Colour-Field Based Particle Categorization for Residual Stress

Detection and Reduction in Solid SPH Simulations

Gizem Kayar

a

Computer Science Department, New York University, 251 Mercer Street, New York, U.S.A.

Keywords: Smoothed Particle Hydrodynamics, Residual Stress, Von-MissesYield, Physically-Based Simulations,

Solid Simulations.

Abstract: Residual stress remains in an object even in the absence of external forces or thermal pressure, which, in turn,

may cause significant plastic deformations. In case the residual stress creates unwanted effects on the material

and so is undesirable, an efficient solution is necessary to track and eliminate this stress. Smoothed Particle

Hydrodynamics has been extensively used in solid mechanics simulations and the inherent colour-field

generation approach is a promising tracker for the residual stress. In this paper, we propose a way to use the

colour-field approach for eliminating the residual stress and prevent the undesirable premature failure of solid

objects.

1 INTRODUCTION

Residual stresses describe any stress remain in the

material even after the external forces and thermal

effects are excluded from the environment. These

stresses may originate from many causes, e.g. cooling

rates, volume changes, etc. and they may be created

by welding, rolling, forging, casting, machining, heat

treatments or surface treatments. After that point,

residual stress is generated when an object is stressed

beyond its elastic limit, resulting in plastic

deformation.

Residual stress should be managed properly for

the design, manufacturing, and maintenance phases.

Although it may be desirable in some certain

conditions, residual stress generally causes the

material to fail prematurely. It may affect the fatigue

life, stability, resistance and also brittle fractures of

objects. Elimination process of residual stresses are

extensively researched in material science.

Simulations of such conditions help the researchers to

understand the problem further and therefore, to

create a solution.

Since its introduction (Gingold & Monaghan,

1977; Lucy, 1977), Smoothed Particle

Hydrodynamics (SPH) has been accepted as one of

the major development mediums for the mechanics of

a

https://orcid.org/0000-0002-7811-9357

continuum media. Although it was introduced for

astrophysical problems, later it has been used in

various research fields including but not limited to

fluid simulations (e.g. Solenthaler & Pajarola, 2009;

Shadloo et al., 2016; Gissler et al., 2019) and solid

mechanics (e.g. Libersky & Petschek, 1990; Libersky

et al., 1993). Although SPH is still in the process of

development, the method has been drastically

improved over the years to overcome some major,

inherent problems. SPH is still one of the easy-to-use

numerical methods to model complex systems.

Residual stress has been generated and/or

determined by researchers in some SPH simulations

for different purposes, such as arc welding (Das &

Cleary, 2010), friction stir welding (Eivani et. al,

2021), etc. In our experiments, we observed that the

undesired residual stress is the major cause of

instability in SPH solid simulations.

Our contribution in this ongoing work is to

eliminate the undesired residual stress behaviour

from solid mechanics simulations by applying a

colour-field technique which is extensively used in

SPH fluid simulations. Colour-field approach helps

us to identify the particles with potential residual

stress which, in turn, are handled differently to reduce

the overall stress.

Kayar, G.

Colour-Field Based Particle Categorization for Residual Stress Detection and Reduction in Solid SPH Simulations.

DOI: 10.5220/0011716100003417

In Proceedings of the 18th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2023) - Volume 1: GRAPP, pages

237-241

ISBN: 978-989-758-634-7; ISSN: 2184-4321

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

237

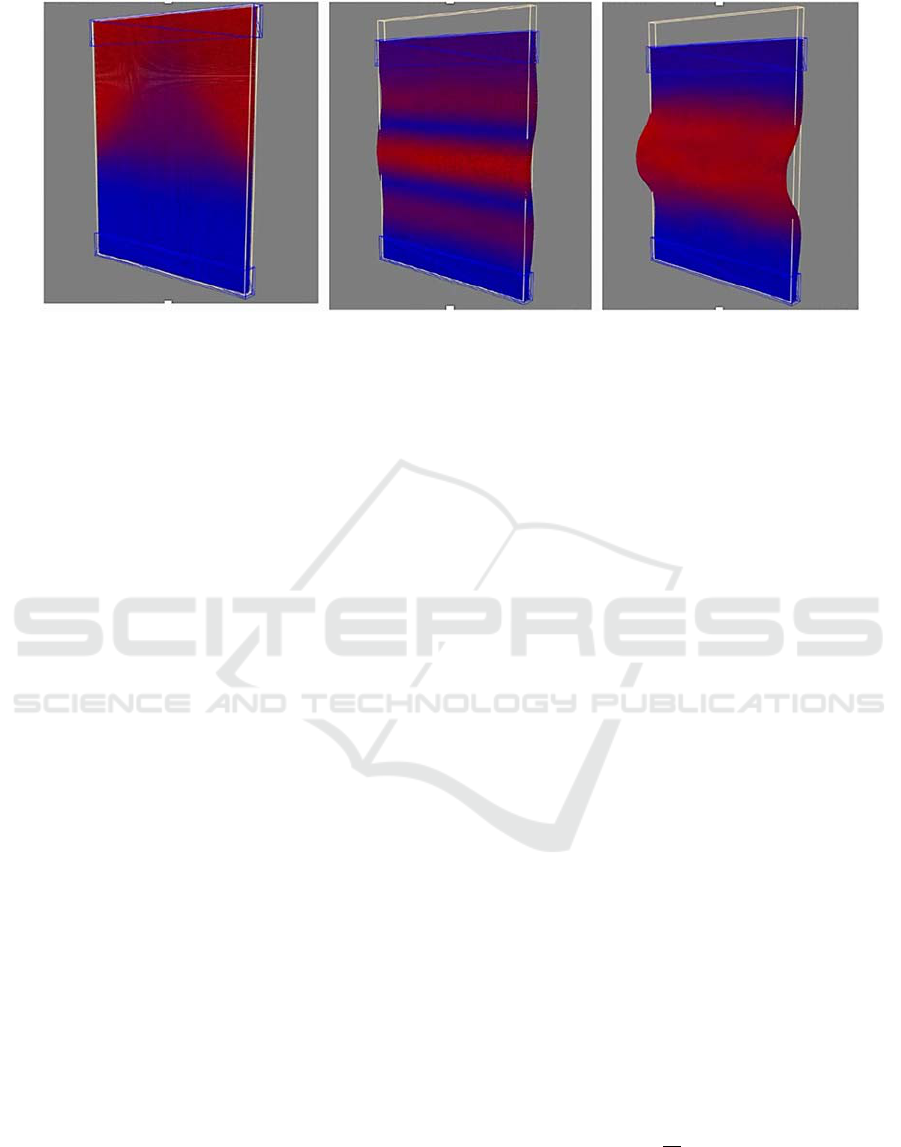

Figure 1: Compressed ductile material implemented with our SPH model and visualized with pressure-based colouring.

2 RELATED WORK

SPH has started to be researched in computer

graphics for the last couple of years and still

extensively researched in material science. For

instance, Ihmsen et al. discusses the force

computation problems and visual inefficiency in

granular SPH in (Ihmsen et al, 2013). Here, they

propose to use a coarsely sampled simulation for

force computations, and couple high resolution set of

particles to base particles via up-sampling which

improves both the computation time and visual

quality. In (Nguyen et al, 2017), Nguyen et al. discuss

how to use viscous damping and stress regularisation

for granular flows. Later, Ghaitanellis et al. proposed

a new elastic-viscoplastic model for granular flows in

(Ghaitanellis et al, 2018).

In 2016, Pan et al. proposed an application where

SPH is used create solitary wave impact on offshore

platforms to understand the interaction between large

waves and offshore structures which is a good

example of SPH’s usage in civil engineering and geo-

numerics field (Pan et al., 2016). In the same year,

Holmes et al. proposed a model for grain-scale fluid

flows in porous rocks (Holmes et al., 2016).

Regarding our focus, the elimination process of

residual stresses is vital especially when the stress is

unwanted. Simulations of such conditions help the

researchers to understand the problem further and

therefore, to create better solutions.

Residual stress has been generated and/or

determined by researchers in some SPH simulations

for different purposes, such as arc welding (Das &

Cleary, 2010), friction stir welding (Eivani et. al,

2021), etc. Eivani shows a specific example on AZ91

Mg alloy where they combine SPH with neuro-fuzzy

computations and ultrasonic testing.

Another specific example comes from Saleh,

Luzin and Spencer where they analyse the residual

stress in cold spray technique using some numerical

and empirical methods (Saleh et al, 2014). Liu and

his fellow teammates also propose another technique

for the numerical simulation and elimination of

residual stress by using shot peening in (Liu et al.,

2019)

Discussing other fields, such as fluids, is beyond

the scope of this paper. However, state of the art

reports like (Koschier et al, 2022) are some of the

good resources for those who are interested in the

topic.

3 SPH

SPH is a method of discretizing spatial quantities

using a set of particles equipped with a kernel

function. Each particle is defined by a position, mass

and a support radius where mass can be computed as:

𝑚=𝜌∙𝑉 (1)

with 𝜌:fluid density and 𝑉:particle volume. The

word “smoothed” in SPH comes from the smoothing

operation which actually means calculating any

physical quantity of the particle using the weighted

sum of the same quantity of the neighboring particles

that lie in the range of a kernel function. So, after the

continuous approximation is discretized, he

smoothing operation looks as:

𝐴

=

∑

𝑚

𝑊

(

𝐱

−𝐱

,ℎ

)

(2)

where A is an arbitrary scalar quantity, x is the

position, b is the iterator over all contributing

particles and h is the smoothing length.

GRAPP 2023 - 18th International Conference on Computer Graphics Theory and Applications

238

As we stated before, contributions of the

neighbouring particles are governed by the kernel

function and can be calculated as, e.g.:

𝑊

(

𝐱

−𝐱

,ℎ

)

=

𝜎

ℎ

⎩

⎪

⎨

⎪

⎧

6𝑞

−6𝑞

+1 0≤𝑞≤

1

2

2(1−𝑞)

1

2

<𝑞≤1

0𝑞>1

(3)

𝑞=

|

𝐱

−𝐱

|

/ℎ

𝜎 varies depending on the dimensionality of the

system.

In such a system, for both fluids and solids,

equations of motion in Lagrangian perspective can be

given as:

𝑚

𝐯

=−𝑉

𝛻𝑝

+𝑉

𝜇𝛻

𝐯

+𝑉

𝐟

(4)

which, in turn, can be written as the sum of forces as:

𝑚

𝐯

=𝐅

𝐢

(5)

𝐅

𝐢

=𝐅

+𝐅

+𝐅

(6)

Here, forces can be computed using SPH

interpolation and later be integrated using one of the

explicit or implicit numerical integration schemes,

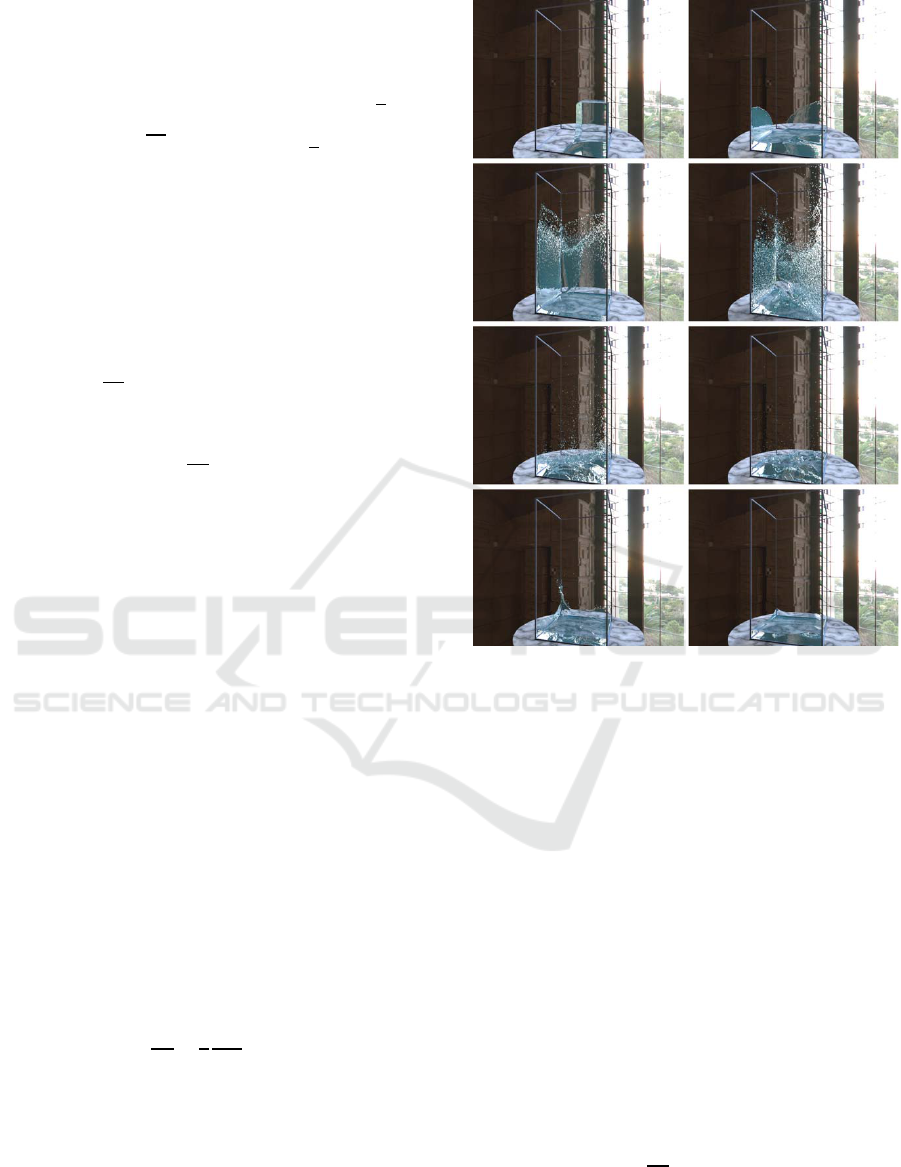

e.g. Euler-Cromer, Verlet, etc, With this approach,

thousands to billions of particles can be simulated

efficiently (see Figure 2).

4 SPH FOR SOLIDS AND

RESIDUAL STRESS

DETECTION

It is important to mention that all solid SPH

simulations in our work rely on the methodology

discussed in the previous section.

However, the SPH method should be extended so

that it may reflect the solid behaviour and yielding

criterion (see Figure 1 and Figure 3). Therefore, we

firstly implemented elastoplastic solid behaviour in

our system by integrating the momentum equation:

=

+𝑔

(7)

where

𝜎

=−𝑃𝛿

+𝑆

(8)

with pressure P, deviatoric stress tensor S. Stress can

be computed using Hooke’s Law.

At this stage, maximum distortion energy

criterion can be introduced to the system to estimate

the yield of ductile materials. We can even compare

Figure 2: Our SPH fluid simulation with 1.7 million

particles.

the material’s yield stress to Von Misses stress to

observe the its resistance and yielding thresholds.

Our main focus in this ongoing work is to

determine particles which are potentially carrying

residual stress. We therefore propose to use the colour

field approach. This approach was first proposed by

Müller et al. in (Müller et. al, 2003) for determining

surface particles in fluid flows. The same approach

helps us to categorize the solid particles. We can

identify a particle as a surface particle in two

conditions combined: 1) if it has less than a certain

number of neighbouring particles and 2) if its surface

normal n is showing more than a meaningful

threshold. Surface normal in this situation can be

computed as:

𝐧=∇𝑐

(9)

and

𝑐

(𝐩

)=

∑

𝑊(𝐩

−𝐩

,ℎ)

(10)

After identifying surface particles, we generated

one more additional layer right behind the surface

Colour-Field Based Particle Categorization for Residual Stress Detection and Reduction in Solid SPH Simulations

239

particles and we constrain those two sets to apply only

hydrostatic stress to other particles.

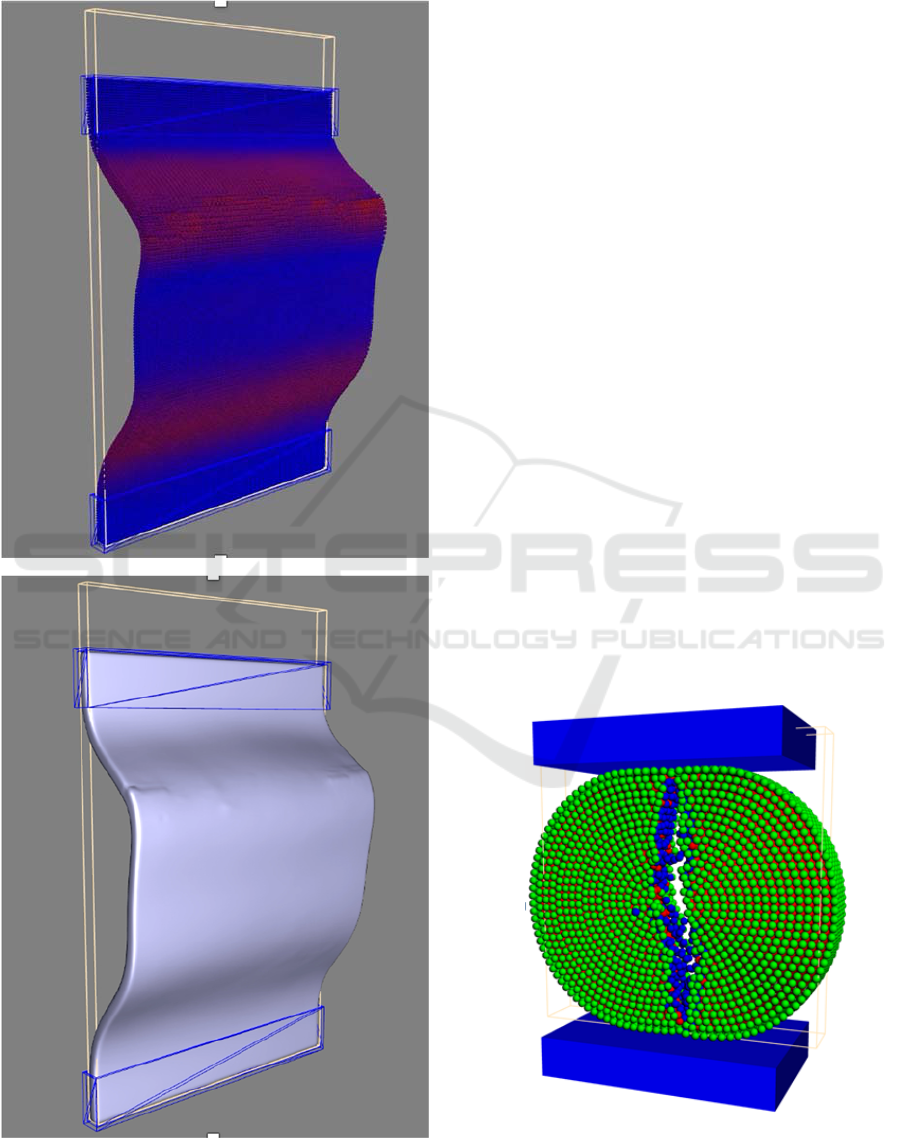

Figure 3: Compressed iron with pressure based particle

coloring and marching cubes based surface reconstruction.

5 RESULTS

During this approach, we observed that the stability

of the system improved significantly and we could

use larger time steps for our simulations. To be

specific, our simulation time steps has been increased

almost twice for all presented scenes. Additionally,

we could prevent all undesired crashes and undesired

forces from our system.

As an unexpected effect, we also noticed that we

could simulate brittle fractures without using an ad-

hoc damage model (see Figure 4).

6 CONCLUSIONS

In this paper, we presented a technique to improve the

stability of a solid system simulation by using

smoothed particle hydrodynamics. Based on the

conventional SPH model, we integrated elastoplastic

solid physics and used the idea of surface extraction

for isolating the force computation on certain fields.

We observed that the technique works well for both

ductile and brittle materials.

This is obviously an ongoing work and needs

further improvement. We plan to utilize more test

scenes and various comparisons for different material

properties in the future. Furthermore, we only

discussed the general stability but we did not discuss

the performance in detail. In the future, we would like

to investigate parallelization techniques for the

model.

Figure 4: Surface particle generation (green), inner layer

additional surface set particles (red) and completely fully

particles (blue) during a brittle fracture.

GRAPP 2023 - 18th International Conference on Computer Graphics Theory and Applications

240

REFERENCES

Gingold, R.A., Monaghan, J.J. (1977). Smoothed Particle

Hydrodynamics: theory and application to non-

spherical stars. Mon.Not.R. Astron. Soc, 181(3): 375-

389.

Lucy, L.B. (1977). A numerical approach to the testing of

the fission hypothesis. Astronomy Journal, 82: 1013-

1024.

Solenthaler, B., Pajarola, R. (2009). Predictive-corrective

incompressible SPH. ACM SIGGRAPH 2009 papers

(SIGGRAPH '09). Association for Computing

Machinery. New York, NY, USA, Article 40, 1–6.

https://doi.org/10.1145/1576246.1531346

Shadloo, M.S., Oger, G., LeTouze, D. (2016). Smoothed

particle hydrodynamics method for fluid flows, towards

industrial applications: Motivations, current state, and

challenges. Computers&Fluids, 136: 11-34.

Gissler, C., Peer, A., Band, S., Bender, J., Teschner, M.

(2019). Interlinked SPH Pressure Solvers for Strong

Fluid - Rigid Coupling. ACM Transactions on

Graphics, 38(1), article no. 5: 1-13.

Ihmsen, M., Wahl, A., Teschner, M.(2013). A Lagrangian

Framework for Simulating Granular Material with High

Detail. Computers&Graphics.37(7):800-808

Libersky, L.D., Petschek, A.G. (1990). Smooth Particle

Hydrodynamics with Strength of Materials, Advances

in the Free Lagrange Method. Lecture Notes in Physics.

Vol. 395. pp. 248–257. doi:10.1007/3-540-54960-

9_58. ISBN 978-3-540-54960-4.

Libersky, L.D., Petschek, A.G. Carney, T.C. Hipp, J.R.

Allahdadi, High, F.A (1993). Strain Lagrangian

hydrodynamics: a three-dimensional SPH code for

dynamic material response. J. Comput. Phys. 109 (1):

67–75. Bibcode:1993JCoPh.109...67L. doi:10.1006/

jcph.1993.1199.

Das, R., Cleary, P.W. (2010). Application of SPH for

modelling heat transfer and residual stress generation in

arc welding. Material Science Forum. 654-656.

Eivani, A.R., Vafaeenezhad, H., Jafarian, H.R., Zhou & J.

(2021). A novel approach to determine residual stress

field during FSW of AZ91 Mg alloy using combined

smoothed particle hydrodynamics/neuro-fuzzy

computations and ultrasonic testing. Journal of

Magnesium and Alloys, 9(4),1304-1328.

Ghaïtanellis, A., Violeau, D., Ferrand,M., Abderrezzak,

K.A.K., Leroy, A., Joly, A. (2018) A SPH elastic-

viscoplastic model for granular flows and bed-load

transport. Advances in Water Resources, Volume 111,

p. 156-173.

Holmes, D.W., Williams, J.R., Tilke, P., Leonardi, C.R..

(2016). Characterizing flow in oil reservoir rock using

SPH: absolute permeability. Computational Particle

Mechanics. Volume 3, pages141–154

Koschier, D., Bender, J., Solenthaler, B. and Teschner, M.

(2022), A Survey on SPH Methods in Computer

Graphics. Computer Graphics Forum, 41: 737-760.

https://doi.org/10.1111/cgf.14508

Liu, Z., Xiu, L., Wu, J., Lv, G. & Ma, J. (2019). Numerical

simulation on residual stress eliminated by shot peening

using SPH method. Fusion Engineering and Design,

147, doi.org/10.1016/j.fusengdes.2019.06.004.

Nguyen, C.T., Nguyen, C.T., Bui, H.H. et al. (2017). A new

SPH-based approach to simulation of granular flows

using viscous damping and stress regularisation.

Landslides 14, 69–81. https://doi.org/10.1007/s10346-

016-0681-y

Saleh, M., Luzin, V. & Spencer, K. (2014). Analysis of the

residual stress and bonding mechanism in the cold

spray technique using experimental and numerical

methods. Surface and Coatings Technology, 252, 15-

28.

Pan, K., IJzermans, R.H.A., Jones, B.D., Thyagarajan, A.,

van Beest, B.W.H. & Williams, J.R. (2016).

Application of the SPH method to solitary wave impact

on an offshore platform. Computational Part. Mech., 3,

155-166.

Holmes, D.W., Williams, J.R., Tilke, P. & Leonardi, C.R..

(2016). Characterizing flow in oil reservoir rock using

SPH: absolute permeability. Computational Part.

Mech., 3, 141-154.

Müller M., Charypar D., Gross M.(2003) Particle based

fluid simulation for interactive applications. In

SCA’03: Proceedings of the 2003 ACM SIGGRAPH

/Eurographics symposium on Computer animation

(Aire-la-Ville, Switzerland, Switzerland, 2003),

Eurographics Association, pp. 154–159. 2, 3, 4.

Colour-Field Based Particle Categorization for Residual Stress Detection and Reduction in Solid SPH Simulations

241