Enhancement of Three-Body Wear Resistance of Steel Substrate

using Molybdenum Coating for Steel Roller Conveyor

Arunadevi M

1 a

and Vivek Bhandarkar V N

1 b

1

Department of Mechanical Engineering, Dayananda Sagar College of Engineering, Bangalore, India

Keywords: Wear, Resistance, Steel, Molybdenum Coating.

Abstract: The main focus of this work is enhancing the steel rollers wear resistance which is used in mining industry

conveyor systems. Wear and efficiency of steel conveyor system is affected by the presence of sand, dust and

grit (abrasive particles) and by the continuous contact between metal surface with steel roller. To overcome

the above issue, application of molybdenum powder coating for the steel is suggested using plasma thermal

spray coating. As per the ASTM (American Society for Testing and Materials) standards the experiments are

conducted and the performance enhancement analyzed for the coated samples by comparing with uncoated

samples. ASTM G65 is a test method developed by ASTM International to evaluate the abrasive wear

resistance of materials using a dry sand/rubber wheel abrasion test. This test method is commonly used to

assess the durability and wear performance of various materials, coatings, and surface treatments. SEM

(Scanning Electron Microscope), EDAX (Energy Dispersive X-Ray analysis) and hardness tests are

performed to measure the wear resistance and wear surface properties. It is proven that the molybdenum

coating plays very important role in improving the three-body wear resistance of steel conveyor rollers. SEM

analysis confirmed a smooth and well-adhered coating, while EDAX revealed the presence of molybdenum

on the coated surface. Hardness tests indicates a notable increase in hardness, further supporting the enhanced

wear resistance. This research highlights the potential of molybdenum powder coatings to enhance the

durability and lifespan of steel rollers in conveyor systems operating in harsh environments. The findings

contribute to the development of effective strategies for reducing wear and optimizing the performance of

mining and construction equipment.

1 INTRODUCTION

Abrasive wear is observed in manufacturing,

transportation, mining and construction industries,

also in day-to-day life. It has very significant effect

on the life span and efficiency of the components or

parts subjected to abrasive wear. It may lead to

material loss, decrease in dimensional accuracy,

higher surface roughness and reduction in efficiency.

In industries it may occurs in parts or components

exposed to harsh environments such as grinding tools,

engine components, conveyor belts and also in

cutting machinery. To overcome the above issue,

application of molybdenum powder coating for the

steel is suggested using plasma thermal spray coating.

C S Ramesh (2018) et.al highlighted the effect of

molybdenum and molybdenum silicon carbide

a

https://orcid.org/0000-0002-2831-8198

b

https://orcid.org/0000-0003-2706-3848

coatings on mild steel to improve the wear resistance,

to improve the tribological properties and also to

reduce the friction. High-velocity oxy-fuel (HVOF)

technique is used for the coating to achieve less

porosity, higher coating density and good bonding

with the material and microstructure, composition,

phase change and mechanical properties are

evaluated using microhardness testing, EDX, XRD,

and SEM. The tests were conducted as per ASTM

standards and the improved wear resistance and

reduction in friction are demonstrated by the ASTM

G65 abrasion tests (C.S. , et al. 2018).

Patel G C (2022) et.al studied the wear loss and

microhardness of Mo-Ni-Cr coated super duplex

stainless steel to optimize and analyze the plasma

spray parameters effect on experimentation. The

parameters such as current, voltage, spray distance

116

M., A. and N., V.

Enhancement of Three-Body Wear Resistance of Steel Substrate Using Molybdenum Coating for Steel Roller Conveyor.

DOI: 10.5220/0012525700003808

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Intelligent and Sustainable Power and Energy Systems (ISPES 2023), pages 116-124

ISBN: 978-989-758-689-7

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

and powder feed rate are influencing factors to

achieve required coating properties. The wear

behavior, hardness and microstructure were evaluated

using wear testing, microhardness testing and surface

roughness analysis. It is discovered that proper

optimization of plasma spray variables on

microhardness and wear loss is needed to achieve the

better quality and performance of coatings. Han. Ya-

guang (2017) et.al focused on the correlation between

wear resistance and micro structural properties of

molybdenum coatings on different substrates using

APS (Atmospheric Plasma Spraying). The authors

discussed the importance of process parameters of

plasma spray coating such as gas flow rate, powder

flow rate and spray distance in controlling properties

and microstructure of coatings using EDX, SEM and

microhardness testing.

Cristian Puscasu et.al investigated the thermal

spray molybdenum coating properties to increase the

durability and enhance the wear resistance of railway

axles. It is proved that wear related damages are

reduced, performance of axles are improved and

service life is also extended using molybdenum

coatings. The main challenges of railway axles such

as cyclic loading, harsh operating conditions and high

loads are handled using protective coatings using

molybdenum. This study discussed the coating

properties such as microstructure, mechanical

strength, hardness and adhesion and also their

significant importance on performance of railway

axle applications. H Adarsha (2018) et.al highlighted

the influence of HVOF(High-Velocity Oxy-Fuel)

technique on manufacturing well-bonded and dense

coatings with better mechanical properties such as

less friction coefficient, higher hardness value and

better adhesion to the substrate material( SS304 and

A36). These materials are mainly used in the mining

and construction industries under abrasive

environment, which required the wear enhancement

and extended life span. Huang Long (2018) et.al

studied the wear resistance comparison of the steel

with and without (Ti,Mo)C particles. This study

explores the influence of parameters such as

concentration, particle size and distribution of

particles on the improvement of wear resistance

performance and also characterization of materials is

performed using harness testing, SEM and EDX to

analyze the composition, the microstructure and

mechanical properties of coatings on steel.

R Riastuti (2018) et.al focused the study on

corrosion behavior improvement of 316L stainless

steel by molybdenum and aluminum coatings.

Coating thickness is varied to analyze the good

adhesion property and characterization is done using

SEM, EDX, and microhardness testing. It is

recommended by the authors to optimize the coating

parameters which will increase the durability and

performance of the component which is subjected to

corrosive environments. S Ilaiyavel (2012) et.al

studied the behavior of manganese phosphate-

coatings on AISI D2 steel which is used in tool and

die material. The manganese phosphate coating is

achieved by forming a layer of manganese phosphate

compound which involves chemical conversion of

steel surface and different influencing parameters

such as surface preparation, coating parameters and

post treatment processes are analyzed to obtain

uniform and adherent coatings. The wear resistance

of the coated steel is evaluated using pin-on-disk and

abrasive wear test. Chávez (2018) et.al investigated

the microstructural and tribological behavior of

coatings on AISI/SAE D2 grade tool steels using

HVOF (High-Velocity Oxy-Fuel) thermal spraying

process and GTAW (Gas Tungsten Arc Welding)

process. The performance and wear resistance are

enhanced and desired properties such as low porosity,

high adhesion and improved mechanical properties

are also achieved. It explored tribological behavior of

the coatings such as surface damage resistance, wear

and friction and the microstructural changes also

examined.

L Bourithis (2005) et.al explored the various

surface treatment methods such as heat treatments,

surface engineering methods and coatings to enhance

the wear behavior of low carbon steel. The authors

introduced the modified strategies to enhance the

wear resistance of low carbon steel surfaces.

S. Piçarra (2019) et.al proved in their studies that the

molybdenum coating improved the adhesion, stability

and durability of staphylococcus aureus which is a

common bacterium with nosocomial infections.

N González (2020) et.al studied the effect of alumina

coatings on steel using automated image processing

techniques applied on isolated splat samples.

Excellent thermal properties and wear resistance can

be achieved by these coatings, but achieving defect

free and uniform coating is challenging due to

complexity involved in bonding between coating and

substrate material during thermal spray process.

Spray distance, powder feed rate and spray angle are

identified the influencing parameters on thermal

spray process using statistical techniques.

M.M.A. Bepari and Shorowordi K.M (2004)

studied the effect of nickel and molybdenum coating

on carburized and hardened low carbon steels to

improve the wear resistance and also further addition

of coating leads to improve the mechanical properties

such as yield strength, tensile strength and impact

Enhancement of Three-Body Wear Resistance of Steel Substrate Using Molybdenum Coating for Steel Roller Conveyor

117

toughness. Hwang (2004) et.al demonstrated that the

MoO3-Al coating using plasma spray on the substrate

exhibit a dense and well bonded structure with less

porosity. Compared to pure Al coating, MoO3-Al

gives better wear resistance and hardness. G. Bruno

(2006) et.al presented the study on residual stress

analysis of steel gear wheels with molybdenum

coating using thermal spray coating process to find

the influence of coating in wear resistance

enhancement. The stress distribution of coating may

affect the performance which is analyzed using

residual stress analysis. Zhongsheng (2023) et.al

investigated the effect of multilayer coating of

MSZ(mullite-stabilized zirconia) and molybdenum

using plasma spray and hot isostatic pressing to

enhance the resistance which is able to withstand high

temperature ablation in extreme conditions. Good

bonding and less cracking are exhibited between the

layers which leads to efficient stress transfer and good

mechanical integrity.

It is observed that three-body abrasive wear

research is lagging and less papers on abrasive

particles impact on coatings. Therefore, this paper is

aiming to assess and compare the effectiveness of

molybdenum thermal sprayed coating system with

the uncoated system in order to address the issue of

wear rate in steel conveyor rollers. Based on the

observations made from literature, stainless steel is

the predominant choice of material for the rollers and

the main dis advantage of the steel rollers is abrasion

wear. To overcome this, among various techniques

the plasma spray process is identified as effective

technique to achieve effective bonding and less wear

rate. A molybdenum coating is selected to enhance

the wear characteristics in this study.

The main objective of this study is to find the

coating influence on steel in wear environment and

enhancing wear resistance by various grain size and

by achieving the following objectives

To provide molybdenum coating on

stainless steel SS304 using plasma spray coating

process and asses the coating properties

To compare the performance of a

Molybdenum coated steel with uncoated steel when

exposed to a wear environment.

To determine the optimal range of

Molybdenum coating thickness on the substrate.

2 EXPERIMENTATION

The experimentation process is explained in the

below sections.

2.1 Methodology

1. A comprehensive review of the literature is

conducted to gain insights into various

materials, their applications, coating

substrates, and their characteristic properties.

2. Based on the findings from the literature

survey and considering the desired properties,

appropriate materials are selected and

procured for the specific application.

3. Initially uncoated stainless steel SS304

characterized to assess the performance

without coating using SEM, EDAX and

hardness test.

4. Stainless steel SS304 is coated by

Molybdenum using plasma spray technique.

5. Characterization of Molybdenum coated

stainless steel SS304 samples using SEM,

EDAX and hardness test.

6. Comparison of performance characteristics of

coated and uncoated stainless steel SS304 in

terms of microstructure, composition and

hardness.

SS304 is austenitic steel of T300 series is selected as

base material for this research which is widely used

in different industrial applications because of its high

corrosion resistance, high tensile strength and higher

temperature resistance. It consists of minimum 18 %

of chromium and maximum 0.08 % of carbon. The

material is obtained from Sri Durga sales in

Bengaluru. The purchased material had dimensions of

75 mm by 25 mm with a thickness of 8 mm which is

shown in figure 1.

A steel strip measuring 25 mm by 8 mm was cut

from the obtained material using a Bandsaw-Double

column machine, with each piece being cut to a length

of 75 mm. Subsequently, the cut specimens

underwent hand grinding to achieve a flat surface

along the edges, ensuring proper fitting into the

specimen holder which is shown in figure 2. In this

research, ASTM G65 standard test is used to evaluate

the three-body abrasion. In this test, a dry sand/rubber

wheel abrasion test is conducted using rubber wheel

abrasion tester which is shown in figure 3.

The standard test specimen, with dimensions of

75*25*8, is securely mounted on a clamp, while the

rubber wheel is pressed against it with a specified

ISPES 2023 - International Conference on Intelligent and Sustainable Power and Energy Systems

118

force using a lever arm. The setup configuration and

details are shown in table 1.

Figure 1: Stainless steel-304.

Figure 2: Grinding.

Figure 3: Rubber wheel abrasion tester.

Table 1: Rubber wheel abrasion test rig specifications.

Test parameter

Details

Wheel

Chlorobutyl rubber A-60, dia

228.6*32.7mm

Sand

AFS50/70, Quartz sand

Sand Flow rate

350 gms/min

Pre-load on rubber

wheel

2.62 kg

Loading lever ratio

1:2.42

Happer capacity

15 kg

The abrasion wear of the test surface of the sample

is regulated by the flow of grain in terms of grain size,

speed or sliding distance and load. Grain size is varied

from fine sand to coarse sand (200um, 300um and

600um), speed varies from 50rpm t0 150rpm (50 rpm,

100rpm and 150 rpm) and load varies from 25.702N

to 72.986N(25.702N, 49.344N and 72.986N).

Figure 4: Dry Sand of different grain size (200,

300,600micron).

Mass loss is calculated by measuring the weight

before and after the test using electro weighing scale

which has 0,01 precision. The formula used to

calculate the Mass loss is given below

Mass loss = Initial weight – Final weight

Then the volume loss is converted from Mass loss in

cubic millimeters.

Volume loss = [Mass loss * 1000 / Density]

Then the Specific wear is calculated using

Specific wear rate = [ (Volume loss) / (Load *

Abrading distance)]

The obtained data from the test procedure for both the

uncoated and coated specimens undergoes a series of

Enhancement of Three-Body Wear Resistance of Steel Substrate Using Molybdenum Coating for Steel Roller Conveyor

119

calculation procedures, and their respective

characteristics are considered for comparison.

3 RESULTS AND DISCUSSIONS

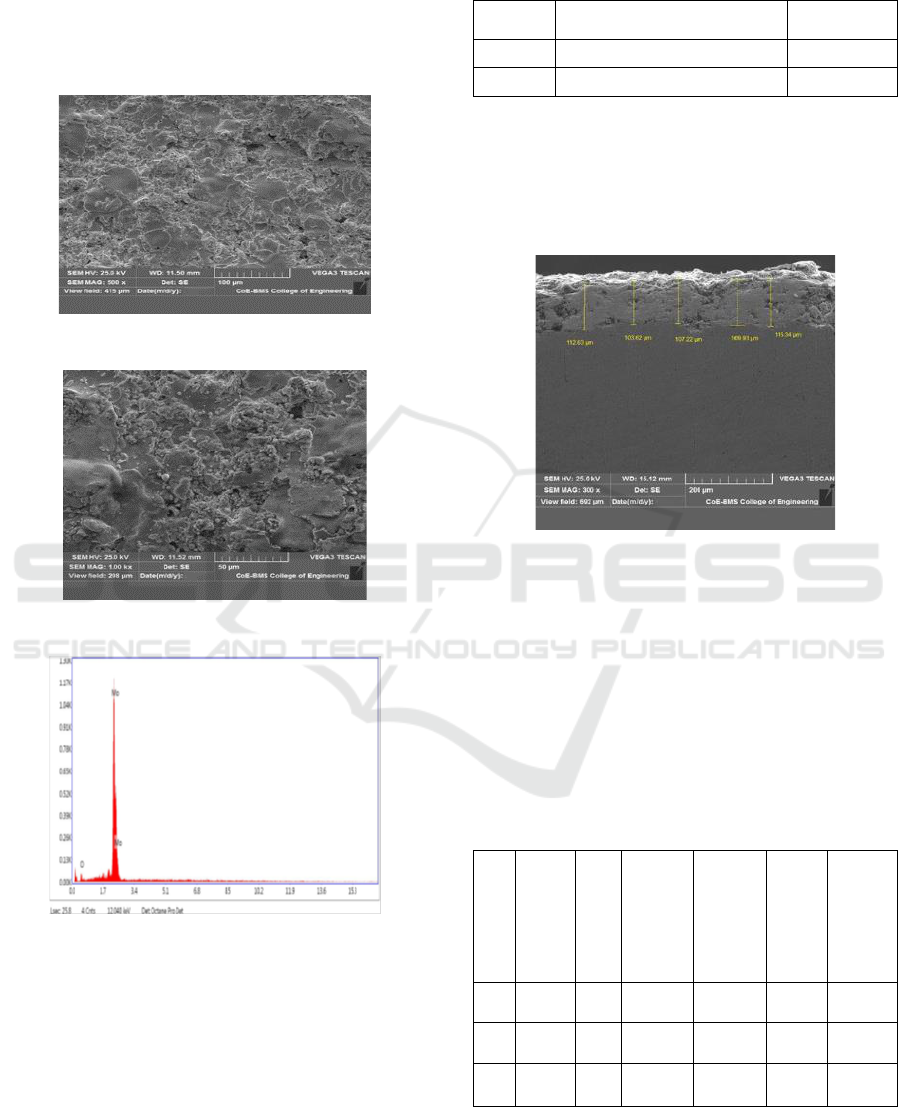

Figure 5a: SEM image of coated sample at 500X.

Figure 5b: SEM image of coated sample at1000X.

Figure 6: EDAX spectrum of coated sample.

SEM images of coated sample at different

magnification such as 500X and 1000X are shown in

figure 5 and EDAX analysis is performed to find the

composition of coated sample which is shown in

Figure 6. The spectrum obtained from EDAX

provides confirmation of Molybdenum presence in

coated sample. The atomic and weight percentage of

the elements obtained through EDAX analysis is as

shown in table 2.

Table 2: Atomic and Weight Percentage of Elements in

Coated Sample.

Element

Weight %

Atomic %

MoL

89.28

58.13

OK

10.72

41.87

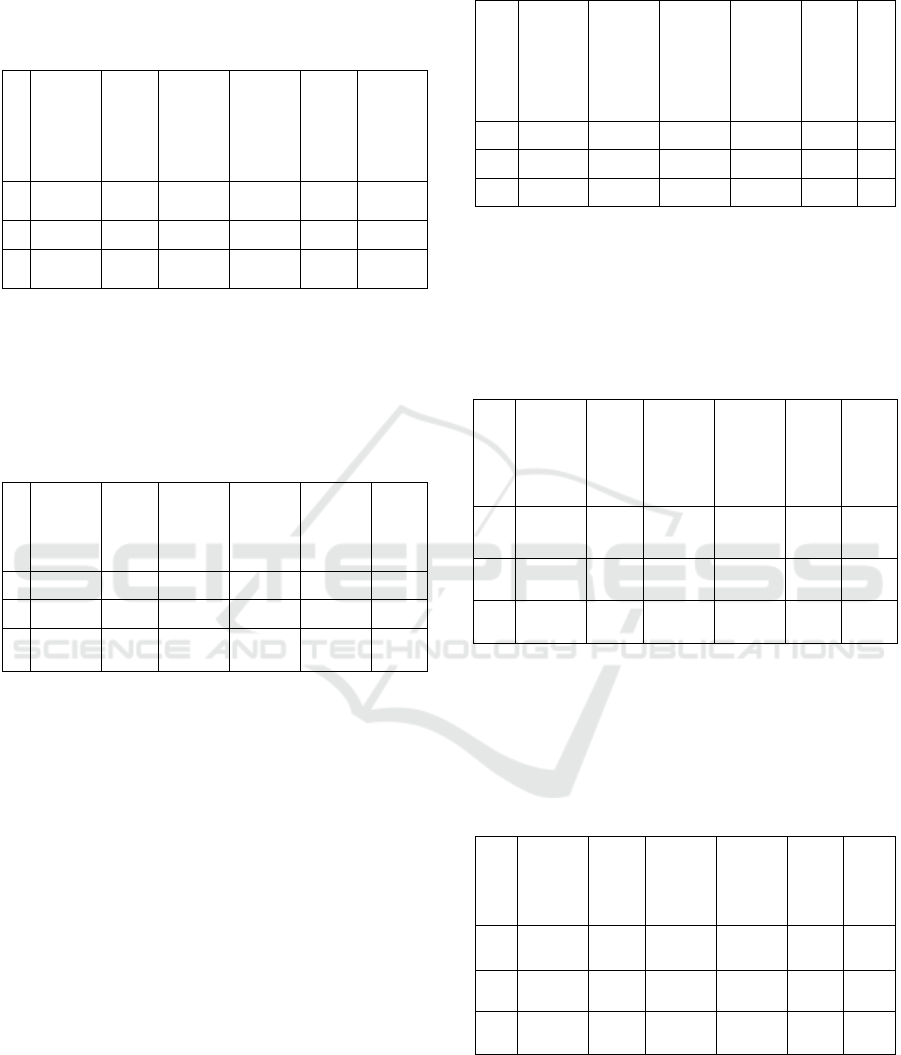

There are five different coating thicknesses along

the length from SEM image are considered for the

thickness measurement. The average thickness

measured from the image is 110 microns from the

Figure 7.

Figure 7: Coating thickness measured using SEM.

The uncoated specimen is clamped in specimen

holder of rubber wheel abrasive tester and surface

contact with rubber wheel is ensured. Sand hopper is

filled with sand and the speed in terms of number of

revolutions of wheel is fixed accordingly load is also

placed on the lever arm. The results of 200, 300, 600

microns are tabulated in table 3, table 4 and table 5

which is shown below.

Table 3: Abrasion wear test results of uncoated specimen

(200 microns).

Sl.

no

Load

(N)

Spe

ed

(rp

m)

Initial

weight

(g)

Final

weight

(g)

Mass

Loss

(g)

Volum

e loss

(mmt)

1

25.70

2

50

121.37

2

121.35

9

0.013

1.639

2

49.34

4

100

122.70

9

122.69

1

0.018

2.269

3

72.98

6

150

121.62

4

121.59

7

0.027

5.170

The table shows that least value of volume loss

(1.639) was found for 50rpm and 25.072N load. the

ISPES 2023 - International Conference on Intelligent and Sustainable Power and Energy Systems

120

volume loss increased linearly for increased speed

and load conditions.

Table 4: Abrasion wear test results of uncoated specimen

(300 microns).

S

l

.

n

o

Load

(N)

Speed

(rpm)

Initial

weight

(g)

Final

weight

(g)

Mass

Loss

(g)

Volume

loss

(mmt)

1

25.702

50

122.534

122.519

0.015

1.891

2

49.344

100

121.156

121.134

0.022

2.774

3

72.986

150

122.262

122.218

0.044

5.548

The table shows that least value of volume loss

(1.891) was found for 50rpm and 25.072N load. the

volume loss increased linearly for increased speed

and load conditions.

Table 5: Abrasion wear test results of uncoated specimen

(600 microns).

S

l

.

n

o

Load

(N)

Speed

(rpm)

Initial

weight

(g)

Final

weight

(g)

Mass

Loss (g)

Volu

me

Loss

(mmt

)

1

25.702

50

120.388

120.370

0.016

2.017

2

49.344

100

118.839

118.184

0.025

3.152

3

72.986

150

121.717

121.669

0.048

6.052

The table shows that least value of volume loss

(2.017) was found for 50rpm and 25.072N load. the

volume loss increased linearly for increased speed

and load conditions.

The coated specimen is clamped in specimen

holder of rubber wheel abrasive tester and surface

contact with rubber wheel is ensured. Sand hopper is

filled with sand and the speed in terms of number of

revolutions of wheel is fixed accordingly load is also

placed on the lever arm. The results of 200, 300, 600

microns are tabulated in table 6, table 7 and table 8

which is shown below.

Table 6: Abrasion wear test results of coated specimen (200

microns).

Sl.

no

Load

(N)

Speed

(rpm)

Initial

weight

(g)

Final

weight

(g)

Mass

Loss

(g)

V

ol

u

m

e

lo

ss(

m

mt

)

1

25.702

50

123.043

123.032

0.011

1.

38

7

2

49.344

100

123.118

123.104

0.014

1.

76

5

3

72.986

150

124.171

124.154

0.017

2.

14

3

The table shows that least value of volume loss

(1.387) was found for 50rpm and 25.072N load. the

volume loss increased linearly for increased speed

and load conditions.

Table 7: Abrasion wear test results of coated specimen (300

microns).

Sl.

no

Load

(N)

Speed

(rpm)

Initial

weight

(g)

Final

weight

(g)

Mass

Loss

(g)

Volu

me

Loss

(mmt

)

1

25.702

50

123.877

123.864

0.013

1.639

2

49.344

100

123.638

123.621

0.017

2.143

3

72.986

150

124.051

124.026

0.025

3.404

The table shows that least value of volume loss

(1.639) was found for 50rpm and 25.072N load. the

volume loss increased linearly for increased speed

and load conditions.

Table 8: Abrasion wear test results of coated specimen (600

microns).

Sl.

no

Load

(N)

Speed

(rpm)

Initial

weight

(g)

Final

weight

(g)

Mass

Loss

(g)

Volu

me

loss(

mmt

)

1

25.702

50

124.670

124.654

0.016

2.01

7

2

49.344

100

124.353

124.334

0.019

2.39

5

3

72.986

150

124.469

124.420

0.027

3.40

4

Enhancement of Three-Body Wear Resistance of Steel Substrate Using Molybdenum Coating for Steel Roller Conveyor

121

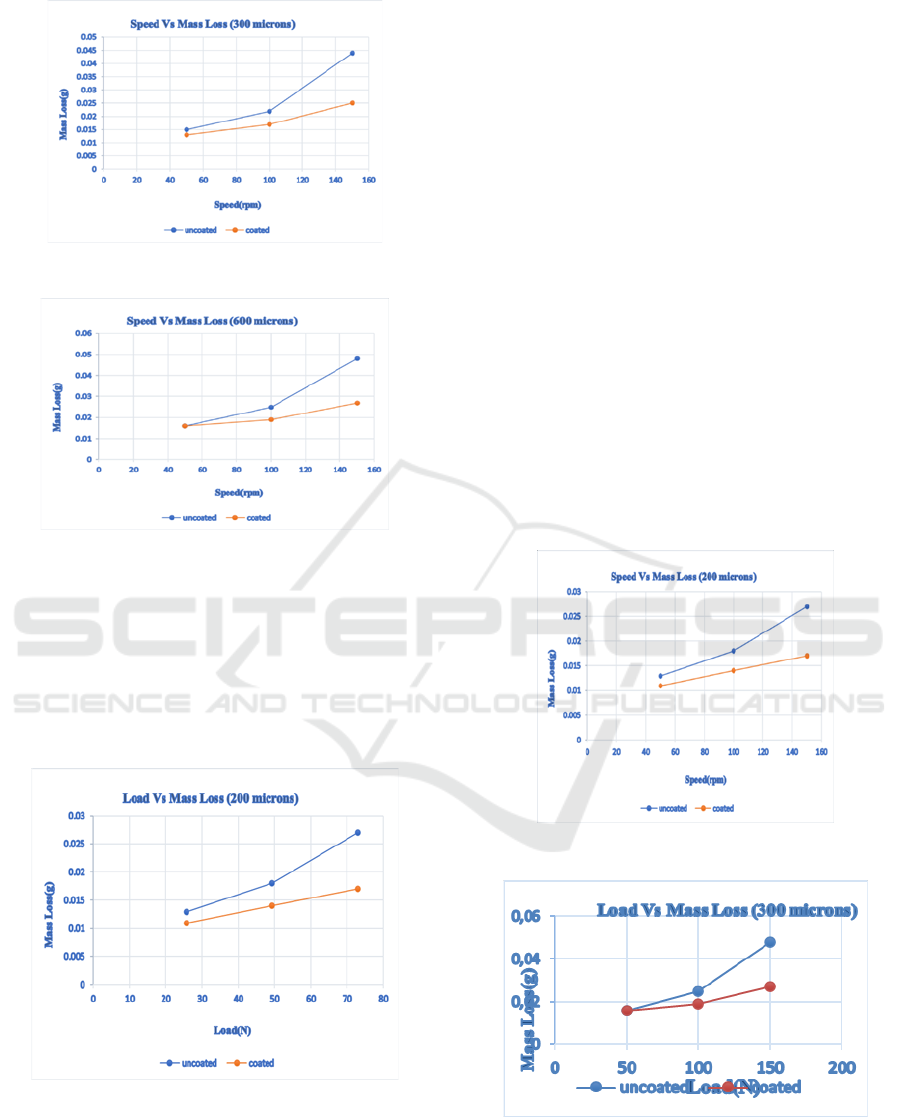

Figure 8: Load Vs Mass (200 microns).

Figure 9: Load Vs Mass (300 microns).

The table shows that least value of volume loss

(2.017) was found for 50rpm and 25.072N load. the

volume loss increased linearly for increased speed

and load conditions.

Load versus Mass loss graphs of both coated and

uncoated samples are plotted for different grain size

and shown in Figure 8-10.

Figure 10: Load Vs Mass (600 microns).

Linear relationship between load and Mass loss is

proved by all three graphs. Irrespective of Load and

grain size, coated samples mass loss is less compared

to uncoated steel samples which is proved by graphs.

From figure 9, it is observed that mass loss for both

coated and uncoated steel substrate are same for

minimum load value. At minimum load, with higher

grain size (600 micron) coating does not enhance the

abrasive wear resistance.

Speed versus Mass loss graphs of both coated and

uncoated samples are plotted for different grain size

and shown in Figure 10-12. Linear relationship

between speed and Mass loss is proved by all three

graphs. Irrespective of speed and grain size, coated

samples mass loss is less compared to uncoated steel

samples which is proved by graphs. From figure 12,

it is observed that mass loss for both coated and

uncoated steel substrate are same for minimum speed

value. At minimum speed, with higher grain size (600

micron) coating does not enhance the abrasive wear

resistance.

At minimum loads and speeds, the difference in

mass loss between the coated specimen and the

uncoated specimen is negligible in comparison to

higher loads and speeds. Coating has the influence

only on higher loads, because of oxide layer

generation in surface which acts as lubricant, which

leads to less mass loss and abrasive wear.

Figure 11: Speed Vs Mass (200 microns).

Figure 12: Speed Vs Mass (600 microns).

ISPES 2023 - International Conference on Intelligent and Sustainable Power and Energy Systems

122

4 CONCLUSION

This paper focused on evaluation of coating

performance of steel substrate which is used in

conveyor rollers which works under highly abrasive

environments. Main objective is to increase the three-

body wear resistance by molybdenum coating using

plasma spray technique. The results obtained from the

experimental analysis proved the improvement in

wear resistance after molybdenum coating. EDAX

and SEM analysis are performed to composition

identification and to find thickness of the coating.

Enhanced resistance to mass loss indicates the

improvement in wear resistance of molybdenum

coated steel. Following observations are made from

the experimental result and analysis

The observed trend indicates that both the

uncoated and coated samples exhibit a linear variation

as the parameters such as speed, load, and grain size

increase.

At lower loads and speeds, the disparity in wear

between the coated specimen and the uncoated

specimen is negligible in comparison to higher loads

and speeds.

The findings indicate that when subjected to

higher loads, an oxide layer is generated on the

surface, acting as a lubricant and decreasing the

friction coefficient. As a result, the presence of

abrasives is reduced, leading to a decrease in mass

loss and material wear.

The experiment was conducted with a consistent

coating thickness ranging from 100 to 150 microns.

This approach can be expanded to create coatings of

different thicknesses.

This research highlights the potential of

molybdenum powder coatings to enhance the

durability and lifespan of steel rollers in conveyor

systems operating in harsh environments. The

findings contribute to the development of effective

strategies for reducing wear and optimizing the

performance of mining and construction equipment.

The experimentation was conducted using the

atmospheric plasma spray process, but it is possible

to expand the study by employing various thermal

spray processes and assessing their performance.

REFERENCES

C.S. , Ramesh, Adarsha H., Anoushka Chaturvedi, and

Nikitha Nair. 2018. “Investigations on the Effect of

Molybdenum (Mo) and Molybdenum Silicon Carbide

(Mo-10% Sic) Composite Coatings on Mild Steel

Substrate using HVOF Technique,.” Materials Today:

Proceedings (Materials Today) 5 (11): 24422-24427.

doi:https://doi.org/10.1016/j.matpr.2018.10.238.

Chávez, Carlos Alberto Guevara, Jorge Leobardo Acevedo

Dávila, Pedro Hernandez Gutierrez, Jose Jorge Ruiz

Mondragon, and Patricia del Carmen Zambrano-

Robledo. 2018. “Tribological and microstructural

behaviour in coatings applied using GTAW and HVOF

(thermal spraying process) and used to recover

AISI/SAE D2 grade tool steels.” Intl.Journal of

Welding 32 (10): 660-666. doi: doi:

10.1080/09507116.2017.1347347.

G, Bruno, Fanara C, Guglielmetti F, and Malard B. 2006.

“Characterization and residual stress analysis of wear

resistant Mo thermal spray-coated steel gear wheels,.”

Surface and Coatings Technology 200 (14-15): 4266-

4276.

H., Adarsha, Ramesh C.S. , Nair Nikitha,

Karisiddeshwaraswamy K.M., and Chaturvedi,

Anoushka . 2018. “Investigations on the Abrasive Wear

Behaviour of Molybdenum Coating on SS304 and A36

using HVOF Technique,.” Materials Today:

Proceedings, 5 (11): 25667-25676.

Han, Ya-guang, Yong Yang, Lei Wang,, Xue-guang Chen,

Zhenhua Chu, Xu-ning Zhang, Yanchun Dong, et al.

2017. “Microstructure and properties of in-situ TiB 2

matrix composite coatings prepared by plasma

spraying.” Applied Surface Science 431. doi:Applied

Surface Science.

Huang, , Long, Xiangtao Deng, Ye Jia, Chengru Li, and

Zhaodong Wang. 2018. “Effects of using (Ti,Mo)C

particles to reduce the three-body abrasive wear of a

low alloy steel.” Wear 410-411.

doi:10.1016/j.wear.2018.06.008.

Hwang, Byoungchul, Sunghak Lee, and Jeehoon Ahn.

2004. “Correlation of microstructure and wear

resistance of molybdenum blendcoatings fabricated by

atmospheric plasma spraying.” Materials Science and

Engineering 152-163.

M.M.A. , Bepari, and Shorowordi K.M. 2004. “Effects of

molybdenum and nickel additions on the structure and

properties of carburized and hardened low carbon

steels,.” Journal of Materials Processing Technology,

155-156: 1972-1979.

doi:https://doi.org/10.1016/j.jmatprotec.2004.04.060.

Matache, Gheorghe & Puscasu, Cristian & Paraschiv,,

Alexandru & Trusca, and Oana. 2015. “Investigation of

some Intrinsic Properties of Thermal Sprayed

Molybdenum Coatings for Railway Axle

Applications.” Investigation of some Intrinsic

Properties of Thermal Sprayed Molybdenum Coatings

for Railway Axle Applications 811: 19-23.

N, González, Juan Zapata Pérez, Martínez V, Gadow R, and

García J. 2020. “Manufacturing parameter analysis for

alumina coating on steel substrate by automated image

processing of isolated splats samples.” PLoS ONE 15:

e0240928.

Patel G C, Manjunath, Pradeep N B, Girisha L, Harsha H

M, and Arun Kumar Shettigar. 2022. “Experimental

analysis and optimization of plasma spray parameters

on microhardness and wear loss of Mo-Ni-Cr coated

Enhancement of Three-Body Wear Resistance of Steel Substrate Using Molybdenum Coating for Steel Roller Conveyor

123

super duplex stainless steel.” Australian Journal of

Mechanical Engineering (Taylor & Francis) 20 (5):

1426-1438. doi:10.1080/14484846.2020.1808760.

R, Riastuti,, Siallagan S T, Rahmat Z, and Bancin B. 2018.

“The study of mechanical properties and corrosion

resistance of Molybdenum coating and Aluminum

coating using Thermal Spray method on stainless steel

316L.” IOP Conf. Series: Materials Science and

Engineering 420. doi:doi:10.1088/1757-

899X/420/1/012058 .

S, Ilaiyavel, and Venkatesan A. 2012. “Experimental

investigation of wear characteristics on manganese

phosphate coated AISI D2 steel.” International Journal

of Precision Engineering and Manufacturing 13: 581-

586. doi:https://doi.org/10.1007/s12541-012-0074-7.

S, Picarra, Elizeth Lopes, Pedro De Almeida, Herminia de

Lencastre, and Marta Aires-de-Sousa. 2019. “Novel

coating containing molybdenum oxide nanoparticles to

reduce Staphylococcus aureus contamination on

inanimate surfaces.” PLoS ONE 14: e0213151.

Zhongsheng, Li, Wu Hulin , Wei Zixiang , Song Kaiqiang

, Cong Dalong , Huang Anwei, Min Zhang, et al. 2023.

“Ablation behavior of Mo/MSZ thick alternate

multilayer fabricated by combinative processes of

plasma spray and hot isostatic pressing.” Ceramics

International, 49 (10): 15242-15252.

ISPES 2023 - International Conference on Intelligent and Sustainable Power and Energy Systems

124