Towards a Fleet of Autonomous Haul-Dump Vehicles in Hybrid Mines

Alexander Ferrein

a

, Michael Reke

b

, Ingrid Scholl, Benjamin Decker, Nicolas Limpert,

Gjorgji Nikolovski

c

, and Stefan Schiffer

d

Mobile Autonomous Systems and Cognitive Robotics Institute (MASCOR),

FH Aachen University of Applied Sciences, Aachen, Germany

Keywords:

Automation, Mining, Control, Autonomous Fleet, Object Detection, Planning, Robotics, Semantic Mapping.

Abstract:

Like many industries, the mining industry is facing major transformations towards more sustainable and de-

carbonised operations with smaller environmental footprints. Even though the mining industry, in general, is

quite conservative, key drivers for future developments are digitalisation and automation. Another direction

forward is to mine deeper and reduce the mine footprint at the surface. This leads to so-called hybrid mines,

where part of the operation is open pit, and part of the mining takes place underground. In this paper, we

present our approach to running a fleet of autonomous hauling vehicles suitable for hybrid mining operations.

We present a ROS 2-based architecture for running the vehicles. The fleet of currently three vehicles is con-

trolled by a SHOP3-based planner which dispatches missions to the vehicles. The basic actions of the vehicles

are realised as behaviour trees in ROS 2. We used a deep learning network for detection and classification

of mining objects trained with a mixing of synthetic and real world training images. In a life-long mapping

approach, we define lanelets and show their integration into HD maps. We demonstrate a proof-of-concept of

the vehicles in operation in simulation and in real-world experiments in a gravel pit.

1 INTRODUCTION

In the future, the European raw materials industry will

undergo an increasing change from open pit mining

to underground mining. Digitalisation and automa-

tion are keys for further transforming mining oper-

ations into a decarbonised and more sustainable op-

erations (see, e.g. (Batterham, 2017; Sánchez and

Hartlieb, 2020; Clausen and Sörensen, 2022)). This

transition usually requires big investment on the part

of the operator to upgrade the entire infrastructure

(e.g. crusher and conveyor system) from surface to

underground. The requirement to lower the surface

footprint means that the mining operation will go un-

derground. This leads to hybrid mining operations,

where parts of the mine are still open pit and parts are

underground mines. Already today, especially in the

stone and earth industry, some raw materials mining

companies are already using a hybrid mode of oper-

ation and are deploying their machinery both under

and above ground.

a

https://orcid.org/0000-0002-0643-5422

b

https://orcid.org/0000-0002-4209-8574

c

https://orcid.org/0000-0002-6009-8148

d

https://orcid.org/0000-0003-1343-7140

An autonomous system, suitable for both under-

ground and surface operation, would be able to carry

out transport and unloading processes around the

clock under the most difficult conditions. This also

enables a continuous production process, while in-

juries could be significantly reduced. Accordingly,

mining companies are increasingly seeking to use au-

tonomous machines (see, e.g. (Petty, 2017)) for the

extraction of raw materials. Autonomous machinery

embeds intelligence into mining machines so that they

are more efficient, self-correcting, safer, and more

connected. Especially in times of skilled labor short-

ages, this can also free up personnel from everyday

tasks. They can, hence, focus on observing the sys-

tem as a whole.

Autonomous mining machines offer three key

benefits: (1) Machines can be deployed with longer

daily working hours; (2) they continuously deliver

consistent results, regardless of time, to increase ef-

ficiency and productivity while also improving safety

of employees if operating in a 24/7 mode; (3) through

the use of an autonomous fleet and a system-wide

and even cross-system optimization, the economic ef-

ficiency of raw material extraction will be increased,

accident rates can be reduced and a continuous pro-

278

Ferrein, A., Reke, M., Scholl, I., Decker, B., Limpert, N., Nikolovski, G. and Schiffer, S.

Towards a Fleet of Autonomous Haul-Dump Vehicles in Hybrid Mines.

DOI: 10.5220/0011693600003393

In Proceedings of the 15th International Conference on Agents and Artificial Intelligence (ICAART 2023) - Volume 1, pages 278-288

ISBN: 978-989-758-623-1; ISSN: 2184-433X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

duction process around the clock can be implemented.

In this paper we report on our steps towards these

goals. Continuing our efforts of automating mine op-

erations in a previous project on site exploration and

mapping (Ferrein et al., 2019; Donner et al., 2019),

we here present the ongoing work on a fleet of three

dumper vehicles suitable for autonomous hauling op-

erations in hybrid mines.

The contribution is threefold. First, we cre-

ated and realized a vehicle setup that allows for au-

tonomous operation and we established a software

architecture for the vehicle based on version two

of the Robot Operating System (ROS) (Reke et al.,

2020)(Macenski et al., 2022). Second, we developed

and integrated a high-level control component for the

vehicles as well as an overall fleet management sys-

tem. This includes coordination planning for multi-

vehicle situations. Third, we integrate semantic 3D

mapping and a life-long mapping approach to contin-

uously monitor the environment and update the sys-

tem’s representation accordingly.

2 BACKGROUND AND RELATED

WORK

Compared to autonomously driving road vehicles and

autonomously acting robotic vehicles, autonomous

dump trucks are an application that is right in between

in several ways. The differences lie in the following:

• speed: With a maximum speed of dump trucks in

the range of 20-30 km/h, the application is signif-

icantly higher than robotic vehicles but also still

well below the maximum speed of road traffic.

• routes: In the area of surface and underground

mines, traffic mostly takes place on defined

paths. However, these paths cannot be compared

with a well-developed and sign-posted road net-

work. The paths are also not completely arbitrary,

though, as it is the case with many robotic vehi-

cles.

• vehicles: Although the vehicles have an Ack-

ermann 4-wheel kinematics (Delrobaei and

McIsaac, 2011), they are still special because they

have articulated steering. Robotic vehicles, on the

other hand, many times are able to turn on the

spot. This is because they mostly feature direct

electric drives, and no gear ratios need to be cho-

sen and stepless switching between forward and

reverse is possible.

For the design and realization of the hardware and

software architecture for the vehicles we face mixed

implications. Due to the similarities in approaches

for road vehicles and robot vehicles, some ideas can

be adopted. However, due to the differences in many

areas other solutions and extensions to existing tech-

nology have to be found.

Irrespective of the current standardization efforts

of the industry, ROS is often used in the development

of control systems for autonomous driving vehicles

(cf. e.g. (Aeberhard, 2015)). The reason for this is,

on the one hand, the flexible architecture, in which

it is possible to compute many functions in parallel

nodes and on the other hand the availability of help-

ful development tools like RViz for visualization or

different simulators. Particularly promising for au-

tonomous driving are the new functions provided by

ROS 2

1

offers, such as the real-time communication

via DDS and a real-time capable multithreading de-

sign. In the field of self-driving car software, some

systems have already been ported to ROS 2. Exam-

ples are Apollo

2

and Autoware

3

. In our own previ-

ous work, we also proposed a ROS 2-based system

architecture for self-driving cars (Reke et al., 2020).

Life-long mapping approaches aim to detect dynamic

changes in the environment and adapt local environ-

ment maps to these changes. For this purpose, seman-

tically enriched maps have been successfully used

in robotics, both indoors and outdoors (Lang et al.,

2014). Semantic object recognition and classification

is usually acquired continuously in time using convo-

lutional neural networks (Qi et al., 2017). With simul-

taneous localization and mapping approaches (Tipaldi

et al., 2013), the detected object and localization data

can be registered and integrated with the environment

map (Rosen et al., 2016).

3 VEHICLE SETUP AND

SOFTWARE ARCHITECTURE

The software architecture we present is an adaptable

model-based specification we use on multiple auto-

mated vehicles. It is based on an architecture de-

sign which has been used for self-driving vehicles

with Ackermann steering proposed in our previous

work (Reke et al., 2020). As the architecture does

not make specific assumptions about the vehicle type,

it was particularly easy to adopt the software archi-

tecture to the articulated dump vehicles used in this

work.

1

https://design.ROS2.org/. For an overview on the

ROS 2 performance also see (Maruyama et al., 2016).

2

https://www.apollo.auto/

3

https://www.autoware.auto/

Towards a Fleet of Autonomous Haul-Dump Vehicles in Hybrid Mines

279

Figure 1: Picture of one of the articulated haul-dumpers at

the test site.

3.1 Hardware

The base vehicle we use is an articulated haul-dumper

by the company Wacker Neuson (Model 1501).

4

Our

fleet consists of three of those vehicles. Figure 1

shows an examplary prototype. The model we se-

lected is designed for smaller loads of only 1.5 tons.

It is human-operated through a steering wheel, ped-

als for the brake and throttle and levers to control the

skip movement. The control of the brakes and the an-

gle of the articulated joint of the vehicle is realized by

a hydraulic system, which depends on the hydraulic

pressure generated by a diesel engine. To automate

the vehicle, we have installed electric linear actuators

to control the brake and the throttle. Additionally we

attached a rotational servo-motor to the steering-axis

and the manual valves by electromagnetic valves to

control the skip. We also installed hall-sensors on

each wheel to obtain information on the vehicle state.

The control system is subdivided into different

hardware components as can be seen in Figure 2.

These parts are presented in the following.

Real-Time Controller. The control unit we use in

the vehicle to process the signals to control the elec-

tric motors and the feedback signals from installed

sensors, is a programmable logic controller (PLC) by

Beckhoff. To transfer information to and from the

PLC we utilise CAN. The PLC serves as a message

filter, that prevents unsafe commands to be propa-

gated to the motors, and kill-switch manager. For

safety there are multiple kill-switches on the vehi-

cle as well as one radio kill-switch. In addition the

PLC serves as a PID-controller regulating the angle

of the articulated joint and the engine speed by prop-

erly actuating the motor moving the steering axis and

4

https://www.wackerneuson.de/produkte/dumper/

raddumper/raddumper-1501/

Figure 2: System architecture of haul-dumper control sys-

tem.

the motor opening and closing the throttle valve. For

more detail, we refer to (Sürken, 2021).

Compute Nodes. As described below, we use a

CUDA-based model-predictive path-follower as well

as high level control and computer vision algorithms.

These algorithms run on two dedicated compute de-

vices. We make use of a Zotac ZBOX Magnus One

to run the path-follower, high-level control, and se-

mantic and life-long mapping algorithms. In addition,

we deploy an Nvidia Drive AGX Xavier that runs the

computer vision tasks. The AGX interfaces directly

with high-bandwidth sensors such as the cameras and

directly processes them. Both compute devices run a

linux-based operating system with no modifications

to obtain deterministic time execution of the tasks

running on the devices.

Sensors. Our main localization hardware is an

OxTS RT3000v3 dGPS on one unit and two OxTS

xNav650 on the remaining two units. Each dGPS con-

tains an inertial measurement unit. As vision sensors

we utilise two VLP-16 Lidars and six cameras using

gigabit multimedia serial link transport (abbreviated

to GMSL cameras).

3.2 Software Architecture

Our software architecture features a modular design

(Reke et al., 2020) separating the task of automa-

tion into encapsulated nodes that each solve a specific

problem. The software components communicate

with each other where appropriate based on ROS 2

publisher / subscriber communication along with ser-

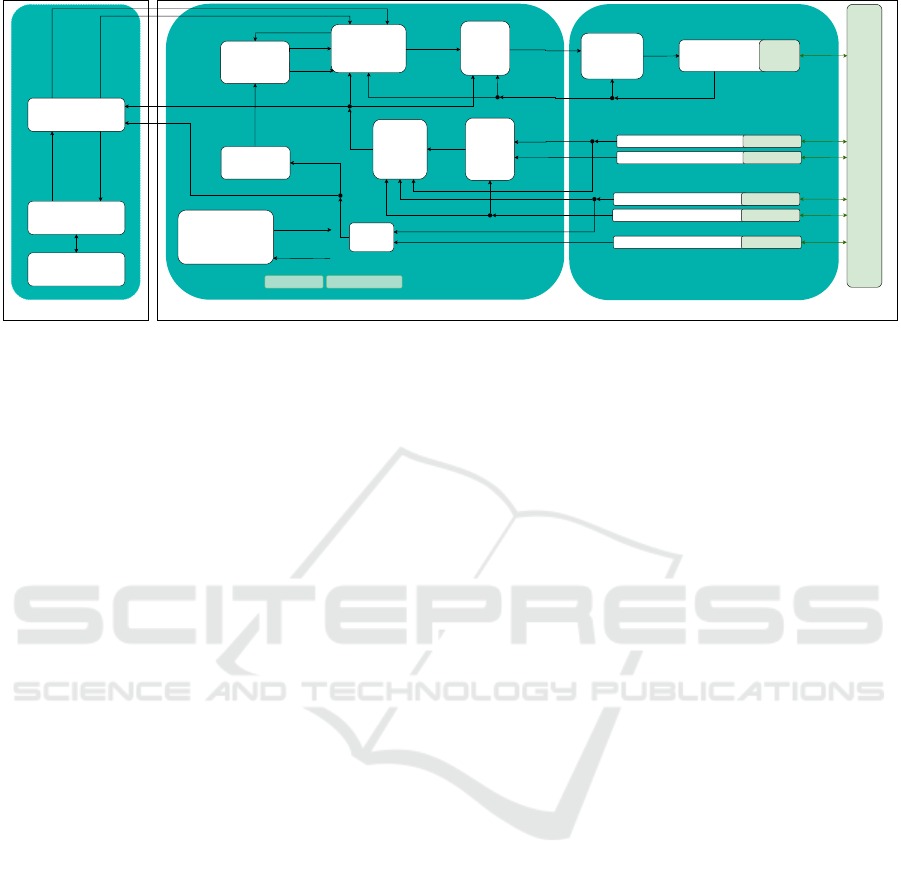

vices. Figure 3 shows an overview of our architecture.

We use concepts and approaches of other projects

commonly used in ROS such as Navigation2 (Macen-

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

280

Vehicle-unspecific

Behaviour

Planning

(BehaviourTree,

Monitoring)

Vehicle & Sensor-specific

Coordinator

(NodesStates

Monitoring, Lifecycle

Management)

Global Route

Planning

(Lanelet2 /

Smac)

CAM (Driver, Detection) HW - Driver

Object Lists (dynamic, free space)

Object Lists (dynamic)

Global

path

MAP/HD-MAP Node Parameters Data:

Dumper

High Level Control

Goal

Maneuver

List

global

path

Node

transition

(every Node)

SHOP Planer

(Fleet Management)

RVIZ Visualisation

Lanelet / Position /

Obstacles

Action

Node status

(every Node)

Status

Base Station

Dumper 1 .. X

Pose

Path

Control

(MPC)

velocity

control

Localization

(UKF

Global)

ROS2Dumper

Vehicle

Control

(Veh.)

ROS2Dumper

Vehicle Interface

(Veh.)

HW -

Driver

Wheelencoder (Odom)

Lidar (Environment detection)

GPS (Driver)

IMU (Driver)

HW - Driver

HW - Driver

Vehicle

CMDs

Actual steering

angle, speed

Target

steering

angle,

speed

filtered

Pose

GPS Data

IMU Data

HW - Driver

HW - Driver

Localization

(UKF Local)

filt.

global

Position

Goal

Action

Feedback

Actual steering

angle, speed

Object

List

Live-Long-

Mapping

map

updates

Objects/Obstacle

Pose

Odometry

IMU Data

Figure 3: Diagram of the software architecture.

ski et al., 2020) and robot_localization (Moore and

Stouch, 2014).

Centralized Mission Management Block. At the

top-most level in the hierarchy of decision making

and control of the fleet is the high-level control block.

Given a daily goal defined by the operator the high-

level task is to generate plans consisting of hierarchi-

cally ordered actions. The action plans are generated

using SHOP3 (Goldman and Kuter, 2019). The fleet

manager module then takes care of dispatching the ac-

tions in the plans rendered by SHOP 3. During exe-

cution a world model is updated given the positions

of the trucks and their currently locked resources, the

status of the excavators and how much tonnage has

been hauled. In case major discrepancies to the previ-

ous plan occur a re-planning is initiated.

Vehicle Unspecific Block.

The separation of concerns into local and global

localization is inspired by the implementation of

robot-localization (Moore and Stouch, 2014). The

global localization filters signals of sensors deliver-

ing predominantly discrete information on the posi-

tion of the vehicle in a global coordinate frame such

as the Universal Transverse Mercator (UTM). In con-

trast, the local localization filters mostly signals from

sensors delivering continuous differential information

on the vehicle, which can be then integrated to esti-

mate the state of the vehicle. The global route plan-

ner is either a free-space planner or an HD-Map-based

planner that generates paths, that the path-follower

has to follow. The path-follower is a controller, that

keeps the vehicle on track of the global route and

gives feedback on the success of following the given

path. (Pivtoraiko et al., 2007; Limpert et al., 2015)

As path-follower we use a model-predictive controller

which uses a CUDA-based grid-search on a set of

predicted trajectories achievable by the vehicles kine-

matic model. It is a modified version of the model-

predictive control (MPC) presented by (Chajan et al.,

2021). The behaviour planning module coordinates

the execution of tasks prescribed by the fleet (or mis-

sion) management.

The life-long mapping module consists of soft-

ware that updates the map which is used as basis for

the global route-planner to crate routes. In our case

the maps used for navigation consist of HD-maps in

the Lanelet2 format (Poggenhans et al., 2018a).

Vehicle Specific Block. The vehicle specific

block mostly consists of drivers and vehicle commu-

nication modules.

The drivers are for cameras, inertial measurement

units (IMUs), GPS-units, LiDARs and Wheel en-

coders. It is essential to notice, that vision systems

such as cameras or LiDARs should implement detec-

tion closely coupled to the driver. The fusion of de-

tected objects is optional according to our architecture

design, but if fused, a late-fusion approach is the pre-

ferred method. We have implemented an object detec-

tion with cameras using YOLOv5 to aid in the seman-

tic and life-long mapping. We also implemented a

modular way of integrating state-of-the-art deep neu-

ral networks for 3D object detection in point-clouds.

The detailed presentation of the latter is part of previ-

ous work presented in (Nikolovski et al., 2021).

All modules in both the vehicle-specific and un-

specific blocks run on each vehicle in the fleet.

Currently, the architecture is implemented using the

ROS 2 middleware. Communication between the

modules and the centralized high-level control is pro-

vided by Cyclone DDS on a shared network.

Towards a Fleet of Autonomous Haul-Dump Vehicles in Hybrid Mines

281

4 HIGH-LEVEL CONTROL AND

FLEET MANAGEMENT

A common scenario at the mission level for open pit

or underground mining activities is that the ore is be-

ing mined at some mining face and it is then being

loaded by an excavator to a hauling vehicle. This

vehicle transports the material to a so-called crusher

which further grinds the material. So, for coordinat-

ing a fleet of autonomous hauling vehicles the typi-

cal actions are: drive to the excavator, load the mate-

rial, drive to the crusher and unload. For controlling

our hauling vehicles, we deployed the SHOP 3 plan-

ner (Goldman and Kuter, 2019). With this planner, a

day-plan was created taking into account the respec-

tive resources contraints such as number of availabe

vehicles, tonnages etc. The sub-tasks were communi-

cated to the different vehicles as ROS 2 actions. Each

action was implemented as a behaviour tree in ROS 2.

In addition, we make use of a separate lock-broker to

manage the locking of resources.

4.1 World Model

The system features a world model that is continu-

ously updated. It consists of the environmental re-

sources and the total tonnage to be hauled and it

is used as the problem definition to be used with

SHOP 3. The resources comprise of the trucks

and excavators with their activity level, the positions

along with path segments that are either occupied or

traversable. The latter is later used for navigation pur-

poses for egocentric path planning within multiple ve-

hicles. To represent the path segments as static re-

sources within the world model and traversable parts

we use Lanelet2 (Poggenhans et al., 2018b). The nav-

igation graph in Lanelet2 represents discrete lanelets

consisting of global navigation system (GNS) posi-

tions. We focus on the plain paths and area represen-

tations with no further traffic rules or velocity lim-

itations. A lanelet is considered a resource that is

either occupied or traversable. The area representa-

tion of Lanelet2 is used to provide lockable resources

to the planning system. Examples are areas that are

maintained by an excavator which then should only be

used by one truck at the same time for safety reasons.

The identifications of lanelets are used as discrete re-

sources which are only to be used by one truck at the

same time. The excavators are considered to stay at

one position during the shift that is considered to be

the time window of the planning.

4.2 High-Level Task Planning with

Behavior Trees

The tasks to fulfill from the high-level planning per-

spective require abstraction of the actions that the

platform can perform. The high-level planning should

be able to send actions which do not take low-level

properties of the vehicle into account (such as lat-

eral acceleration). Therefore the high-level planning

has the following actions defined in the domain de-

scription: DRIVE - Bring the vehicle to a desired goal

lanelet; LOAD - Issue a loading action close to an ex-

cavator; UNLOAD - Unload the material into a crusher;

QUEUING - Wait at the current position for a certain

amount of time. The plan generated by the SHOP 3

planner is read by the dispatcher which keeps track

of the actions dispatched to the vehicles. During the

execution the dispatcher receives feedback from the

executing ROS node that hosts the action server. This

also gives the opportunity to decide to cancel the run-

ning action. On the vehicle side the action servers

consist of behavior trees following encapsulated be-

haviors in order to fulfill the respective action. A

prominent example is the DRIVE action as defined in a

behavior tree which, from a conceptual point of view

adheres to the following scheme:

1. Compute a route to the desired goal lanelet given

the Lanelet2 library and the static map defining

the environment

2. In case a route was successfully found forward

this path to our model predictive controller to fol-

low the path

3. Finalize the motion once the goal is reached

4. During the motion the velocity commands are val-

idated for lead to collision free motion. In case

a collision would occur the MPC is instructed to

stop and the DRIVE action is considered to fail

The DRIVE behaviour also includes a locking mecha-

nism for path segments (junctions, one way roads).

A resource broker is in charge for overseeing the

locks and giving permissions to cross path segments.

For more information on this, we refer to (Mühlens,

2021).

Static routes do not cover navigation with dy-

namic obstacles. For local obstacle passing we fol-

low an alternative route planning method which takes

local obstacles into account. The strategy of the be-

havior tree is to find a follow-up point that leads back

to the static route. Ideally, the LOAD action issues

the truck to end up being fully loaded and ready for

the next DRIVE actions regularly followed by UNLOAD.

Similar to the local resource handling to pass junc-

tions, the LOAD and UNLOAD actions require proper

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

282

negotiation between the trucks and the excavator or

crusher. Controlled by queues, trucks have to be

loaded one after another in case of multiple trucks

queuing at the loading point. The loading queue is

controlled by the excavator which instructs the trucks

to move from their queuing position to either the next

point in queue or to the final loading pose. The

UNLOAD action behaves similarly - given the fact that

a crusher point can usually only be used by one truck

at a time.

4.3 Fleet Level Planning with SHOP3

Individual mining sites require custom optimization

criteria from the planning perspective and the scope

of the remaining time of the current shift. In some

cases a meaningful heuristic is to aim for minimizing

the waiting time of trucks or excavators while other

situations require the minimization of the cycle time

or the shovel saturation. With the world model known

a priori, trucks, excavators, and crushers along with a

routing graph are coordinated to respect optimization

criteria. In its original form, SHOP 3 does not support

planning with temporal aspects. To overcome this, we

added times as additional properties.

4.4 Machine-to-Machine Resource

Locking

The characteristics of large open cast and under-

ground mining sites prevent reliable global communi-

cation between all participating entities. The systems

thus have to be able to locally negotiate with each

other in order to execute the action. Instead of coordi-

nating the orders in which vehicles pass junctions the

global fleet management has to coordinate the global

environment. Lanelet segments being resources can

therefore also be used to queue up vehicles along the

way by considering that each lanelet segment can only

be occupied by one vehicle at a time. As a result,

basic physical computing instances host the queues

required to lock and unlock the respective resources

close to the actual resource (i.e. lanelet segments).

5 SEMANTIC AND LIFE-LONG

MAPPING

The semantic and life-long mapping in our project

consists of four parts: the object detection and clas-

sification of static and dynamic objects, the localiza-

tion of static objects in a global coordinate system,

and the (continuous) integration of these information

(a) Virtual reality world with relevant 3D mod-

els.

(b) Simulated image. (c) Labeled image.

Figure 4: Virtual reality world with 3D models created with

Unreal Engine 5 to get annotated training data from simu-

lated driving.

into an HD-Map. The following sections explain the

four parts in more detail.

5.1 Object Detection

For object recognition, the deep learning network

YOLOv5 was used to recognize people, beacons for

lane marking, and other vehicles in the mining envi-

ronment. To recognize new objects with the YOLOv5

network, a three-stage training approach was devel-

oped:

1. Creating Synthetic Training Data Set:

Deep Learning networks require millions of pre-

annotated images to recognize objects. To an-

notate all these images manually, especially of

new objects in new environments, is a very time-

consuming and expensive process. To automate

this process, a similar environment to the mining

world, the dumper as well as the beacons were

modeled in 3D and with these models a virtual

world as realistic as possible was created as a sim-

ulation environment using Unreal Engine 5 and

can be seen in Figure 4a. In addition, virtual

cameras from the first-person perspective of the

dumper were integrated into the virtual reality en-

vironment. Through animated virtual driving of

the dumpers, the virtual camera images along with

their annotation can be saved to the hard disk as

annotated data sets, see Figures 4b and 4c. These

annotated image data are the synthetic training

data set for the YOLOv5 network.

2. Image Augmentation Tool:

One problem with synthetically generated data for

Towards a Fleet of Autonomous Haul-Dump Vehicles in Hybrid Mines

283

neural network training is its purity. This means

that the synthetic training images taken in the vir-

tual world should not have any impurities such

as noise or blur. One solution is to subsequently

incorporate these variations into the training im-

ages. For this purpose, we have developed an

image augmentation tool that uses varying pa-

rameters to add noise and modify lighting, sat-

uration, image resolution, and horizontal image

alignment. Using this technique, the synthetic

training data becomes more realistic.

3. Training Data From Real Driving Scenarios:

Image recordings from real drivings were man-

ually annotated and additionally varied with the

image augmentation tool. In this way, a multiple

of the manually annotated image data can be ob-

tained as training data from real image recordings.

The classifier is trained from mixing synthetic im-

ages with real images with 299 epochs of training,

reaching 0.9835 mAP@0.5 and 0.9836 mAP@0.95

based on YOLOv5m. The classifier also reliably de-

tects partially hidden objects. Deployment on the

Nvidia AGX Drive is achieved by converting the

trained classifier from PyTorch to ONNX and then to

TensorRT. The deployed classifier runs on the AGX

Drive with an inference time of about 35 milliseconds.

5.2 Lane Detection

We use the beacons as static objects defining the

boundaries of the navigable roads. With the classi-

fied bounding box we then estimate the 3D position of

the beacons by projecting the mid-point of the lower

bounding-box-boundary to a ground plane using the

extrinsic parameters of the cameras relative to the ve-

hicle center. At last, we obtain the world position of

the beacons by transforming the estimated, vehicle-

relative position into the UTM frame.

5.3 Boundary Matching and Map

Correction

To match the positions of the beacons to a lane

boundary we first filter the position-list created by

the object-detection. Initially, a binning filter down-

samples the positions by averaging the positions

which are close to each other. With this we can re-

duce the effects of measurement noise of the beacon

position. Then we pass the down-sampled through a

logical constraint filter which checks if the interpo-

lation of the new lane-boundary is feasible. After-

wards, we proceed with re-indexing the positions of

the beacons according the current lane boundary. The

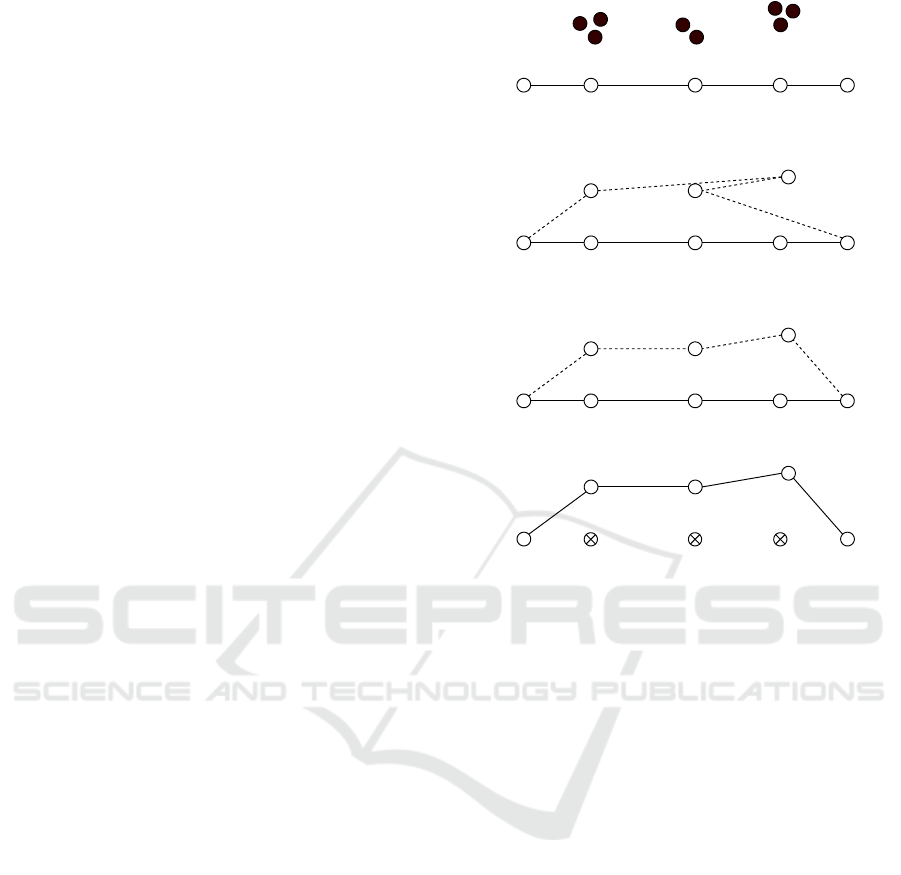

(a) Initial state of the estimate for the beacon

positions (circles with infill) next to the lane

boundary points (circles without infill).

2

31

(b) State after filtering the positions of the bea-

cons. Dotted line denotes the proposition for

the new lane boundary at this point.

3

2

1

(c) State after re-indexing the beacon-position

groups.

3

2

1

(d) In the final stage old points of the lane

boundary are removed and the new lane bound-

ary is created.

Figure 5: State of the lane boundary at the four stages of the

lane boundary correction process.

order of positions is now determined by the medial

distance of each position from a beginning point of a

lane-boundary segment. The beginning point of the

lane boundary segment is the first point in the under-

lying geometric line structure of the lane boundary.

Accordingly the end point of a lane boundary seg-

ment is the last point in the underlying geometric line

structure of the lane boundary. The newly indexed list

of positions then replaces the list of points between

the beginning point and the ending point of the lane

boundary segment. The state of the lane boundary in

each step is depicted in Figure 5.

5.4 LiDAR Map to HD-Map

Our approach of generating an HD-map from a Li-

DAR map consists of six parts: segmenting the navi-

gable ground-segment from the point-cloud, calculat-

ing the concave hull of the navigable ground-segment,

calculating a Voronoi-graph for the concave hull, find-

ing the longest chain of vertices in the Voronoi-

graph (Bhattacharya and Gavrilova, 2007), smooth

the vertices of the chain to make the path-following

easier and convert trajectory described by the pro-

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

284

cessed chain of vertices into a lane. In Figure 6 we

show a visualization of the result of each part. To

extract the ground-segment of the point-cloud map,

we first create an elevation map from the point-cloud

map. From the elevation map we sample a grid of

points uniformly from. We then filter the sample

points with an neighbor-elevation-difference heuris-

tic. If the difference of the elevation of a point to

its direct neighbors is to large, its remove from the

sampled points. It is similar to the implementation

of the simple-morphological filter from (Pingel et al.,

2013). Once the sampled points are filtered, we cal-

culate a two dimensional spanning-polygon by flat-

tening the points to the xy-Plane and estimating their

concave hull with alpha shapes. On the polygon we

apply a Delaunay-triangulation (Musin, 1997). We

then use the graph of the resulting Voronoi-diagram

to estimate the longest chains of vertices that passes

through each part of the point-cloud. After finding

the longest chains of vertices we apply a moving-

average to smooth out the vertices in sections where

the Delauney triangulation created local snaking pat-

tern. Then we take those vertices and form a lane of

fixed width around the path described by the vertices

in each chain.

6 EXPERIMENTAL RESULTS

In the following we present the results we created

throughout our research in terms of quantitative anal-

ysis of certain modules and qualitative observations

on a multi-module level.

Vehicle Automation. The hardware setup we use

has been reliable for the duration of our project.

Throughout our testing we have driven multiple hun-

dreds of hours and have yet to see critical failures

which compromise the whole system. The most com-

mon failure point is the supply of power to the com-

ponents on the vehicle. With the installed PLC and

the overall systems sluggishness due to the underly-

ing hydraulic mechanism, we observe mean 200 ms of

latency from sending a command to the actuators real-

izing the target values. We also observe latency when

using the emergency stops. The time to full stop af-

ter pressing an emergency switch is 1.5 seconds. The

path-following we implemented results in a 0.1 me-

ters mean lateral deviation from path on straight sec-

tions and 0.9 meters mean lateral deviation from path

in curves.

Fleet-Level Planning. We have tested the fleet level

planning in two ways. We have used rough simu-

lations to emulate the work process in a mine and

we have tested its integration to the lower modules

in the architecture. The integration test is described

later. For simulation we created 2 scenarios with dif-

ferent complexities. The first one consists of simple

goals and resources and the second simulates a hybrid

mine with multiple types of resources and outputs. In

each scenario we investigate 4 strategies minimizing

a different heuristic. Strategy one minimizes the idle-

time of all vehicles in a fleet. Strategy two minimizes

the average time a wheel-dumper needs to complete

a load and unload. The third strategy minimizes the

time the wheel-dumpers spend without moving loads.

The last strategy is selecting a plan from a set of ran-

domly generated plans that maximizes the haulage

mass. We simulated a period of 8 hours and observe

accumulation of idle-time and overall haulage mass.

The results can be found in Table 1.

Long-Term Mapping. The functional test we con-

duct to examine the results of our findings in live map-

correction is to manipulate the map manually and ob-

serve the reaction of for example the global route

planner and the vehicle itself. The most frequent sce-

nario tested in this regard is the manipulation of parts

of the lane leading up to the loading-station in the in-

tegration scenario depicted in Figure 7.

Integration Scenario. In an integration test sce-

nario we have unloading and loading stations to pick

up and unload payload. The unloading-heap can be

accessed at two locations while the loading-station is

accessible only from one location. There are two bidi-

rectional lanes leading up to the unloading-heaps ac-

cess locations and only one bidirectional lane leading

up to the loading-stations access location.

The day hauling schedule given to the fleet man-

agement is a sequence of repeated load-unload tasks

for both vehicles. The loading point on the right is

only accessible through one bidirectional lane. We

use this to our advantage to make the loading resource

scarce. It can be locked and occupied by one vehicle

only. The high-level control has to coordinate the ac-

cess of each resource so that no conflicts arise. The

locking of resources is managed by the mission plan-

ning. Each vehicle individually has to try to acquire

the lock on the resource. The first vehicle to reach

the fork in the middle of the traffic network, while

the loading resource is uncontested, receives the lock

on resource and with that blocks the lane leading up

to the resource. If the following vehicle, has to ac-

cess the locked resource it is required to wait until

the fleet management unlocks the resource. In an

eight hour operation it showed that the locking mech-

Towards a Fleet of Autonomous Haul-Dump Vehicles in Hybrid Mines

285

(a) (b) (c) (d) (e) (f)

Figure 6: Processed point-cloud map after each step of the conversion from point-cloud map to HD-map.

Presenta�on at Demonstra�on Day

Integra�on Scenario

Unloading

heap

loader

sta�on

Bidirec�onal

lane locked by

one vehicle

Figure 7: Visualization of the integration scenario, which were presented at a demonstration day.

anism works robustly and the day plan could be im-

plemented by the vehicle fleet.

7 CONCLUSION

Addressing the challenges of hauling in a hybrid un-

derground and open pit mine, we realised a fleet of

three wheel-dumpers. Because of their small turn-

ing radius in mining environments, mainly wheel-

dumpers with articulated kinematics are used.

The daily plan for the complete fleet is automati-

cally generated by a high-level controller. In our ex-

perimental evaluation we generated simple plans for

our small fleet of vehicles. However, in simulation we

could generate plans for up 75 vehicles with different

optimisation goals such as minimizing the idle time of

the vehicles or maximizing the transported tonnage.

From the high-level controller each vehicle gets

its individual plan, which is fulfilled by an on-board

automation system. In our experimental results we

could show, that it is possible to follow a given path

with a precision of below 1 m, which was suitable for

our application. The most negative influence to the

precision is caused by a high system delay of about

200 ms of the steering system. Nevertheless, it was

possible to stay within the given lanes in our experi-

mental environment.

Following their plan, the vehicles move on given

lanes within the mine. But when they detect obstacles,

they autonomously change their given plan. There-

fore we implemented a 2D object detection by cam-

eras and a 3D object detection by LiDARs. We could

show that it is possible to reach high detection rates

(>0.95) even at high frequencies (>20 Hz). Addition-

ally the lane layout of the complete mine is recorded

within a HD map in Lanelet2 format and distributed

to the fleet. But the mine layout changes continuously

by material extraction or accidents. Via our on-board

vision systems we were able to detect these changes

and adapt the map continuously to the new conditions.

Our real-world experimental results in a gravel pit

show in a proof-of-concept that the overall system

works in practice. Next steps are to further develop

the system towards a 24/7 operation.

ACKNOWLEDGEMENTS

This work presented in this paper was funded with

a grant from the German Federal Ministry of Ed-

ucation and Research (BMBF) under grant number

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

286

Table 1: Table on the quantified key performance indices for some of our modules we have researched by now.

Module KPIs

Model Predictive Control

Mean lateral error in curves Mean lateral error on straight section

0.9 [m] 0.1 [m]

System Delays

Mean steering delay Mean engine RPM delay

200 [ms] 100 [ms]

Mission Planning (SHOP3)

Idle-time [min] of fleet after 8 hours in simulation

Senario Name Number of vehicles simulated Strategy 1 Strategy 2 Strategy 3 Strategy 4

Simulation Scenario 1 75 25782 26096 26046 25938

Simulation Scenario 2 40 2093 5343 3512 3084

Overall hauled ressources [t]

Scenario Name Number of vehicles simulated Strategy 1 Strategy 2 Strategy 3 Strategy 4

Simulation Scenario 1 75 18550 18550 18550 18550

Simulation Scenario 2 40 13865 12685 13080 10305

Object Detection

Model mAP@0.5 Person mAP@0.5 Wheel-dumper mAP@0.5 Car mAP@0.5 Beacon Detection Frequency [hz]

PointPillar (3D)* 0.34 0.4 0.4 - 20

YOLOv5m (2D) 0.994 0.978 - 0.966 30

033R126CN.

REFERENCES

Aeberhard, M. (2015). Automated Driving with ROS at

BMW. In ROSCon Hamburg.

Batterham, R. (2017). The mine of the future – even more

sustainable. Minerals Engineering, 107:2–7. Sustain-

able Minerals.

Bhattacharya, P. and Gavrilova, M. L. (2007). Voronoi di-

agram in optimal path planning. In 4th International

Symposium on Voronoi Diagrams in Science and En-

gineering (ISVD 2007), pages 38–47.

Chajan, E., Schulte-Tigges, J., Reke, M., Ferrein, A., Math-

eis, D., and Walter, T. (2021). Gpu based model-

predictive path control for self-driving vehicles. In

2021 IEEE Intelligent Vehicles Symposium (IV), pages

1243–1248.

Clausen, E. and Sörensen, A. (2022). Required and desired:

breakthroughs for future-proofing mineral and metal

extraction. Mineral Economics, 35(3):521–537.

Delrobaei, M. and McIsaac, K. A. (2011). Design and steer-

ing control of a center-articulated mobile robot mod-

ule. Journal of Robotics, 2011.

Donner, R., Rabel, M., Scholl, I., Ferrein, A., Donner,

M., Geier, A., John, A., Köhler, C., and Varga, S.

(2019). Die Extraktion bergbaulich relevanter Merk-

male aus 3D-Punktwolken eines untertagetauglichen

mobilen Multisensorsystems.

Ferrein, A., Scholl, I., Neumann, T., Krückel, K., and Schif-

fer, S. (2019). A System for Continuous Underground

Site Mapping and Exploration. In Reyhanoglu, M.

and Cubber, G. D., editors, Unmanned Robotic Sys-

tems and Applications, chapter 4. IntechOpen, Rijeka.

Goldman, R. P. and Kuter, U. (2019). Hierarchical task net-

work planning in common lisp: the case of shop3. In

ELS, pages 73–80.

Lang, D., Friedmann, S., Häselich, M., and Paulus, D.

(2014). Definition of semantic maps for outdoor

robotic tasks. In 2014 IEEE International Conference

on Robotics and Biomimetics (ROBIO 2014), pages

2547–2552.

Limpert, N., Schiffer, S., and Ferrein, A. (2015). A local

planner for ackermann-driven vehicles in ros sbpl. In

2015 Pattern Recognition Association of South Africa

and Robotics and Mechatronics International Confer-

ence (PRASA-RobMech), pages 172–177. IEEE.

Macenski, S., Foote, T., Gerkey, B., Lalancette, C., and

Woodall, W. (2022). Robot operating system 2: De-

sign, architecture, and uses in the wild. Science

Robotics, 7(66):eabm6074.

Macenski, S., Martin, F., White, R., and Ginés Clavero, J.

(2020). The marathon 2: A navigation system. In

2020 IEEE/RSJ International Conference on Intelli-

gent Robots and Systems (IROS).

Maruyama, Y., Kato, S., and Azumi, T. (2016). Ex-

ploring the performance of ros2. In Proceedings of

the 13th International Conference on Embedded Soft-

ware, pages 1–10.

Moore, T. and Stouch, D. (2014). A generalized extended

kalman filter implementation for the robot operating

system. In Proceedings of the 13th International Con-

ference on Intelligent Autonomous Systems (IAS-13).

Springer.

Mühlens, L. (2021). A Behaviour Engine for an Au-

tonomous Mining Vehicle in ROS. Bachelor’s thesis,

FH Aachen University of Applied Sciences.

Musin, O. R. (1997). Properties of the delaunay triangula-

tion. In Proceedings of the thirteenth annual sympo-

sium on Computational geometry, pages 424–426.

Nikolovski, G., Reke, M., Elsen, I., and Schiffer, S. (2021).

Machine learning based 3D object detection for navi-

gation in unstructured environments. In IEEE Intelli-

gent Vehicles Symposium Workshops, IV 2021, pages

236–242. IEEE.

Petty, J. (2017). Getting the best out of autonomous mining

fleets. AusIMM Bulletin, (Dec 2017):58–62.

Pingel, T. J., Clarke, K. C., and McBride, W. A. (2013). An

improved simple morphological filter for the terrain

classification of airborne lidar data. ISPRS Journal of

Photogrammetry and Remote Sensing, 77:21–30.

Pivtoraiko, M., Knepper, R. A., and Kelly, A. (2007). Op-

timal, smooth, nonholonomic mobile robot motion

planning in state lattices. Robotics Institute, Carnegie

Mellon University, Pittsburgh, PA, Tech. Rep. CMU-

RI-TR-07-15.

Poggenhans, F., Pauls, J.-H., Janosovits, J., Orf, S., Nau-

mann, M., Kuhnt, F., and Mayr, M. (2018a). Lanelet2:

A high-definition map framework for the future of

Towards a Fleet of Autonomous Haul-Dump Vehicles in Hybrid Mines

287

automated driving. In 2018 21st International Con-

ference on Intelligent Transportation Systems (ITSC),

pages 1672–1679.

Poggenhans, F., Pauls, J.-H., Janosovits, J., Orf, S., Nau-

mann, M., Kuhnt, F., and Mayr, M. (2018b). Lanelet2:

A high-definition map framework for the future of

automated driving. In 2018 21st international con-

ference on intelligent transportation systems (ITSC),

pages 1672–1679. IEEE.

Qi, C. R., Su, H., Mo, K., and Guibas, L. J. (2017). Point-

Net: Deep Learning on Point Sets for 3D Classifica-

tion and Segmentation. In The IEEE Conference on

Computer Vision and Pattern Recognition (CVPR).

Reke, M., Peter, D., Schulte-Tigges, J., Schiffer, S., Fer-

rein, A., Walter, T., and Matheis, D. (2020). A Self-

Driving Car Architecture in ROS2. In 2020 Interna-

tional SAUPEC/RobMech/PRASA Conference, pages

1–6. IEEE.

Rosen, D. M., Mason, J., and Leonard, J. J. (2016). Towards

lifelong feature-based mapping in semi-static environ-

ments. In 2016 IEEE International Conference on

Robotics and Automation (ICRA), pages 1063–1070.

Sánchez, F. and Hartlieb, P. (2020). Innovation in the min-

ing industry: Technological trends and a case study of

the challenges of disruptive innovation. Mining, Met-

allurgy & Exploration, 37(5):1385–1399.

Sürken, D. (2021). Programmierung einer Basisautoma-

tisierung für eine Wacker Neuson 1501 Modellmulde.

Bachelor’s thesis, FH Aachen University of Applied

Sciences. in German.

Tipaldi, G. D., Meyer-Delius, D., and Burgard, W.

(2013). Lifelong localization in changing environ-

ments. The International Journal of Robotics Re-

search, 32(14):1662–1678.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

288