gabas, A., Corona, E., Aleny

`

a, G., and Torras, C. (2016).

Robot-aided cloth classification using depth informa-

tion and cnns. In Articulated Motion and Deformable

Objects.

Goodfellow, I., Bengio, Y., and Courville, A. (2016). Rep-

resentation Learning, page 536. MIT Press. http:

//www.deeplearningbook.org.

He, K., Zhang, X., Ren, S., and Sun, J. (2015). Deep resid-

ual learning for image recognition.

Inwatec (2023a). Inwatec. https://inwatec.dk/. Accessed:

14-09-2023.

Inwatec (2023b). Thor. https://inwatec.dk/products/

thor-robot-separator/. Accessed: 14-09-2023.

Ioffe, S. and Szegedy, C. (2015). Batch normalization: Ac-

celerating deep network training by reducing internal

covariate shift.

Kingma, D. P. and Ba, J. (2017). Adam: A method for

stochastic optimization.

Lyngbye, M. A. and Jakobsgaard, M. S. (2021). Garment

classification using neural networks. Master’s thesis,

University of Southern Denmark, Odense, Denmark.

Maitin-Shepard, J., Cusumano-Towner, M., Lei, J., and

Abbeel, P. (2010). Cloth grasp point detection based

on multiple-view geometric cues with application to

robotic towel folding. In 2010 IEEE International

Conference on Robotics and Automation, pages 2308–

2315.

Paulauskaite-Taraseviciene, A., Noreika, E., Purtokas,

R., Lagzdinyte-Budnike, I., Daniulaitis, V., and

Salickaite-Zukauskiene, R. (2022). An intelligent so-

lution for automatic garment measurement using im-

age recognition technologies. Applied Sciences, 12(9).

Ronneberger, O., Fischer, P., and Brox, T. (2015). U-

net: Convolutional networks for biomedical image

segmentation. In Navab, N., Hornegger, J., Wells,

W. M., and Frangi, A. F., editors, Medical Image Com-

puting and Computer-Assisted Intervention – MICCAI

2015, pages 234–241, Cham. Springer International

Publishing.

Sewts (2023). Velum. https://www.sewts.com/velum/. Ac-

cessed: 14-09-2023.

Srivastava, N., Hinton, G., Krizhevsky, A., Sutskever, I.,

and Salakhutdinov, R. (2014). Dropout: A simple way

to prevent neural networks from overfitting. J. Mach.

Learn. Res., 15(1):1929–1958.

Stanford Vision Lab (2023). Imagenet. https://www.

image-net.org/. Accessed: 14-09-2023.

Tensorflow (2023). Resnet50-preprocess

input.

https://www.tensorflow.org/api docs/python/tf/keras/

applications/resnet50/preprocess input. Accessed:

27-08-2023.

Yu, Y., Wang, C., Fu, Q., Kou, R., Huang, F., Yang, B.,

Yang, T., and Gao, M. (2023). Techniques and chal-

lenges of image segmentation: A review. Electronics,

12(5).

VISAPP 2024 - 19th International Conference on Computer Vision Theory and Applications

316