CFD Simulation and Application of Semi-Closed Inclined Simple

Cold Channel in a Data Center Server Room

Kaili Zhao

1

, Dongyang Cai

1

, Yanshan Deng

1

, Rui Bo

1

, Xuening Zhang

1

, Yongmin Cao

1

, Li Wang

2

and Yanpeng Wu

3

1

Tangshan Power Supply Company, Tangshan, China

2

Beijing Siji Zhiyuan Technology Co., Ltd, Beijing, China

3

University of Science and Technology Beijing, Beijing, China

Keywords: Existing Server Room, CFD Simulation, Hot and Cold Mixing, Simple Cold Channel, Semi-Closed Inclined

Simple Cold Channel.

Abstract: An experimental study has been conducted on the simulation and application of semi-closed inclined simple

cold channel in a data center server room. We simulated the airflow condition of each channel inside an

existing server room and the effectiveness of the original semi-closed inclined simple cold channel with the

assistance of Computational fluid dynamics (CFD) simulation,and then analyzed the airflow problem of the

cabinet inlet in the hot and cold mixed flow channel. In this study, high degree of hot and cold airflow mixing,

short circuiting of air in front of cabinets and uneven air conditioning operation load in the server room are

main problems. Three-dimensional numerical simulation technology can not only simulate the expected effect

of the project, but discover potential problems, lay the foundation for later project implementation, and show

the direction for field verification after completion.

1 INTRODUCTION

"Carbon peak" and "carbon neutrality" are hot topics

in today's society, and it is imperative to implement

energy saving and thermal environment optimization

for existing server rooms. In 2011, China's data

centers consumed 70 billion kWh of electricity,

accounting for 1.5% of society's electricity

consumption (Gao C F, 2013). The energy

consumption of the server rooms is proportional to

the operation safety of the IT equipment. High energy

consumption leads to high security, while low energy

consumption leads to reduced security. The

prerequisite for energy saving is to ensure the safety

of the equipment in server rooms. Measuring whether

a data center is energy efficient is actually a measure

of the optimal ratio of energy consumption of each

part under the premise of ensuring the safe and stable

operation of equipment, and ensuring the maximum

energy efficiency ratio of equipment such as servers

and network storage (Qian X D, 2012) As cooling is

responsible for the considerable fraction of the total

facility energy consumption, it is apparent that most

data centers possess ineffective cooling systems and

need effective air and thermal management (Ahmadi

V E, 2020) In order to meet the requirements of the

equipment in the server room for temperature and

humidity, cleanliness, air supply speed and other air

environment parameters, as well as to meet the

requirements of energy saving and consumption

reduction, a reasonable airflow organization is

required to effectively eliminate the heat in the server

room (Liu T T, 2015) In many earlier server rooms,

the arrangement of the internal cabinets is not

completely separated from the cold and hot channels,

and there are cold and hot mixed flow channels (Gao

C F, 2013) The usual approach to optimize the

thermal environment of the server room is to close the

hot and cold channels, (Gao C, 2015) if the average

power of the cabinet in server rooms is not high and

the equipment density is low, then the cost-

effectiveness ratio of the project will be too high,

obviously not worth the loss, and most of the channels

of hot and cold mixed flow are not suitable for closure

in the conventional sense. In view of this

phenomenon, a semi-closed bevel simple cold

channel is created according to local conditions to

separate the cold and hot air flow in the channel as

much as possible, reduce the degree of cold and hot

air mixed flow, eliminate the phenomenon of short

circuit in front of the cabinet, and optimize the

average air inlet temperature of the cabinet. Before

542

Zhao, K., Cai, D., Deng, Y., Bo, R., Zhang, X., Cao, Y., Wang, L. and Wu, Y.

CFD Simulation and Application of Semi-Closed Inclined Simple Cold Channel in a Data Center Server Room.

DOI: 10.5220/0012287300003807

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Seminar on Artificial Intelligence, Networking and Information Technology (ANIT 2023), pages 542-551

ISBN: 978-989-758-677-4

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

the implementation of the project, it is necessary to

use CFD simulation software to conduct simulation

tests, to see whether the optimization results meet the

expectations, and to see the impact of the chain

reaction of air flow changes on the thermal

environment of other channels.

2 CFD SOFTWARE

The research on the thermal environment of the

equipment room mainly evaluates the parameters of

the equipment room by establishing mathematical

models, establishing equal scale model tests and

using CFD simulation to simulate and construct the

thermal environment of the equipment room. The

conditions of the model experiment are strict, and the

research process is time-consuming and labor-

intensive. In contrast, CFD simulation modeling is

more efficient and convenient. CFD is an acronym for

Computational Fluid Dynamics. CFD simulation

software is based on the three conservation laws of

fluid flow (conservation of mass, conservation of

momentum and conservation of energy). It is used to

analyze, calculate and predict different physical

quantities (pressure, temperature, speed, etc.) in the

convection field through computer numerical

simulation and graphic images. It is mainly used to

solve various practical problems such as fluid flow,

heat conduction and momentum transfer in

engineering field. Different CFD software, its

functional focus and application areas are different,

can be subdivided into dozens of.

To construct the physical model of the machine

room and simulate the temperature and velocity fields

inside it, it is first necessary to determine the

mathematical model of the machine room, mainly the

control equation model, and the turbulence model.

Control equation modeling describes the basic

physical laws of fluids and macroscopic flow

phenomena. By solving these equations through

numerical methods, the distribution of physical

quantities such as velocity, pressure, and temperature

of the flow field in time and space can be obtained.

The control equation modeling starts with the

assumption that the machine room is well sealed, that

internal and external gases do not communicate

through doors and windows, and that the gas flow in

the machine room must satisfy the law of

conservation of mass, which is:

0

)()()(

z

w

y

v

x

u

t

Where u, v and w are the components of the

velocity vector u on the X, Y, and Z axes, respectively,

in m/s. ρ is the gas density in kg/m

3

, and t is the time

in s. This equation represents the mass conservation

of the fluid in the control volume. That is, the mass of

the inflow control body is equal to the mass of the

outflow control body.

The gas flow in the machine room also needs to

meet the law of conservation of momentum, so the

momentum components of the gas in the machine

room on the X, Y, and Z axes must meet the law of

conservation of momentum, which is:

F

zyxz

p

pwudiv

t

w

F

zyxy

p

pvudiv

t

v

F

zyxx

p

puudiv

t

u

z

zz

yz

xz

y

zyyyxy

x

zx

yx

xx

)(

)(

)(

)(

)(

)(

Where, p is the pressure on the fluid cell body, and

the unit is Pa;

F

n

is the force on the fluid element, the unit is N;

τ

nn

is the viscous stress on the fluid element, the

unit is N/m

2

.

Since the machine room contains heat exchange, it

must also meet the law of conservation of energy,

which is:

T

sgardT

cp

k

divuTdiv

t

T

)()(

)(

This formula can be expanded to:

T

ppp

ssss

s

z

T

c

k

zy

T

c

k

yx

T

c

k

xz

wc

y

vc

x

uc

t

c

)()()()(

where c

p

is the specific heat capacity, the unit is

J/kg•K;

T is the temperature, the unit is K;

k is the fluid heat transfer coefficient;

S

T

is the viscous dissipation term, which is the

fraction of mechanical energy converted to thermal

energy due to viscous action on the gas, the unit is J.

Turbulence modeling refers to the introduction of

additional equations to describe the turbulence effect

of the fluid on the basis of the control equation model,

and the turbulence characteristics of the flow field are

obtained by solving the control equation and the

additional equations through numerical methods.

Because of the slow flow rate of the gas in the

machine room, its pressure change is small, so the gas

density is mainly caused by the temperature change.

Therefore, it is assumed that the gas meets the

Boussinesq assumption, i.e., ignoring the change in

gas density caused by the change in pressure and only

CFD Simulation and Application of Semi-Closed Inclined Simple Cold Channel in a Data Center Server Room

543

considering the change in density caused by the

change in temperature. Given that the gas flow in the

computer room is a large space air flow problem, the

standard k-ε model of turbulence calculation with

high Rayleigh number is used here, and the turbulent

flow viscosity is expressed as a function of the

turbulent pulsation kinetic energy k and the flow

dissipation rate ε. The turbulent flow viscosity is

expressed as a function of the turbulent flow

dissipation rate. The turbulent pulsation kinetic

energy k and flow dissipation rate ε are:

))((

)vu(

2

1

K

222

k

l

k

l

x

u

x

u

u

w

Then the turbulent flow viscosity μ

t

is:

2

t

KC

C

μ

is the empirical coefficient.

In this paper, the simulation operations involved in

testing and practice are all carried out with the help of

a mainstream CFD software - 6SigmaDC, which is

developed by Future Facilities in the UK, and has a

rich and diverse model library, which is easy to build

a data center room, simulate, emulate, and predict the

thermal environment in the data center, and can

display the temperature field, airflow field, pressure

field, humidity, and other environmental conditions in

a variety of ways, such as animation, video, and so on.

3 THE CFD MODELLING AND

SIMULATION OF AN

EXISTING SERVER ROOM

The server room was built and put into use in 2012,

and the IT equipment in the cabinets is old but still

meets the demand. With the adjustment of the

information security policy within the industry, some

functions of the server room were relocated elsewhere,

and some of the equipment in the cabinets are

currently out of service, and the overall load of the

server room has decreased compared to the previous

period.

3.1 Basic Parameters of Server Room

The length of the server room is about 2400mm, the

width is about 1600mm, and the total area is about

384m

2

.

The floor height of the server room is 4500mm, the

walls and columns are covered with color steel plates,

and the internal net height of the server room is

2850mm.

The height of electrostatic movable floor overhead

is 470mm, and the ceiling height of aluminum alloy

microporous square plate is 1180mm.

The air is supplied under the elevated floor, the

grille size is 600*600mm, the opening rate is 50%,

and the natural return air is used.

The server room is equipped with 4 precision air

conditioners with a total nominal cooling capacity of

284kW and a total nominal air volume of 80-640m3/h.

The 77 network cabinets and 7 double-sided

distribution head cabinets in the server room are

distributed in 7 columns (ABCDEFG), each column

consists of 11 network cabinets and 1 double-sided

distribution head cabinet, and the middle of each

column is disconnected by the channel and column,

separated into two groups (5+7). Cold and hot

channels are not closed design, in which the cold

channel of column F and the hot channel of column G

are mixed side by side.

In addition, there are 6 UPS power supply cabinets

in the server room, supplying power to 7 double-sided

power distribution cabinets and 4 precision air

conditioners as well as lighting and security

equipment.

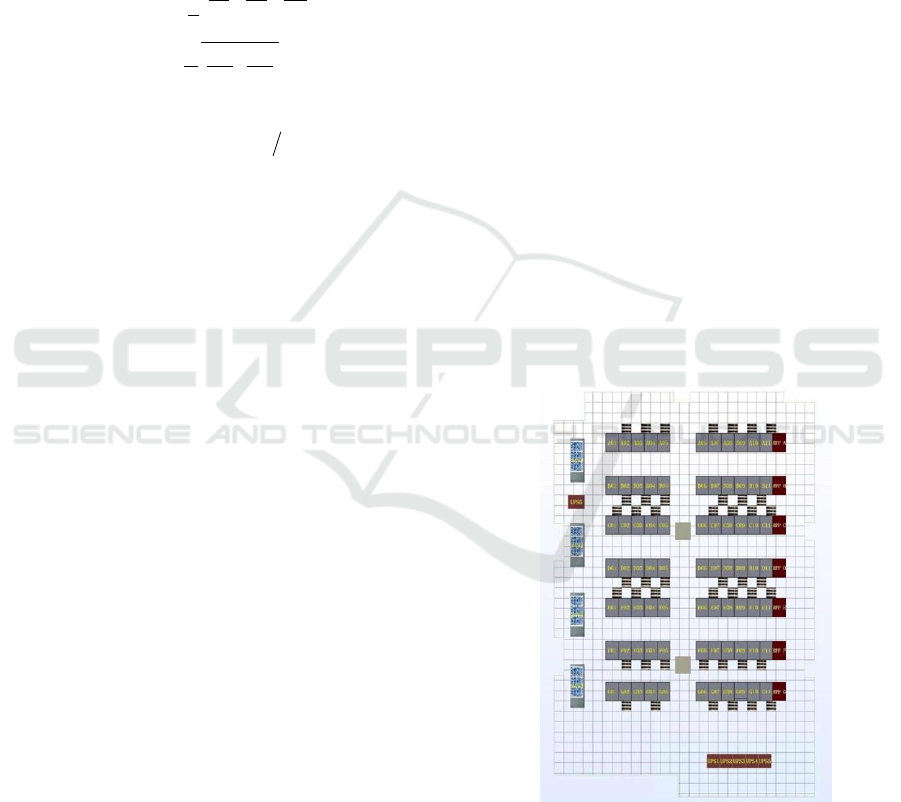

Figure 1: Floor plan of the server room.

3.2 Floor Plan and 3D Model of the

Server Room Constructed by CFD

The floor plan of the server room (Figure 1) and the

3D model of the server room (Figure 2) show the

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

544

main equipment and facilities such as walls, columns,

network cabinets, power distribution column head

cabinets, precision air conditioners, UPS power

supply cabinets, and delivery grilles.

Figure 2: 3D model of the server room.

3.3 CFD Simulation and Analysis of the

Current State of the Thermal

Environment of the Server Room

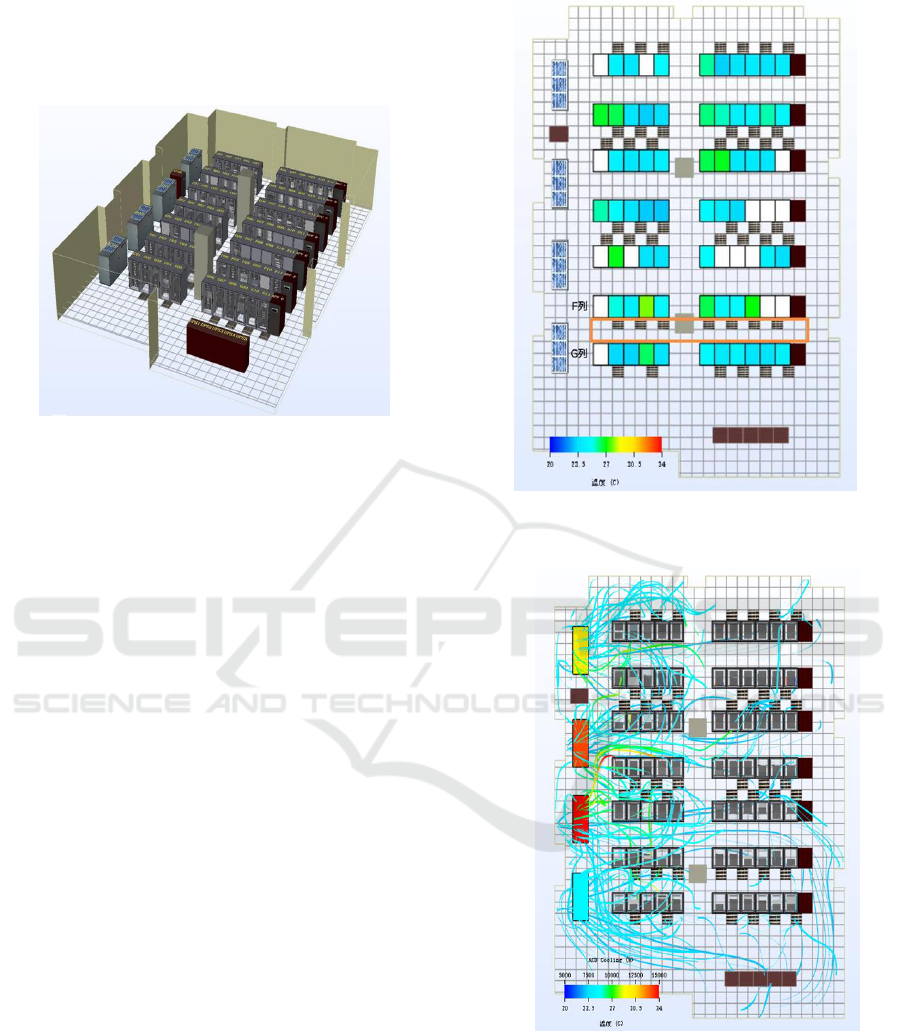

The four precision air conditioners in the server room

were all in operation, with a total nominal cooling

capacity of 284kW and the air supply temperature set

at 23℃. According to the site statistics, among the 77

network cabinets, except for the wiring equipment

cabinets and the cabinets out of operation, the total

operating power of the remaining 61 cabinets was

about 49.9kW. The hot and cold channels in the server

room were not designed to be closed, and there was a

mixed heat channel between columns F and G. CFD

software was used for 3D modeling of the server

room, and the overall thermal environment status was

obtained by simulation. The average inlet air

temperature of the cabinets (Figure 3) basically

conforms to the safety range of 18℃-27℃ as

stipulated in GB50174-2017 Code for Design of Data

Centers; the maximum sensible cooling power of the

precision air conditioner is 15kW, the minimum

sensible cooling power is 8.484kW, the maximum

return air temperature is 25.2℃, and the minimum

return air temperature is 23℃ (Figure 4); the return

heat index (RHI) of the server room is 0.803, and the

return temperature index (RTI) is 31.5.

The above data reflect the following problems in

the internal airflow organization of the server room:

high degree of mixing of hot and cold airflow inside

the server room; prevalence of air short-circuit in

front of the cabinet; uneven load of precision air

conditioning operation.

Figure 3: Average inlet air temperature distribution of

cabinets in the server room.

Figure 4: The power and flow diagram of precision air

conditioning in the server room.

CFD Simulation and Application of Semi-Closed Inclined Simple Cold Channel in a Data Center Server Room

545

4 CFD SIMULATION AND

ANALYSIS OF A SIMPLE

COLD CHANNEL WITH SEMI-

CLOSED INCLINED SURFACE

The hot and cold channels in the server room were not

closed, and there was a hot and cold mixing channel

between columns F and G. The cold channel of

column F is prepared to be semi-closed in order to

optimize the average air inlet temperature of column

F cabinets. The simulation will be carried out by CFD

software before construction to verify whether the

engineering effect meets the expectation.

4.1 Current Status of Hot and Cold

Mixed Flow Channels

The four cabinets of F column (F03, F04, F08, F09)

and eight cabinets of G column (G02, G03, G04, G05,

G07, G08, G09, G10) were installed with gigabit

enterprise switches and routers. The total power of G

column cabinet is the highest, and the hot channel of

G column and the cold channel of F column are mixed.

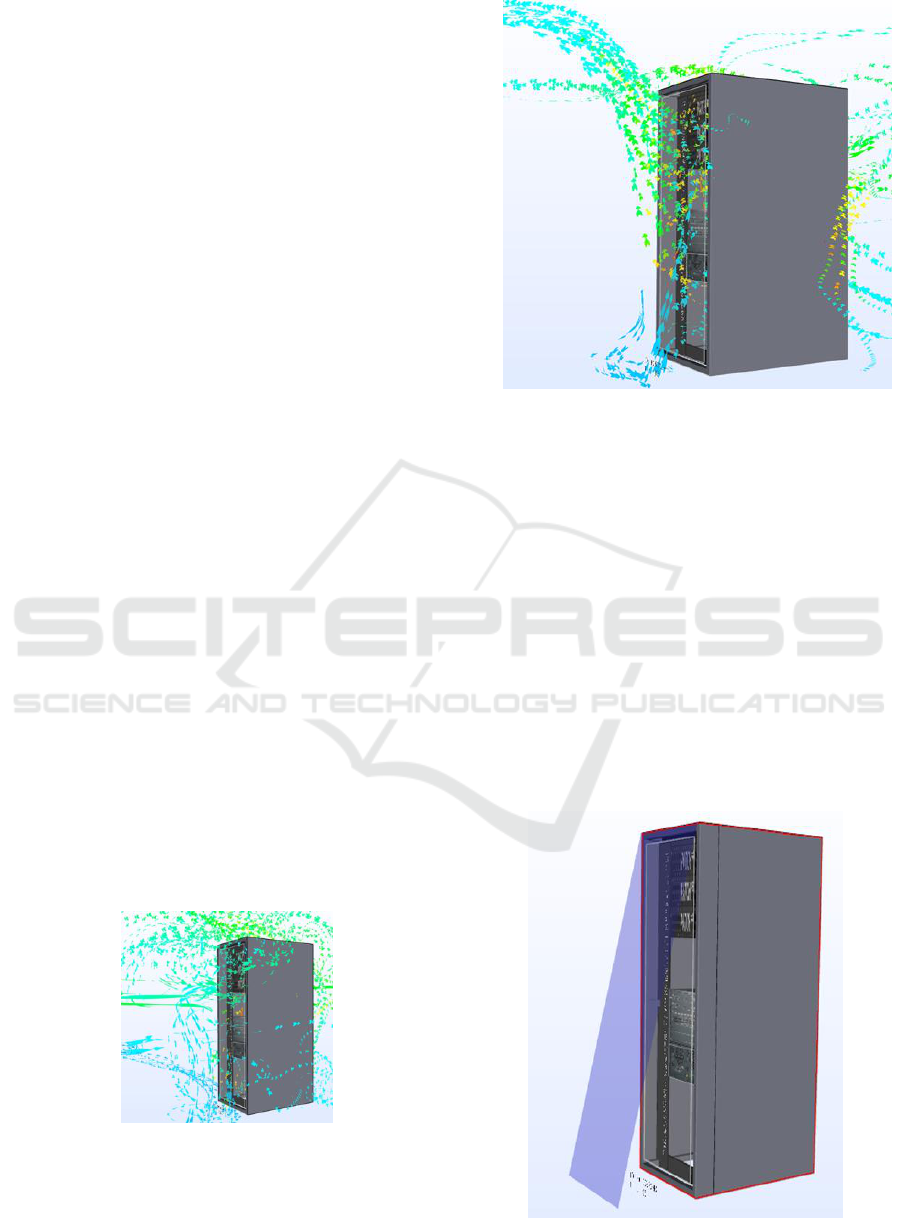

CFD simulation results show that the hot air

exhausted from the high-powered equipment in

column G cabinets either enters directly into column

F cabinets to form air recirculation at the top (Figure

5), or mixes into the grille air supply to bring the cold

airflow directly to the top of the channel causing air

short circuit in front of the cabinets (Figure 6), these

phenomena make the average inlet air temperature of

the three cabinets in column F high, exceeding 26°C,

and the interior is prone to invisible hot spots.

The width of the channel between the cabinets in

column G and the cabinets in column F is only

1200mm, it is not possible to carry out a full cold

channel closure in the conventional sense.

Figure 5: F09 Mixed flow in front of the cabinet and air

recirculation at the top.

Figure 6: Mixed flow and short circuit in front of the F04

cabinet.

4.2 CFD Simulation Results for a

Simple Cold Channel with a Semi-

Closed Inclined Surface in Column

F

In view of the limited space in the channel and the

ease of daily observation and maintenance of the

equipment inside the cabinets, the individual air

curtains in the sloping cold channel take the form of

transparent roller blinds that can be freely retracted

(Figure 7). The cold channel constructed from

continuous air curtains is open on both sides with

triangular sides and a 4mm gap between adjacent air

curtains between cabinets (Figure 8).

Figure 7: Single cabinet air curtain.

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

546

Figure 8: Semi-closed inclined simple cold channel for F

column 01-05 cabinets.

The CFD simulation results show that the semi-

closed inclined simple cold channel can effectively

separate cold and hot air forward. On the one hand,

the hot air discharged from the cabinets in column G

is directed to the top of the channel, and on the other

hand, the cold air sent from the floor grille is

introduced into the cabinets in column F, basically

eliminating the air short circuit in front of the cabinets

in column F and the air recirculation at the top of the

cabinet (Figure 9). The average inlet air temperature

of the cabinets in column F is reduced by 1.6℃ to

below 26℃, and the temperature field is obviously

optimized (Figure 10).

Figure 9: Single cabinet air curtain flow diagram.

Figure 10: Average inlet air temperature distribution of

cabinets after retrofitting.

4.3 Chain Effects and Refinement

Measures for the Establishment of

a Semi-Enclosed Sloping Simple

Cold Aisle in Column F

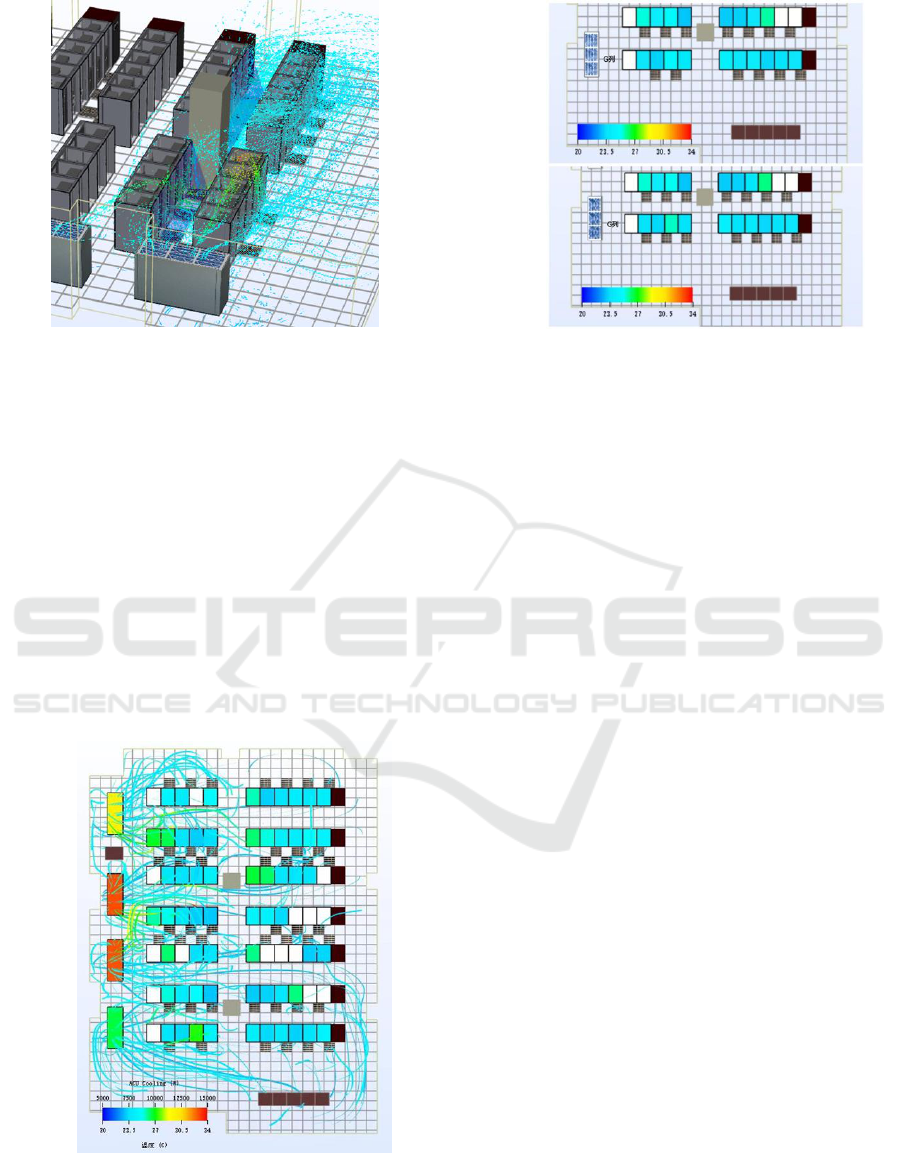

By comparing the CFD simulation results, we found

that before the renovation, the exhaust air from the

high-powered equipment in column G not only

directly affected the inlet air temperature of column F,

but also indirectly affected the temperature field of

column E (Figure 11). This not only significantly

reduces the chance of mixing hot and cold airflow in

adjacent channels, but also partially improves the

uneven loading of the air conditioners. The apparent

cooling power of the four precision air conditioners

was 12.2kW, 14.3kW, 15kW and 8.484kW before the

retrofit, and 11.8kW, 14.2kW, 14.1kW and 9.808kW

respectively after the retrofit (Figure 13). The heat

return index of the server room was increased from

0.803 before the retrofit to 0.865.

Figure 11: Flow diagram of the G-column cabinets before

the renovation.

CFD Simulation and Application of Semi-Closed Inclined Simple Cold Channel in a Data Center Server Room

547

Figure 12: Flow diagram of G-column cabinets after retrofit.

The semi-closed inclined cold channel in column

F separates the hot and cold airflow at the same time,

its wind-blocking effect also affects the exhaust air of

the left inlet and right outlet equipment in individual

cabinets in column G. The simulation results show

that the average inlet air temperature of cabinet G04

has increased by 0.3°C to 26.6°C. In response to this

phenomenon, two optimization solutions are obtained

through CFD software testing, one is to adjust the

position of the air supply grille in front of cabinets 01-

05 in column G, and the other is to add an additional

air supply grille in front of cabinets 01-05 in column

G. Both could reduce the average air inlet temperature

of cabinet G04 by 1.7°C and 1.5°C respectively

(Figure 14), with similar effects.

Figure 13: Sensible cooling power and flow diagram of

precision air conditioners in the renovated server room.

Figure 14: Comparison of average inlet air temperature

distribution after adjusting grilles in column G.

5 PRACTICE AND TESTING OF

A SIMPLE COLD CHANNEL

WITH SEMI-CLOSED

INCLINED SURFACES

After obtaining the simulation results through CFD

software, the field construction was carried out in the

server room, and the field effectiveness of the semi-

enclosed inclined simple cold channel was installed

and monitored.

5.1 Install Air Curtains in Front of Key

Cabinets in Column F

The single wind curtain of the inclined cold channel

is a transparent polyester film (PET film) with a

thickness of 10μm, a width of 780mm and a

maximum length of 2300mm. The rolling curtain

base was made of PVC. The length of the rolling

curtain is 800mm, which is the same as the width of

the cabinet top. The two ends and the middle part are

fixed to the cabinet top. The roller handle is equipped

with a hook, which is easily fixed to the elevated floor

or the air supply grille.

Since the average inlet air temperature of F03, F04,

F08, and F09 cabinets with key equipment in column

F is high, continuous air curtains are first installed in

front of these four cabinets and in front of F02, F05,

F07, and F10 cabinets on both sides (Figure 15 and

Figure 16).

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

548

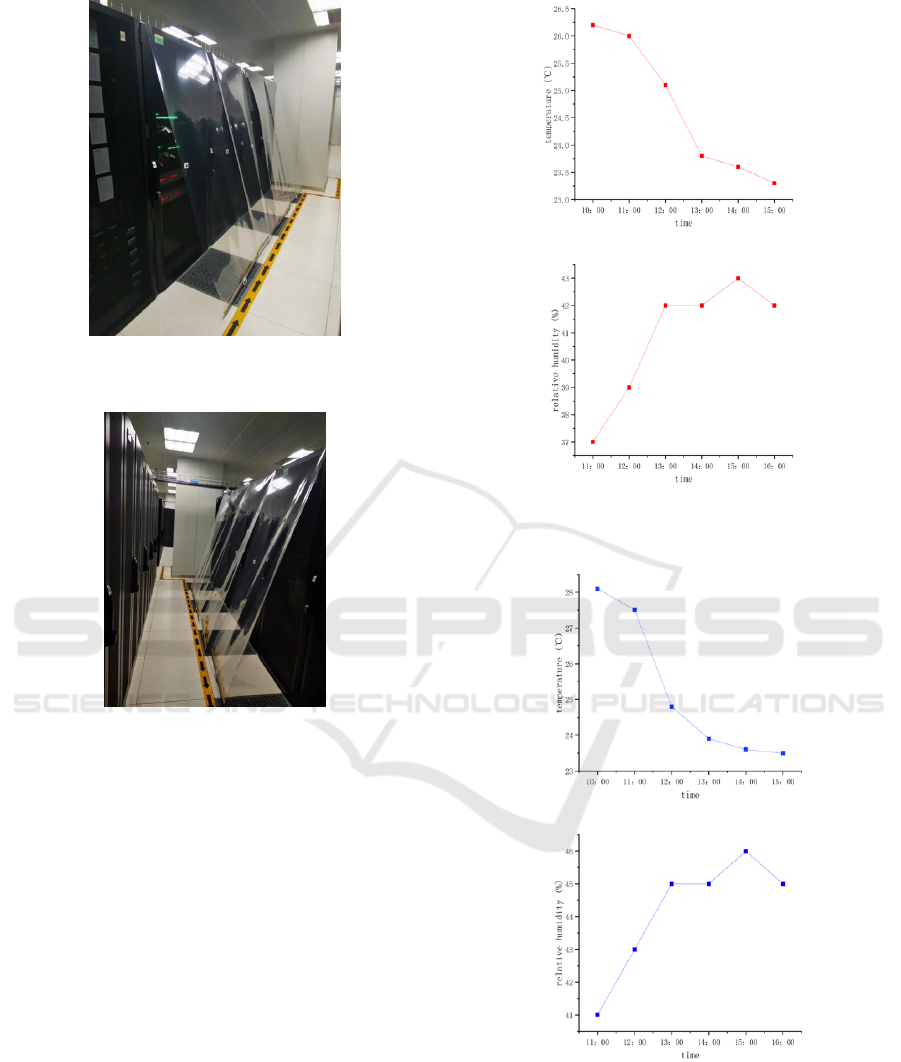

Figure 15: Continuous air curtain in front of the F02-F05

cabinets.

Figure 16: Continuous air curtain in front of the F07-F10

cabinets.

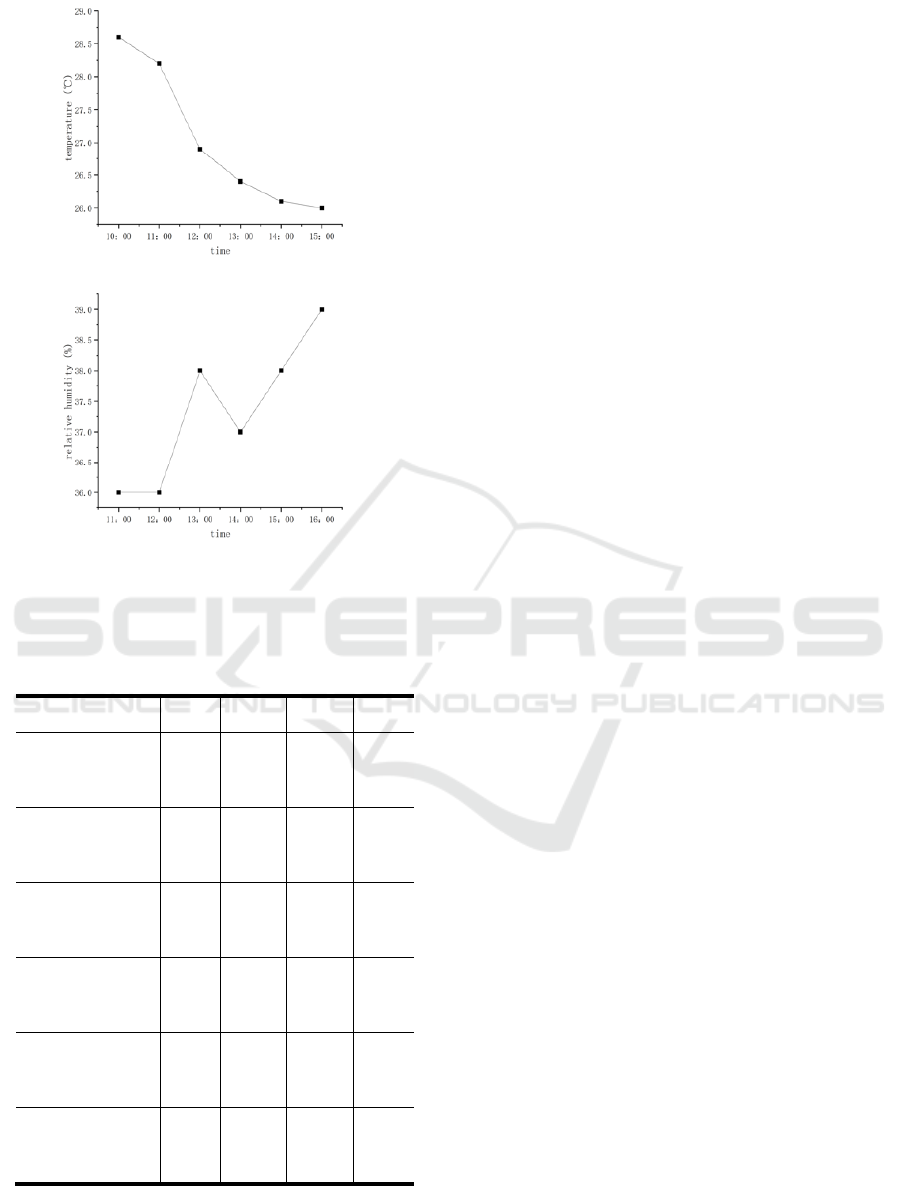

5.2 Monitor the Temperature Change

of Key Cabinets in Column F

Before and After Construction

In order to monitor the temperature changes inside

and outside the cabinets before and after construction,

Bluetooth temperature and humidity monitoring

modules were installed 1m away from the ground at

the door of the F03, F04, F08, and F09 cabinets, at the

upper side air inlet of key devices in cabinets, and at

the lower side air inlet of key devices in cabinets,

respectively, to record the real-time temperature and

humidity changes (Figure 17, Figure 18, Figure 19).

Figure 17: Temperature and humidity change of F09 cabinet

door 1m from ground 3 hours before and after construction.

Figure 18: Temperature and humidity changes in the 3 hours

before and after the side air inlet of the upper part of the

equipment in the F09 cabinet.

CFD Simulation and Application of Semi-Closed Inclined Simple Cold Channel in a Data Center Server Room

549

Figure 19: Temperature and humidity changes at the lower

part of the F09 cabinet before and after air inlet construction.

Table 1: Comparison of temperature monitoring results of

F03, F04, F08 and F09 cabinets before and after

construction.

F03

F04

F08

F09

Cabinet door 1m from

ground (average

temperature)

25℃±0.1

24.7℃±0.1

26.8℃±0.1

25.9℃±0.1

(behind the air curtain)

Cabinet door 1m from the

ground (average

temperature)

24.8℃±0.1

24.4℃±0.1

25.8℃±0.1

24.5℃±0.1

Key equipment in the

cabinet upper side air

(average temperature)

27.1℃±0.1

26.4℃±0.1

28.3℃±0.1

27.5℃±0.1

(behind the air curtain)

Upper side air intake of key

equipment in cabinet

(average temperature)

24.7℃±0.1

24.6℃±0.1

25.1℃±0.1

24.8℃±0.1

Key equipment in the

cabinet lower side air intake

(average temperature)

27.4℃±0.1

25.9℃±0.1

28.8℃±0.1

28.4℃±0.1

(behind the air curtain) Key

equipment in the cabinet

lower side air intake

(average temperature)

25.3℃±0.1

25.4℃±0.1

26.5℃±0.1

26.4℃±0.1

By comparing and analyzing the monitored

temperature data, it is found (Table 1) that the average

difference between the temperature 1m from the

ground of cabinets door and the air inlet temperature

of the equipment inside cabinets before construction

was 1.9℃, and the average temperature difference

dropped to 0.4℃ after construction, indicating that

the semi-closed inclined simple cold channel can

effectively import the cold air sent by the grille into

the cabinet. In particular, it has a very obvious effect

on reducing the temperature of the middle and upper

layers of cabinets.

In addition, the return air temperature index RTI

mainly reflects the energy characteristics of the

airflow organization of a certain cabinet, and its

calculation formula is expressed as:

RTI=(T

RETURN

-T

SUPPLY

)/∆T

EQUIPMENT

)×100%

Where T

RETURN

is the return air temperature of the

computer room; T

SUPPLY

is the floor supply air

temperature; and ∆T

EQUIPMENT

is the temperature

difference between the incoming and outgoing air of

the IT equipment in the cabinet.

Before the construction of CFD software

simulation results show that the temperature index of

the return air in the server room is 31.5, after the

installation of the air curtain through the calculation

of the return air temperature index of the eight key

cabinets in column F is 77.4, indicating that the

phenomenon of short-circuiting of air in front of the

cabinets has been significantly reduced.

5.3 Temperature Change of Key

Cabinets in Column G after

Construction

The simulation results of CFD software show that

after the semi-closed inclined simple cold channel

was installed in column F, the air blocking effect will

affect the hot air discharge of individual high-power

cabinets in column G, resulting in an increase in the

average inlet air temperature of the equipment in the

cabinet.

Before construction, a Bluetooth temperature and

humidity monitoring module was installed at 1m from

the ground of the G03, G04, G08, and G09 cabinets

in column G and at the air inlet of the upper side of

key devices in the cabinet to record real-time

temperature and humidity changes. Field monitoring

results show that the eight air curtains in front of the

cabinet in column F have no effect on the temperature

at 1m from the ground of the four cabinet doors in

column G, and the air inlet temperature of the upper

side of the key equipment in the four cabinets is less

than 0.2 ° C, indicating that the establishment of a

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

550

semi-closed inclined simple cold aisle in column F

will not produce obvious chain effect on the cabinet

in column G, and there is no need to field test the

corresponding alternative optimization scheme.

6 CONCLUSION

In the server room, there are problems such as high

mixing degree of hot and cold air, short circuit of the

air in front of the cabinet, and uneven load of the air

conditioner. Installing a semi-closed inclined simple

cold channel can improve these problems.

(1) In the server room, the hot air from the high-

power devices in cabinets at column G of the

equipment room either enters cabinets at column F

and circulates air at the top of cabinets, or the hot air

is mixed with the grates and carries the cold air

directly to the top of the channel, which shorts the air

in front of cabinets and affects the heat dissipation of

cabinets at column F.

(2) The semi-closed inclined simple cooling channel

directs the hot air from the G-cabinets to the top of

the channel and the cool air from the floor grille to the

inside of the F-cabinets, optimizing the temperature

field of the F-cabinets.

(3) The exhaust air of high-power equipment in

column G cabinets before the transformation also

indirectly affects the temperature field of column E

cabinets. After the inclined cold channel was set up in

column F, the hot air discharged from cabinets in

column G returns to the air conditioner return air

outlet, reducing the mixing probability of hot and cold

air in the adjacent channel and improving the uneven

load of the air conditioner. However, the air blocking

effect also affects the exhaust air of cabinets in

column G. The effect can be eliminated by adjusting

the position of the air supply grille in column G or

adding the air supply grilles.

(4) After experiments, the installation of a semi-

closed inclined simple cold channel in F-column

cabinets can effectively channel the cold air sent by

the grille into cabinets interior, especially for

reducing the temperature of the middle and upper

layers of cabinets interior has a very obvious effect,

and there is no obvious chain effect on the G-column

cabinets.

REFERENCES

Gao C F, Yu Z, Wu J L. Thermal environment analysis and

air distribution optimization for a typical data room (J).

Heating Ventilating & Air Conditioning, 2013, 43(9):

101-106.

Qian X D, Li Z. Energy saving research on air conditioning

system in data centers (J). Heating Ventilating & Air

Conditioning, 2012, 42(3): 91-96.

Ahmadi V E, Erden H S. A parametric CFD study of

computer room air handling bypass in air-cooled data

centers (J/OL). Applied Thermal Engineering, 2020, 166:

114685. DOI:10.1016/j.applthermaleng.2019.114685.

Liu T T. Air distribution simulation and operation

optimization for a data room (J). Heating Ventilating &

Air Conditioning, 2015, 45(3): 71-75.

Gao C, Yu Z, Wu J. Investigation of Airflow Pattern of a

Typical Data Center by CFD Simulation (J/OL). Energy

Procedia, 2015, 78: 2687-2693. DOI:

10.1016/j.egypro.2015.11.350.

CFD Simulation and Application of Semi-Closed Inclined Simple Cold Channel in a Data Center Server Room

551