Quantitative Performance Analysis from Discrete Perspective: A

Case Study of Chip Detection in Turning Process

Sharmin Sultana Sheuly

1

, Mobyen Uddin Ahmed

2

and Shahina Begum

3

School of Innovation, Design and Engineering, Mälardalen University, 722 20 Västerås, Sweden

Keywords: Machine Learning, Manufacturing System, Quantification, Performance Analysis.

Abstract: Good performance of the Machine Learning (ML) model is an important requirement associated with ML-

integrated manufacturing. An increase in performance improvement methods such as hyperparameter tuning,

data size increment, feature extraction, and architecture change leads to random attempts while improving

performance. This can result in unnecessary consumption of time and performance improvement solely

depending on luck. In the proposed study, a quantitative performance analysis on the case study of chip

detection is performed from six perspectives: hyperparameter change, feature extraction method, data size

increment, and concatenated Artificial Neural Network (ANN) architecture. The focus of the analysis is to

create a consolidated knowledge of factors affecting ML model performance in turning process quality

prediction. Metal peels such as chips are designed at the time of metal cutting (turning process) and the shape

of these chips indicates the quality of the turning process. The result of the proposed study shows that

following a fixed recipe does not always improve performance. In the case of performance improvement, data

quality plays the main role. Additionally, the choice of an ML algorithm and hyperparameter tuning plays an

essential role in performance.

1 INTRODUCTION

The concept of ”zero human intervention” stepped

into the scene with the rise of Artificial intelligence

(AI). AI is the science of intelligent machine

development (Watson, 2005) (McCarthy, 2007).

Machine Learning(ML) is a black-box AI technology

which learns an unknown function based on provided

data (Zhang, 2020). Sensor technologies have

advanced in an unprecedented manner. These new

sensors can produce large amounts of data which

paves the way for ML applications in the

manufacturing domain (Kusiak, 2018), (Tiwari,

2021) . Distributed and autonomous manufacturing

has laid a new milestone (Wang, 2015), (Zhuang,

2007). Data in the manufacturing domain are stored

for a short period for maintenance purposes and have

a chaotic structure (Wuest, 2016).

These data can foster automation in the

manufacturing domain with the application of ML for

managing uncertainties (Zhang, 2020), tool condition

1

https://orcid.org/0000-0003-0883-0044

2

https://orcid.org/0000-0003-1953-6086

3

https://orcid.org/0000-0002-1212-7637

monitoring (Alfaro-Cortes, 2020), process modelling,

adaptive control (Monostori, 2003), quality

prediction (CHO, 2020) etc. Cloud and IoT-based

devices are used for deploying models for scheduling

(Jian, 2021), self-organised task scheduling (Chen,

2018), and manufacturing collaboration (Tao, 2019).

Supervised and unsupervised learning are the two

main contributors to manufacturing from an ML

perspective (Dogan, 2021) (Bricher, 2020). The

widely used algorithms are the Support vector

machine (SVM) (Liao, 2019), Artificial Neural

Network (ANN) (Casalino, 2016), Decision Trees

(DT) (Ronowicz, 2015), and k Nearest Neighbors

(kNN) (Kong, 2016).

In the period 2015-2020, research publications

were mainly focused on the application of ML in the

manufacturing domain (Sheuly, 2021), (Hamidur,

2023). However, after 2020 only an application of ML

to a certain domain is no more considered a significant

contribution to the state of the art (Doulgkeroglou,

2020), (Syafrudin, 2018), (Romero, 2019).

368

Sheuly, S., Ahmed, M. and Begum, S.

Quantitative Performance Analysis from Discrete Perspective: A Case Study of Chip Detection in Turning Process.

DOI: 10.5220/0011800100003393

In Proceedings of the 15th International Conference on Agents and Artificial Intelligence (ICAART 2023) - Volume 2, pages 368-379

ISBN: 978-989-758-623-1; ISSN: 2184-433X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Additionally, according to (Chui, 2017), 64% of total

work spent in the manufacturing domain can be

automated with the latest technology instead of human

resource and it could save 478 billion working hours.

ML with significant performance can reduce

economic loss and required time in manufacturing

(Zhao, 2020), (Uzkent, 2019), (Brisk, 2019). As a

result of this new requirement for improved

performance, the application of ML with changed ML

architecture, versatile data source, and edge device

found its way into the manufacturing domain.

However, good performance is a prerequisite in the

case of ML applications in the manufacturing domain

(Sharmin 2021). No research study quantifies the

change in performance with perspective variation such

as a change in ML architecture, the inclusion of

versatile data sources, and hyperparameter tuning.

This can give rise to a random search for performance

improvement methods which is a time-consuming and

unrealistic method.

In the proposed study, a case study combining

cutting-edge technologies such as ML, embedded

systems and cloud technology of chip detection is

presented where a change in performance is quantified

with perspective variation such as hyperparameter

change, the inclusion of feature extractor and new data

source, change in ML model architecture.

The proposed study contributes to the state-of-the-

art works by creating hyperparameter-tuned models,

followed by performance comparison from a different

perspective and a complete hardware setup. The

proposed work will create an efficient path of

performance improvement for the future researcher.

Most turning process prediction systems predict

surface roughness (Singh, 2007), cutting parameters

(Jurkovic, 2018), and tool life (Laghari, 2019). To our

knowledge, no other study implements a turning

process prediction system for machine health

monitoring with ML, embedded systems and cloud

technology followed by an analysis of different

perspectives. A local manufacturing company

1

manufactures cutting tools that cut metal into a

predefined shape. One of the cutting processes is

turning (kim, 2018). In the turning process, the

workpiece moves, and the cutting tool remains

stationary while cutting the metal. The by-product of

the turning process is metal chips and technicians

examine these chips to understand whether the turning

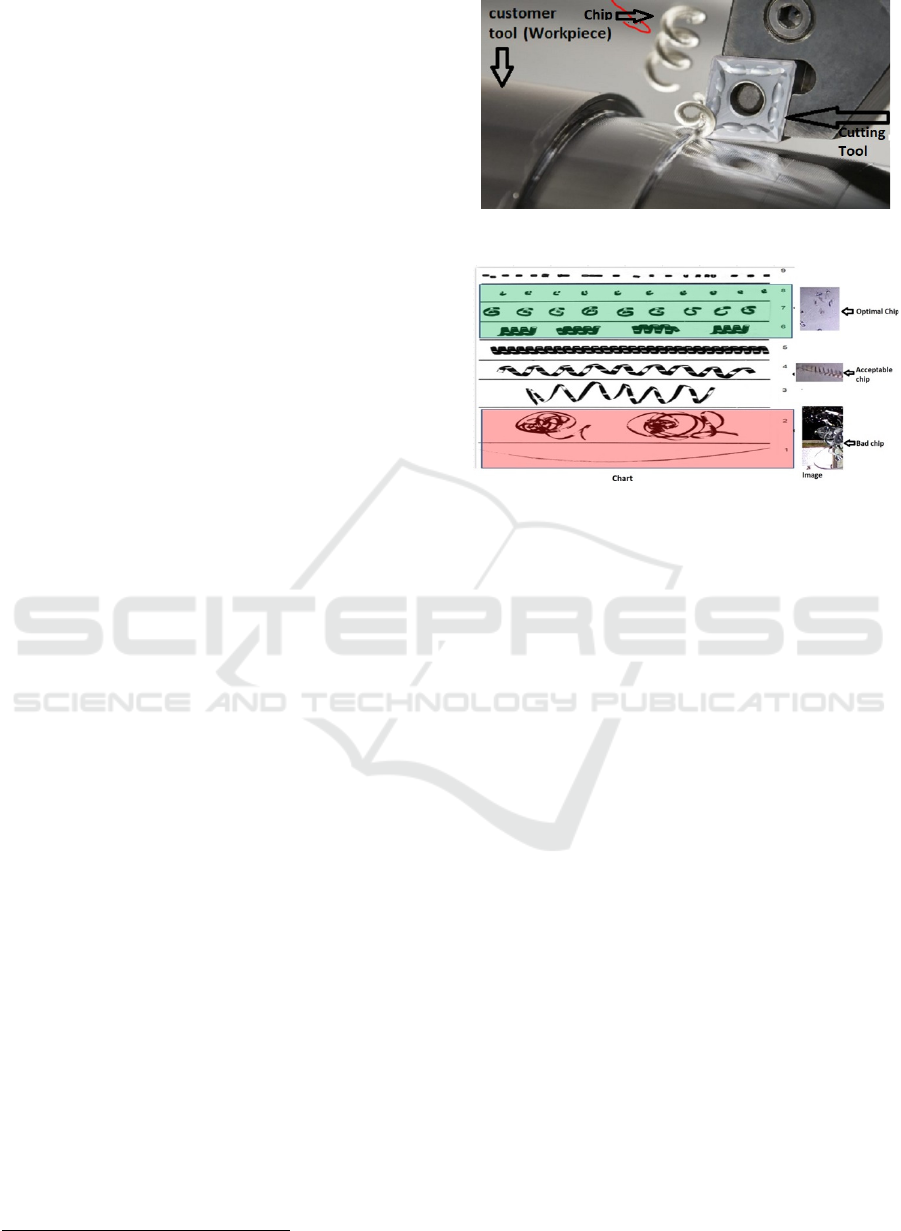

process is in a good condition. Figure 1 shows the

turning process using a cutting tool and Figure 2

shows chip classes:(a)acceptable chip (b)optimal chip

(c)bad chip.

1

https://www.secotools.com/

Figure 1: Turning Process with a cutting tool.

Figure 2: Chip classes depending on size.

In this proposed study, the final ML model runs

on Raspberry Pi replacing the human technician by

predicting the chip class based on the chip image and

machine parameters. In addition, the images were

saved on the Azure cloud platform. The rest of the

paper is structured as follows: Section 2 presents an

overview of the approach, section 3 presents the

implementation method, section 4 shows the results

and finally section 5 concludes the study with a

discussion.

2 OVERVIEWS OF APPROACH

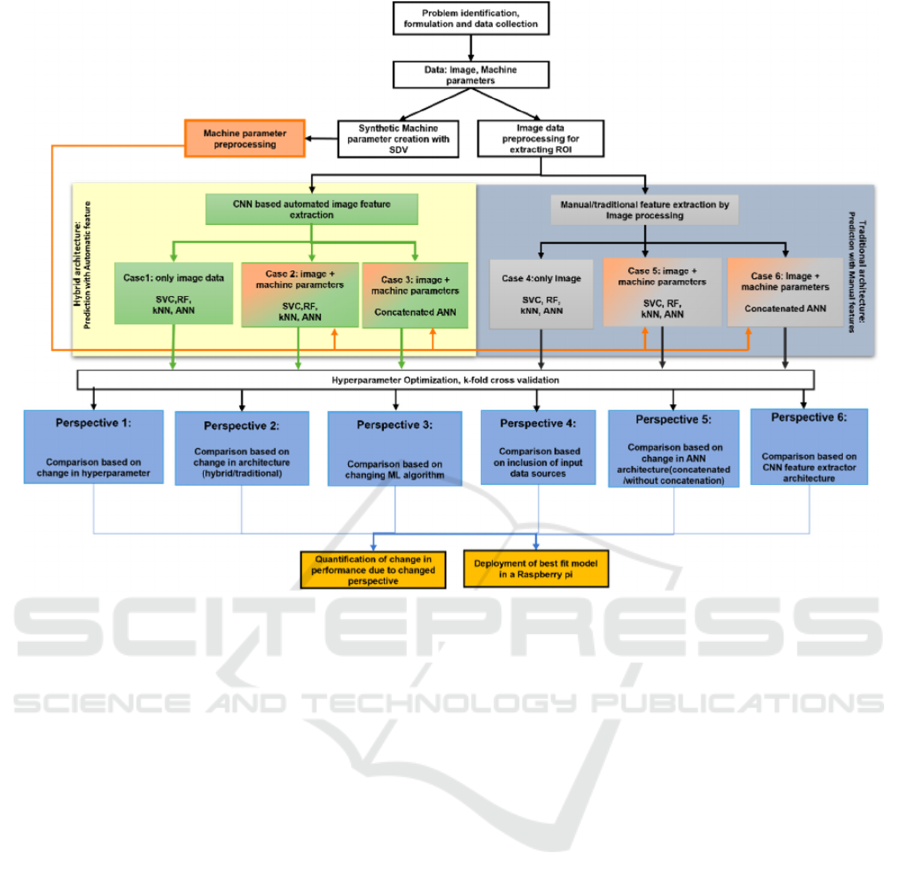

This research study started with the offline process by

gathering domain knowledge, data, requirements, and

ideas provided by the local manufacturing company

(Figure 3). The formulated problem was to automate

the turning process using ML models and

quantification of change in performance because of

the changed perspective. The state of the art in the

manufacturing domain was reviewed to find

concurrent ML algorithms appropriate for the

formulated problem. ML algorithms such as ANN,

Convolutional Neural Network (CNN), SVM, kNN

and RF were selected. There are two types of data: the

image of chips and numerical machine parameters.

Quantitative Performance Analysis from Discrete Perspective: A Case Study of Chip Detection in Turning Process

369

Figure 3: Step-by-step offline process.

On image data several pre-processing steps such

as Gaussian blur filter, foreground mask, and Canny

edge filter were performed to convert the images to

an appropriate form. For the numeric machine

parameters cardinality, missing values were checked.

After pre-processing, classification models were

trained on the processed data. Two sets of models

were created: one set with automatic features such as

features extracted with help of CNN which are named

‘hybrid architecture’. Conversely, another set of

models was created with manually extracted features

which are named ‘traditional architecture’.

Both hybrid and traditional architecture have

varying inputs. Certain models were created with

only image data as input such as Case 1 and Case 4

(coloured in green) while certain models were created

with both image and machine parameters as input

such as Case 2, Case 3, Case 5, Case 6 (coloured in

green and orange). Two types of models were created

for ANN: one set with concatenated architecture

(Case 3 and Case 6) and the other set without

concatenation (Case 2 and Case 5 ). In the case of

concatenated architecture, two ANN models, one

considering machine parameters as input (Model 1)

and one considering the image as input (Model 2)

were concatenated at the final layer. Conversely, in

the case of a model without concatenation machine

parameters were combined with the image and the

combined data was used as input to the ANN model.

All the models were created with hyperparameter

optimization. SVC, RF, and kNN were created with

5-fold cross-validation while ANN (both

concatenated and without concatenation) were

created with train, validation, and test split (80%,

10% and 10%). In the following stage, the created

eighteen ML models were evaluated to quantify the

change in performance with change in perspective.

The considered perspectives are

1) Change in hyperparameter.

2) Change in architecture (Hybrid/traditional

feature extraction).

3) Change in ML algorithm (ANN, SVC, RF or

kNN).

4) Inclusion of new data sources such as machine

parameters.

5) Change in ANN architecture (Concatenated or

without concatenation).

6) Change in CNN feature extractor architecture

(shallow layer or deep layer).

The ML model with the best performance was

deployed in raspberry pi. In case of bad chips, the

raspberry Pi switched the red LED on and signalling

the technician.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

370

3 IMPLEMENTATIONS

3.1 Data Collection and Pre-Processing

There was no image-capturing system at the local

manufacturing company. To capture images during

the turning process a GoPro Hero 9 camera was

installed on top of the workpiece. An additional light

source was used in the setup. In total, 42 videos were

captured with the highest speed, feed, and chip

breaker (a tool that breaks the chips). A total of 20023

images were extracted from the videos for training. In

addition, 6429 images were extracted for testing.

In the case of machine parameters, 2105 data

instances were provided by the manufacturing

company. Synthetic Data Vault (SDV) (Watson,

2005) is a set of libraries that were used to generate

synthetic data of the same format and statistical

properties. The SDV was used to create a hierarchical

statistical model of the machine parameters. This

fitted model was subsequently used to generate

additional data instances. A total of 20023 data

instances of machine parameters were created to align

with 20023 image data.

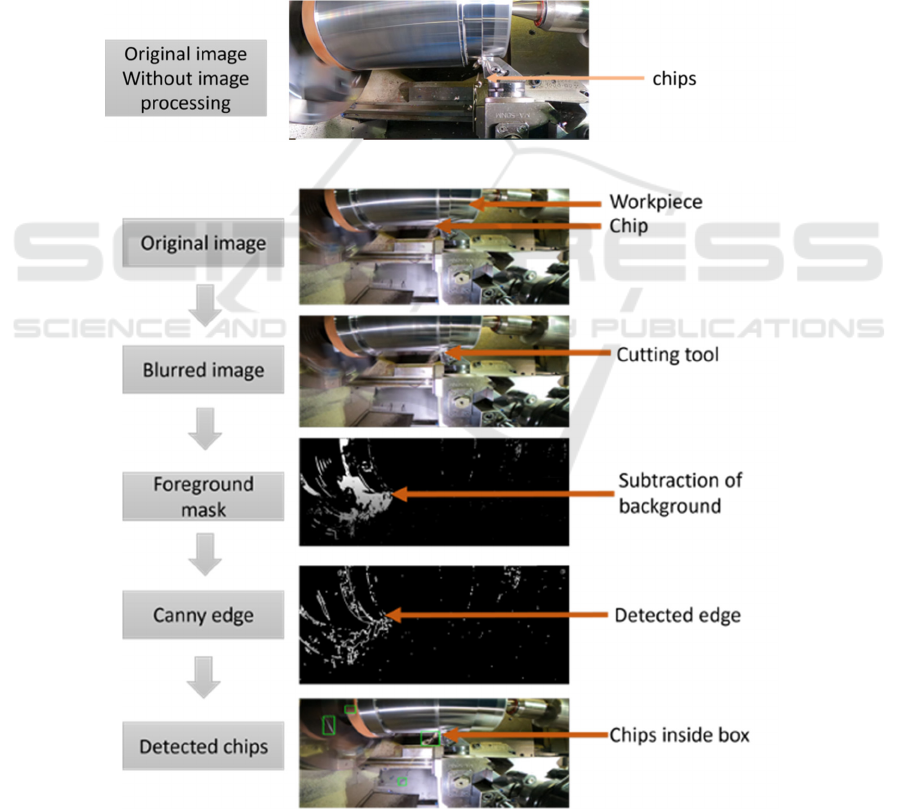

The primary goal of pre-processing is to improve

image quality by suppressing irrelevant information

and enhancing important features for ML

classification. However, this step adds additional time

to the classification. Figure 4b shows pre-processing

a) Undetected chips because of an absence of image processing

b) Detected chips because of image processing

Figure 4: Comparison of the image in the presence and absence of image processing techniques.

Quantitative Performance Analysis from Discrete Perspective: A Case Study of Chip Detection in Turning Process

371

steps performed on the images while Figure 4a shows

an image without pre-processing. It is visible that

without pre-processing chip detection is not

possible. In this work, the images were at first

smoothed with help of a Gaussian filter (Figure 4b).

Gaussian filter reduces the details of an image by

replacing pixel values with a value closer to the

nearby pixel value. This smoothing helps detect

edges. In the later stage, a foreground mask was

applied to the blurred image. The white area in the

figure represents the moving objects (rotating

workpieces and chips) and the black area is the

stationary background. The stationary background is

removed from the image to enhance only the

moving chips. To detect the edges of an object, the

canny edge detection technique is used. In the

proposed work, canny edge detection is used to

separate chips from other moving parts. Changes in

pixel, intensity are used to define the boundary. A fast

change in pixel intensity is regarded as an edge. In the

last stage, the green bounding box is showing the

potential chips. In the case of numerical data, the

missing values were first located and populated with

the median value. In the later stage, the cardinality

of the variables was checked, one of the variables

had cardinality 1 (all the values were the same), and

it was removed from the dataset because it does not

contribute any information. To identify outliers

minimum and maximum values of each variable were

investigated. Outliers are absent in the dataset. The

variables were scaled to the range [0,1] resulting in

similar effects from all data instances.

3.2 Feature Extraction with CNN

CNN was used for feature extraction. Two CNN

models were trained on the image data and the final

layer output of CNN is used as the input feature. The

first model has seven layers while the second model

was created with two layers. The performance of

these two models was compared considering

accuracy.

3.3 Classification Model Building and

Concatenation

Several classification models were created to classify

the chip images and machine parameters into three

classes: (a) acceptable chip (b) optimal chip (c) bad

chip (Figure 2).

The hyperparameter of the SVC was tuned with

the help of the scikit-learn function ‘GridSearchCV’

through an exhaustive search over specified

hyperparameter space. A 5-fold cross-validation was

used. A linear kernel along with ‘C’ value 1000

stopped the grid search process, for this reason, the

linear kernel was removed from the candidate

hyperparameter list. The grid search process for the

SVC model hyperparameter took 48 hours. The final

optimized hyperparameter values are provided in

Table 1. Hyperparameters of the kNN and RF model

were tuned with help of ‘GridSearchCV’ with 5-fold

cross-validation. The grid search process for the kNN

model hyperparameter took 5 minutes. The final

optimized hyperparameter values are provided in

Table 1.

Figure 5: Concatenated model construction.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

372

Table 1: Optimized hyperparameter values of the ML models.

Hyperparameter Candidate value

Optimized value

Case 1 Case 2 Case

4

Case 5

SVC

C

0.1, 1, 10, 100, 1000 1000 1000 0.1

1

gamma 1, 0.1, 0.01, 0.001, 0.0001

11

0.0001 0.001

kernel ’rbf’ ’rbf’ ’rbf’ ’rbf’ ’rbf’

Random Forest

max depth 10, 20, 30 30 30 30 30

max features ’auto’, ’sqrt’ ’sqrt’ ’auto’ ’auto’ ’sqrt’

min samples leaf 1, 2

1 1 1 1

min samples spli

t

2, 5

2 2 2 2

n estimators 800, 1000 1000 1000 800 1000

k Nearest Neighbour

n neighbors 5,7,9,11,13,15

5

11

5 5

Weights ’uniform’,’distance’ ’distance’ ’distance’ ’distance’ ’distance’

Metric ’minkowski’,’euclidean’,’manhattan’ ’manhattan’ ’manhattan’ ’manhattan’ ’manhattan’

ANN

Learning rate 1,0.1,0.01,0.001 0.1 0.1 0.1 0.1

Activation ’relu’, ’elu’ ’relu’ ’relu’ ’relu’ ’relu’

Neurons 10, 20, 30, 40, 80 40 40 40 30

b

atch siz

e

16, 32, 64, 128 64 64 64 16

Optimize

r

‘Nadam’,’Adam’ ‘Nadam’ ‘Nadam’ ‘Nadam’ ‘Nadam’

Table 2: Optimized Hyperparameter values of the concrete-

naked model.

Hyperparameter Candidate value

Optimized value

Case 3 Case

6

Activation ’relu’, ’elu’ ’relu’ ’relu’

Batch siz

e

16,32,64,128 64 64

model1 neuron numbe

r

10,20, 30, 40,100 10 10

learning rate

0.01,0.1,0.001,

0.00001

0.1 0.1

dropou

t

0, 0.1, 0.2

0 0

Optimize

r

’Adam’,’Nadam’ ’Nadam’’Nadam’

model2 neuron numbe

r

20,30,100, 300 30 30

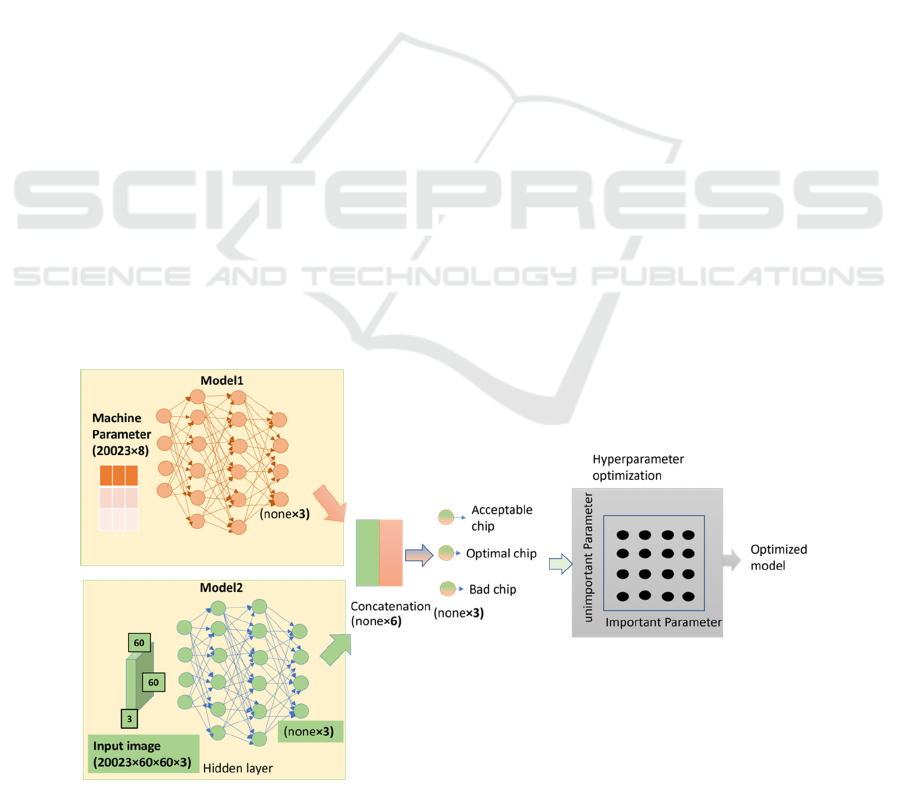

In the concatenated model, three dense layers were

used which is followed by a flattened layer and finally

the output layer (Figure 5). At the time of training, the

model ‘Categorical Crossentropy’ was used as the

loss. After building both ANN models’, the outputs

were concatenated (Figure 5). The models’

hyperparameters were optimized with Talos

21

. The

output is the probability of a specific class. The final

optimized hyperparameter values are provided in

Table 2.

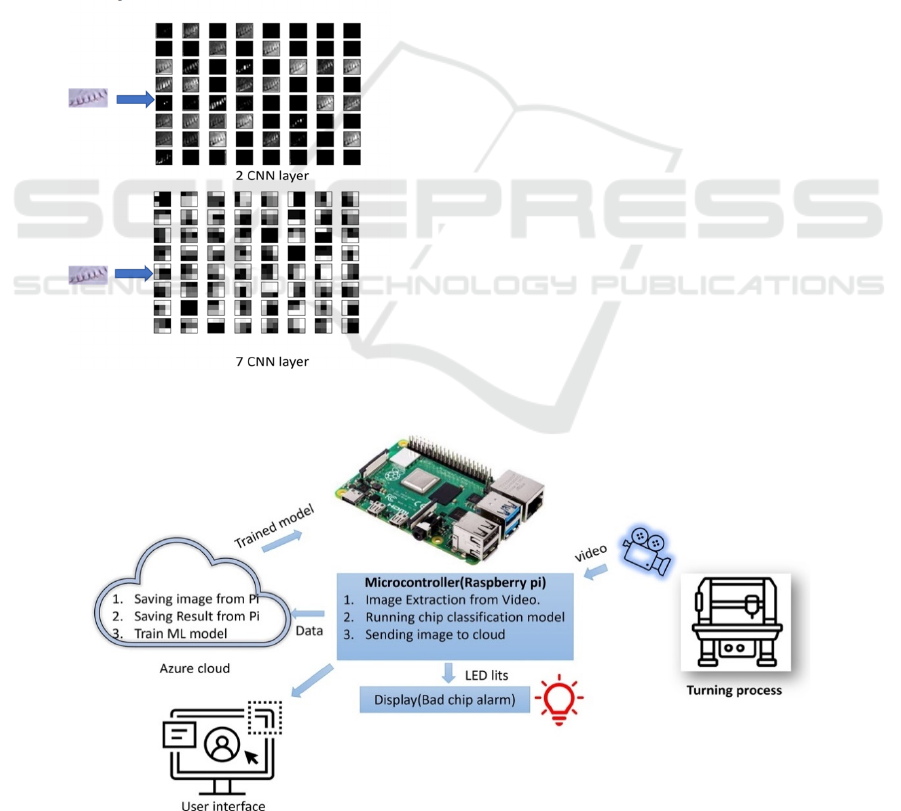

3.4 Deployment in Raspberry Pi

The model with significant performance was

deployed in Raspberry Pi. The Raspberry Pi 4 Model

B with 8GB of RAM was used in the proposed study.

The Raspberry Pi can send the results of the ML

model and extracted images to the Azure cloud.

2

Autonomio Talos [Computer software]

4 RESULTS

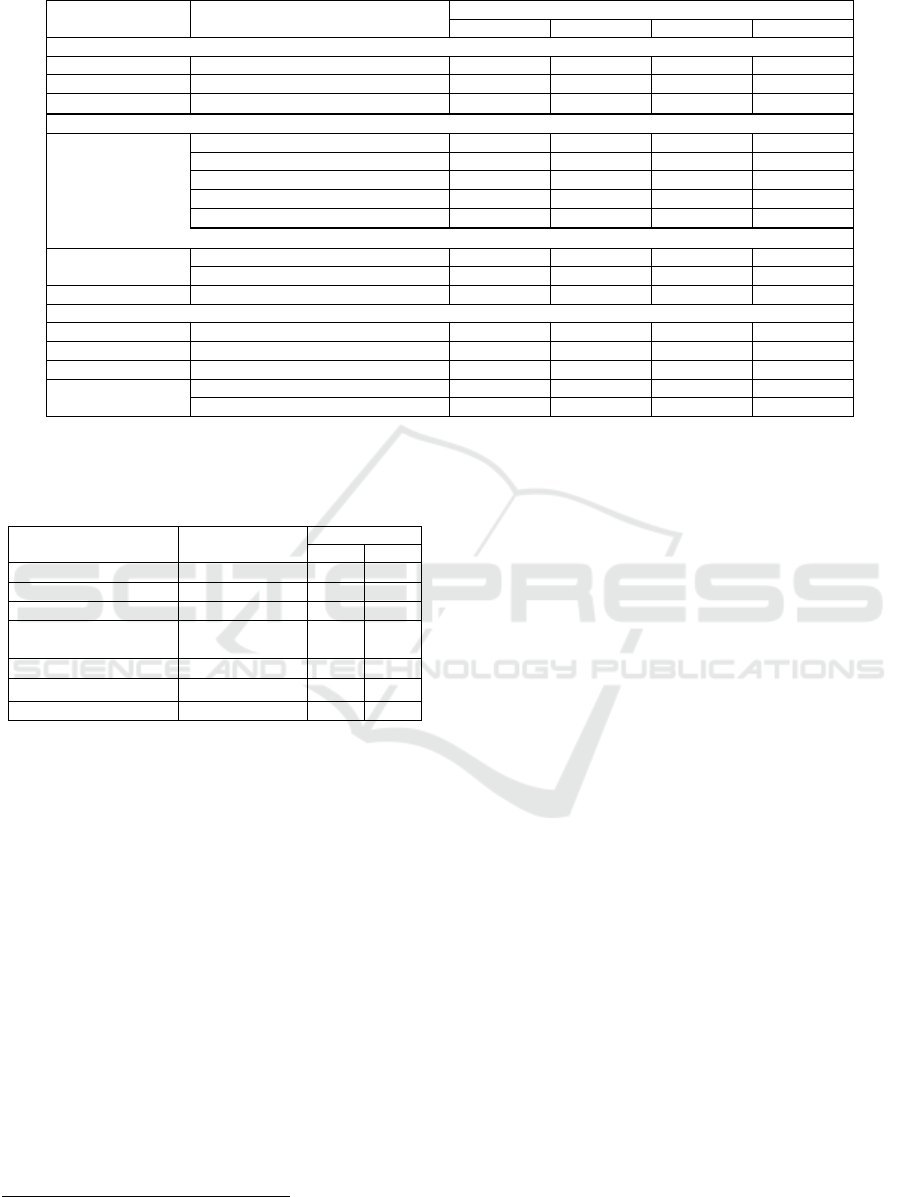

4.1 Perspective 1: Change in

Hyperparameter

In this perspective, change in performance with

hyperparameters is focused. Table 1 shows the

candidate and optimized hyperparameters while

Figure 6 shows the change in hyperparameters with

cases (hyperparameters that remained constant are

not included in the figure).

The C value in SVC is the term used to control

misclassification for hybrid architecture (Case 1 and

Case 2), C in SVC has a value of 1000 while for

traditional architecture (Case 5 and Case 6), the value

is 1. The hybrid architecture has higher accuracy on

test data with a higher C value. The penalty for

misclassification is higher in the case of hybrid

architecture which implies hybrid architecture

considers the outliers in the case of classification.

Conversely, in traditional architecture outliers are not

considered. However, the test accuracy increased

with the inclusion of outliers (Figure 6).

The data distributions of pixel values explain this

result (Figure 7). The figure shows, for an acceptable

and optimal chip the pixel values follow a normal

distribution, and most data points fall within the

distribution curve. However, for bad chips, pixel

values do not ideally follow any distribution. The

closest data distribution is the ‘rayleigh’ distribution.

Quantitative Performance Analysis from Discrete Perspective: A Case Study of Chip Detection in Turning Process

373

Figure 6: Change in performance with hyperparameter.

Figure 7: Data distribution of image pixels.

However, most data point shows random

frequency. Considering outliers while creating the

model showed success because of this distribution.

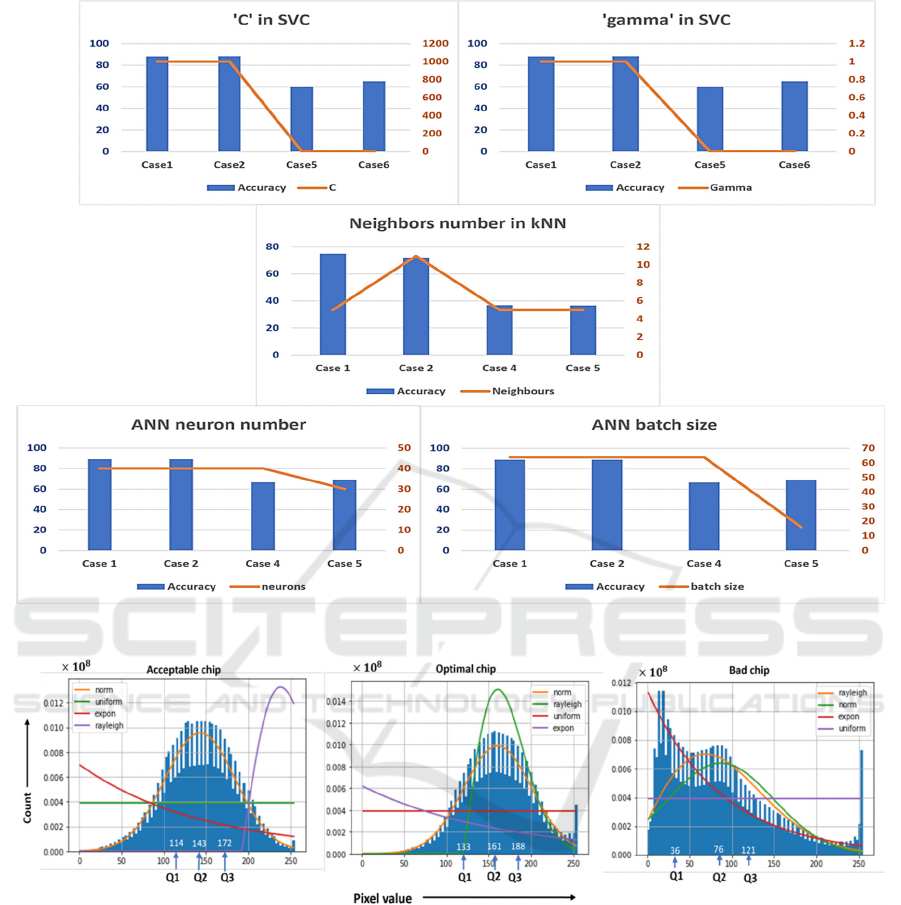

4.2 Perspective 2: Change in

Architecture

In this perspective, two types of architecture such as

hybrid (Case 1, Case 2, Case 3) and traditional (Case

4, Case 5, Case 6) architecture were considered

(Figure 8). Hybrid architecture comprised of CNN

features extractor and ML model while traditional

architecture comprised of manual feature extractor

and ML model. The accuracy increased by 20%

because of hybrid architecture.

4.3 Perspective 3: Change in ML

Algorithm

Certain ML algorithms such as SVC, RF, kNN, and

ANN were used to find the best model. ANN

outperformed all the other models. The accuracy

increased by a factor of 15% because of the changed

ML algorithm (ANN:90% and kNN:75%).

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

374

4.4 Perspective 4: Inclusion of New

Data Source

In this perspective, a new data set i.e., machine

parameters were used as input in addition to image

data resulting in two sets of cases ((a)Only image set,

(b)Image and machine parameter set). Only the image

set includes Case 1 and Case 4 while the image and

machine parameter set includes Case 2, Case 3, Case

5, and Case 6 (Figure 8).

Both the image and machine parameter set (Case

2) and only the image set (Case 1) have 90%

accuracy. This implies the inclusion of a new data

source does not increase the accuracy.

4.5 Perspective 5: Change in ANN

Architecture

In this perspective, concatenated ANN architecture

(Case 3 and Case 6) was compared with ANN without

concatenation (Case 2 and Case 5). A concatenated

ANN architecture was created to test if the changed

architecture can improve accuracy in addition to the

inclusion of a new data source (perspective 2). In

hybrid architecture, accuracy decreased by a factor of

2% with the introduction of concatenated architecture

(Case 2 and Case 3) while in traditional architecture,

the introduction of concatenated architecture did not

affect accuracy (Case 5 and Case 6).

Conversely, the inclusion of feature extractors

such as hybrid or traditional architecture (Perspective

2: Change in architecture) changed performance

significantly which indicates feature extraction can

lead to the loss of significant information. To quantify

the change in information aspect with change in

input such as the inclusion of feature extractor and

machine parameter data normalized mutual

information was calculated.

Normalized mutual information considers

Shanon’s entropy for the quantification of change in

the information aspect of one variable with the

observation of another variable. In the proposed

study, the added information to the true response

because of the predictions from the ML models is

quantified (Figure 9). As shown in the figure, 4 sets

of input are considered:

• Input 1: Raw (no feature extraction) image data

• Input 2: Hybrid (feature extraction with CNN)

image data

• Input 3: Traditional (manual feature extraction)

image data

• Input 4: Only Machine parameter

The information bits added by the raw image is

65% while feature extractions from the raw image with

CNN increased the information aspect by only 3%.

Manual feature extraction decreased the information

aspect by 40%. Conversely, for only machine

parameters, mutual information is only 5%. This

Figure 9: Mutual information associated with a different set

of data.

Figure 8: Change in performance with change in perspective.

Quantitative Performance Analysis from Discrete Perspective: A Case Study of Chip Detection in Turning Process

375

explains unchanged accuracy with the addition of

machine parameters (Perspective 4).

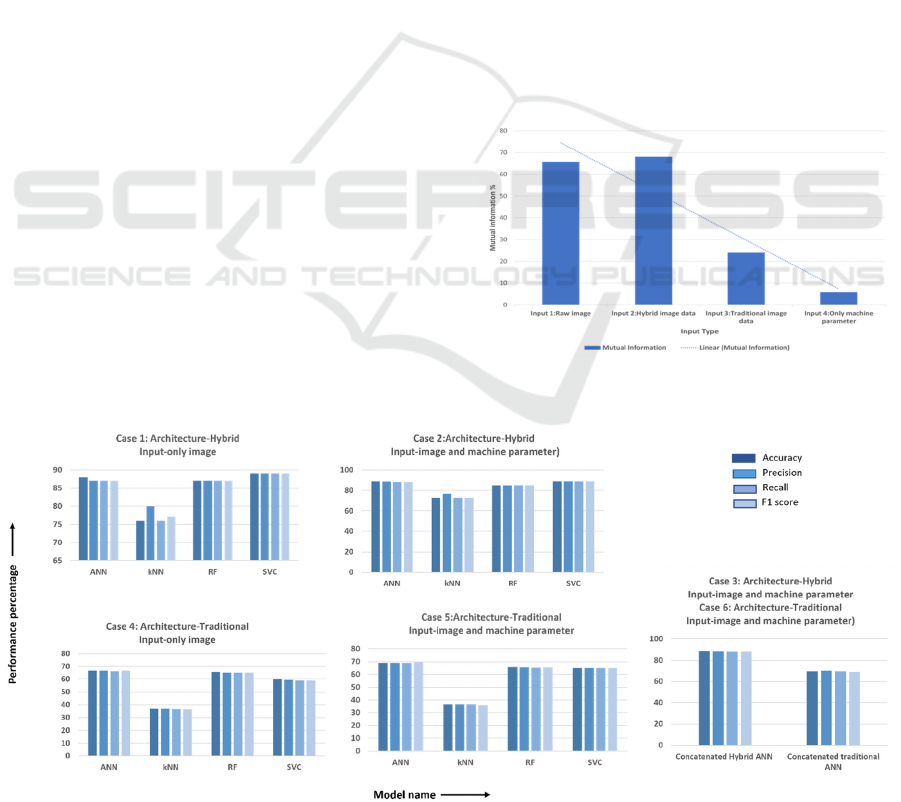

4.6 Perspective 6: Change in CNN

Feature Extractor Architecture

Several research studies state deep layers such as 14

layers (Rahman, 2021), and 50 layers (Qadir, 2019)

of CNN for feature extraction. However, in the

proposed study it is observed that with an increment

of the CNN feature extractor layer the accuracy

dropped in a proportional way.

To find the reason for degraded performance the

extracted features are plotted as an image for 2-layer

CNN and 7-layer CNN, (Figure 10). It is shown in the

figure that with an increase in the feature extractor

layer the images become abstract and it loses

information significant for classification.

Figure 10: Chip image feature extraction with 2-layer and

7-layer CNN.

4.7 Significance Test

Wilcoxon signed-rank test is a non-parametric test

used for the hypothesis test. In the proposed study, all

the data do not follow the Gaussian distribution

(Figure 7). For this reason, parametric test such as

ANOVA was not used.

Wilcoxon signed-rank test was performed to test

the null hypothesis ”The difference in true response

and ML predicted response is equal to 0” The p-value

for hybrid ANN (Case 2) is 0.664 while the p-value

for traditional ANN (Case 5) is 0.443. Therefore, the

null hypothesis cannot be rejected because the p-

value is greater than the significance level alpha =

0.05. Additionally, hybrid ANN (Case 2) has a higher

p-value compared to traditional ANN (Case 5) which

implies hybrid ANN (Case 2) is more related to true

response.

4.8 Hardware Setup Result

The complete hardware setup deployed in the

manufacturing company workshop is shown in Figure

11. The microcontroller extracts frames from the

video and sends them to the Azure cloud. To send

8603 frames to the azure cloud through an internet of

speed 9 MB/s the microcontroller takes 8 seconds.

5 DISCUSSION AND

CONCLUSION

The manufacturing industry is stepping into the era of

industry 4.0 with the advancement of technology. A

manufacturing system comprises numerous parts and

Figure 11: Complete setup in the manufacturing workshop.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

376

malfunction of any of these parts can lead to faulty

functionality. ML-integrated manufacturing can

solve this problem by reducing economic loss.

However, good ML performance is a prerequisite.

In the proposed study, chip images and machine

parameters are used as input to several ML models for

the prediction of the chip class and a quantified

performance analysis from six discrete perspectives

was performed.

One of the findings of the proposed study is that

SVC, kNN and ANN are the top three ML models

which are affected by hyperparameters significantly.

The C value of the SVC classifier is an indication of

data distribution. A significant C value indicates the

presence of an outlier. Additionally, accuracy can be

increased by a factor of 30% with hyperparameter

tuning.

However, ML performance improvement can be a

paradox. In the proposed study, the initial target was

to achieve an accuracy above 90%. For this reason,

hyperparameters were tuned increasing accuracy by

30%. For further improvement, automatic feature

extraction with CNN instead of traditional feature

extraction was implemented which increased the

accuracy by a factor of 20%.

Several state-of-the-art ML models such as SVC,

kNN, RF and ANN are trained to find the best-

performing model. Changing the ML model increased

the performance by a factor of 15%. The best-

performing model is ANN.

The findings of the proposed analysis show that

an increment of data which does not contribute any

information will not increase performance. The pitfall

of data is the widely accepted belief ”more data

means better performance”. However, more data does

not always lead to better performance. An added data

source only increases performance if the posterior

probability of the response variable changes

significantly with the inclusion of a new data source.

Additionally, the concatenation two ANN model will

contribute to better performance only if the input data

quality is better. Therefore, data plays a significant

role compared to model architecture.

A significant number of scientific publications

show performance increment with the extraction of

features such as edge, and colour. However, the

analysis based on perspectives 5 and 6 shows feature

extraction does not always contribute to model

performance increment. In certain cases, feature

extraction can suppress information significant for

classification. For this reason, raw pixel values have

a similar performance as the CNN extracted features.

It can be concluded that an industrial case study

can have a distinct characteristic which can lead to the

failure of popular performance improvement

methods. In the proposed study, the detected objects

(chips) can be a few millimetres resulting decrease in

accuracy with feature extraction compared to raw

pixel values. Additionally, it can be concluded that

data quality plays the main role in performance

improvement compared to hyperparameter tuning,

model architecture changing, feature extraction

method, size of data, and algorithm selection. The ML

model predictions are not produced by chance

(according to Wilcoxon signed-rank test).

The limitation of the proposed study is the latency

introduced due to image processing leading to limited

application for real-time object detection. The

findings of the proposed study apply to the specific

case study and case studies with similar types of data.

In future, the same analysis can be performed on

benchmark data sets to draw a more generalized

conclusion.

ACKNOWLEDGEMENTS

The study was conducted through the DIGICOGS

project which is financed by Vinnova (Vinnovas

Diarienr: 2019-0532) and the innovation program

Process Industrial IT and Automation (PiiA) at

Mälardalen University. Thanks to Amir Karim,

Vyacheslav Kryzhanivskyy, Abhishek Ranjan, Nick

Grannas, Robin Andersson Dickfors and Go¨zde

Akpak for their initial work in DIGICOGS project.

REFERENCES

Watson D. P., Scheidt D. H., (2005), Autonomous systems,

Johns Hopkins APL technical digest 26 (4) 368–376.

McCarthy J., ? (2007). What is artificial intelligence

Zhang X.-D., (2020), Machine learning, in A Matrix

Algebra Approach to Artificial Intelligence, Springer,

2020, pp. 223–440.

Wang L., Torngren M., Onori M., (2015), Current status

and advancement of cyber-physical systems in

manufacturing, Journal of Manufacturing Systems 37

517–527.

Zhuang L., Goh K. M., Zhang J.-B., (2007), The wireless

sensor networks for factory automation: Issues and

challenges, in 2007 IEEE Conference on Emerging

Technologies and Factory Automation (EFTA 2007),

IEEE, , pp. 141–148.

Wuest T., Weimer D., Irgens C., Thoben K.-D., (2016),

Machine learning in manufacturing: advantages,

challenges, and applications, Production &

Manufacturing Research 4 (1) 23–45.

Kusiak A., (2018), Smart manufacturing, International

Journal of Production Research 56 (1-2) 508–517.

Quantitative Performance Analysis from Discrete Perspective: A Case Study of Chip Detection in Turning Process

377

Monostori L., (2003), AI and machine learning techniques

for managing complexity, changes and uncertainties in

manufacturing, Engineering applications of artificial

intelligence 16 (4) 277–291.

Alfaro-Cortes E., Alfaro-Navarro J.-L., Gamez M., Garcıa

N., (2020), Using random forest to interpret out-of-

control signals, Acta Polytech. Hung. 17 (6) 115–130.

Zhang X., Kano M., Tani M., Mori J., Harada J. Ise, K.,

(2020), Prediction and causal analysis of defects in steel

products: Handling nonnegative and highly

overdispersed count data, Control Engineering Practice

95, 104258.

Cho E., Jun J.-H., Chang T.-W., Choi Y., (2020), Quality

prediction modelling of plastic extrusion process, ICIC

express letters. Part B, Applications: an international

journal of research and surveys 11 (5) ,447–452.

Dogan A., Birant D., (2021) Machine learning and data

mining in manufacturing, Expert Systems with

Applications 166 ,114060.

Tiwari R. Rai, M. K., Ivanov D., Dolgui A., (2021). Machine

learning in manufacturing and industry 4.0 applications

Jian C., Ping J., Zhang M., (2021), A cloud edge-based two-

level hybrid scheduling learning model in cloud

manufacturing, International Journal of Production

Research 59 (16) 4836–4850.

Chen B., Wan J., Celesti A., Abbas D. Li, H., Zhang Q.,

(2018), Edge computing in iot-based manufacturing,

IEEE Communications Magazine 56 (9) ,103–109.

Tao Q. Qi, F., (2019), A smart manufacturing service

system based on edge computing, fog computing, and

cloud computing, IEEE Access 7, 86769–86777.

Liao J. Lu, X., Ouyang S. Li, H., Chen K., Huang B.,

(2019), An effective ABC-SVM approach for surface

roughness prediction in manufacturing processes,

Complexity 2019

Casalino G., Facchini F., Mortello M., Mummolo G.,

(2016), Ann modelling to optimize manufacturing

processes: The case of laser welding, IFAC-

PapersOnLine 49 (12), 378–383.

Ronowicz J., Thommes M., Kleinebudde P., Krysinski J.,

(2015), A data mining approach to optimize pellets

manufacturing process based on a decision tree

algorithm, European Journal of Pharmaceutical

Sciences 73, 44–48.

Kong N. Li, H., Gong Y. Ma, G., Huai W., (2016), Human

performance modelling for manufacturing based on an

improved KNN algorithm, The International Journal of

Advanced Manufacturing Technology 84 (1-4) 473–483.

Doulgkeroglou M.-N., Nubila A. Di, Niessing B., Konig N.,

Schmitt R. H., Damen J., Szilvassy S. J., Chang W.,

Csontos L., Louis S., et al., (2020), Automation,

monitoring, and standardization of cell product

manufacturing, Frontiers in Bioengineering and

Biotechnology 8, 811.

Syafrudin M., Alfian G., Fitriyani N. L., Rhee J., (2018),

Performance analysis of iot-based sensor, big data

processing, and machine learning model for real-time

monitoring system in automotive manufacturing,

Sensors 18 (9), 2946.

Romero D., Gaiardelli P., Powell D., Wuest T., Thurer M.,

(2019), Rethinking jidoka systems under automation &

learning perspectives in the digital lean manufacturing

world, IFAC-PapersOnLine 52 (13) , 899–903

Chui M., George K., Manyika J., Miremadi M., (2017),

Human+ machine: A new era of automation in

manufacturing, McKinsey & Company 13.

Bricher D., Muller A., (2020), A supervised machine

learning approach for in- telligent process automation

in container logistics, Journal of Computing and

Information Science in Engineering 20 (3)

Singh, D. and Venkateswara R. P, (2007), A surface

roughness prediction model for hard turning process,

The International Journal of Advanced Manufacturing

Technology, 1115–1124.

Jurkovic, Z., Cukor G., Brezocnik M., and Brajkovic T,

(2018), A comparison of machine learning methods for

cutting parameters prediction in high speed turning

process, Journal of Intelligent Manufacturing, 1683–

1693.

Laghari, R. A., Li, J., Laghari, A. A., Mia, M., Wang, S. A.,

Wang P. KK, (2019) , Carbide tool life prediction and

modelling in SiCp/Al turning process via artificial

neural network approach, IOP Conference Series:

Materials Science and Engineering 012022.

Zhao X., Lovreglio R. and Nilsson D., (2020) , Modelling

and interpreting pre-evacuation decision-making using

machine learning, Automation in Construction,

103140.

Uzkent B., Sheehan E., Meng C., Tang Z, Burke M, Lobell

D, and Ermon S, (2019), Learning to interpret satellite

images using Wikipedia, Proceedings of the Twenty-

Eighth International Joint Conference on Artificial

Intelligence.

Brisk R, Bond RR, Banks E, Piadlo A, Finlay D,

McLaughlin J, and David M, (2019), Deep learning to

automatically interpret images of the

electrocardiogram: Do we need the raw samples?,

Journal of electrocardiology, S65–S69

Kim D-H, Kim T, Wang X, Kim M, Quan Y, Oh J, Min S-

H, Kim H, Bhandari B, Yang I, and Ahn, S-H, (2018),

Smart Machining Process Using Machine Learning: A

Review and Perspective on Machining Industry,

International Journal of Precision Engineering and

Manufacturing-Green Technology, 555-568.

Rahman H, Ahmed M.U, Barua, S, Funk P, and Begum S,

(2021) Vision-Based Driver’s Cognitive Load

Classification Considering Eye Movement Using

Machine Learning and Deep Learning, Sensors, 1424-

8220.

Qadir H A, Shin Y, Solhusvik, J, Bergsland J, Aabakken L,

Balasingham I, (2019), Polyp detection and

segmentation using mask R-CNN: Does a deeper

feature extractor CNN always perform better?, 2019

13th International Symposium on Medical Information

and Communication Technology (ISMICT) 1–6.

Sheuly, S.S., Ahmed M U, and Begum S, (2021), Machine

Learning Based Digital Twin in Manufacturing: A

Bibliometric Analysis and Evolutionary Overview,

submitted to Journal of applied sciences, 1424-8220.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

378

Hamidur R, Ricky S D C, Ahmed M U, Rickard S,

Tomohiko S, Peter F, (2023), Artificial Intelligence-

based Life Cycle Engineering in Industrial Production:

A Systematic Literature Review (Jan 2023), Journal of

IEEE ACCESS (IEEE ACCESS)

Sharmin S S, Shaibal B, Shahina B, Ahmed M U, Ekrem G,

Michael O, (2021), Data Analytics using Statistical

Methods and Machine Learning: A Case Study of

Power Transfer Units (Mar 2021), International Journal

of Advanced Manufacturing Technology (IJAMT).

Quantitative Performance Analysis from Discrete Perspective: A Case Study of Chip Detection in Turning Process

379