Joint Training of Product Detection and Recognition Using Task-Specific

Datasets

Floris De Feyter

a

and Toon Goedem

´

e

b

EAVISE—PSI—ESAT, KU Leuven, Sint-Katelijne-Waver, Belgium

{floris.defeyter, toon.goedeme}@kuleuven.be

Keywords:

Product Detection and Recognition, Joint Detection and Recognition, Task-Specific Training.

Abstract:

Training a single model jointly for detection and recognition is typically done with a dataset that is fully

annotated, i.e., the annotations consist of boxes with class labels. In the case of retail product detection and

recognition, however, developing such a dataset is very expensive due to the large variety of products. It would

be much more cost-efficient and scalable if we could employ two task-specific datasets: one detection-only

and one recognition-only dataset. Unfortunately, experiments indicate a significant drop in performance when

trained on task-specific data. Due to the potential cost savings, we are convinced that more research should

be done on this matter and, therefore, we propose a set of training procedures that allows us to carefully

investigate the differences between training with fully-annotated vs. task-specific data. We demonstrate this

on a product detection and recognition dataset and as such reveal one of the core issues that is inherent to

task-specific training. We hope that our results will motivate and inspire researchers to further look into the

problem of employing task-specific datasets to train joint detection and recognition models.

1 INTRODUCTION

In the retail industry, planogram compliance refers to

the compliance between the planned layout of a store

rack (i.e., the planogram) and its true layout. These

planograms are the result of negotiations between

the retailer and the manufacturers. Sales representa-

tives of the manufacturing companies have the task

to regularly verify that the true shelf layout complies

with the agreements that were made. This involves

taking a photo of the store rack, drawing bounding

boxes around each product and annotating each prod-

uct with a label. Clearly, this is a time-intensive and

cumbersome job. A system that could automatically

recognize the products that are on the shelves of a

supermarket, would make the process of verifying

planogram compliance much more efficient.

In general, there are two ways to develop such

a system. First, a pipeline consisting of two mod-

els could be built: one model (the detector) detects

where there are products in the image, another model

(the encoder) extracts an embedding for each product

region that can be employed for comparison. This ap-

proach is frequently used in facial recognition (Wang

et al., 2019), but has also already been proposed for

a

https://orcid.org/0000-0003-2690-0181

b

https://orcid.org/0000-0002-7477-8961

(a) (b) (c)

Figure 1: Samples from (a) a detection-only dataset; (b) a

recognition-only dataset; (c) a dataset with both detection

and recognition annotations.

retail product recognition (Tonioni et al., 2018). Sec-

ond, a single model could be trained to jointly per-

form product detection and recognition. In person

search literature (Munjal et al., 2019; Xiao et al.,

2017; Xiao et al., 2019), this combination of detec-

tion and recognition has been achieved by adding an

extra Region of Interest (RoI) head to a typical de-

tector network like Faster R-CNN (Ren et al., 2015).

This extra head outputs the necessary recognition em-

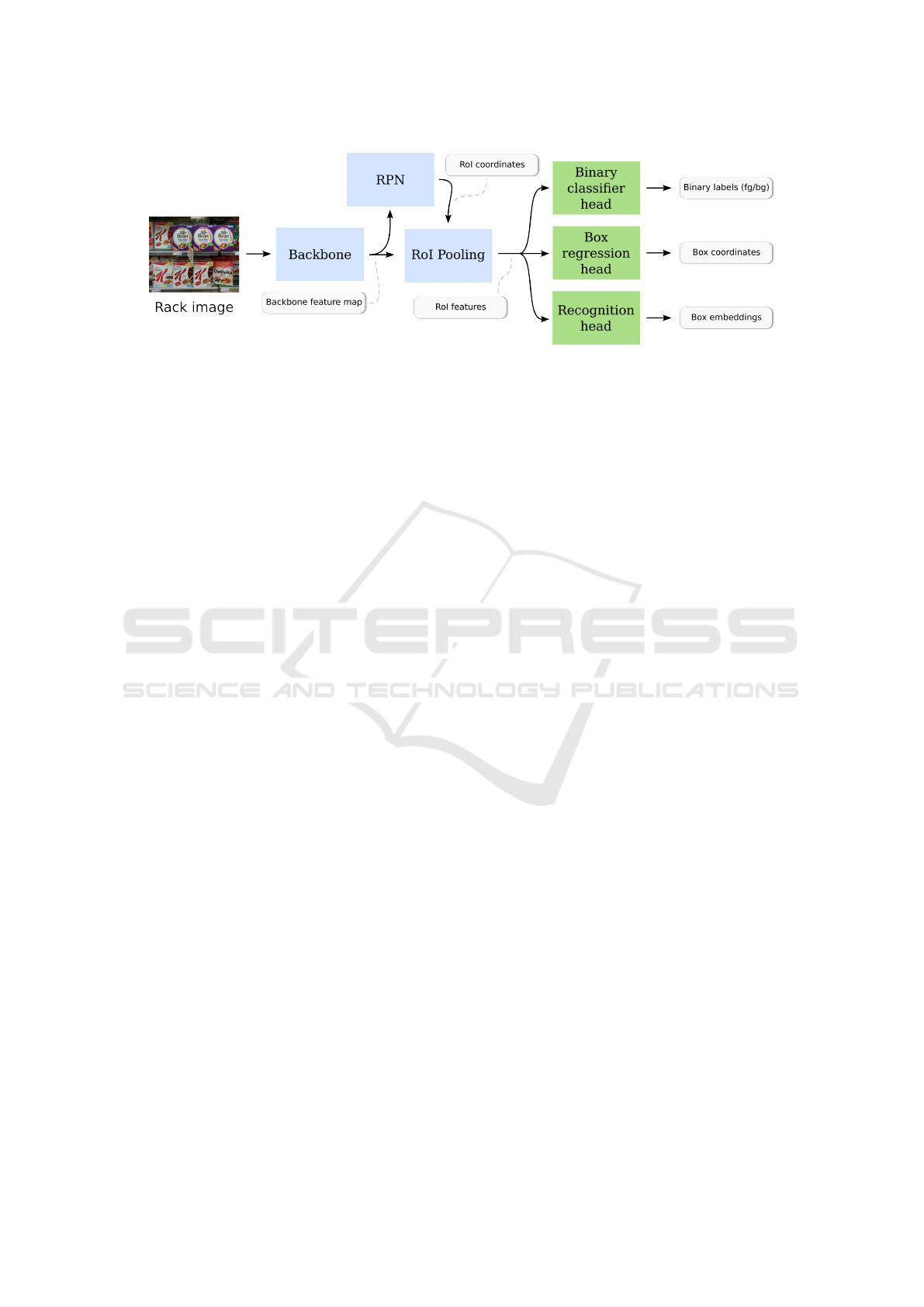

bedding. Figure 2 shows an example of such a joint

network architecture.

The advantage of the two-models approach is

that we can train on two task-specific datasets (see

Figs. 1 (a) and (b)), i.e., one dataset that contains de-

tection annotations and one dataset that contains la-

beled single products. This leads to interesting cost

reductions in dataset development. Indeed, a recog-

nition dataset containing individual products is read-

De Feyter, F. and Goedemé, T.

Joint Training of Product Detection and Recognition Using Task-Specific Datasets.

DOI: 10.5220/0011725100003417

In Proceedings of the 18th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2023) - Volume 5: VISAPP, pages

715-722

ISBN: 978-989-758-634-7; ISSN: 2184-4321

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

715

ily available to most retail stores, so only a dataset

with bounding boxes (without a class label) would

need to be developed. The disadvantage of the two-

models approach is that it is very computationally ex-

pensive, since all detected products need to be passed

through a second model. The joint approach does not

have such a computational bottleneck. However, pre-

vious work has always trained such a model on a fully-

annotated dataset (see Fig. 1 (c)), i.e., a dataset that

contains a product label for each bounding box (Mun-

jal et al., 2019; Ranst et al., 2018; Xiao et al., 2019;

Xiao et al., 2017). Such a dataset is much more costly

to develop.

One could wonder if, instead, the joint approach

could also be trained on task-specific datasets. Sur-

prisingly, however, to the best of our ability, we

were unable to find any previous work that con-

cerned this topic. A lot of research has been done on

semi-supervised object (SSOD) detection (Fang et al.,

2021; Redmon and Farhadi, 2016; Zhou et al., 2022),

and while parallels can be drawn, SSOD is clearly dif-

ferent from the approach proposed here. With SSOD,

part of the data is fully annotated with bounding boxes

and class labels, and another part of the data is only

annotated on the image level with one or more labels

per image (i.e., weak labeling). The annotations of the

detection dataset should contain class labels that even

partly overlap with the labels in the weakly-labeled

dataset. In the set-up we wish to investigate, there is

a strict boundary between both datasets: one dataset

only contains bounding boxes, the other one only con-

tains labeled images of individual products.

Our experiments suggest why we could not find

any previous publications on the matter: a joint

model trained on task-specific datasets clearly per-

forms worse than the same joint model trained on a

fully-annotated dataset. Due to the potential cost sav-

ings, however, we are convinced that training on task-

specific datasets deserves more exposure in the litera-

ture, and that it is worth the effort to look for causes

of its lower performance. Therefore, we propose a

novel method to carefully evaluate the differences be-

tween both training procedures. We first train a joint

model on a fully-annotated dataset and gradually ap-

ply changes to the training procedure until we end

up with training on task-specific datasets. With this

framework, any issues that occur during the transfor-

mation process can be pointed out and as such provide

focus points to work on when attempting to close the

performance gap.

2 RELATED WORK

2.1 Product Detection and Recognition

The automated recognition of products in stores is

a long-standing problem with many proposed solu-

tions. Many of the early proposed works focus on

using RFID-tags, barcodes or QR-codes that are at-

tached to each product (Kulyukin et al., 2005; L

´

opez-

de-Ipi

˜

na et al., 2011). Computer vision-based tech-

niques, however, offer a potentially less intrusive and

more scalable approach to product recognition. There

are two tasks to be performed: detection, i.e., find-

ing out where there are products in the image; and

recognition (or, classification), i.e., finding out which

product is present in a product region. While a lot

of research has been done on employing classic com-

puter vision techniques for both product detection and

product classification (George et al., 2015; Merler

et al., 2007; Tonioni and Di Stefano, 2017), most re-

cent work focuses on using deep learning techniques.

Solutions have been proposed for both deep learning-

based product classification and deep learning-based

product detection (Goldman et al., 2019; Qiao et al.,

2017; Srivastava, 2020).

Most relevant to our work, however, are the meth-

ods that combine product detection and classifica-

tion (Fuchs et al., 2019; Hao et al., 2019). Often,

these models need to be (partly) retrained every time

a new product class is added, limiting the scalabil-

ity of the pipelines. In the product recognition liter-

ature, only Tonioni et al. (Tonioni et al., 2018) and

Osokin et al. (Osokin et al., 2020) propose a prod-

uct detection and recognition system that can also be

used for products that were not present in the origi-

nal training dataset. Tonioni et al. use a separate de-

tector and encoder model, where each detected prod-

uct is cropped out and passed through the encoder.

While their results are satisfactory, the two-stage de-

sign causes a computational bottleneck at the encoder

part of the pipeline (Tonioni et al., 2018). Osokin

et al. propose a solution in a one-shot object detec-

tion setting (Osokin et al., 2020). Via a pairwise-

correlation of the feature maps of the query (rack)

image and of each of the gallery images, their model

computes geometric transformation parameters that

map the gallery images to matching locations in the

query image. Adding new products to the gallery only

requires the computation of their feature maps once.

However, their method needs a training dataset that

is annotated with bounding boxes and class labels,

which we explicitly wish to avoid.

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

716

Figure 2: High-level overview of the joint architecture we use in this paper. The outputs of the different components are

indicated with the light gray boxes.

2.2 Joint Detection and Recognition

An important property of the model considered in

this paper, is that both product detection and product

recognition are performed at once. In the area of per-

son search and person re-identification, this has been

coined as joint detection and recognition (Munjal

et al., 2019; Ranst et al., 2018; Xiao et al., 2017; Xiao

et al., 2019). All of these methods start from a stan-

dard detector (either Faster R-CNN (Ren et al., 2015)

or YOLOv2 (Redmon and Farhadi, 2016)) and mod-

ify it in such a way that, for each bounding box, an

embedding is returned that can be used for the recog-

nition task. Similar architectures can also be found

in the field of few-shot object detection (Kang et al.,

2019; Wang et al., 2020; Zhou et al., 2022), where

the task is to detect and classify an object based on

only a few (typically < 10) examples. While product

detection and recognition certainly is a valid use-case

of few-shot object detection (as (Osokin et al., 2020)

shows), all these methods require a fully-annotated

dataset.

3 METHOD

To identify issues that arise when training a joint

model on task-specific datasets, we define four pro-

cedures for training the model. The first one, Proc. 1,

is simply the well-known multi-class detector train-

ing, trained on a fully-annotated dataset. The last one,

Proc. 4, describes how one could train a joint architec-

ture on task-specific datasets. Starting from Proc. 1,

each next procedure is a slightly modified version of

the previous one. When one of the procedures fails

while the previous one worked, we have identified an

issue that decreases the performance of Proc. 4.

Note that, for all except Proc. 4, we need a fully-

annotated dataset. In our experiments, we used the

GroZi-3.2k dataset (George and Floerkemeier, 2014)

with annotations from Tonioni and Di Stefano (To-

nioni and Di Stefano, 2017). This dataset is not large

enough for a production-ready model (see Sec. 4 for

more details), but it suffices to demonstrate how the

procedures below can be applied. Also, note that

the forward pass during test time is exactly the same

for all the procedures: a store rack image is passed

through the model, which returns a set of bound-

ing boxes, binary class labels and recognition embed-

dings.

Procedure 1 (Conventional Detector Training). The

model is trained with a fully-annotated dataset. A

batch of product rack images is passed through the

joint architecture and we obtain a set of bounding

boxes, binary class labels (foreground/background)

and recognition embeddings (along with region pro-

posals and objectness scores from the RPN). For each

of these outputs, we have an annotated ground truth,

so we can compute a loss value and train the network

with a gradient descent-like optimization algorithm.

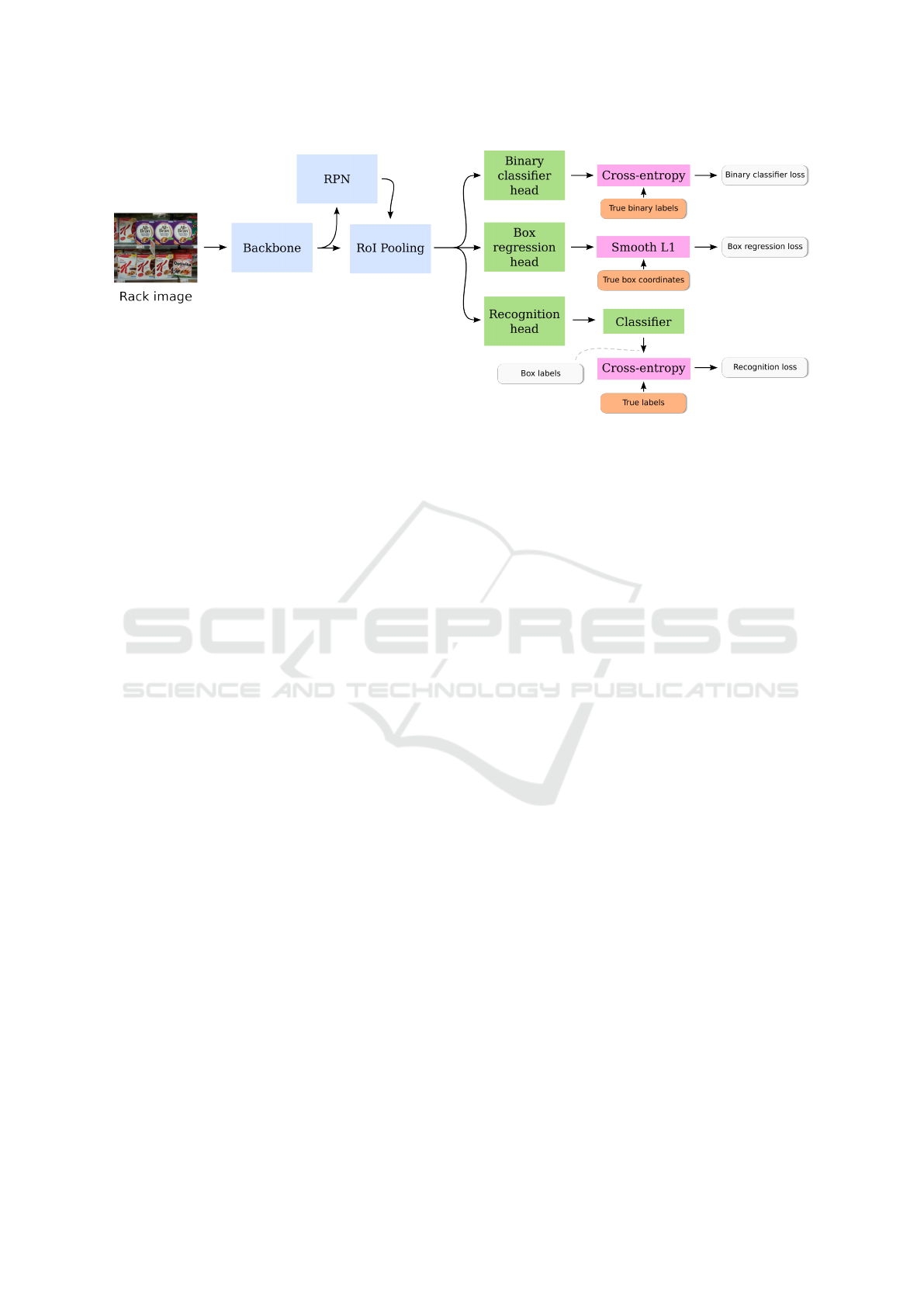

Fig. 3 shows an example of how these losses could be

computed.

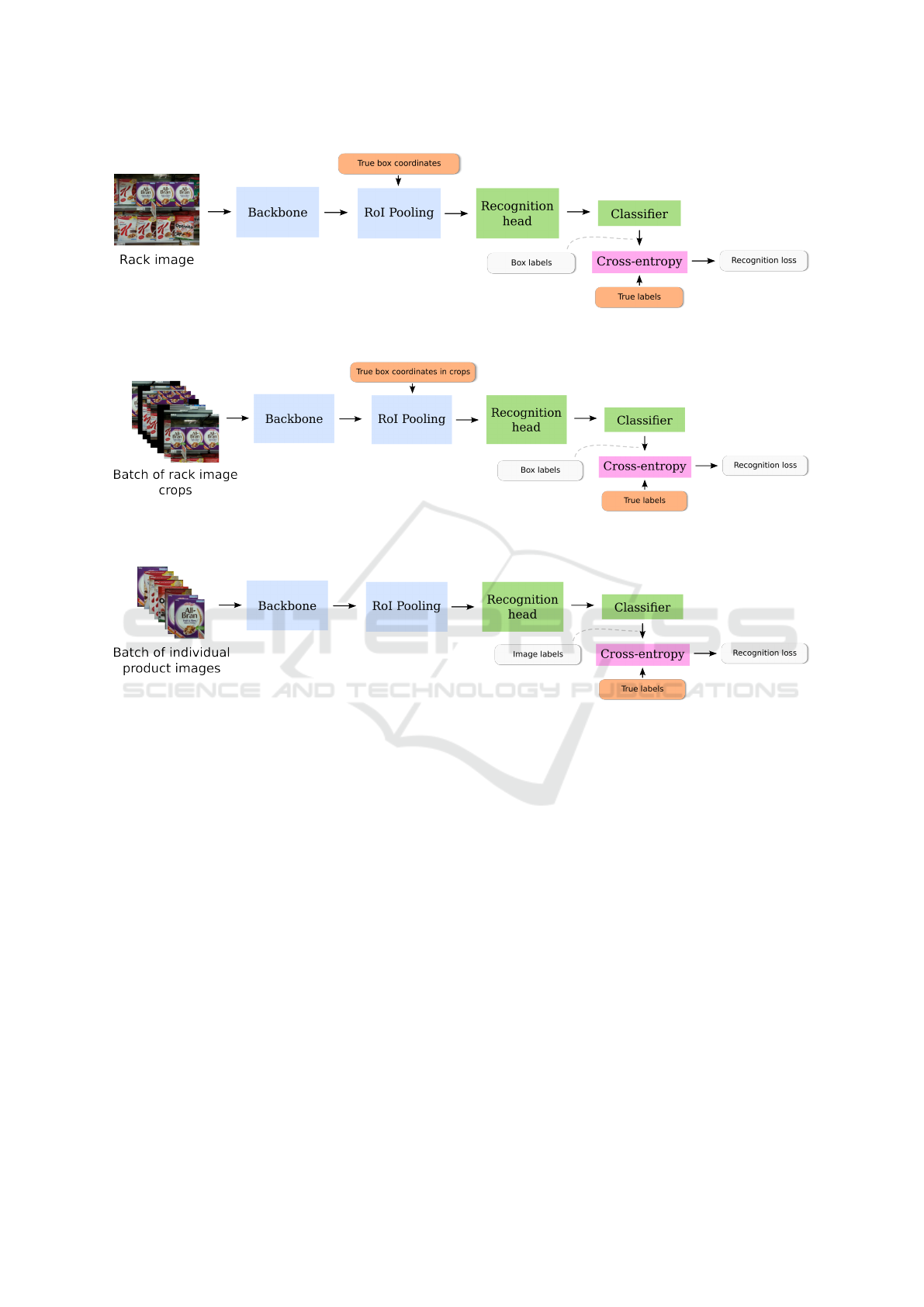

Procedure 2 (Two-Phase Training). Unlike Proce-

dure 1, the batch of rack images is passed through

the joint architecture twice. Weight updates are ap-

plied after each training phase separately. During

the detection training phase, the batch goes through

all the network components, except the recognition

head. Losses are computed for the RPN, bounding

box regression and foreground vs. background classi-

fication. During the recognition training phase, the

batch only goes through the backbone and the recog-

nition head. We use the ground truth bounding boxes

to apply RoI pooling on the feature maps that come

out of the backbone. During this phase, only the

recognition loss is computed. More specifically, the

loss is calculated from the ground-truth product label

of the bounding box used during RoI pooling. An ex-

ample of the loss computation during the recognition

training phase, is illustrated in Fig. 4.

Joint Training of Product Detection and Recognition Using Task-Specific Datasets

717

Figure 3: Computation of the detection and recognition losses of a joint architecture trained with Procedure 1 (Conventional

detector training). The outputs of the model components shown in Fig. 2 are omitted for clarity.

Procedure 3 (Crop-Batch Training). The training

phase for detection is the same as in Proc. 2, but dur-

ing the recognition training phase, we use a batch of

image crops as input, instead of the entire images. We

again use the respective ground-truth bounding boxes

of each crop in the batch to apply RoI pooling on the

feature maps that are returned by the backbone. This

is illustrated in Fig. 5. Note that we do not resize the

crops, such that the absolute size of products in im-

ages during both training phases stays the same.

Procedure 4 (Task-Specific Training). Again, the de-

tection training phase is the same as in Proc. 2. The

input of the recognition training phase, however, now

consists of individual product images. RoI pooling

is applied on the entire backbone feature map. See

Fig. 6 for an example.

4 IMPLEMENTATION

In this section, we demonstrate how the procedures

described in Sec. 3 can be applied. The code, data

and instructions on how to reproduce the results can

be found on https://github.com/florisdf/jpdr.

For our joint model, we follow previous

work (Munjal et al., 2019; Ranst et al., 2018; Xiao

et al., 2017; Xiao et al., 2019) and add an extra RoI

head (Girshick, 2015) to a well-studied detector archi-

tecture, in our case Faster R-CNN with a ResNet-50

Feature Pyramid Network (FPN) backbone (He et al.,

2016; Lin et al., 2017; Ren et al., 2015). The extra RoI

head returns a 512-dimensional recognition embed-

ding for the corresponding region of interest by pass-

ing the RoI features through a fully-connected layer.

Each model is trained on the GroZi-3.2k (George

and Floerkemeier, 2014) dataset with the improved

annotations of Tonioni and Di Stefano (Tonioni and

Di Stefano, 2017). This dataset consists of 123 im-

ages of store racks (similar to the input image shown

in Fig. 2) with an average of 13 products per image.

In total, the dataset contains 286 different products.

We split up the images in the dataset into five equally-

sized random folds from which four are used for train-

ing and one is used for validation. The results that we

report are always the average of five runs, each with a

different combination of training and validation folds.

For the RPN, the bounding box regression head

and the binary classifier head, we use the same losses

as described in (Ren et al., 2015). To compute a loss

for the recognition head, we append an extra fully-

connected layer that transforms the recognition em-

bedding into a vector of dimension L—with L the

number of product labels in the dataset—and apply

softmax cross-entropy loss to that vector. We train

each model for 500 epochs with a constant learning

rate of 0.01 on an NVIDIA Tesla V100 GPU. The

ResNet-50 FPN backbone of our model is pretrained

on ImageNet (Deng et al., 2009) and frozen, except

for the last layer. The layers of the RPN and the RoI

heads are randomly initialized. We use stochastic gra-

dient descent to optimize the model weights.

For Proc. 1 and the detection phases of the other

procedures, the input images are resized so that their

shortest size is 960 px and are then randomly cropped

to a size of 800 × 800 px. We use a batch size of 2.

The recognition phase of Proc. 2 uses the same input

data, transformation pipeline and batch size. For the

recognition phase of Proc. 3, we also start from the

same data and, as we want the products in the crops

to have the same absolute size as during the detection

phase, we apply the same transformation pipeline. To

create the crops, we center a box of size s

c

×s

c

at each

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

718

Figure 4: Computation of the recognition loss during Procedure 2 (Two-phase training). We use the ground-truth bounding

boxes for RoI pooling instead of region proposals.

Figure 5: Computation of the recognition loss during Procedure 3 (Crop-batch training). Note that the input is a batch of

crops of a rack image. We use the ground-truth bounding boxes in each crop for RoI pooling.

Figure 6: Computation of the recognition loss during Procedure 4 (Task-specific training). Note that the input is a batch of

individual product images. The RoI pooling is now applied on the entire feature map.

product location, with s

c

a predefined crop size. When

multiple boxes overlap with more than 50% IoU, only

one of them will be kept. Crops that partly fall outside

the image will be filled up with zeroes in that area. If

more than 50% of a crop’s area is outside the image,

the crop is not used.

During validation, we resize the store rack images

to a shortest size of 960 px and apply a center crop of

800×800 px. The images are passed through the joint

network (including all three RoI heads). We employ

the classifier that was used to compute the softmax

cross-entropy training loss to classify the recognition

embedding of each detection. Together with the re-

sult of the bounding box regression head, these prod-

uct labels and confidence scores can be employed to

compute the COCO AP (Doll

´

ar and Lin, 2022; Lin

et al., 2015) metric.

5 RESULTS

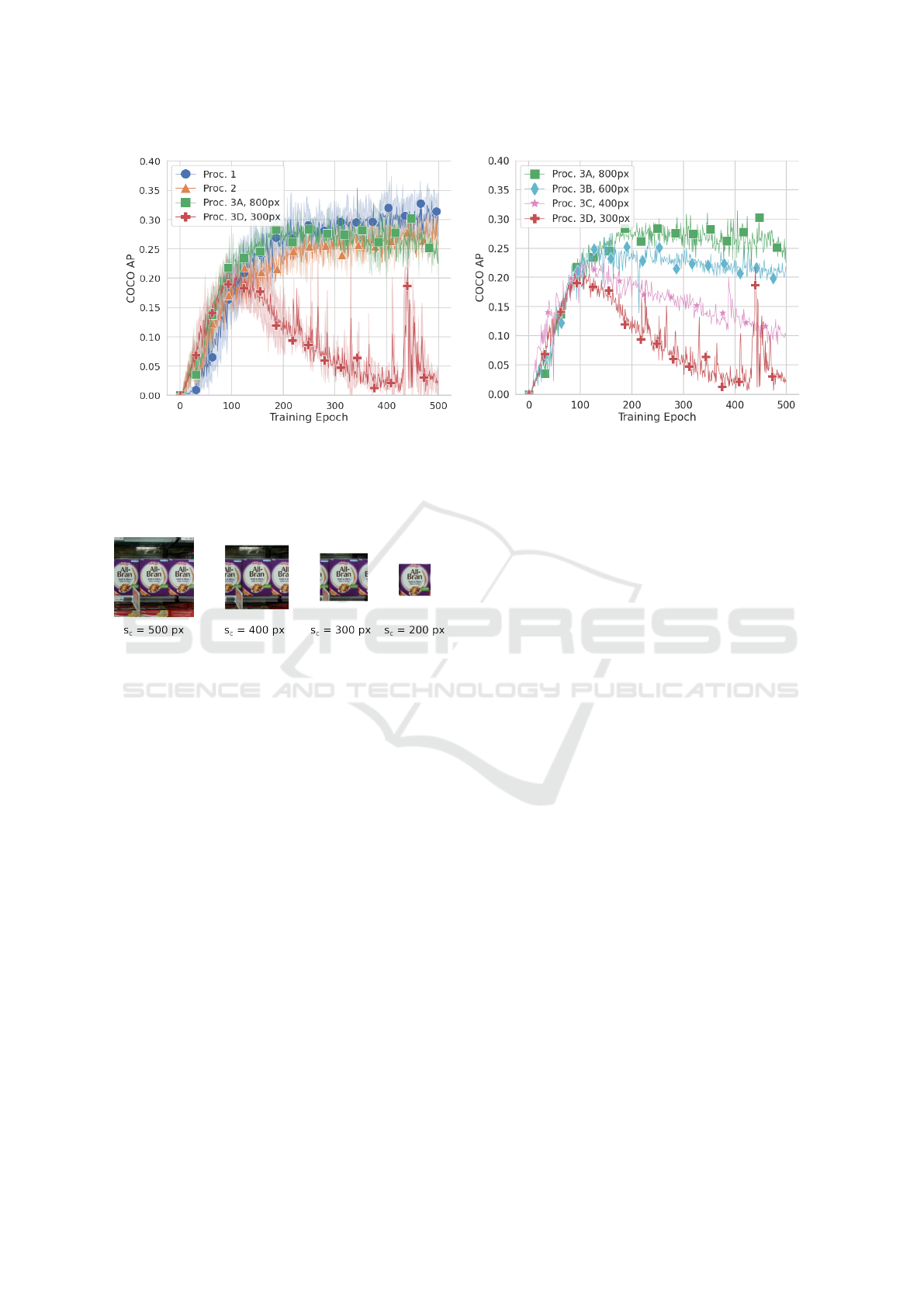

Figure 8 shows the COCO AP for Procs. 1, 2 and

3 (for s

c

= 800 px and s

c

= 300 px). When s

c

=

800 px, a lot of crop boxes will overlap and/or fall

largely outside the 800 × 800 px input image and

as such be removed (see Sec. 4). In fact, only a

single 800 × 800 px “crop” will remain, positioned

around the center of the image, such that Proc. 3 be-

comes similar to Proc. 2. Since, after the transfor-

mation pipeline, the average size of the products in

the GroZi-3.2k dataset is around 300 × 300 px, when

s

c

= 300 px, Proc. 3 is similar to Proc. 4. To get an

idea of what these crops look like for different crop

sizes, see Fig. 7.

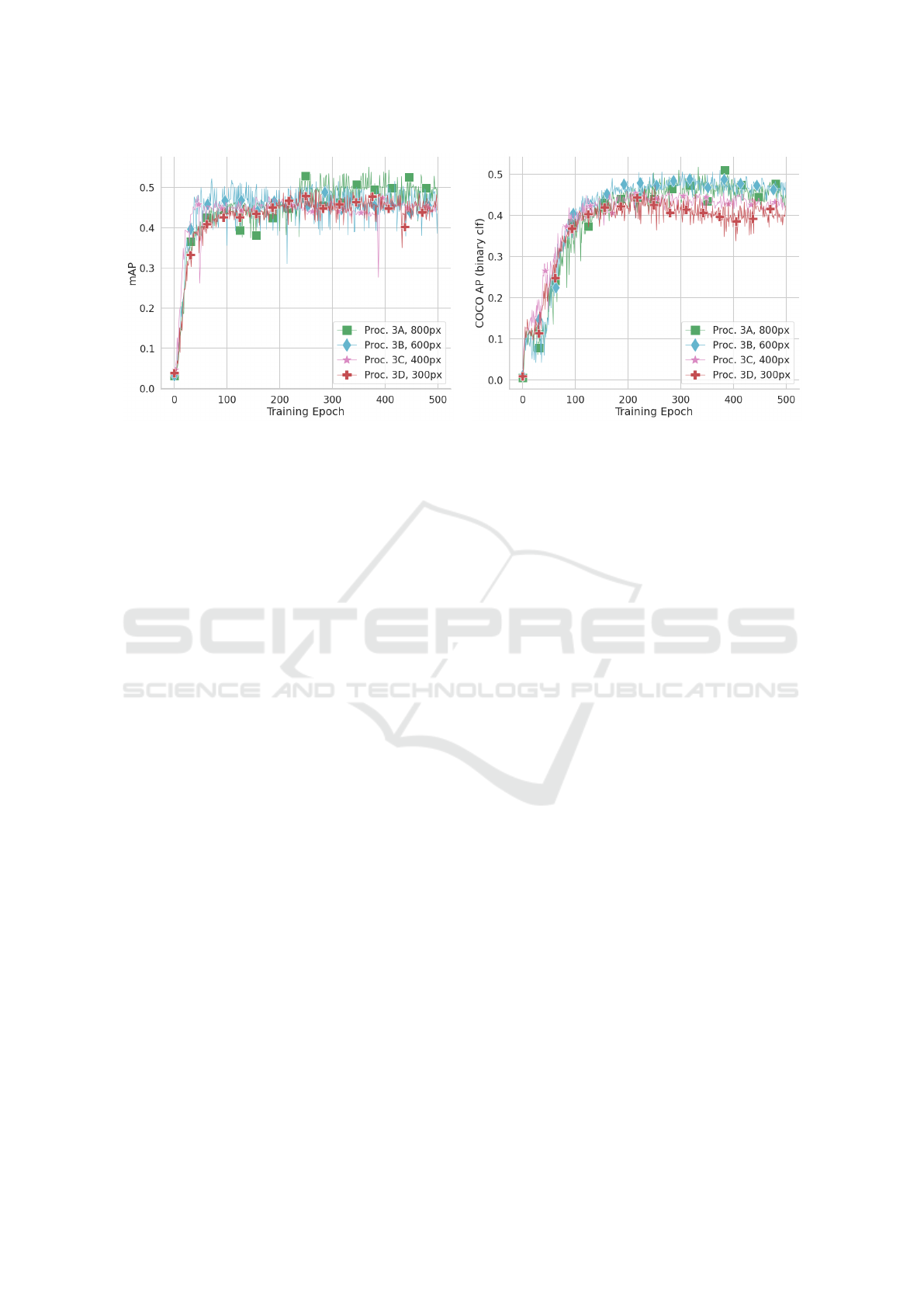

As we can see in Fig. 8 (a), Procs. 1, 2 and 3A

perform similarly. This indicates that splitting up

the training in a detection and a recognition phase,

does not harm the performance of the model com-

Joint Training of Product Detection and Recognition Using Task-Specific Datasets

719

(a) (b)

Figure 8: Validation COCO AP evaluated during training on the GroZi-3.2k dataset for (a) Procs. 1, 2 and two versions of

Proc. 3; and (b) multiple versions of Proc. 3. The lines indicate the mean after five-fold cross-validation and the bands in (a)

show the standard deviation. As crops fit more tightly around individual products, the validation AP starts to drop after 100

epochs.

Figure 7: Example of multiple crop sizes (centered around

the same product) that can be used for Proc. 3. As the crop

size becomes smaller, the amount of rack context decreases.

pared to training it as a conventional multi-class de-

tector. Also, employing ground-truth bounding boxes

for RoI pooling during recognition training, does not

seem to be a problem. Proc. 3D, however, clearly

yields inferior results. The COCO AP rises the first

100 epochs, but drops significantly after that. The

maximum COCO AP achieved by Proc. 3 is clearly

about ten percent points lower than the other proce-

dures. These results suggest that separately training

the recognition head on crops that tightly fit around

individual products, seriously harms the performance

of a joint product detection and recognition architec-

ture. This is also confirmed by Fig. 8 (a), where we

let s

c

decrease from 800 px to 300 px with more in-

termediary crop sizes.

6 DISCUSSION

In Section 5, we ran our implementations of Procs. 1,

2 and 3. The experiments show that when s

c

= 800 px,

Proc. 3 performed similarly to the previous proce-

dures. However, when s

c

= 300 px, we saw a per-

formance drop. Due to the careful definition of the

procedures in Sec. 3, we can easily identify that a

smaller crop size is causing a difference in model per-

formance.

Why is this the case? First of all, it could be that,

as the crop size becomes smaller, either the recog-

nition or the detection task is performing worse. To

investigate this, we keep track of two extra metrics

during training. The first one evaluates the recogni-

tion performance. More specifically, we crop individ-

ual products out of the validation data and pass these

through the backbone and recognition head. The re-

sulting product embeddings are classified using the

trained classifier from the softmax cross-entropy loss

function. As such, we obtain a predicted label, along

with a confidence score that can be used to compute

a Precision-Recall-curve and an AP. For each valida-

tion epoch, we report the average of all image APs as

the mAP. Fig. 9 (a) shows that there is no noteworthy

difference in the recognition validation performance

of any of the versions of Proc. 3. Second, we evaluate

the COCO AP for product/no product classification

during training. When this metric is low, it indicates

that the detection task itself is failing. Figure 9 (b)

shows a slight decrease in the COCO AP when the

crop size becomes smaller, but by no means compa-

rable to the drastic decrease we see in Fig. 8 (b).

We conclude that, for all crop sizes, the individ-

ual subtasks perform similar on validation data. Only

when we combine both tasks and pass RoI features

that come from an entire rack image to the recogni-

tion head, performance decreases. As such, we are

convinced that, when trained on smaller crops, the

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

720

(a) (b)

Figure 9: Validation (a) mAP of the recognition pipeline; and (b) COCO AP of detection pipeline during training for multiple

versions of Proc. 3 on the GroZi-3.2k validation folds. Both recognition and detection seem to perform more ore less equally

for different crop sizes.

recognition head does not learn to cope with the extra

context that is unavoidably present in the RoI features

during validation. This causes the total pipeline to

perform worse.

7 CONCLUSION

In this paper, we proposed a set of training procedures

to investigate the issue of employing task-specific

training for a joint detection and recognition network

architecture. With these procedures, we exposed an

important problem that hinders task-specific training.

Our experiments suggest that, by training on tightly-

fit product crops, the recognition head of the joint ar-

chitecture never learns to cope with the context infor-

mation that is present in feature maps during infer-

ence. This inability hinders the model to achieve sim-

ilar performance to a model trained on fully-annotated

data.

We hope that both the proposed training proce-

dures and our findings on the influence of context

during validation will aid future research in solving

task-specific training of joint detection and recogni-

tion models.

REFERENCES

Deng, J., Dong, W., Socher, R., Li, L., Kai Li, and Li Fei-

Fei (2009). ImageNet: A large-scale hierarchical im-

age database. In 2009 IEEE Conference on Computer

Vision and Pattern Recognition, pages 248–255.

Doll

´

ar, P. and Lin, T.-Y. (2022). Cocodataset/cocoapi. coco-

dataset.

Fang, S., Cao, Y., Wang, X., Chen, K., Lin, D., and Zhang,

W. (2021). WSSOD: A New Pipeline for Weakly- and

Semi-Supervised Object Detection.

Fuchs, K., Grundmann, T., and Fleisch, E. (2019). Towards

identification of packaged products via computer vi-

sion: Convolutional neural networks for object detec-

tion and image classification in retail environments.

In ACM International Conference Proceeding Series,

pages 1–8, New York, New York, USA. Association

for Computing Machinery.

George, M. and Floerkemeier, C. (2014). Recognizing

Products: A Per-exemplar Multi-label Image Classifi-

cation Approach. In Fleet, D., Pajdla, T., Schiele, B.,

and Tuytelaars, T., editors, Computer Vision – ECCV

2014, volume 8690, pages 440–455. Springer Interna-

tional Publishing, Cham.

George, M., Mircic, D., Soros, G., Floerkemeier, C.,

and Mattern, F. (2015). Fine-Grained Product Class

Recognition for Assisted Shopping. In 2015 IEEE In-

ternational Conference on Computer Vision Workshop

(ICCVW), pages 546–554, Santiago. IEEE.

Girshick, R. (2015). Fast R-CNN. In The IEEE Interna-

tional Conference on Computer Vision (ICCV), pages

1440–1448, Santiago, Chile.

Goldman, E., Herzig, R., Eisenschtat, A., Goldberger, J.,

and Hassner, T. (2019). Precise Detection in Densely

Packed Scenes. In The IEEE Conference on Computer

Vision and Pattern Recognition (CVPR), pages 5227–

5236.

Hao, Y., Fu, Y., and Jiang, Y.-G. (2019). Take Goods from

Shelves: A Dataset for Class-Incremental Object De-

tection. In Proceedings of the 2019 on International

Conference on Multimedia Retrieval, pages 271–278,

Ottawa ON Canada. ACM.

He, K., Zhang, X., Ren, S., and Sun, J. (2016). Deep Resid-

ual Learning for Image Recognition. In The IEEE

Joint Training of Product Detection and Recognition Using Task-Specific Datasets

721

Conference on Computer Vision and Pattern Recog-

nition (CVPR), pages 770–778, Las Vegas, NV, USA.

IEEE.

Kang, B., Liu, Z., Wang, X., Yu, F., Feng, J., and Dar-

rell, T. (2019). Few-Shot Object Detection via Fea-

ture Reweighting. In Proceedings of the IEEE/CVF

International Conference on Computer Vision, pages

8420–8429.

Kulyukin, V., Gharpure, C., and Nicholson, J. (2005).

RoboCart: Toward robot-assisted navigation of gro-

cery stores by the visually impaired. In 2005

IEEE/RSJ International Conference on Intelligent

Robots and Systems, pages 2845–2850.

Lin, T.-Y., Doll

´

ar, P., Girshick, R., He, K., Hariharan,

B., and Belongie, S. (2017). Feature Pyramid Net-

works for Object Detection. In The IEEE Conference

on Computer Vision and Pattern Recognition, pages

2117–2125, Honolulu.

Lin, T.-Y., Maire, M., Belongie, S., Bourdev, L., Girshick,

R., Hays, J., Perona, P., Ramanan, D., Zitnick, C. L.,

and Doll

´

ar, P. (2015). Microsoft COCO: Common Ob-

jects in Context. arXiv:1405.0312 [cs].

L

´

opez-de-Ipi

˜

na, D., Lorido, T., and L

´

opez, U. (2011). In-

door Navigation and Product Recognition for Blind

People Assisted Shopping. In Bravo, J., Herv

´

as, R.,

and Villarreal, V., editors, Ambient Assisted Living,

volume 6693, pages 33–40. Springer Berlin Heidel-

berg, Berlin, Heidelberg.

Merler, M., Galleguillos, C., and Belongie, S. (2007). Rec-

ognizing Groceries in situ Using in vitro Training

Data. In 2007 IEEE Conference on Computer Vision

and Pattern Recognition, Minneapolis. IEEE.

Munjal, B., Amin, S., Tombari, F., and Galasso, F. (2019).

Query-Guided End-To-End Person Search. In 2019

IEEE/CVF Conference on Computer Vision and Pat-

tern Recognition (CVPR), pages 811–820.

Osokin, A., Sumin, D., and Lomakin, V. (2020). OS2D:

One-Stage One-Shot Object Detection by Matching

Anchor Features.

Qiao, S., Shen, W., Qiu, W., Liu, C., and Yuille, A. (2017).

ScaleNet: Guiding Object Proposal Generation in Su-

permarkets and Beyond. In 2017 IEEE International

Conference on Computer Vision (ICCV), pages 1809–

1818, Venice. IEEE.

Ranst, W. V., Smedt, F. D., Berte, J., and Goedem

´

e, T.

(2018). Fast Simultaneous People Detection and Re-

identification in a Single Shot Network. In 2018 15th

IEEE International Conference on Advanced Video

and Signal Based Surveillance (AVSS), pages 1–6.

Redmon, J. and Farhadi, A. (2016). YOLO9000: Better,

Faster, Stronger. arXiv:1612.08242 [cs].

Ren, S., He, K., Girshick, R., and Sun, J. (2015). Faster R-

CNN: Towards Real-Time Object Detection with Re-

gion Proposal Networks. In Advances in Neural In-

formation Processing Systems 28 (NIPS 2015), pages

91–99.

Srivastava, M. M. (2020). Bag of Tricks for Retail Prod-

uct Image Classification. In Campilho, A., Karray, F.,

and Wang, Z., editors, Image Analysis and Recogni-

tion, volume 12131, pages 71–82. Springer Interna-

tional Publishing, Cham.

Tonioni, A. and Di Stefano, L. (2017). Product recognition

in store shelves as a sub-graph isomorphism problem.

In Lecture Notes in Computer Science (Including Sub-

series Lecture Notes in Artificial Intelligence and Lec-

ture Notes in Bioinformatics), volume 10484 LNCS,

pages 682–693. Springer Verlag.

Tonioni, A., Serra, E., and Stefano, L. D. (2018). A

deep learning pipeline for product recognition on store

shelves. In 2018 IEEE International Conference on

Image Processing, Applications and Systems (IPAS),

pages 25–31.

Wang, W., Cui, Y., Li, G., Jiang, C., and Deng, S. (2020).

A self-attention-based destruction and construction

learning fine-grained image classification method for

retail product recognition. Neural Computing and Ap-

plications, 32(18):14613–14622.

Wang, Z., Zheng, L., Li, Y., and Wang, S. (2019). Linkage

Based Face Clustering via Graph Convolution Net-

work.

Xiao, J., Xie, Y., Tillo, T., Huang, K., Wei, Y., and Feng,

J. (2019). IAN: The Individual Aggregation Network

for Person Search. Pattern Recognition, 87:332–340.

Xiao, T., Li, S., Wang, B., Lin, L., and Wang, X. (2017).

Joint Detection and Identification Feature Learning

for Person Search. In 2017 IEEE Conference on Com-

puter Vision and Pattern Recognition (CVPR), pages

3376–3385, Honolulu, HI. IEEE.

Zhou, X., Girdhar, R., Joulin, A., Kr

¨

ahenb

¨

uhl, P., and

Misra, I. (2022). Detecting Twenty-thousand Classes

using Image-level Supervision. arXiv:2201.02605

[cs].

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

722