Pattern Genomic Probes Inside Capillary Tubes by Magneto

Lithography Method Producing Parallel Detection of DNA and RNA

Amos Bardea

1,2 a

1

Holon Institute of Technology (HIT), Golomv Street, Holon, Israel

2

Faculty of Engineering, Holon Institute of Technology (HIT), Israel

Keywords: Lithography, Patterning, DNA Sensors, Parallel Sensing.

Abstract: Here we present a new technique that introduces the possibility to pattern inside closed volume using the

Magneto lithography (ML) method which allows the chemical patterning of the inside of the micro-channel

tube. The ML method is a bottom-up method but at the same time, it provides the desired high-throughput

capabilities for mass production. The ML method simplifies chemical surface patterning because it does not

require resist, which may contaminate the substrate. ML can also be applied for applications combining both

microelectronics and chemical patterning. Furthermore, ML does not depend on the surface topography and

planarity, and can pattern non-flat surfaces and the inside surfaces of a closed volume, therefore, ML allows

the chemical patterning of the inside of tubes.

1 INTRODUCTION

Magneto lithography (ML) is based on ‘‘patterning’’

a magnetic field on a substrate by applying a constant

magnet and using paramagnetic metal masks that

define the spatial distribution and shape of the applied

field. The second component in ML is ferromagnetic

nanoparticles that are assembled onto the substrate

according to the field induced by the mask. Similar to

Photolithography (Pease 2008), ML can be used to

apply either a positive or negative mode. In the

positive mode, the magnetic nanoparticles react

chemically or interact via chemical recognition with

the substrate. Hence, the magnetic nanoparticles are

immobilized at selected locations, where the mask

induces a magnetic field, resulting in a patterned

substrate. In the negative mode, the magnetic

nanoparticles do not interact chemically with the

substrate. Hence, once they pattern the substrate, they

block their site on the substrate. The exposed areas,

not covered by the nanoparticles, can at this stage, be

covered by molecules that chemically bind to the

substrate. After the binding of these molecules, the

nanoparticles are removed, resulting in a “negatively”

patterned substrate. We introduced the ML method,

in which a paramagnetic mask is applied for

a

https://orcid.org/0000-0002-0512-4120

patterning of surfaces with high throughput (Ito,

2000, Service 2001, Hoeppener 2003, Stewart 2007,

De Marco 2008). It can be easily applied for chemical

patterning surfaces (Li, 2003, McClelland 2002) and

for common microelectronic processes such as

etching and deposition with various magnetic masks,

permanent, dynamic and hard disk masks (Bandic

2003, Urbach 2003, Bardea 2009, Bardea 2017,

Bardea 2018). Here, we show the capabilities of ML

for patterning the inside of tubes by demonstrating

positive and negative ML processes and sequential

reactions made possible by these processes.

2 METHODOLOGY AND

RESULTS

As previously mentioned, the ability to apply the ML

method does not depend on the surface topography

and planarity; therefore, ML allows the chemical

patterning of the inside of tubes. The ML can pattern

the inside of tubes by applying either positive or

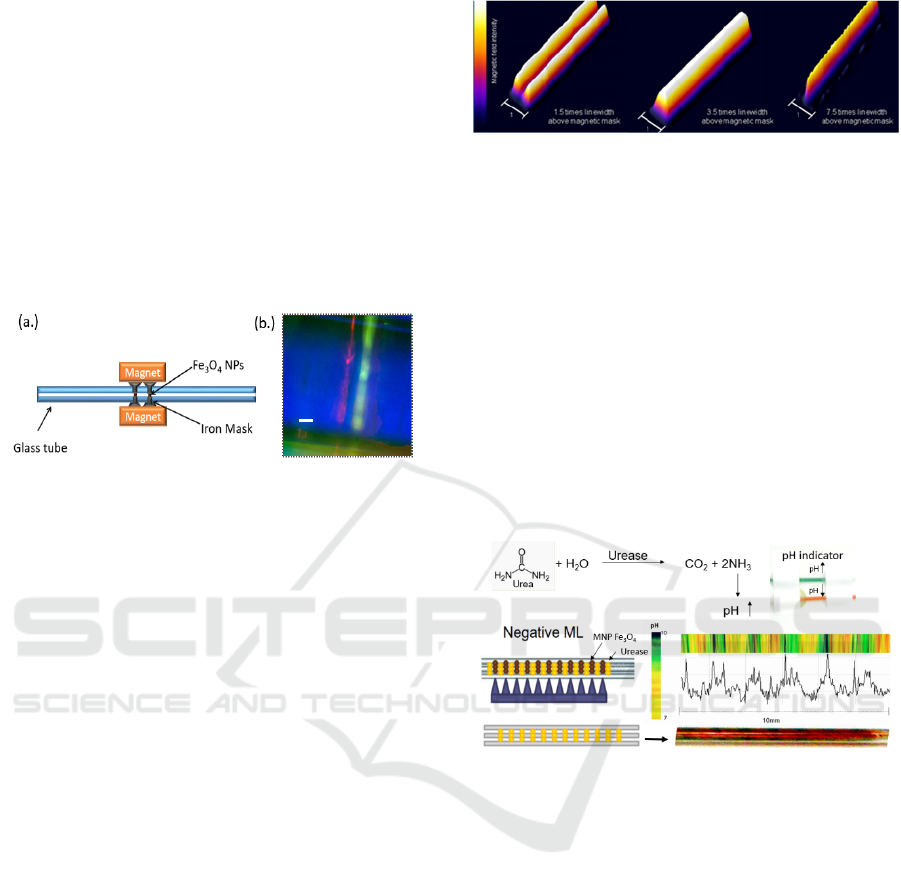

negative routes. Figure 1 shows the positive ML

process for patterning the surface of inner tubes (100-

μm inner diameter). The inner surface of a glass tube

was functionalized with mercaptosilane. Ten-

80

Bardea, A.

Pattern Genomic Probes Inside Capillary Tubes by Magneto Lithography Method Producing Parallel Detection of DNA and RNA.

DOI: 10.5220/0011872000003414

In Proceedings of the 16th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2023) - Volume 1: BIODEVICES, pages 80-84

ISBN: 978-989-758-631-6; ISSN: 2184-4305

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

nanometer-diameter magnetic nanoparticles (Fe

3

O

4

)

were coated by fluorescein and sulforhodamine. A

magnetic field was applied on the tube by using a

permanent magnet. The fluorescein-labeled magnetic

nanoparticles were injected into the tube and

adsorbed at those sites where the magnetic field

gradient was maximal. Thereafter the tube was

washed with ethanol and the magnet field was shifted

to another site. Next, sulforhodamine-labeled

magnetic nanoparticles were injected into the tube

and they concentrated at the new site. This process

resulted in two fluorescence bands and profile of the

fluorescence signal as shown in Figure 1.

Figure 1: (a) A scheme describing the patterning of the

inner tube surface by applying positive ML. (b) The

fluorescence of both fluorescein and sulforhodamine

observed from the two bands of the nanoparticles adsorbed

within the tube.

In the ML process, we expose a substrate whose

surface is patterned by a magnetic field, to magnetic

NPs. The force applied on the magnetic NPs is given

by:

F=ΔχV(∇∙B)Bμ

0

-1

(1)

where B is the magnetic flux density (Tesla), Δχ is

the difference in susceptibility between an object and

its surroundings (10

3

-10

5

m

-3

for paramagnetic

materials in air), V is the volume (~1x10

-19

cm

3

for a

10-nm diameter particle), and μ

0

is the vacuum

permeability constant (1.2566 10

−6

H/m).

By carefully tuning the deposition time, it is

possible to obtain patterns whose width is narrower

than the width of the lines in the mask. This is due to

the gradient of the magnetic field within the line-

width defined by the mask. The magnetic field is

stronger in the center than at the edges. As a result,

the nanoparticles are first organized in the center of

the line. The simulation of the field on the mask as a

function of the distance from the mask demonstrates

an interesting property of ML, as shown in figure 2.

In the present work the average magnetic field on

the substrate is about 10

-2

Tesla. Decreasing the size

of the patterns, for example the width of a line, while

keeping good uniformity requires using smaller

particles, for example 2 nm particles. This size

of particles will allow achieving line widths of about

Figure 2: The magnetic field distribution above the mask,

as calculated using the COMSOL program. The field

distribution at distances of 1.5, 3.5, and 7.5 times the width

of the mask.

20±3 nm. Assuming that the magnetic dipole of the

NPs is proportional to its volume and that the gradient

of the field will increase proportionally with the field,

then the magnetic field required for working with 2

nm particles is about 0.1 Tesla. Such a field can be

easily applied in a dedicated ML system.

Figure 3 shows the negative ML process for

patterning the surface of inner tubes with enzyme and

we will reveal the localization of the reaction. Here,

the enzyme urease was patterned on the inside of the

500-µm diameter tube at different places using the

negative ML approach.

Figure 3: A scheme describing the multi-peg magnet for

applying ML in the tube. The color of a pH indicator

flushed in a solution of urea and pH indicator through a tube

patterned with the enzyme urease. The change in pH along

the tube, as obtained from the variation of the indicator’s

color.

The tube was exposed to a multi-peg magnet that

induced a magnetic field of 100 Gauss and a solution

of magnetic nanoparticles was injected into the tube.

The magnetic nanoparticles were arranged along the

tube according to the magnetic field induced by the

magnetic pegs, as shown in Figure 3. The urease

covalently bound to sites that were not protected by

the magnetic NPs. A solution containing urea and a

pH indicator was flown through the tube. At the

regions where the urease was patterned, the enzyme

decomposed the urea, producing NH

3

. As a result, the

pH in that region increased and the indicator changed

its color to green/blue at urease binding sites. As is

clearly shown in Figure 3, the high pH regions appear

as green spots inside the tube. The pH variation along

50μm

Pattern Genomic Probes Inside Capillary Tubes by Magneto Lithography Method Producing Parallel Detection of DNA and RNA

81

the tube can be analyzed, based on the change in the

color of the indicator.

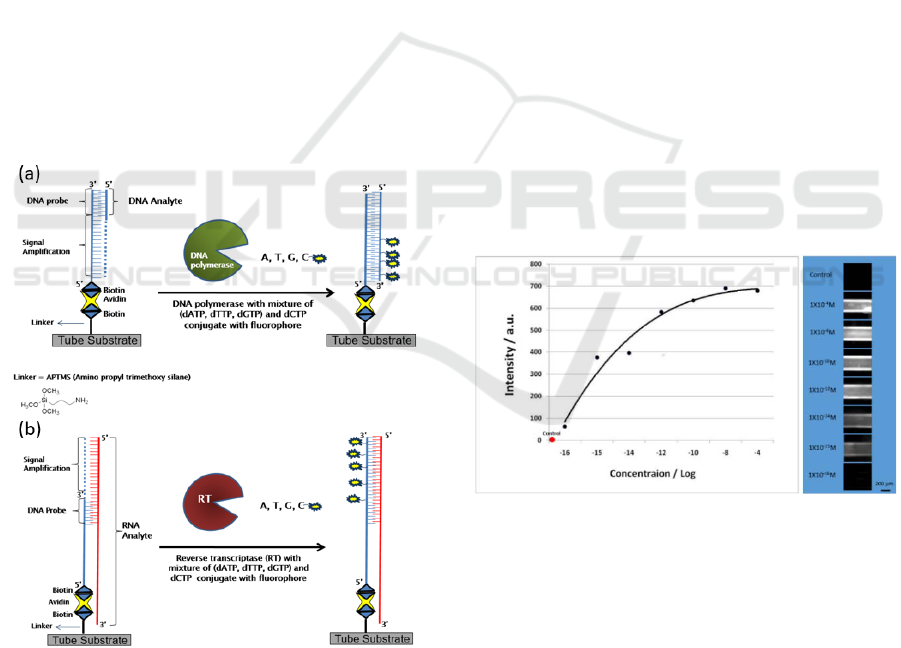

A new method for DNA and RNA detection and

identification using ML is presented. The detectors

both DNA and RNA are determining the presence of

the pathogens and their level of activity. The apply

real time poly chain reaction (RT-PCR) are expensive

and not portable, therefore, the proposed producing

sensing device based on genomic probes inside

capillary tubes will enhance the portability and the

cost effectiveness of the detection process.

Furthermore, the RT-PCR is mostly linear and not

parallel. The new method is such RT-PCR located on

top of the surface along the inner capillary tube is

based on a Patterned Capillary Tube (PCT) in which

the internal surface of a glass tube is patterned with

rings of different single-stranded DNA probes. A

solution containing the single-stranded analytes flows

through the tube. Upon hybridization of appropriate

DNA and RNA from the solution, DNA polymerase

and reverse transcriptase (RT) are employed to

synthesize the complementary nucleic acids with

deoxynucleoside triphosphate (dNTP) labeled with

fluorophores. The sample-analyte hybrids are

detected by their fluorescence signal.

Figure 4: (a) A scheme describing the detection of DNA and

amplification of the signal by using DNA polymerase and

dNTPs, which include fluorescent dCTP. (b) A scheme

describing the detection of RNA and amplification of the

signal by using reverse transcriptase and dNTPs, which

include fluorescent dCTP.

This method is sensitive, fairly simple and can

detect both DNA and RNA simultaneously without

pre-treatment. It is based on the ability to pattern the

inner surface of a capillary tube with oligonucleotide

probe molecules in well-defined locations, and

subsequently flowing a solution containing the

analyte DNA, RNA, or both, through the tube. Upon

detection of appropriate DNA and RNA from the

sample, DNA polymerase and RT are employed to

synthesize the complementary nucleic acids with

dNTP labeled with fluorophores (Figure 4). The

formed hybrids are sensitively detected by their

fluorescence signal.

The detected fluorescence signal for injection of

1µl solution containing between 10

2

to 10

14

analyte

DNA molecules (equivalent to 10

-16

to 10

-4

M) is

shown in Figure 5. The number of molecules detected

was determined by appropriate dilution of a stock

solution. The signal was linear for solutions with

lower than 10

5

analyte molecules and it is saturated at

10

8

molecules. The detection sensitivity to the

number (rather than concentration) of molecules.

Specifically, the same number of molecules was

introduced into the tube, but they were dissolved in

different volumes of solutions; thus the

concentrations differed. The total volumes were

injected into the tubes at a rate of 40 µl min-1. The

signal intensity remained nearly constant, even when

the solution was diluted by four orders of magnitude.

Figure 5: The fluorescence signal intensity of a DNA

analyte as a function of the number of DNA molecules

injected, spanning a concentration range of 12 orders of

magnitude.

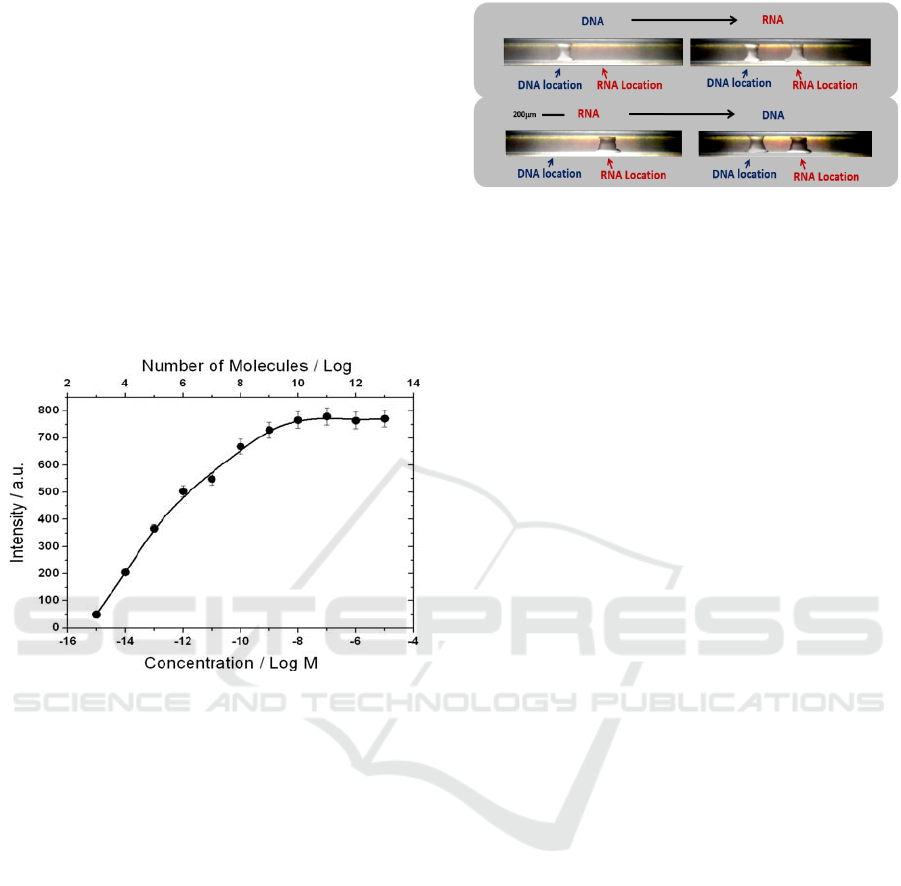

RNA detection was studied by designing and

synthesizing a 40-base-long RNA that was used as

analyte. This analyte had two sections: 1) a 3’ end

region of 20 bases that complement the probe

(detector) sequence and 2) an additional section of a

3’ end region of 20 bases which is used as a template

for elongation. The second section included six

guanine bases, designed to incorporate six cytosine

fluorescent bases into the probe strand during RT

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

82

polymerization. Hence, six fluorescing chromophore

units were bound in every analyte-probe

hybridization event. The fluorescence signal

obtained, as a function of the RNA analyte

concentration, is shown in Figure 5. The signal

spanned a range of 10 orders of magnitude in the

RNA analyte concentration until reaching saturation

in the presence of 10

10

analyte molecules.

The sensitivity for native mRNA detection was

tested with an 80-base-long probe, where the 20 bases

at the 3’ end complement N. crassa actin mRNA. A

solution of 10

-11

M (10

7

molecules in 1 µl) total

mRNA, which is within the linear response range of

the device (Figure 6), was injected; the fluorescent

signal saturated after 20 minutes.

Figure 6: Concentration-dependent curve of a RNA analyte.

It is possible to use PCT without special sample

preparation and to characterize both DNA and RNA

from the same sample. Selectivity is obtained by

appropriate design and application of the “developing

solution”; to first include an enzyme that elongates

one type of oligonucleotide (i.e. DNA polymerase)

and subsequently injecting another developing

solution that contains the enzyme required for a

different elongation process (i.e. RT). This is

demonstrated in Figure 7, with a tube patterned with

dual-probes: one for DNA and one for RNA.

An analyte solution containing 1 pM of DNA was

first injected through the tube, followed by a solution

containing DNA polymerase and dNTPs. At this

stage, only the DNA probe was elongated, whereas

the RNA probe did not incorporate fluorescent

chromophores. After injecting a solution of 1 pM

RNA and addition of RT with dNTPs, the RNA probe

was elongated and fluorescence was observed at the

two sites. The reciprocal experiment was performed

with another patterned tube and showed similar

behavior.

Figure 7: Demonstration of specificity and selectivity of a

PCT, using a PCT patterned for both DNA and RNA

detection. A DNA analyte sample was injected into the

tube, followed by a “developing” solution containing DNA

polymerase with dNTPs. The DNA probe site fluoresces,

whereas the RNA probe site remains without signal.

Following injection of RNA analyte, and a developing

solution containing RT with dNTPs, the RNA site also

fluoresces. A reciprocal experiment is also presented.

Here we demonstrated the ability to pattern the

inside of a tube and to use the patterned substrate for

sensing and catalyzing reactions in spatially localized

regions. The new abilities demonstrated here open up

the possibility of inducing chemical and biochemical

patterning of the inner tube surfaces, especially when

using tubes with a small diameter as efficient for

sensitive detection and identification of DNA and

RNA, lab on a chip (LOC) and for DNA sequencing.

3 CONCLUSIONS

The ML can pattern the inside of tubes by applying

either positive or negative routes. The ability to

pattern tubes opens up new dimensions in sensors

development and applications. We report on a new

ultra-sensitive and fast technique for the detection and

identification of both DNA and RNA with detection

sensitivity of a few molecules based on ML method.

The new method is based on a Patterned Capillary

Tube (PCT) in which the internal surface of a glass

tube is patterned with rings of different single-

stranded DNA probes using ML.

REFERENCES

Pease, R. F., Chou, S. Y. (2008) "Lithography and other

patterning techniques for future electronics,"

Proceedings of the IEEE vol. 96, no.2, pp. 248-270.

Ito, T., Okazaki, S. (2000) "Pushing the limits of

lithography," Nature vol. 406, pp. 1027-1031.

Service R. F.

(2001) "EUV lithography - Optical

lithography goes to extremes - and beyond," Science

vol. 293, pp. 785-786.

Pattern Genomic Probes Inside Capillary Tubes by Magneto Lithography Method Producing Parallel Detection of DNA and RNA

83

Stewart M. E., Motala, M. J., Yao, J., Thompson, L. B.,

Nuzzo, R.G. (2007) "Unconventional methods for

forming nanopatterns," J. Nanoengineering and

Nanosystems vol. 220, pp. 81-138.

Hoeppener, S., Maoz, R., Sagiv, J (2003)"Constructive

microlithography: Electrochemical printing of

monolayer template patterns extends constructive

nanolithography to the micrometer-millimeter

dimension range," Nano Lett. vol. 3, pp. 761-767.

De Marco, C., Girardo S., Mele, E., Cingolania, R.,

Pisignano, D. (2008) "Ultraviolet-based bonding for

perfluoropolyether low aspect-ratio microchannels and

hybrid devices," Lab Chip vol. 8, pp. 1394–1397.

Li, H. W., Muir, B. V. O., Fichet, G., Huck, W. T. S (2003)

"Nanocontact printing: A route to sub-50-nm-scale

chemical and biological patterning," Langmuir, vol. 19,

pp. 1963-1965.

McClelland, G. M. Hart, M. W. Rettner, C. T. Best, M. E.

Carter, K. R. Terris, B. D. (2002) "Nanoscale patterning

of magnetic islands by imprint lithography using a

flexible mold," Appl. Phys. Lett. vol. 81, pp. 1483-

1485.

Bandic, Z. Z. Xu, H. Hsu, Y. Albrecht, T. R. (2003)

"Magnetic lithography using flexible magnetic masks:

applications to servowriting," IEEE Transactions on

Magnetics, vol. 39, pp. 2231-2233.

Urbach, A. R. J. Love, C. Prentiss, M. G. Whitesides, G. M.

(2003)"Sub-100 nm confinement of magnetic

nanoparticles using localized, magnetic field

gradients," JACS, vol. 125, pp. 12704-12705.

Bardea A., Naaman, R. (2009) "Magnetolithography: From

Bottom-Up Route to High Throughput," Small, vol. 5,

pp. 316-319.

Bardea A. Yoffe, A. (2017) "Magneto-Lithography, a

simple and inexpensive method for high throughput,

surface patterning,", IEEE Trans. on Nanotechnology,

vol. 16, no. 3, pp. 439-444.

Bardea A. (2018)“Novel approach of backside lithography

using dynamic magnetic mask” Int'l. Conf. on the

Science of Electrical Engineering (ICSEE).

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

84