Modelling Agents in Industry 4.0 Applications Using Asset

Administration Shell

Nikoletta Nikolova

a

and Sjoerd Rongen

b

TNO, Anna van Burenplein 1, 2595 DA The Hague, Netherlands

Keywords:

Agents, Industry 4.0, Asset Administration Shell, Modelling, Interoperability.

Abstract:

Within Industry 4.0, more applications include multi-agent systems and integrated software agents in the newly

developed solutions, as they can provide a valuable contribution to the manufacturing processes. This makes it

important to create a digital representation of those virtual assets, similar to how this is done for physical ones.

The Asset Administration Shell (AAS) has been designed for just this purpose - to create models of assets,

containing all the relevant information. Currently, this is standard for physical assets, however, it could be of

value to extend it beyond. We propose the usage of the AAS for creating information models of software agents

and suggest a generic approach to apply the AAS meta-model to ensure semantic interoperability between

them. For this purpose, we outline a structure and a set of specific submodels to group agent attributes, which

can provide a description of all relevant information for a given task. We provide two examples of concrete

agents and outline how this approach will be further validated within future use cases.

1 INTRODUCTION

In the current digital world, industry is giving a lot of

attention to digitization and the creation of smart fac-

tories. The transition to Industry 4.0 focuses on the

idea of digitizing physical assets and creating smart

control mechanisms, which are able to automate pro-

duction and assist humans in complex tasks. The use

of software agents for tasks such as production plan-

ning or quality assurance is becoming more common,

as this helps in achieving higher efficiency and ro-

bustness in the manufacturing process. To facilitate

this growing digital ecosystem, a standard has been

developed by the Industry 4.0 group, which aims to

provide a universal way to describe assets. The As-

set Administration Shell (AAS) (Plattform Industrie

4.0, 2019) is an industry-driven initiative to create

semantic models of assets and expose standard in-

terfaces to interact with these models. For exam-

ple for a given physical machine, an AAS model can

be created, holding all the relevant information about

this asset, ranging from details such as manufacturer,

markings, to system outputs, control nodes etc. This

provides a way for all machines within a given factory

to be described using the same meta-model and thus

a

https://orcid.org/0000-0001-9141-4054

b

https://orcid.org/0000-0002-4302-1050

makes coupling of the total system simpler. However,

when considering smart factories, we no longer have

just physical assets active in our manufacturing envi-

ronment. As software agents are introduced to con-

trol and execute different tasks, it becomes essential

to model, represent and reason with them as with ev-

ery other asset. This may enable new software agents

to automatically be used in the environment upon be-

ing deployed, dynamically determine which agent is

best suited for the task at hand, and increase the ro-

bustness of the manufacturing control systems. The

current developments, however, have not yet been ex-

tended to the world of non-physical assets and more

specifically digital assets such as software and agents.

We consider this to be important, as software solu-

tions fulfill an integral role in Industry 4.0 by taking

the available data and transforming this into meaning-

ful insights and actions.

To tackle this challenge, we propose an approach

on how the same AAS standard, which is used to

model physical assets, can also be used to model

digital ones, and more specifically agents. This pa-

per is based on our work in the HORIZON MAS4AI

project (MAS4AI, 2020) in combination with the ear-

lier work done in the HORIZON DIMOFAC project

(DIMOFAC, 2020). We consider software agents to

be assets just as the manufacturing equipment they

control. This enables a deeper level of control over

Nikolova, N. and Rongen, S.

Modelling Agents in Industry 4.0 Applications Using Asset Administration Shell.

DOI: 10.5220/0011746100003393

In Proceedings of the 15th International Conference on Agents and Artificial Intelligence (ICAART 2023) - Volume 1, pages 315-321

ISBN: 978-989-758-623-1; ISSN: 2184-433X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

315

factories and better fits the current paradigm of de-

creasing boundaries between the physical and digital

world.

We propose a standard structure, which can be

used when creating AAS models for representing

software agents. More specifically we provide an out-

line of the different types of information, which must

be represented, and how it can be split between differ-

ent categories. We consider this important, as at this

time there is very limited literature available and even

fewer semantic standards on how to model software

applications as assets. This makes integration of this

software in manufacturing environments complex and

the adoption of Industry 4.0 slow. Moreover, an in-

terpretation of the AAS standard applied to software

assets is missing, which creates the risk of different

initiatives using a different interpretation and through

this harming standardization efforts. Therefore it is

essential to establish a common understanding.

In this paper, we provide a structure towards how

a software agent can be modelled using the AAS. Sec-

tion 2 provides an overview of the relevant work and

theory for this paper. In Section 3 we outline the gen-

eral structure of the agent model, with Section 4 fo-

cusing on the general submodels and Section 5 on the

particular submodels, including examples of how two

different types of agents can be modelled conceptu-

ally. Lastly, in Section 6 we outline how we are going

to further test and develop the proposed modelling ap-

proach.

2 BACKGROUND

Within industry the challenge of semantic interoper-

ability has largely been tackled so far through the def-

inition of static standards in lengthy standardization

processes. This top-down approach often takes a long

time to deliver implementable standards, which is at

odds with the increasing speed of innovation and de-

velopment in industry. To mitigate this issue, the In-

dustry 4.0 Alliance introduced the Asset Administra-

tion Shell (AAS) (Plattform Industrie 4.0, 2019). This

provides a digital representation of an asset, which it

describes through the usage of multiple standardized

submodels, each of which contains a set of elements

in the form of properties, relations, references to other

AAS (sub)models etc. The structure of an AAS is

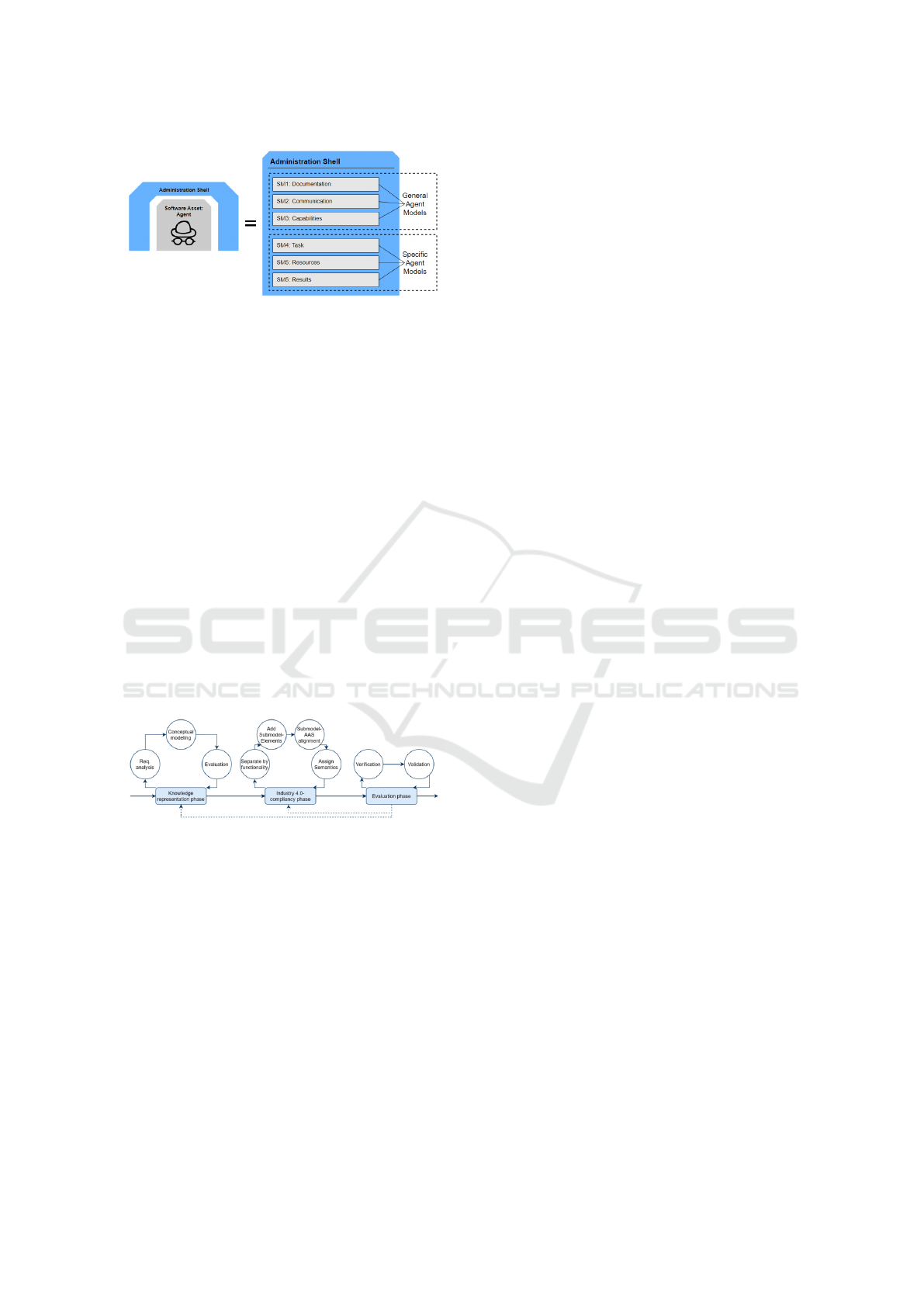

shown in Figure 1.

Within the AAS, concepts are given a Seman-

tic Identifier, which is globally unique and may be

reused across different models and instantiations of

AAS models to relate to the same concepts used in

different places, similar to how the URI works within

Figure 1: General structure of an AAS model.

the semantic web. Furthermore, the AAS provides

standardized interfaces to interact with these seman-

tic models (Bader et al., 2022)).

The AAS initially gained traction as a way to dig-

itally represent physical assets such as manufacturing

equipment. However, with the implementation of in-

dustry 4.0 concepts, the boundary between the physi-

cal and digital world is blurring and increasingly there

is a need to integrate with digital assets in a similar

way as one would integrate with physical assets. As

an example, one may think of a planning algorithm or

the logic controlling a machine. These pieces of soft-

ware themselves are something to interact with and to

a large extent responsible for the competitive position

of a company through facilitating predictive mainte-

nance or the optimal utilization of available resources.

Moreover, these systems are not implemented once

and then left for years or decades, as the manufactur-

ing equipment itself may be. They are actively up-

dated, new software is added and the amount of in-

teractions between these systems can quickly grow.

We consider these pieces of software to be agents in a

multi agent system, which supports the large amount

of interactions and provides a way to structure the var-

ious applications in a holonic architecture.

Using a multi agent system to support Industry

4.0 and overall the use of agents in such setting has

been researched before. (Hoffmann, 2019) argues

there is a need to represent the vast amount of infor-

mation within a factory described in a simple way.

The work presents an approach to integrate smart

entities(agents) in the shop floor and corresponding

model creations using OPC-UA. Similarly, (Vogel-

Heuser et al., 2020) presents an overview of the differ-

ent challenges within an industry 4.0 systems and ar-

gues in favour of using multi-agent systems to tackle

these.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

316

To implement agents within industry systems it is

important to determine what types of agents are useful

given the use case. The work of (Cruz Salazar et al.,

2019) outlines patterns when it comes to the basic (re-

ferred to as mandatory) set of agents required within a

factory - Resource Agent, Process Agent, Agent Man-

agement System and Communication Agent. The au-

thors further argue about the importance of having

such agents on the shop floor, as they execute basic

functionality.

Given the strive towards interoperability enabling

these agents to collaborate, it is important to define a

way to model agents used within the manufacturing

process. This entails a methodology to model agents

and mapping the standardization approach to the one

used for other assets. The work of (Sakurada et al.,

2022) explores the idea of considering agents as assets

when applying the AAS in Industry 4.0 applications.

But, it does yet not look at how these agents would be

modelled exactly.

The work of (Ocker et al., 2021) comes closest

to the idea of modelling agents for a factory using

the AAS. The authors provide a suggestion regarding

how in particular the Planning and Resource agents

can be modelled using the AAS for multi-agent sys-

tems (MAS), further pointing towards how the actual

MAS can be build using those agents. Our work con-

tinues the direction Ocker et al. , however we take a

broader look at agent modelling. We choose to fo-

cus on how a general structure for an agent model

could look, providing an outline of the different types

of models and do not consider specific agent types

or their definitions. Our method aims to provide a

structure which can be used regardless of specifics

for agents and can be applied in multiple cases. To

the best of our knowledge, there is no general agent

model structure at the time of this work. Therefore

we investigate and propose how this problem can be

tackled within the next sections.

3 STRUCTURE OF THE AAS FOR

AGENTS

When describing software agents in a generic way us-

ing the AAS as a semantic standard, there are a couple

of design decisions to consider. What is the structure

of the model, what information should it contain and

how should this be grouped. Our model aims to pro-

vide maximum flexibility in describing agents, while

also providing enough structure to support reuse, con-

straint by what the AAS meta model provides. The

process of populating an agent is placed out of scope

for now.

3.1 General Structure of Agent Model

Within an AAS model, one may define properties

within reusable submodels whose values can be read

through a standard API. As such, the main goal of the

model is to make it clear to any user or application

which properties they are interested in. As there is no

direct approach to do this, we considered two differ-

ent approaches, which can be offered to support this.

An intuitive approach to present information of

a given software application (in our case an agent)

may be to look at the model elements as agent in-

puts, outputs or static description of the agent itself.

Within these three categories, properties may then be

defined. Resulting in an input, output and description

submodel which has an arbitrary amount of proper-

ties. Such an approach makes it very simple for de-

velopers to know which properties to use when inter-

acting with the agent, but at the same time makes the

model highly specific, loosing the interoperability be-

tween agents, as it is not possible to create reusable

submodels for different agents. That is to say, all

agents have the same submodels, but these may be

completely different in their actual content.

As we strive for interoperability in the models

to be created, we instead consider to group relevant

properties based on their semantic meaning and in-

tended usage. This provides us with models regard-

ing the creation of the agent, the connectivity details,

work order schedules (for a planning agent specifi-

cally), etc. This leads to a greatly increased amount of

submodels, some of which may contain less informa-

tion than others. At first impression this may appear

more complex, but it allows reusing of well defined

models across different agents, resulting in faster de-

velopment, easier reuse and the ability to better match

to domain specific information models.

Our suggested approach provides a possible struc-

ture for how such semantic grouping can be formed

for agents. We build our suggestion based on

the needs of different use cases represented in the

MAS4AI project, where we build an initial set of

reusable submodels, used to describe an agent. Un-

like standard submodels, we did not provide a com-

plete set of submodel elements, but instead proposed

a set of groupings which can be used to structure all

the relevant information and provide a base point for

developers to start from.

We split the agent model structure into two groups

of three types of components each, as shown in Fig-

ure 2.

An Agent has a set of Generic Agent Submod-

els, which contain information such as documenta-

tion, communication, capabilities. This is considered

Modelling Agents in Industry 4.0 Applications Using Asset Administration Shell

317

Figure 2: General structure of an agent AAS.

to be information, which should be provided with ev-

ery agent and should thus contain similar type of data

disregarding the exact task. The second set of Sub-

models is Specific Agent Submodels, which refers to

the type of information that an agent needs based on

the specific task it needs to execute - such as Re-

sources, Analysis, Task etc. Each of those sets of

submodels is further evaluated in the following two

chapters.

3.2 Development of AAS Model

The general structure of the agent shown in the sec-

tion above provides an overview regarding how the

model should look and what type of information can

be included. When it comes to the way the model

should be filled, we refer the readers to the method-

ology of (Bouter et al., 2021). Their work proposes

a clear and robust approach towards iterative AAS

model development, as shown in Figure 3.

Figure 3: Overview of AAS modelling methodology

(Bouter et al., 2021).

The iterative structure assures that the created

model contains all the relevant information for an as-

set, in our case an agent, and helps provide a structure

for the development process.

4 STANDARD AGENT

SUBMODEL

Within the description of every agent, similar to a

machine, there is a set of information that must al-

ways be represented, no matter the specific applica-

tion type. When looking at the current set of provided

standard AAS submodels, developed by the Interna-

tional Digital Twin Association (IDTA), every cre-

ated asset model uses the Nameplate and Technical

Information submodels. This already encompasses

all the relevant information in relation to all the speci-

fications of the machine. When looking towards soft-

ware, there is a similar set of requirements that must

be provided within such a model. We consider, that

there are (at least) three different submodels, which

should be standard for every agent.

4.1 Documentation

Following the current modelling approach, when cre-

ating an AAS for a physical asset, an agent needs

to have documentation presented in its model. The

current IDTA standard submodels Nameplate and

Technical Information are created with purely

physical assets in mind. These contain properties

which are not relevant for an agent, such as CE

Markings. For a software component there are other

relevant components, such as Software Version,

Programming Language etc. This means that the

current standard models are insufficient for the mod-

elling of software agents. However, the recently

released IDTA Software Nameplate (IDTA, 2022)

provides a good starting point to cover most docu-

mentation needs.

4.2 Connection

An agent, whether placed within a multi-agent sys-

tem or another type of architecture, contains a set of

predefined connections, communication channels and

protocols. These may differ slightly based on the ex-

act implementation details and use case considered.

One example of the information that such a submodel

would encapsulate can be chosen following the FIPA

Agent Management standard (FIPA, 1996). For ex-

ample, such a submodel would contain information

such as:

• Agent Status, Agent Lifecycle

• Communication Channels and Protocols

Depending on the exact situation the information

within this submodel can be determined based on

what the (multi-agent) system needs and requires for

functions. This can also mean that there are some

highly specific properties (such as trigger for activat-

ing certain agent property).

4.3 Capabilities

Every agent has a set of capabilities describing what

tasks it is able to perform. We consider, when defin-

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

318

ing such submodel as standard, that it is crucial to de-

fine the exact capabilities of a given agent, as they

are specific to the developed algorithm. This is not a

new idea, as for example within ISA-95 every com-

ponent, which falls under Manufacturing Operations

Management has a Capability Information. Similar

to that, Industry 4.0 also argues in favor of that within

the work of (Bayha et al., 2020), as the white paper

presents an approach to provide information about the

offered functionality of a system by combining prop-

erty descriptions and ontology. The capabilities de-

scription of an agent do not have to be limited to a

single submodel, as depending on the exact situation

it may be beneficial to split the information. An ex-

ample for data, which would be encapsulated in such

a submodel could be:

• Planning capability - what type of planning can

the agent actually do, such as deviation plan-

ning, re-planning, production planning, person-

nel planning etc.

• Quality assessment - what type of quality check

does the agent actually do, such as measurement

evaluations, deviation detection, error analysis

etc.

5 EXTENDING FOR SPECIFIC

USE CASES

Besides the standard agent submodels, an agent can

also have ones, which are further tailored to the actual

usage and environment it operates in. Within indus-

try applications there are numerous different use cases

where agents are tasked with various assignments. We

propose a further generalization of how those com-

ponents can be considered and grouped based on the

type of knowledge they carry.

• Task - every agent has a particular task that it has

to execute and therefore has a related set of infor-

mation that is required for it.

• Resources - set of information to which the agent

has access to. This can be other machines, soft-

ware, agent, resources etc.

• Results / Output / Analysis - set of information

and/or analysis which the agent produces based

on all the incoming data and task specifications.

These three submodels would contain the general set

of information that an agent may need. The exact

submodel elements can differ depending on the par-

ticular use case. To illustrate this we present how this

planning method could be used to create general AAS

models for two different agents within a factory.

Planning Agent. First, we consider a planning

agent, which is responsible for optimizing the overall

work plan to be executed by the other agents. Such an

agent can have a variety of different tasks, all related

to the scope of the planning assignment. For the small

created example, visualized in Figure 4, we provide

just a sample of the possible properties, which can be

present within a given model and how those map to

the structure presented above:

• Task - Current production plan, Set of orders.

• Resources - Maintenance schedule, Personnel

shifts, Personnel capabilities, Machine capabili-

ties.

• Results/Output/Analysis - New production plan-

ning.

Figure 4: Structure of AAS model for a planning agent.

Quality Inspection Agent. Second, we look at a

quality inspection agent, which needs to assess the

level of quality of a product. The structure is visual-

ized in Figure 5, and for it, the following information

can be present:

• Task - Quality inspection task, Quality targets

• Resources - Product specifications, Machine

specifications.

• Results/Output/Analysis - Quality analysis,

Quality measurement.

Figure 5: Structure of AAS model for a quality agent.

The provided examples

1

are in no way exhaustive of

all the information such an agent would contain but

1

For access to the examples developed in the MAS4AI

project, please contact the authors or go to https://admin-

shell-library.eu/

Modelling Agents in Industry 4.0 Applications Using Asset Administration Shell

319

aim to provide an idea of how the intended structure

would look like for different situations. Depending

on the particular use case the type of functionality for

an agent can change, for example, a planning agent

can have a varying set of tasks, each with its own set

of requirements (the information needed for logistics

planning is different from a maintenance plan).

6 OUTLOOK

In the previous sections, we presented our view on

how agents should be modelled using AAS, providing

a general structure that can be followed, which is not

connected to a particular use case. This work is based

on the HORIZON MAS4AI project, in which real-life

use cases are investigated. The next step for the fur-

ther development of this agent modelling methodol-

ogy is to test how well it fits when applied to these

use cases. Within MAS4AI we will test this with

eight different general types of agents (product agent,

resource agent, process orchestration agent, planning

agent, safety agent, information agent, quality agent,

and human-machine interaction agent) in up to six

varying use cases. This provides a solid evaluation en-

vironment for whether our idea lines up with the real

needs of different manufacturing entities. Our pro-

posed approach would follow the structure shown in

Figure 6.

Figure 6: Steps in AAS generation.

There will be multiple different variations of the same

type of agent, for example, the planning agent. This

would provide a suitable way to test whether the same

agent in different settings and with different require-

ments, would still be able to be modelled following

the provided structure. Furthermore, we plan to test

how this process works when the use case directly

tries to implement the methodology so that we can

get a clear overview of not only the usefulness of

this methodology but also the understandability and

logic for external parties. This is important as even-

tually this work is aimed towards helping manufac-

turing companies further implement agent modelling

in their factories following the Industry 4.0 specifica-

tions. We plan to use the results from those use case

pilots to determine the suitability of our approach and

any potential missing elements.

Aside from that, another point we plan to fur-

ther evaluate is how the ISA-95 standard can be fur-

ther properly represented within the visualized model

structure. In order to be able to achieve interoper-

ability of the created models, it is important to follow

a standard when creating the information definitions.

Therefore, we plan to further define the methodology

to align better with the standard.

Finally, by deploying these agents and connect-

ing them to the MAS4AI framework using an AAS

representation. Other applications can interact with

an AAS as if it’s an active entity which responds,

initiates actions and adapts to its environment. This

closely matches the functionality of an Active AAS as

described in AAS literature, despite not fully match-

ing the often shared conceptual diagrams putting the

logic within the AAS. However, this semantic de-

scription of agents may provide a different, but valid

way of implementing an active AAS.

7 CONCLUSION

In this paper we presented our position on how an

agent can be modelled using the Asset Administration

Shell. We propose a systematic approach outlining

what the standard groups of information for an agent

could be when creating a model. Our structure pro-

vides a way to represent the corresponding inputs and

outputs in the same way one may model a machine

with materials and products going in or out. That is

to say, an Administration Shell of an agent vs that of

a physical asset are not fundamentally different. We

found this to be advantageous in separating complex-

ity, as often the software development and semantic

modelling are usually performed by different special-

ists. This approach simplifies development by con-

sidering these as two different components, instead of

adding the logic to the semantics and centralizing all

complexity.

The model structure that we presented provides

a standard overview of how the information can be

presented without specifying solution-specific com-

ponents. To address how the approach can be used

we also developed examples, two of which are pre-

sented here. These examples provide an overview of

how a particular agent can be modelled. In the up-

coming year we intend to test the approach and mod-

els for validation in the MAS4AI project’s use cases.

Finally, we aim to further develop standard submod-

els which may speed up future agent development as

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

320

well as providing a catalyst of agent submodel stan-

dardization.

ACKNOWLEDGEMENTS

This project is supported by the European Union‘s

Horizon 2020 research and innovation program under

grant agreement No. 957204, the project MAS4AI

(Multi-Agent Systems for Pervasive Artificial Intelli-

gence for assisting Humans in Modular Production)

and grand agreement No. 870092, the project DIMO-

FAC (Digital & Intelligent MOdular FACtories). We

specifically would like to thank our colleagues work-

ing on both projects for their support by providing in-

sights into their use cases and application of the AAS.

REFERENCES

Bader, S., Barnstedt, E., Bedenbender, H., Berres, B., Bill-

mann, M., Boss, B., Braunisch, N., Braunmandl, A.,

Clauer, E., Diedrich, C., Flubacher, B., Fritsche, W.,

Garrels, K., Gatterburg, A., Hankel, M., Heppner, S.,

Hoffmeister, M., J

¨

anicke, L., Jochem, M., and Zi-

esche, C. (2022). Details of the Asset Administration

Shell. Part 1 -The exchange of information between

partners in the value chain of Industrie 4.0 (Version

3.0RC02).

Bayha, A., Bock, J., Boss, B., and Diedrich, C. (2020).

Describing capabilities of industrie 4.0 components.

Technical report, Industry 4.0.

Bouter, C., Pourjafarian, M., Simar, L., and Wilterdink, R.

(2021). Towards a comprehensive methodology for

modelling submodels in the industry 4.0 asset admin-

istration shell. In 2021 IEEE 23rd Conference on

Business Informatics (CBI), volume 02, pages 10–19.

Cruz Salazar, L., Ryashentseva, D., L

¨

uder, A., and Vogel-

Heuser, B. (2019). Cyber-physical production sys-

tems architecture based on multi-agent’s design pat-

tern—comparison of selected approaches mapping

four agent patterns. The International Journal of Ad-

vanced Manufacturing Technology, 105.

DIMOFAC (2020). Digital intelligent modular factories.

FIPA (1996). Foundation for intelligent physical agents.

Hoffmann, M. (2019). Smart Agents for the Industry 4.0:

Enabling Machine Learning in Industrial Production.

IDTA (2022). Digital nameplate.

MAS4AI (2020). Multi-agent systems for pervasive artifi-

cial intelligence for assisting humans in modular pro-

duction.

Ocker, F., Urban, C., Vogel-Heuser, B., and Diedrich,

C. (2021). Leveraging the asset administration

shell for agent-based production systems. IFAC-

PapersOnLine, 54(1):837–844. 17th IFAC Sympo-

sium on Information Control Problems in Manufac-

turing INCOM 2021.

Plattform Industrie 4.0 (2019). Details of the asset admin-

istration shell from idea to implementation.

Sakurada, L., Leitao, P., and la Prieta, F. D. (2022). Agent-

based asset administration shell approach for digitiz-

ing industrial assets. IFAC-PapersOnLine, 55(2):193–

198. 14th IFAC Workshop on Intelligent Manufactur-

ing Systems IMS 2022.

Vogel-Heuser, B., Seitz, M., Salazar, L. A. C., Gehlhoff, F.,

Dogan, A., and Fay, A. (2020). Multi-agent systems

to enable industry 4.0. at - Automatisierungstechnik,

68(6):445–458.

Modelling Agents in Industry 4.0 Applications Using Asset Administration Shell

321