On Data-Preprocessing for Effective Predictive Maintenance on

Multi-Purpose Machines

Lukas Meitz

1 a

, Michael Heider

2 b

, Thorsten Sch

¨

oler

1 c

and J

¨

org H

¨

ahner

2 d

1

Hochschule Augsburg, An der Hochschule 1, Augsburg, Germany

2

Universit

¨

at Augsburg, Am Technologiezentrum 8, Augsburg, Germany

Keywords:

Predictive Maintenance, Data Preprocessing, Multi-Purpose Machines.

Abstract:

Maintenance of complex machinery is time and resource intensive. Therefore, decreasing maintenance cycles

by employing Predictive Maintenance (PdM) is sought after by many manufacturers of machines and can be

a valuable selling point. However, currently PdM is a hard to solve problem getting increasingly harder with

the complexity of the maintained system. One challenge is to adequately prepare data for model training and

analysis. In this paper, we propose the use of expert knowledge–based preprocessing techniques to extend the

standard data science–workflow. We define complex multi-purpose machinery as an application domain and

test our proposed techniques on real-world data generated by numerous machines deployed in the wild. We

find that our techniques enable and enhance model training.

1 INTRODUCTION

Using data-driven models, Predictive Maintenance

(PdM)—a Machine Learning (ML) application do-

main made possible by the ML advances in recent

years—detects and predicts machine failures based on

collected data, which can lead to better efficiency and

reliability while reducing maintenance cost. While

there are many models that have been successfully

applied (Serradilla et al., 2022), implementations of

preprocessing and training are mostly based on a few

openly-available or easy-to-collect data-sets.

However, for some real-world applications, data

needs to be processed even further before model train-

ing. This is especially the case for multi-purpose ma-

chinery, which produces heterogeneous data not di-

rectly suited for learning. The goal of this article is to

introduce three more considerations and steps in pre-

processing for PdM in order to make heterogeneous

data suitable for model training.

The following article will first give a brief

overview of related publications on PdM preprocess-

ing and different representative PdM datasets. The

motivation for preprocessing is discussed in a founda-

a

https://orcid.org/0000-0001-7409-2401

b

https://orcid.org/0000-0003-3140-1993

c

https://orcid.org/0000-0001-5487-1862

d

https://orcid.org/0000-0003-0107-264X

tion section, followed by a definition of the term com-

plex machinery. Based on the properties and chal-

lenges of data collected from the described type of

machines, three additional steps for data preprocess-

ing in PdM applications are introduced. A short illus-

trative example is introduced, which is based on real-

world data. The article ends with a short discussion

and outlook.

2 RELATED WORK

Maintenance is a huge cost factor in industry and

manufacturing, with up to 60% of production cost be-

ing spent on it in some cases (Mobley, 2002). Addi-

tionally, because of ineffective maintenance actions,

about one third of the maintenance cost is estimated

to be wasted (Mobley, 2002).

Using the predictive paradigm for maintenance,

these cost factors can be reduced. Predictive Mainte-

nance can be described as condition based preventive

maintenance, with preventive maintenance meaning

replacing parts before a breakdown occurs (Mobley,

2002). If the observed condition changes into a un-

healthy state, maintenance is carried out before a ma-

chine breakdown occurs.

The condition of machinery is observed using

monitoring systems, most of which are data-driven

606

Meitz, L., Heider, M., SchÃ˝uler, T. and HÃd’hner, J.

On Data-Preprocessing for Effective Predictive Maintenance on Multi-Purpose Machines.

DOI: 10.5220/0012146700003541

In Proceedings of the 12th International Conference on Data Science, Technology and Applications (DATA 2023), pages 606-612

ISBN: 978-989-758-664-4; ISSN: 2184-285X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

and based on recorded sensor-values. In this section,

we will highlight some research regarding the pre-

processing of data in PdM applications and give an

overview of different types of data-sets that are typi-

cally used.

2.1 Preprocessing in PdM

As in any data science project, recorded raw data has

to be prepared in order to be used in an application.

An extensive overview of the then state-of-the-art in

preprocessing of data for PdM was given by (Cer-

nuda, 2019). They focused primarily on standard sta-

tistical features and workflows common in other types

of ML and their usage in PdM.

(Cofre-Martel et al., 2021) apply similar prepro-

cessing steps and then propose the labelling of this

more concise data with the use of expert knowledge.

This facilitates the application of supervised learning

techniques which is commonly very difficult in PdM

due to the rarity of breakdowns but has advantages

over unsupervised clustering as run-to-failure cases

are highlighted directly (Yun et al., 2021). In their

work they highlighted the need for differentiation be-

tween the use of real-world and benchmark data.

(Bekar et al., 2020) propose preprocessing to be

based on the CRISP-DM cycle and K-Means cluster-

ing. In their accompanying case study, they validate

their proposed method with data of a simple spindle

application which consists of load and vibration ob-

servations.

2.2 Data-Sets in PdM Studies

In most cases, data-sets for predictive maintenance

applications consist of time-series. They are sen-

sor readings including one or more physical observa-

tions, like noise level, vibration, or power consump-

tion. In most of these cases, only a single machine

is used to generate the data, which leads to inher-

ent homogeneity and comparability, thus, eliminat-

ing the need for excessive data preparation. Some

examples of this type of application are centrifugal

pumps (Chen et al., 2022), electrical load of wash-

ing machines (Casagrande et al., 2021), refrigera-

tors (Kulkarni et al., 2018), or vibration data collected

from bearings (Wang et al., 2020; Sugumaran and

Ramachandran, 2011). In other scenarios, the data

used for implementing PdM-applications are bench-

mark data sets such as NASA Turbofan (Bruneo and

De Vita, 2019) that do not need further processing to

effectively train models.

In some cases, only simple statistics of the data

(e.g. mean, variance, skewness, etc.) are used for fur-

ther processing rather than the data itself. This is es-

pecially common in vibration or power level mon-

itoring, where, often, only a shift in the underly-

ing pattern is used for anomaly detection. Exam-

ples have been published by (Ding et al., 2019) and

(da Silva Arantes et al., 2021).

For Deep Learning applications, models handle

feature extraction implicitly, therefore, the prepro-

cessing is limited to standard steps such as data clean-

ing rather than complex manual feature engineering.

Examples are the use of Autoencoders for anomaly

detection (Sun et al., 2019; Bampoula et al., 2021;

Kim et al., 2021).

(Z

¨

ufle et al., 2022) implement an anomaly detec-

tion solution for the degradation of a CNC milling

tool. They incorporate a preprocessing step to high-

light phases of the same machine action in order to get

comparable segments of machine operation, i.e. when

the machine is actively milling material.

PdM literature does rarely focus on specific data

preprocessing articles as many data-sets are rather

simplistic not requiring special preparation or do only

contain very limited sensor and actuator reading vari-

ety, i.e. focus on a singular part and its condition. In

most research studies, the type of application does not

create a need for dealing with data heterogeneity. In

the following, we will describe some techniques for

dealing with the type of complex data that is found in

many real-world applications.

3 FOUNDATIONS

As a foundation for the remainder of this article, the

term complex machinery and its characteristics in the

domain of PdM are introduced. Furthermore, this sec-

tion gives a brief overview of the motivation and im-

portance behind data preparation specific to PdM.

3.1 Data Preprocessing

Preprocessing has multiple roles that are important

for the further progress of a data science project. A

general definition of preprocessing is given in (Cer-

nuda, 2019): ”the set of actions performed to raw data

[...] with the aim of improving the modelling capa-

bilities”. However, there are more specific goals that

all aim for better model performance, as described in

(Luengo et al., 2020):

Reduction of Size and Complexity. Reduced size

improves runtime performance, which speeds up

model training and inference. Reduced complexity

On Data-Preprocessing for Effective Predictive Maintenance on Multi-Purpose Machines

607

enables a model to achieve faster convergence and al-

lows the use of models with less parameters which

might help their explainability.

Format Conversion of the Data. Depending on the

application and model, different sizes or chunks of

data are needed. Most models need fixed-length in-

put or smaller samples of the data. Some work with

aggregations or statistical features, that have to be ex-

tracted from the data.

Retention Only of Important Information. Most

importantly, preprocessing is used to filter data to only

the important information used for model training.

Model performance is greatly aided by eliminating

noise and distracting signals beforehand.

3.2 Heterogeneous Machine Data

Data-driven Predictive Maintenance aims to extract

information about a machine’s condition based on

collected data. The aforementioned preprocessing of

recorded data is a necessary step to extracting this in-

formation.

As shown in Section 2, applications have been im-

plemented based on a variety of sensor values that

are collected from runtime data. Most of the time

however, the data observes a singular component that

performs a specialised task like rotation, pumping,

or pressing. Although this is an important founda-

tion for applications in industry and commerce, there

are many remaining application domains that have

not been subject to research because of their machine

complexity.

Complex machines that can be used for multiple

applications, when observed by sensors, create het-

erogeneous data. To clarify the type of complexity

referred to in this article, the following properties of

complex multi-purpose machinery are introduced:

1. It can be used for more than one application:

The machine is able to perform a specific param-

eterised process, i.e. milling, but is automated to

a level where it can produce results of high vari-

ety which is leading to vastly different data, e.g.

because of different lengths, rotations of the drill,

motor movements of varying speeds, etc. We call

one such parametrisation of the process an appli-

cation.

2. It consists of multiple components:

Such components can be different actuators and

sensors—not accounting for the sensors used

purely for the PdM application or other monitor-

ing tasks. For our definition, we assume that the

number of components is at least five with at least

three actuators. A prototypical example would be

a multi-pump system where distributed pressure

sensors trigger pump activation cycles.

Challenges. When collecting operation data from

complex machines, some challenges emerge for the

further processing of this heterogeneous data. These

challenges are closely related to the domain of big

data and are the result of the properties volume, va-

riety and variance (Sagiroglu and Sinanc, 2013).

There is a high amount of data collected from the

different components, not all of it useful for model

training. This data volume requires space to be stored

and computing performance to be efficiently pro-

cessed.

Another problem is the handling of complexity, or

variety, from the many different components and ap-

plications of complex machines. Each component can

be of a different kind and therefore produce a differ-

ent type of data. For each application of the machine,

the underlying process can be different and subject to

parameters leading to different observable states.

The collected data contains significant hetero-

geneity in its patterns because of the different circum-

stances of machine operation. This results in high

variance and noise in physical observations (i.e. pro-

cess lengths, starting conditions, or material proper-

ties) and can lead to poor model performance.

Example. To give an example of a complex ma-

chine, we will look at the case of a CNC-mill—a com-

monplace machine in modern manufacturing plants.

Its actuators consist of multiple motors, one or more

for each axis, and a spindle for material removal. To

sense the physical state, there are limit switches and

spindle load measurements. Additionally, vibration

and noise sensors are often attached to the machine, to

enable PdM scenarios. Using this set of actuators and

sensors, the machine is able to process different ma-

terials to produce many different parts. When record-

ing the operation data, this application variety leads

to raw data with a high variance, which is not directly

comparable amongst different processes. For this or

similar types of machinery, it is therefore necessary to

further break down and prepare raw machine data to

create usable data sets.

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

608

4 PROPOSED METHODS FOR

PREPROCESSING OF

HETEROGENEOUS MACHINE

DATA

To overcome the challenges mentioned in the last sec-

tion, state-of-the-art data preprocessing, as seen in re-

lated PdM applications, is not sufficient. In this sec-

tion, three additional important considerations are in-

troduced, which have to be taken into account during

the data preparation process for PdM applications of

complex machinery.

These considerations can be implemented as in-

dependent steps and are suited for the preparation of

real-world complex machine data, whose characteris-

tics and challenges have been explained beforehand.

Most of the steps rely on the application of expert

knowledge and are not intended as fully-automatic

implementations.

4.1 Use-Case-Specific Data Selection

There are two possible scenarios for implementing

PdM in an industrial environment. With multiple ma-

chines available, two use-cases can emerge for the

collected data: creating statements relative to a sin-

gle machine and creating statements about a group of

machines. In the case of PdM, the modelling scope,

i.e. one or many supposedly identical machines’ data,

can decide on how to partition the data during prepa-

ration. This partitioning can help reducing the variety

and volume of data.

The decision that is implicitly made is which kind

of data variance will be selected in the course of pre-

processing. For single machine applications, time-

variance will be detected, as this is the main feature

that changes over available data recordings. This is

useful for finding trends or anomalies in the data cre-

ated by the machine in different points in time. A

degradation or failure can be found this way, by com-

paring the past data points to new ones.

When trying to establish time-variance for mul-

tiple machines, the slight difference in hardware of

each device will be enough to introduce enough noise

to mask the time-variance. Therefore, in a multi-

machine setting the suitable application is anomaly

detection based on the bulk of the hardware. When

using multiple machines, one can create statements

about the majority behaviour of such machines. Out-

liers can be found this way, which are machines that

differ from the mean in the data they generate.

To conclude, depending on the target application

and the type of model, a selection of only the rele-

vant parts of the available data is necessary. Single-

machine models can learn from historical data and

establish degradation trends. Multi-machine models

are useful for finding anomalies or outliers in a set

of different machines. Depending on the sought out

information, further selection of only relevant sub-

components may be helpful.

4.2 Discerning Actuators and Sensors

As stated in the introduction of heterogeneous data,

time-series data generated by complex machines can

be split into two distinct categories: actuator control

signals and sensor observations. By distinguishing

these two types of data, the data handling can be im-

proved.

Actuators. Actuator control signals are generated

by the machine’s internal controller. They are often

of binary form, take discrete values from a fixed set of

possibilities, or are real-valued. Because they are gen-

erated by a controller, they encode information about

the machine’s inner state. This is a useful asset for

reducing variety in the data, as each observation can

be annotated with a supposed state as assumed by the

machine controller. Examples for binary signals are

relay-controlled heating, valve opening, or pump op-

eration. More high-level control signals could convey

the current machine status, target temperature, or tar-

get water quantity.

Sensors. Sensors are observers of the physical

world, they measure a value associated with a physi-

cal property, and their values are typically continuous.

Because of the nature of sensing, values can be sub-

jected to noise and outliers. The information encoded

into sensor measurements is useful for observing the

actual physical state (in contrast to the controller’s

‘set’-state) of a machine. Examples are temperature,

pressure, water flow, or electrical energy.

Division and Preparation. Dividing data into the

aforementioned groups can help in creating models

by reducing variance to the desired scope. To illus-

trate: Actuator control signals are useful for discern-

ing the machine state. For a specific machine state,

models can be trained using only sensor measure-

ments, which represent the physical state of a ma-

chine, thereby, automatically discarding multiple in-

put signals of varying noise that would not aid pre-

dictions at all. Because actuator control signals are

generated by the machine controller itself, they do

not change for the same machine state. Physical ob-

servations, however, can change over time based on

On Data-Preprocessing for Effective Predictive Maintenance on Multi-Purpose Machines

609

the underlying hardware and make useful features for

degradation modelling.

4.3 Data Segmentation

Complex (multi-purpose) machines are used for more

than one application (cf. Section 3.2). This means that

processes, e.g. manufacturing a part, are not directly

comparable to each other because every process is ei-

ther different due to its parametrisation or executed

under different circumstances. This difference in cir-

cumstances leads to data variance in collected obser-

vations that is much higher than the possible degrada-

tion effect (or rapid shift) which would warrant main-

tenance. To overcome this issue, data segments have

to be created, that contain only data gathered under

similar circumstances.

Using the separation of control signals and sensor

measurements from the previous section, segments of

similar machine state can be found by comparing con-

trol signals. For similar patterns in actuator signals,

the machine is likely in a similar state and the sensor

measurements are therefore comparable. There are

multiple possibilities for creating such segments of

similar circumstances, some of which are explained

in the following paragraphs.

Rule-Based Segmentation. Using existing expert

knowledge, a simple solution for creating time-series

clusters is creating segmentation rules. This as-

sumes that knowledge about the machine’s processes

is present an can be formulated as simple if-then-

rules.

Pattern Matching. Using a recurring pattern in ac-

tuator signals, common circumstances in the machine

behaviour can be found. This is useful for fixed-

pattern processes that stay the same for every occur-

rence of the process.

Dynamic Time Warping. For processes that do not

have the necessary actuator signals for clustering, Dy-

namic Time Warping (DTW) (M

¨

uller, 2007) can be

used as another approach. Initially, a domain expert

has to establish a reference process and create seg-

ment labels for later segmentation. DTW can now be

used to establish a mapping from an observed time-

series to the already segmented reference process.

The labels can now be transferred from reference to

observation and a new comparable segment is created.

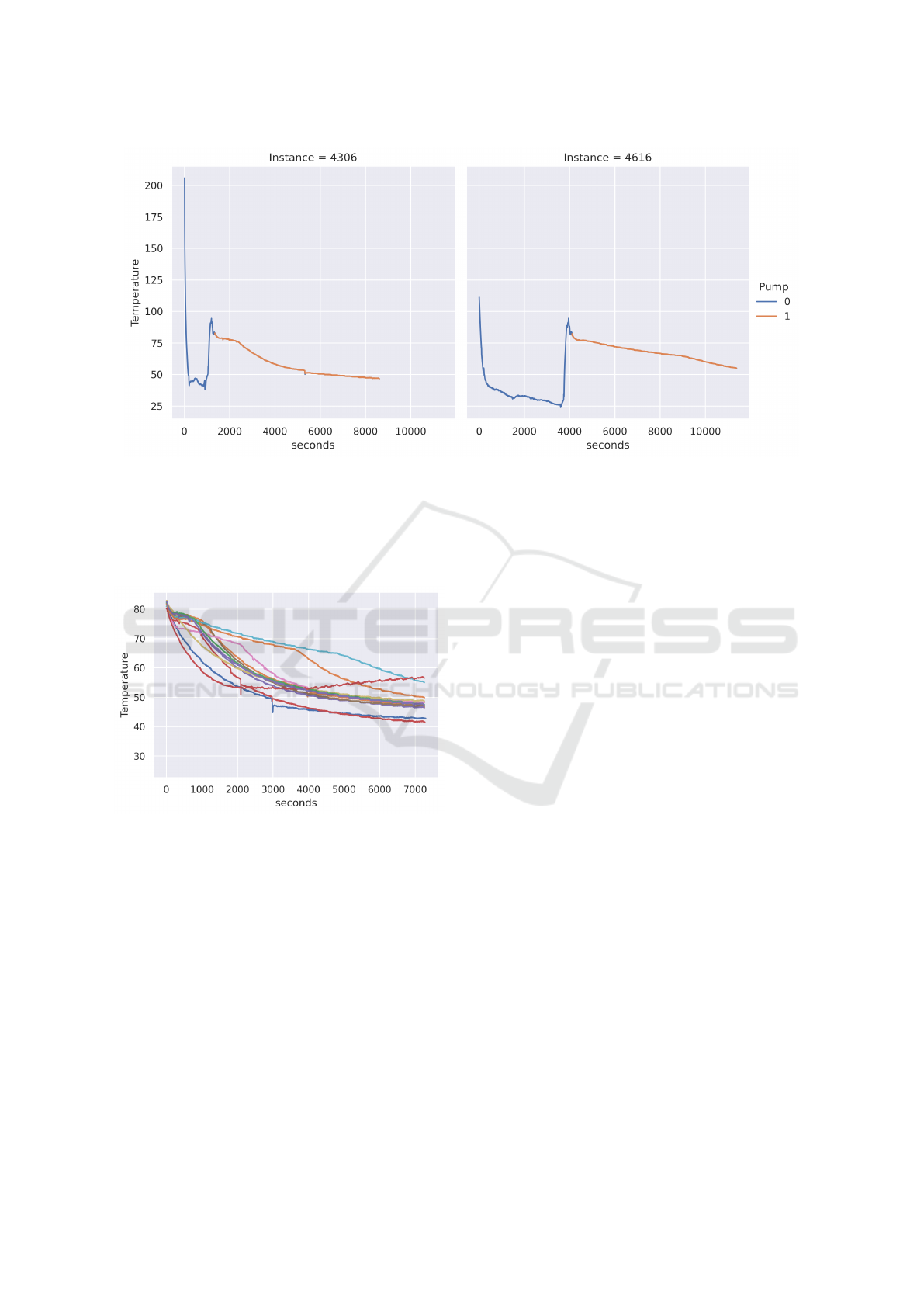

Figure 1: Temperature Readings from the same type of pro-

cess.

5 EXAMPLE IMPLEMENTATION

To illustrate a possible implementation, we will ap-

ply the aforementioned techniques on a small data

set sampled from real-world machine operation. The

data was sampled from a single machine and pro-

cess type, however this process is dependent on dif-

ferent starting conditions and parameters. This leads

to high variance in the process length and sensor val-

ues, which is not suitable for information extraction

in its raw state.

Figure 1 shows a plot of the recorded processes

and illustrates their heterogeneity. Standard data

preparation, as introduced by Cernuda (Cernuda,

2019), was conducted on the data beforehand.

Data Selection. The example data set contains mul-

tiple recordings of the same type of process observed

on a single machine. This machine consists among

others of a heater, a pump, and a temperature sensor.

A first step to implementing a PdM model is to decide

on the model scope. In this case, single-machine trend

detection is the desired application. The goal is to

compare a temperature degradation trend in this type

of process, therefore only relevant observations to this

phenomenon are selected, which are Pump, Heating

and Temperature. Note that while the type of process

is the same for each observation they vary greatly in

length, which is one of the challenges in this setting.

Actuator and Sensor Separation. The example

data set consists of multiple readings: actuators sig-

nals for a pump and a heating element as well as sen-

sor readings of temperature. By employing domain

expertise, the temperature sensor is selected for obser-

vation and heating and pump signals are used for ma-

chine state representation. More complex scenarios

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

610

Figure 2: Two process instances with highlighted active pump segments.

can be handled by creating sets of the unique values

of each variable as actuators take only a small num-

ber of specific values, sensors produce a great amount

of distinct values, as the physical observation is often

bound to be continuous.

Figure 3: Extracted segments of the same process for com-

parison.

Process Segmentation. Using the set of actuator

values, the selected process can be further segmented

to synchronise the sensor readings and aid observa-

tion comparability. Only a part of the process record-

ing is relevant, therefore a simple rule-based approach

for process segmentation is used. In the simple case

of this pump and heating system, the segmentation

is achieved by selecting the process segments with

an active pump signal. Figure 2 highlights the se-

lected and relevant process segment of two specific in-

stances. After extracting only the relevant segments,

observations are already intuitively comparable, as

shown in Figure 3. Using these previously selected

sensor readings, that have afterwards been segmented

into comparable chunks of similar length, further im-

plementation of PdM has been enabled.

6 CONCLUSION

Data preprocessing for PdM applications is notori-

ously hard when data of systems with many interact-

ing components was collected in the wild. This arti-

cle described additional considerations to be made for

data preprocessing in PdM applications and gives an

example of their effects. As many systems for which

PdM has successfully been developed are on the sim-

pler side, i.e. few moving parts, few components, or

few control signals, we gave a definition for complex

multi-purpose machines (multiple components; mul-

tiple applications) and used real-world data from one

such machine for our examples. Three steps for cre-

ating data sets useful for model training and further

processing are proposed in the main section of this

paper. These are data selection based on the desired

use-case, actuator and sensor clustering, and finally

data segmentation.

To highlight the effects of the at-first rather ab-

stract techniques, an example data set of a real-world

machine has been processed by applying the proposed

methods. Using the additional constraints described

in the article, the heterogeneous recorded data was

processed into segments of comparable information.

There are some limitations to our approach and

presented preliminary results, which can be improved

upon in the future. The considerations described in

the main section are dependent upon domain knowl-

edge and the manual application of data science ex-

pertise. This means the process of preprocessing in-

On Data-Preprocessing for Effective Predictive Maintenance on Multi-Purpose Machines

611

corporating the proposed steps has to be implemented

for each application separately. However, the pro-

posed techniques enable a further processing of data

in different use cases. Model training and other ap-

plications can be implemented after creating homo-

geneous data sets, which would not be possible or

well-performing in the case of raw and heterogeneous

machine data.

For future articles, a formalisation of the proposed

process is a necessary step. Additionally, by general-

ising the steps and implementing them in different ap-

plication scenarios, a comprehensive evaluation will

be an important next step.

REFERENCES

Bampoula, X., Siaterlis, G., Nikolakis, N., and Alexopou-

los, K. (2021). A Deep Learning Model for Predic-

tive Maintenance in Cyber-Physical Production Sys-

tems Using LSTM Autoencoders. Sensors, 21:972.

Bekar, E. T., Nyqvist, P., and Skoogh, A. (2020). An intelli-

gent approach for data pre-processing and analysis in

predictive maintenance with an industrial case study.

Advances in Mechanical Engineering, 12.

Bruneo, D. and De Vita, F. (2019). On the Use of LSTM

Networks for Predictive Maintenance in Smart In-

dustries. In 2019 IEEE International Conference on

Smart Computing (SMARTCOMP), pages 241–248.

Casagrande, V., Fenu, G., Pellegrino, F. A., Pin, G., Salvato,

E., and Zorzenon, D. (2021). Machine learning for

computationally efficient electrical loads estimation in

consumer washing machines. Neural Computing and

Applications, 33:15159–15170.

Cernuda, C. (2019). On the Relevance of Preprocessing

in Predictive Maintenance for Dynamic Systems. In

Lughofer, E. and Sayed-Mouchaweh, M., editors, Pre-

dictive Maintenance in Dynamic Systems: Advanced

Methods, Decision Support Tools and Real-World Ap-

plications, pages 53–93. Springer International Pub-

lishing, Cham.

Chen, L., Wei, L., Wang, Y., Wang, J., and Li, W. (2022).

Monitoring and Predictive Maintenance of Centrifu-

gal Pumps Based on Smart Sensors. Sensors, 22:2106.

Cofre-Martel, S., Lopez Droguett, E., and Modarres, M.

(2021). Big Machinery Data Preprocessing Method-

ology for Data-Driven Models in Prognostics and

Health Management. Sensors, 21:6841.

da Silva Arantes, J., da Silva Arantes, M., Fr

¨

ohlich, H. B.,

Siret, L., and Bonnard, R. (2021). A novel unsu-

pervised method for anomaly detection in time series

based on statistical features for industrial predictive

maintenance. International Journal of Data Science

and Analytics, 12:383–404.

Ding, H., Yang, L., and Yang, Z. (2019). A Predictive Main-

tenance Method for Shearer Key Parts Based on Qual-

itative and Quantitative Analysis of Monitoring Data.

IEEE Access, 7:108684–108702.

Kim, D., Lee, S., and Kim, D. (2021). An Applicable Pre-

dictive Maintenance Framework for the Absence of

Run-to-Failure Data. Applied Sciences, 11:5180.

Kulkarni, K., Devi, U., Sirighee, A., Hazra, J., and Rao,

P. (2018). Predictive Maintenance for Supermarket

Refrigeration Systems Using Only Case Temperature

Data. In 2018 Annual American Control Conference

(ACC), pages 4640–4645.

Luengo, J., Garc

´

ıa-Gil, D., Ram

´

ırez-Gallego, S., Garc

´

ıa, S.,

and Herrera, F. (2020). Big Data Preprocessing: En-

abling Smart Data. Springer International Publishing,

Cham.

Mobley, R. (2002). An Introduction to Predictive Mainte-

nance. Plant Engineering. Elsevier Science.

M

¨

uller, M. (2007). Dynamic Time Warping. In Informa-

tion Retrieval for Music and Motion, pages 69–84.

Springer, Berlin, Heidelberg.

Sagiroglu, S. and Sinanc, D. (2013). Big data: A review.

In 2013 International Conference on Collaboration

Technologies and Systems (CTS), pages 42–47.

Serradilla, O., Zugasti, E., Rodriguez, J., and Zurutuza,

U. (2022). Deep learning models for predictive

maintenance: a survey, comparison, challenges and

prospects. Applied Intelligence.

Sugumaran, V. and Ramachandran, K. I. (2011). Fault diag-

nosis of roller bearing using fuzzy classifier and his-

togram features with focus on automatic rule learning.

Expert Systems with Applications, 38:4901–4907.

Sun, C., Ma, M., Zhao, Z., Tian, S., Yan, R., and Chen,

X. (2019). Deep Transfer Learning Based on Sparse

Autoencoder for Remaining Useful Life Prediction of

Tool in Manufacturing. IEEE Transactions on Indus-

trial Informatics, 15:2416–2425. Conference Name:

IEEE Transactions on Industrial Informatics.

Wang, J., Liang, Y., Zheng, Y., Gao, R. X., and Zhang,

F. (2020). An integrated fault diagnosis and progno-

sis approach for predictive maintenance of wind tur-

bine bearing with limited samples. Renewable Energy,

145:642–650.

Yun, H., Kim, H., Jeong, Y. H., and Jun, M. B. G. (2021).

Autoencoder-based anomaly detection of industrial

robot arm using stethoscope based internal sound sen-

sor. Journal of Intelligent Manufacturing.

Z

¨

ufle, M., Moog, F., Lesch, V., Krupitzer, C., and Kounev,

S. (2022). A machine learning-based workflow for au-

tomatic detection of anomalies in machine tools. ISA

Transactions, 125:445–458.

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

612