Towards a Robust Solution for the Supermarket Shelf Audit Problem

Emmanuel F. Mor´an

a

, Boris X. Vintimilla

b

and Miguel A. Realpe

c

ESPOL Polytechnic University, Escuela Superior Politecnica del Litoral, ESPOL, CIDIS,

Campus Gustavo Galindo Km. 30.5 V´ıa Perimetral, P.O. Box 09-01-5863, Guayaquil, Ecuador

Keywords:

Retail, Supermarket, Shelves Auditing, Deep Learning, Supermarket Dataset.

Abstract:

Retail supermarket is an industrial sector with repetitive tasks performed using visual analysis by the store’s

operators. Tasks such as checking the status of the shelves can contain multiple sequential sub-tasks, each of

which needs to be performed correctly. In recent years, there has been some intents to create a solution for the

tasks mentioned without been complete solution for retails. In this article, a first realistic approach is proposed

to solve the supermarket shelf audit problem. For this, a workflow is presented to deliver compliance level

with respect t o the expected store’s planogram.

1 INTRODUCTION

In recent years, A I has begun to be implemented in

a wide number of fields, including medicine (Chua

et al., 2021), agriculture (Zhang et al., 2020), finance

(Patil et al., 2022), among others. We address a topic

that to date and to the best our knowledge, has n ot

been fully analyzed in the public liter ature: Retail Su-

permarket Shelves Auditin g.

Shelves Auditing can be defined as the process of

comparing the curr ent state of shelves against the ex-

pected state according to a planogram (a visual model

for distributing super market products on their respec-

tive shelves). To make this comparison, human oper-

ators must carry out visual check s following the pro-

tocol of the store in order to validate the status of the

shelves. As result of these visual processes, a percent-

age of comp liance between the actual shelves and the

planogram is calculated. Finally, by averaging these

values of all the shelves in the sales area, a store com-

pliance percentage can be obtained.

In this article, a new proposal to solve the super-

market shelf audit problem by defining an acquisition

method for a new dataset and a workflow to process it

will be discussed.

a

https://orcid.org/0000-0001-6915-7370

b

https://orcid.org/0000-0001-8904-0209

c

https://orcid.org/0000-0001-8711-5596

2 SUPERMARKET ISSUES

Many problems in retail supermarkets have been iden-

tified and reported in the literature (Pettigrew et al.,

2005) (Li and Wang, 1970) (Jedlickova, 2016). This

section will fo c us on the issues that involve product

placement in the shelves, since these pr oblems are re-

lated to the fact that produ ct positioning is done by

humans, inevitably leading to some errors.

2.1 Outdated Price Tags

This problem refers to price tags th a t are outdated

(printed or digital) or are in poor condition (torn,

stained, poorly printed, etc.). Price tags are one of

the most impor ta nt objects on the shelves, since they

allow to know what product is being displa yed, its

description, w eight or size and price. If price tags

are out of date, it is impossible for customers to co r-

rectly iden tify the product or to know the real price of

the product. An outdated price on the price tag can

have two negative repercu ssions: If the actual price

is lower than what is displayed (for example, a prod-

uct that should have a special offer), it is probably

not attractive to customers, and therefore sales may

be lost. On the other hand, if the r eal price is higher

than th e one shown, the customer may feel cheated

when checking out. This last one could have legal

repercu ssion as it can be consider a consumer scam.

An option for this to not scale is to sell the product at

the seen price (losing money).

A conventional solution could be dig i-

tal/electronic price tags (Cochoy and Soutjis,

912

Morán, E., Vintimilla, B. and Realpe, M.

Towards a Robust Solution for the Supermarket Shelf Audit Problem.

DOI: 10.5220/0011747000003417

In Proceedings of the 18th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2023) - Volume 4: VISAPP, pages

912-919

ISBN: 978-989-758-634-7; ISSN: 2184-4321

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2020). These are price tags tag can massively

change their content (price, description, code, etc),

but sadly implementing this is expensive, and most

of the retails could not afford. Someone could

also think to use RFID technology to easily catch

informa tion from a price tag, but this technology is

not conventional for this p a rticular use since it is

normally use for identifying product in the supply

chain (Tao et al., 20 22;

ˇ

Skiljo et al., 2020) and ease

inventory in categories with high margin of gain like

clothes and b ottles with alcoholic b everages such as

whiskey(Cilloni et al., 2019; Khalil et al., 2020).

2.2 Inactive Assortment

Inactive A ssortment is the denomination given to

products that should b e displayed in the sales area

(space wh ere shelves are, and produc ts are disp la yed),

but for so me reason are not. Some of the reason s for

this to happen are: out of stock, stock on the way

but not yet in store, or store decision. Inactive as-

sortment could drive shoppers away as they can’t find

some products.

2.3 Product Breaks

Denomina tion for a partially displayed product on the

shelves. This is considered bad for the presenta tion

because the shelf appears to be em pty. This is differ-

ent from inactive assor tment because product is dis-

played in the shelf tray (shelf area for the produ ct)

but is partially empty. This could happen for many

reasons, such as out of stock, replenishment n ot yet

completed , or simply the product is in stock but not

yet displayed on the shelves due to opera tor error. The

latter is the most common mistake and can be fixed by

manually checking all the pr oducts on the shelves.

2.4 Products in Poor State

A product state is how it is d isp la yed in the shelf and

the envelope o f it. If a product is in poor state it could

drive to a customer to not perform the purchase and

even do not return to the sto re ever again. This could

be fault of operators who have not followed the store

protocols or perhaps some children playing around in

the store.

3 THE PROCESS OF SHELVES

AUDITING

In a supermarket, sh elves auditing c an be defined

as the p rocess of comparing the cur rent state of

the shelves with the expected state according to its

planogram. This comparison is necessary for many

aspects, among them, validating contr actual compli-

ance with suppliers who paid extra for strategic posi-

tioning of their products on the shelves, or to be able

to carry out market analysis, i.e. how certain products

behave if they are placed closer to or further away

from others.

Such comparisons are usually made by su permar-

ket operators, and like any repetitive process per-

formed by a hu man being , it is prone to errors and

time consuming due to its visu al nature.

The following states must be validated during the

audit of the supermarket shelves:

• Presence of all products on each shelf according

to the planogram.

• Presence of product price tags in the correc t posi-

tion.

• Conc ordance between the product and its price tag

accordin g to the define d protocol.

• Product price updated in the price tag.

• Presence of product breaks.

• Product status (correct number of shelf tray fronts,

well-organized products, or others that the super-

market may need) .

All validations mention ed are perfor med during

store opening hours, but these are more extensive be-

fore or after hours of operation due to the absence of

customers. The operator will first check the shelves in

all aisles and try to solve problem s like wrongly posi-

tioned price tag s or products. For other issues, such as

product breaks, the operator first will go to the ware-

house to pick up missing products and then will return

to fill the shelf. This process is tedio us and repetitive

enoug h to lead operators to make mistakes. For this

reason, th ere is a need to automate the step of review-

ing the shelves and looking for existing p roblems in

them, thereby the operator s have this information di-

rectly and can attend to them with quick and precise

solutions.

4 DISCUSSION: A WAY

FORWARD

The remarkable work presented by (Goldman et al.,

2019a ) with their dataset named SKU110k ( G oldman

et al., 2019b) has fueled in itiatives for shelves aud it-

ing solutions such as (Chen et al., 2022) with their

dataset named UniTail, that also includes other pro-

cesses like text detection and recognition, but do not

Towards a Robust Solution for the Supermarket Shelf Audit Problem

913

Figure 1: Examples of price tags fr om the SKU110K and

UniDet datasets, from left to right respectively.

provide all the means to solve the problems men-

tioned above in Section 2. For this, it might be bet-

ter to create a dataset capable of addressing all the

requirements in shelf auditing.

As outlined earlier, the price tag is an important

object on the shelves, because it shows the price and

description of the product and is used for limiting

a product’s front space, helping to und erstand if the

product was positioned correctly on the shelves. With

this in mind, datasets like SKU110k and UniDet can-

not be used to validate the mentio ned states since not

all data within the price tag can be collected (read-

ing it, as seen in Figure 1, which means it is not

possible to so lve the problem of outdated prices be-

cause it is impossible to match the object itself with

the databases w here retailers save and update product

prices for transactio ns at checkout.

Furthermore, when using the pr oduct package text

for matching, as done in (Chen et al., 2022), there will

be a considerable number of products that could not

be correctly identified. This is indeed a weakness of

this work. On the other hand, when using the prod uct

price tag, there will always be a full description of the

product, or at least a co de to identify it.

Lastly, not having the price tag localizatio n will

prevent the pip e line from reporting some shelf audit

issues, such as wrongly positioned products.

Current public datasets are the problem because

they were crea te d with little or no knowledge of what

is n eeded to solve the retail problem: Shelf Audit.

Try ing to overcome the whole problem can end up

with pipelines of craft solutions, not generalizable so-

lutions.

4.1 Proposed Dataset

As far as is known, all the approaches that have been

proposed try to solve the shelf audit p roblem using

only RGB images. However, as mentioned above this

is a limitation. For this reason, a new dataset to mee t

all the needs of this problem is proposed in this sec-

tion.

For the dataset, the following aspe cts should be

considered:

1. RGB-UHD Images. RGB is the standard Red-

Green-Blue convention for im a ges, while UHD

Figure 2: Example of proposed images; left: RGB-UHD

image, and right: depth image (this image have been bina-

rized).

means Ultra High Definition images. Figure 2

(left) shows an example for this type o f images,

which are captured using a high definition cam-

era (preferably a resolution of 4k or higher). In

this dataset, the information to be tagged is: the

product and the price tags.

2. Depth Images. these images are captu red by a 3D

camera and allow to obtain the measured depth

from the ca mera lens to the objects (norma lly a

resolution of 640x480 pixels), see Figure 2 (right).

No need for an notations.

3. Positional Information. defines the position or

location information relative to the acq uisition

site. Th is in formation will help understanding

where the image is taken on the store map and

can be delivered in [x,y,z] format, which means

the (x,y) position on the map at (z) meters above

the floor.

4. Planograms. a structure that contains the ex-

pected position of the product on the shelves in

order to compare it with the current position.

5. Master Database. a database to c onsult informa-

tion abou t the produ c ts such as: prices, descrip-

tions, codes, among others. This is comm on in-

formation that all retailers should have.

4.2 Proposed Acquisition System for the

Dataset

For acquiring the proposed dataset, an automated ac-

quisition sy stem is presented (which from now and on

will be referred as ”robot”). This is crucial for reduc-

ing the time consumed by the operators in auditing

the shelves. Using operators to acq uire the informa-

tion will only add more tasks to th em, increasin g time

instead of redu c ing it.

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

914

Figure 3: Collector S tructural Design.

Figure 3 shows the pro posed robot. It is not differ-

ent from others already deployed in retail. It is based

on a mobile base (2 or 4 wheels with suspension sys-

tem, battery, and voltage regulation), with a structure

on it, similar to a tower, where the c ollectors are ver-

tically and equidistantly placed. The collectors con-

sist of low compu ta tional resources pro cessing units

(Raspberry Pi 4, Jetson Nano, In tel Nuc, among oth-

ers), a RGB-UHD came ra an d a 3 D Camera.

This robot needs to move autonomously, so it

is recommended to use state-of-the-art robotic soft-

ware for moving it, like ROS(Stanford Ar tificial In-

telligence Laboratory et al., ), ROS2(Macenski e t al.,

2022). This software is able to estimate the positional

informa tion of the robot with respect to the store map

at all times.

An important part of the robot is the way it cap-

tures the information. It goes thro ugh the hall of

the store taken images with the cameras of collec-

tors. This route is performed by doing steps. A set

of images (rgb-uhd and depth ima ges per collector) is

taken every step. Every step is limited by the fields of

views (FOVs) of the cameras. This is done beca use

the main purpose is to acquir e information, so redun-

dancy is introduced during the acquisition. For hori-

zontal redundancy in the images, the distance of each

step is shorter than the FOV of the cameras, and for

vertical redundancy , the collectors are equidistantly

positioned in the tower of the robot. Have redundant

informa tion provides the ce rtainty of not losing infor-

mation at all.

4.3 Proposed Pipeline

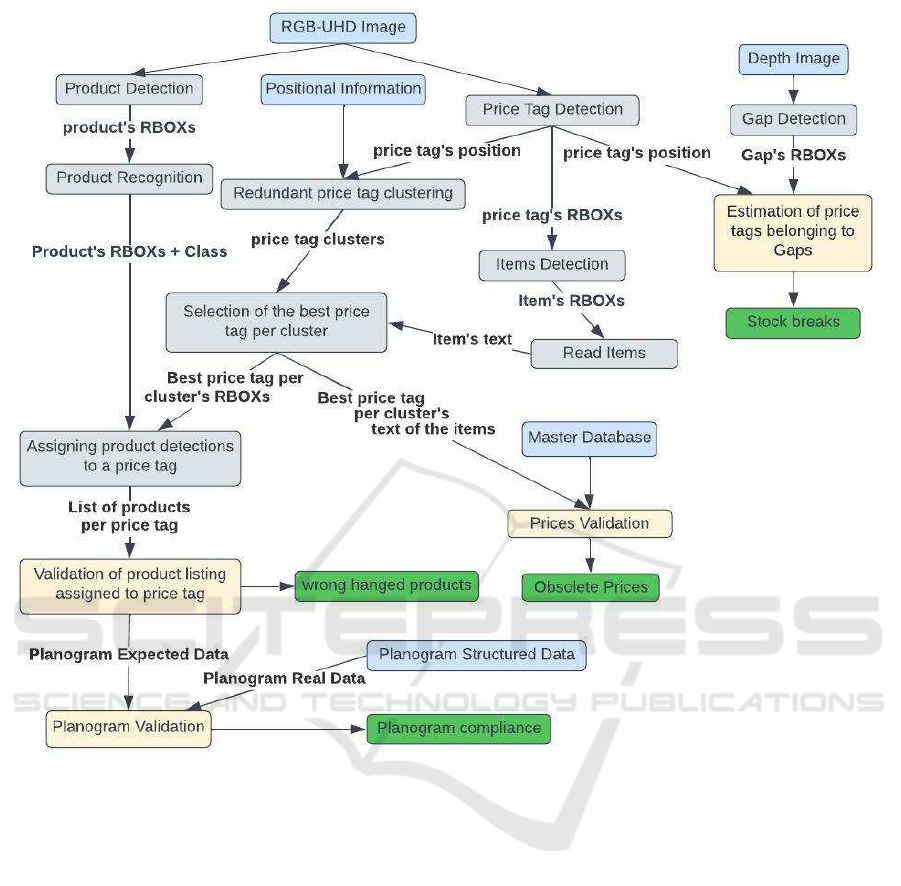

All processes, including the inputs and outputs, are

explained below. Figure 4 shows the pip eline of

the pr oposed solution for the shelf auditing problem.

Blue and green block s are inp uts (data acquired a s

mentioned before ) and outputs ( reports) respectively.

Gray blocks are processes that may involve the use of

artificial intelligen ce algorithms such as object detec-

tion, object recognition, clustering, text re cognition,

among others. Yellow blocks are also processes but

guided to validations or estimations, that is, they use

the manipulated and filtered data for creating the re-

port outputs.

It most be m entioned th a t the proposed pipeline

does not try to add new hardware or pr ocesses to

the sto res, like in the case of implementing digi-

tal/electronic price tags or RFIDs to the price tags or

products, since this will create new exp enses to the

retail.

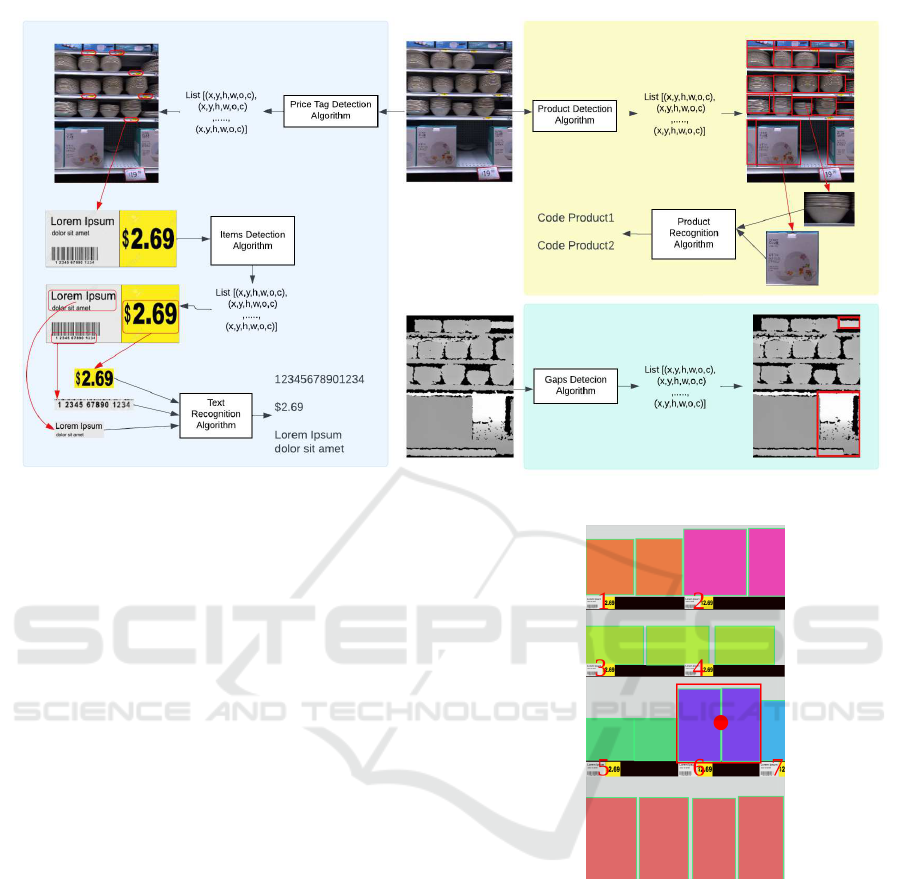

In Figure 5 is shown how the RGB and depth

images are processed during the firsts blocks in the

pipeline. Yellow section r efers to product detection

and recogn ition; blue section refers to price tags de-

tection, item s detection a nd recognition; while the

green section refers to gap detection .

Product Detection. This process requires RGB-UHD

images as input and p roduces RBOXs th at represent

the products as outputs. Each RBOX is defined by

a 7-value list containing the information of the d e-

tection (x axis, y axis, height, width, rota tion angle,

confidence and class). A pre-trained object detection

algorithm could be used to carry o ut this process. To

continue with other processes, crops of the products

should be done, and will be ref erred as uhd-product

images.

Product Recognition. This process requires uhd-

product images as input and produces a text referring

to the product class. The output can be represented

by a descrip tion or a code, but it is recomm end to

use codes instead of description, as the dataset will

be lighter (meaning size, as the code is normally a

shorter string), additio nally, the probability of c hang-

ing products’ descriptions is higher than the one of

changin g codes. A pre- trained multi-classification a l-

gorithm would be needed to carry out this pro cess.

Price Tag Detection. This process requires RGB-

UHD images as input and produ c e RBOXs that re p-

resent the price tags as outp uts. A pre-trained ob-

ject detec tion algorithm for the ta sk of detecting price

tags could be used to c a rry out this process A cu sto m

dataset must be created for this process, since to the

best of our knowledge there is no public dataset cre-

ated for detecting price tags. To continue with other

processes, crops of the price tags should be done, and

will referre d as uhd-price-tag images.

Note that, there is the option of creating a single

detector for price tags and products, but this pipeline

shows them separated ju st to make clear each process

of the pipeline.

Items Detection. This process requires as input uhd-

price-tag images and prod uce RBOXs that represent

the items of the price tags. Items is the denomination

in this article to the important texts in the price tag s

such as, but not limited to, codes, prices and descrip-

tions. A pre-trained object detection algorithm for the

Towards a Robust Solution for the Supermarket Shelf Audit Problem

915

Figure 4: Proposed pipeline to solve the shelves auditing problem.

task of detecting items could be used to ca rry th is pro-

cess and deliver RBOXs of the detection as outputs,

such as text detecto rs. To continue with other pro-

cesses, crops of the items should be done. We will

refer to these as uhd-items images.

Read Items. This pro c ess requires as input the uhd-

items images and produce texts as outputs. The d e-

tected items o f each price tag m ust be read in o r-

der to know what information is shown and subse-

quently contrast that information against the Mas-

ter Database. The items mentioned are texts, thus

the way to read those items is by OCR, for other

items like the barcode a barcode-reader should be im-

plemented (Code 39, Code 128 , GS1-128, EAN-13,

among others). To con tinue with other processes, the

texts generated will be referred as items text.

Gap Detection. This process requires the input of

depth images and produce RBOXs that represent the

gaps in the shelves. Each pixel of the depth im-

age contains the depth measured from the 3D camera

lens. The RBOXs are relative to the d e pth image, and

should be projected to the rgb- uhd images. For ac-

complish this, a co nversion using a translation matrix

should be done.

Redundant Price Tag Clustering. To be able to se-

lect the best of all the price tags (next process) it is

important first to correctly group all the redundant in-

stances of the same object, and then proceed to choose

the best one that r epresents the real instance of the ob -

ject. For this process, spatial information related to

the collection location is required, that is, the infor-

mation of the position where each image is co llec te d

is also saved with r e spect to the reference system of

the sto re. With the help of rotational and translation s

transformations, it is possible to obtain the po sition o f

each o bject’s centroid (x,y) with respect to the refer-

ence system. Finally, using a clustering algorith m that

will have as input the spatial positions of the price tag,

the clusters can be obtained. Initial cluster could fail

given th e dense environment in a shelf, so it is recom-

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

916

Figure 5: Product Detection Process of the pipeline.

mended to use a sub sequent algor ithm to validate the

items inside the cluster using the items text of each

price tag.

Selection of the Best Price Tag per Cluster. Being

redundant means that multiple captures we re obtained

for the same price tag, and therefore it is necessary

to choose the best of all to be the re presentative of

the group. The selection of th is can be varied, but it

is suggested to do it according to the characteristics

of objectness of the price tag and the confidence of

readings of the items belonging to each price tag using

a weighted average as the metric for ordering. The

output of this process is a list of the price tags.

Prices Validation. The texts of the best price tags

of each generated clu ster are require d as input and to

create a list of products. Then, a comparison between

this list and the data on the master database is done.

The output of this validation process is a new list of

products that have obsolete prices (different from the

price in the database). This report is known as ”obso-

lete prices”.

Assigning Product Detections to a Price Tag. T his

process is quite significant. It serves to spatially group

the products with a specific price tag. Taking into ac-

count the co mmon proto col for the loc a tion of each

price tag by product indicated in section 2, an algo-

rithm can assign each detected product instance to a

particular price tag. A case in Figure 6 can be seen,

price tag 6 assigned with the products with purple

colour. T he way to perform this is by first filtering all

the possible price tags by using the product centroid

and the price tags centroid, only the price tags that

Figure 6: P ositioning of the price tags in a shelf.

are at the left and down the cen troid of the product

continue. Then, the minimum Euclidean distance be-

tween each price tag and the product is selected as the

price tag for the product, a nd the pro duct is assigned

to the price tag. This is simple, yet effective to assign

the product detections to labels. It should be noted

that in the case of the hanged products in the shelv ing

hooks, the price tags are on top of the produc t. So the

logic in this algorithm can be mod ified. For products

in the borders th at do not have an assigned price tag,

they will b e discarded on the premise that be ing in the

border of the images, it is likely that a previous, sub-

sequent, spatially h igher or lower collection iteration

contains the complete vision of the product together

to the price tag in order to be assigned correctly.

Towards a Robust Solution for the Supermarket Shelf Audit Problem

917

Estimation of Price Tags Belonging to Gaps. Sim-

ilar to assigning product detection to a rule, in this

case the previously detected gaps will be assigned to

a particular price tag. In the case o f posts, this process

is also valid, however the reader is rem inded that for

spaces with posts, it is more likely that there ar e gaps

that are not actually used for pro ducts. This proc ess

ends by delivering a report of all the ga ps fou nd, the

location (hall) and a n estimation of the product that

can be according to the price tag to which it was as-

signed. This repor t is known as ”stock breaks”.

Validation of Product Listing Assigned to Price

Tag. This process requires as input the list of prod -

ucts per price tag instanc e (best of each cluster ). Each

Product (RBOX) must match the price tag (product

recogn ition o utput vs item recognition output). In

case of having products that do not agree with the

others, they will be used to carry out the report of

Mis-Positioned Products. This report will deliver a

list of the products and their location (spatial) in the

aisle in order to quickly identify and correct the m.

Its output can also be modified to a structure called

a planogram structure. This output is known as the

”real planogram structu re”.

Planogram Validation. This process requires

two planogram data structures as input. The

real planogram structure (EPR) and the exp ected

planogram structure (EPE). The EPR represents what

is real on the premises, while the EPE represents what

should be implemented. I deally, EPR equals EPE,

however stores are likely to make changes mistak-

enly or intentionally. Therefore, the comparison of

these two structures will deliver a percentage value of

planogram compliance. The com parison can be made

accordin g to th e purpose to be measured, be it at a

granular level of product, categories or others.

5 FUTURE WORK

At the moment, the implementatio n of the acquisition

system and datasets have been accomplish gratefully

thanks to a retail company which is interested in repli-

cating this project in many stores. Th e first attempts

to create the ob solete prices report implementing the

light b lue side of Figure 5 has given satisfactory re-

sults, but we will continue working on this for bet-

ter results. Figure 7 shows results of the implementa-

tions.

Additionally, we will be working in parallel in

the hot topic of produ c t de te c tion and recognition for

closing the gaps between the product and the price

tag’s inform ation and location in the shelf.

Figure 7: Results of implementation.

6 CONCLUSIONS

Retail is an important sector whe re AI can help to re-

duce manual and repetitive tasks. To date, AI is ma-

ture enough to be implemented in real world projects.

We proposed a challenging but reachable pipeline to

solve one of the bigg est problems in retail: shelves au-

diting, to help the retail’s operators in their daily tasks

for maintaining the store at it best for customers. Hav-

ing defined a pipeline, future work is to create it a nd

test it. This might sound easy, but it is far from being

the case. There are many complications like creating

the acquisition system or creating agreements w ith re-

tailers to gather data to elaborate, annotate and pub-

lish datasets.

ACKNOWLEDGEMENTS

This work has been partially supported by the

ESPOL-CIDIS-11-2022 project and Tiendas Industri-

ales Asociadas Sociedad Anonima ( TIA S.A.). The

authors would like to acknowledge TIA S. A ., a lead-

ing grocery retailer in Ecuador, for providing access

to an incredible environment for research and testing.

REFERENCES

Chen, F., Z hang, H., Li, Z., Dou, J., Mo, S., Chen, H.,

Zhang, Y., Ahmed, U., Zhu, C., and Savvides, M.

(2022). Unitail: Detecting, reading, and matching i n

retail scene.

Chua, I. S., Gaziel-Yablowitz, M., Korach, Z. T., Kehl,

K. L., Levi tan, N. A., Arriaga, Y. E., Jackson, G. P.,

Bates, D. W., and Hassett, M. (2021). Artificial intel-

ligence in oncology: Path to implementation. Cancer

Medicine, 10(12):4138–4149.

Cilloni, G., Leporati, R., Rizzi, A., and Romagnoli, G.

(2019). State of the art of item-level rfid deployments

in fashion and apparel retail. International Journal of

RF Technologies, 10:65–88. 3-4.

Cochoy, F. and Soutjis, B. (2020). Back to the future of digi-

tal price display: Analyzing patents and other archives

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

918

to understand contemporary market innovations. So-

cial Studies of Science, 50(1):3–29. PMID: 31630628.

Goldman, E., Herzig, R., Eisenschtat, A., Goldberger, J.,

and Hassner, T. (2019a). Precise detection in densely

packed scenes. In Proceedings of the IEEE/CVF Con-

ference on Computer Vision and Pattern Recognition

(CVPR).

Goldman, E., Herzig, R., Eisenschtat, A., Ratzon, O. , Levi,

I., Goldberger, J., and Hassner, T. (2019b).

Jedlickova, B. (2016). Vertical issues arising from conduct

between large supermarket s and small suppliers in the

grocery market: Law and industry codes of conduct.

Khalil, G., Doss, R., and Chowdhury, M. (2020). A novel

rfid-based anti-counterfeiting scheme for retail envi-

ronments. IEEE Access, 8:47952–47962.

Li, B. and Wang, D. (1970). Configuration issues of cashier

staff in supermarket based on queuing theory.

Macenski, S., Foote, T., Gerkey, B. , Lalancette, C ., and

Woodall, W. (2022). Robot operating system 2: De-

sign, architecture, and uses in the wild. Science

Robotics, 7(66):eabm6074.

Patil, D., Patil, S., Patil, S., and Arora, S. (2022). Finan-

cial forecasting of stock market using sentiment anal-

ysis and data analytics. In Nagar, A. K., Jat, D. S.,

Mar´ın-Ravent´os, G., and Mishra, D. K., editors, In-

telligent Sustainable Systems, pages 423–430, Singa-

pore. Springer Nature Singapore.

Pettigrew, S., Mizerski, K., and Donovan, R. (2005). The

three ”big issues” for older supermarket shoppers.

Stanford Artificial Intelligence Laboratory et al. Robotic

operating system.

Tao, F., Wang, L., Fan, T., and Yu, H. (2022). Rfid adoption

strategy in a r et ailer-dominant supply chain with com-

peting suppliers. European Journal of Operational

Research, 302(1):117–129.

Zhang, Q., Liu, Y., Gong, C., Chen, Y., and Yu, H. (2020).

Applications of deep learning for dense scenes analy-

sis in agriculture: A review. Sensors, 20(5).

ˇ

Skiljo, M.,

ˇ

Soli´c, P., Blaˇzevi´c, Z., and Perkovi´c, T. (2020).

Analysis of passive rfid applicability in a retail store:

What can we expect? Sensors, 20(7).

Towards a Robust Solution for the Supermarket Shelf Audit Problem

919