Design and Manufacturing of Microtextured Patient-Specific

Coronary Stent

Francisco Franco-Martínez

1a

, William Solórzano-Requejo

1, 2 b

, Alejandro de Blas-de Miguel

1c

,

Matthias Vostatek

3

, Christian Grasl

3,4

, Marta Bonora

3d

, Francesco Moscato

3,4,5 e

and Andrés Díaz Lantada

1f

1

ETSI Industriales, Universidad Politécnica de Madrid, Madrid, Spain

2

Department of Mechanical and Electrical Engineering, Universidad de Piura, Piura, Peru

3

Center for Medical Physics and Biomedical Engineering, Medical University of Vienna, Vienna, Austria

4

Ludwig Boltzmann Institute for Cardiovascular Research, Vienna, Austria

5

Austrian Cluster for Tissue Regeneration, Vienna, Austria

Keywords: Metasurfaces, Metamaterials, Additive Manufacturing, Coronary Artery Disease, Personalized Medicine.

Abstract: Currently, the most usual treatment for coronary artery disease is the use of stents, which are produced with

standard dimensions and shapes and the surgeon selects the one that best fits the patient’s anatomy. Due to

this treatment, likelihood of restenosis might reach 40%. Additionally, thrombi formation is an important risk

for these patients that is treated with anticoagulant medicines. Therefore, a design and manufacturing method

to produce microtextured patient-specific coronary stent is developed with the aim to minimize the likelihood

of restenosis and thrombosis. Stents consisting of unit cells structures that are regularly repeated to form a

ring and, sometimes connectors to join the rings. To improve the fitting between artery and stent, parametric

design of unit cell as a function of the length and mean radius of coronary artery is required. Then, the unit

cell is microtextured to improve hemocompatibility using a bioinspired design in shark skin, which provide

superhydrophobicity, drag reduction and oleophobicity under water conditions. Once the unit cell is

micropatterned, a reverse engineering reconstruction is done to obtain the stent model. Finally, the design is

manufactured with a 3D printer using two-photon polymerisation technology. SEM is used to evaluate the

design and manufacturing method.

1 INTRODUCTION

Coronary artery disease is a major cause of mortality

and morbidity (Ho et al., 2016), each year causes 3.9

million deaths in Europe and is estimated to cost the

European Union €210 billion per year (CVD

Statistics, n.d.). It occurs when fat, calcium and

cellular debris accumulate in the artery wall blocking

blood flow and causing an inadequate supply of

oxygen and nutrients to the myocardium; resulting in

infarction, cerebral hemorrhage, or ischemic stroke

a

https://orcid.org/0000-0002-7894-7478

b

https://orcid.org/0000-0002-2989-9166

c

https://orcid.org/0000-0003-2375-8327

d

https://orcid.org/0000-0003-3667-0965

e

https://orcid.org/0000-0003-0279-6615

f

https://orcid.org/0000-0002-0358-9186

(Pan et al., 2021). The most popular treatment is

coronary angioplasty (CA), (Ho et al., 2016; Canfield

& Totary-Jain, 2018). CA is a minimal invasive

procedure used to expand the blood vessels and

restore the function of the cardiovascular system by

inserting a stent inside it. Constructively, coronary

stents are small, complex, hollow and cylindrical-

shaped tubes consisting of unit cells structures that

are regularly repeated to form a ring; the ring, a group

of unit cells that are held together; and the connectors,

which join rings to build the stent.

142

Franco-Martínez, F., Solórzano-Requejo, W., de Blas-de Miguel, A., Vostatek, M., Grasl, C., Bonora, M., Moscato, F. and Díaz Lantada, A.

Design and Manufacturing of Microtextured Patient-Specific Coronary Stent.

DOI: 10.5220/0011691600003414

In Proceedings of the 16th Inter national Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2023) - Volume 1: BIODEVICES, pages 142-149

ISBN: 978-989-758-631-6; ISSN: 2184-4305

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

The design of the components defines the

biomechanical performance of the stent, the rings

determine radial support and expandability; the

number of connectors sets longitudinal stability,

flexibility, and longitudinal integrity; and the reduced

number of connectors provides greater flexibility and

reduces arterial injuries (Polanec et al., 2020;

Tomberli et al., 2018).

According to follow-up studies, 10% of patients

require a replacement prosthesis one year after

implantation and the likelihood of restenosis might

reach 40% (Pan et al., 2021; Schillinger et al., 2007).

These issues are the result from geometrical

alterations in a coronary artery once surgery is done

due to the size disparity between the blood vessel and

the expanded stent which is manufactured with

standard dimensions and shapes. A significant

interaction force will be produced if the stent does not

suit the diseased artery, injuring the artery and finally

causing restenosis (Wang et al., 2018). This

pathology is a major challenge and nowadays patients

usually need anticoagulant and antiplatelet therapies

(Movafaghi et al., 2019). Therefore, the combination

of medical and mechanical design can improve

notoriously the function of vascular prostheses and

minimize the use of anticoagulant drugs to meet the

needs of patients worldwide. Currently, many efforts

are being made to minimize the risk of restenosis and

thrombi formation, caused by the adsorption of

plasma proteins and platelets adhesion, modifying the

properties of the surface in contact with the blood

applying controlled micro- and nanopatterns (Koh et

al., 2010; Movafaghi et al., 2019).

Organisms as plants, animals and bacteria among

others, has carried out different solutions to survive

and adapt to the environment. The surface is where

organisms interact with other organisms and the

environment. Therefore, some of them has developed

textured surfaces in micro and nanoscales with

remarkable properties, such as the gecko, lotus flower

or sharks. Regarding the need, it could be chosen one

or another bioinspired microtexture and replicate it

artificially.

Researchers have studied the use of

superhydrophobic surfaces to improve the

hemocompatibility. These surfaces are super-

repellent to water with a static contact angle > 150º

and minimum contact angle hysteresis < 10º.

Moreover, superhydrophobic surfaces present low

blood protein adsorption and low blood cell

interaction which leads to improve

hemocompatibility (Movafaghi et al., 2019). Celik et

al. demonstrated the use of biocompatible materials

with superhydrophobic surfaces by manufacturing

samples rubbing the surface after coated the

polydimethylsiloxane (PDMS) with carnauba wax.

The static (169º) and sliding (3º and 5º respectively)

contact angle measurements with water and blood

showed super-repellency. Additionally, they studied

the contact angle with platelets suspension,

erythrocite concentrate and fresh plasma, all of them

showed superhydrophobic behaviour (Celik et al.,

2021).

Hoshian et al, also used PDMS with

microtextured inner surface coated with titania (TiO

2

)

to produce flexible tubes which repel water and

blood, where the blood contact angle for the

microtextured surface was 161 ± 3º compared with

the control surface (flat PDMS/titania surface) of 90

± 2º. The improvement in repellency is notorious.

Furthermore, they investigated the drag reduction

when tubes were microtextured compared with no-

textured tubes obtaining only 39% and 99%

respectively, when both measurements were

compared to a free falling droplet in air. Finally, some

test were performed comparing the superhydrophobic

surface with smooth titania and PDMS substrate

revealing that only the superhydrophobic one does

not present adhered platelets (Hoshian et al., 2017).

Considering the main causes of restenosis and

thrombi formation, in this study the potential of

designing and manufacturing a patient-specific

microtextured stent based on the disease will be

demonstrated by designing two patient-specific

stents, micropatterning and manufacturing one of

them to test the feasibility of the design methodology

presented above. The shark skin micropattern is

selected because his drag reduction under water

condition, superhydrophobicity in air with contact

angle 155º and oleophobicity in water environment

(Jung & Bhushan, 2009). It will be show a novelty

method to microtextured stents with the aim of

reducing restenosis and thrombi formation.

2 MATERIALS AND METHODS

2.1 Open-Source Coronary Stent

Design

Parametric design is one of the methods to produce

stents for each patient since it can effectively improve

their mechanical properties. For this purpose, the

parameterization of two coronary stents as a function

of the length (𝐿) and mean radius (𝑅) of the artery is

detailed. The first design is distinguished because the

unit cells are joined together, whereas in the second

they are linked by connectors.

Design and Manufacturing of Microtextured Patient-Specific Coronary Stent

143

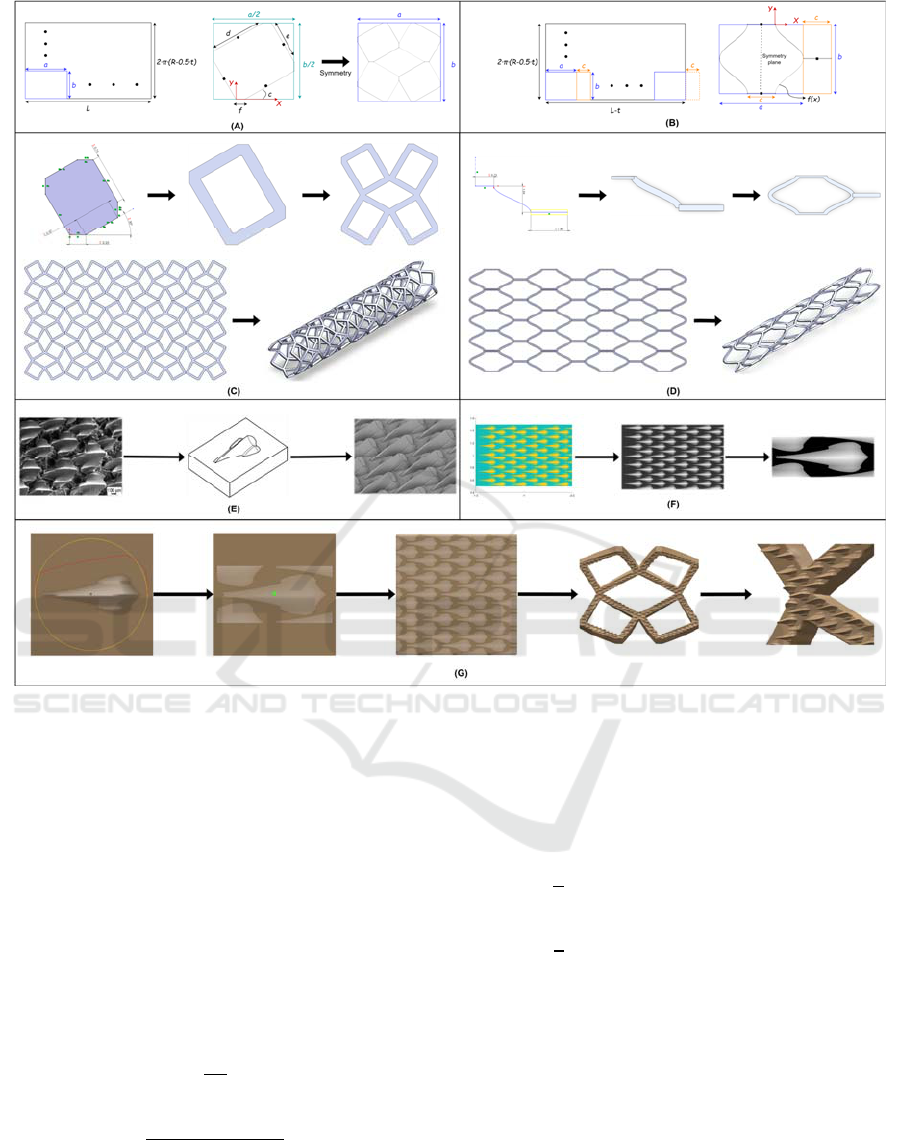

Figure 1: Macro and microstructure design. CAD design process of the (A, C) first and (B, D) second coronary stents. (E)

Bioinspired microstructures CAD design. (F) Mask acquisition. (G) Surface texturing.

2.1.1 First Design Strategy

The parameterization of the first model starts with the

development of a hollow cylinder; a rectangle of

width equal to 𝐿 and length, to the average length of

the artery minus the half of the stent thickness (2𝜋∙

(𝑅− 0.5𝑡)). Macroscopically, the unit cell is another

rectangle of “𝑎” width and “𝑏” length embedded in

the development to be repeated “𝑁𝑥” and “𝑁𝑦” times

in the longitudinal ( 𝑋 ) and radial ( 𝑌 ) axes

respectively (Figure 1A). With these similarities, the

first equivalences are made:

𝑎=

𝐿

𝑁𝑥

(1)

𝑏=

2∙𝜋∙(𝑅−0.5∙𝑡)

𝑁𝑦

(2)

From the microscopic point of view, the unit cell

has a defined shape delimited by the rectangle “𝑎𝑏”

(Figure 1A). Hence, the geometric relationships

between the macro and microscopic parameters must

be expressed mathematically, considering that there

is a more basic unit that with even and odd symmetry

constitutes the unit cell of the stent:

𝑎

2

=𝑑∙𝑐𝑜𝑠

(

𝑐

)

+𝑒∙𝑠𝑖𝑛

(

𝑐

)

+

𝑓

(3)

𝑏

2

=𝑑∙𝑠𝑖𝑛

(

𝑐

)

+𝑒∙𝑐𝑜𝑠

(

𝑐

)

+

𝑓

(4)

The parameters “𝑎” and “𝑏” are constrained by

the artery dimensions (𝐿 and 𝑅) and the designer

controls “ 𝑁𝑥”, “𝑁𝑦” and “𝑡” to obtain the best

performance. So, the other variables are unknowns,

but there are only two equations ((3) and (4)) resulting

in an indeterminate system; therefore, it is considered

that the unit cell opening, quantified through the angle

“𝑐”, is a parameter regulated by the designer and “𝑓”

is equal to “𝑡” to make its cross-section a square. By

partially solving the system of equations:

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

144

𝑚1=𝑑+ 𝑒=

𝑎+𝑏−4∙

𝑓

2∙(𝑠𝑖𝑛

(

𝑐

)

+𝑐𝑜𝑠 (𝑐))

(5)

𝑚2=𝑒− 𝑑=

𝑎−𝑏

2∙

(

𝑠𝑖𝑛

(

𝑐

)

−𝑐𝑜𝑠

(

𝑐

))

(6)

The microscopic variables “𝑑” and “𝑒” are a

combination of “𝑚1” and “𝑚2”

𝑑=

𝑚1 − 𝑚2

2

(7)

𝑒=

𝑚1 + 𝑚2

2

(8)

All these parameters are imported in the

"Equations" command, as global variables, in

SolidWorks 2021

®

(Dassault Systèmes, Waltham,

MA, USA). This software is used for its simplicity

when modelling complex geometries because the

parameterization of parts is highly optimized, and its

interface is user-friendly.

For the modelling, a sketch is made in the “Right

plane” correctly defining the constraints to obtain the

geometrical changes under the modification of the

global variables. Then, it is extruded with a depth

equal to “𝑡” and the “Shell” tool allows get an internal

wall with same thickness. To compose the unit cell

from this basic structure, the “Symmetry” tool is used

and the “Linear Pattern” command replicates “𝑁𝑥”

and “𝑁𝑦” times the unit cell in the 𝑋 and 𝑌 axes to

elaborate a mesh, development of the coronary stent.

Finally, the “Flex” and “Combine” tool folds the

mesh and joins each unit cell to form the coronary

stent (Figure 1C).

2.1.2 Second Design Strategy

The design of the second model starts from the same

development but, in addition to the unit cell, the

connectors that link them must be parameterized.

Therefore, both elements are integrated forming a

larger unit cell that is repeated bidirectionally. From

Figure 1B, the large-scale equivalence is performed:

𝐿−𝑡=𝑁𝑥∙(𝑎+𝑐)−𝑐 (9)

𝑏=

2∙𝜋∙(𝑅−0.5∙𝑡)

𝑁𝑦

(10)

This system has three unknowns (“𝑎”, “𝑏” and

“ 𝑐”) and only two equations. Therefore, it is

indeterminate and one of the unknown variables must

be defined. Due to the symmetry of the design, the

width of the unit cell was related to the length of the

connector:

𝑐=

𝑎

3

(11)

As a result, introducing equation (11) in (9) we

obtain:

𝑎=

𝐿−𝑡

4

3

∙𝑁𝑥−

1

3

(12)

Unlike the previous case, the thickness also

affects the longitudinal axis with the term (𝐿−𝑡)

appearing in equation (12), a consequence of the unit

cell geometry, which is modelled in SolidWorks

®

through sine function:

𝑓

(

𝑥

)

=

𝑐

2

∙𝑠𝑖𝑛

2𝜋

b

∙𝑥−

𝑏

4

+

𝑐

2

;

𝑥∈[0,0.5𝑏]

(13)

The above equations are imported into the

Solidworks

®

file as global variables. The sinusoidal

structure and its connector are sketched at the origin

of the “Top plane” and the “Swept Boss/Base”

command is used to obtain them three-dimensionally

with square cross-section of side “𝑡”. Furthermore, a

double symmetry is performed to produce the

complete unit cell. Then, the “Linear Pattern” tool

replicates the cell “ 𝑁𝑥” and “𝑁𝑦” times, but the

connector only “𝑁𝑥− 1” times because the stent

must start and end with the unit cell. Once the mesh

is prepared, the elements are folded and combined to

form the vascular prosthesis (Figure 1D).

2.2 3D Coronary Artery Model

A STL file of an artery (Model ID 3DPX-012589),

based on a CT scan and segmented by researchers at

the University of Toronto and Toronto General

Hospital, has been downloaded from the NIH 3D

Print Exchange repository (Phantom Coronary

Artery Models | NIH 3D Print Exchange, n.d.) to

quantify its length and average radius, being 22 and

1.71 mm respectively. Accordingly, the two coronary

stent models described above are adapted to extract

the unit cell and connector in the final position for

texturing.

2.3 Attainment of Microtextures

To create a microtexture to pattern the inner surface

of the stent, three different steps are required, from

the bioinspired microtexture to patterning the surface

with it (Figure 1E-G). The design process followed to

create the microtextured stent is described in detail in

(Franco-Martínez et al., 2022) where the authors

explained a design methodology to pattern the 3D

objects surfaces.

Design and Manufacturing of Microtextured Patient-Specific Coronary Stent

145

2.3.1 Microtexture Selection and Computer

Aided Design (CAD)

Previous studies showed that superhydrophobic

surfaces enhance hemocompatibility. Consequently,

shark skin is an adequate surface with the required

attribute. In this study, bioinspired shark skin replica

from (Jung & Bhushan, 2009) was chosen (first image

shown in Figure 1E) because of its high similarity to

nature, complex shape, high superhydrophobicity and

the authors provided the dimensions of replicated

shark scales. Then, one image and dimensions are

required to replicate the shape in CAD software,

obtaining a bioinspired surface model. Autodesk

Inventor 2021

®

(Autodesk, Inc.) was used to design

the pattern; to replicate the chosen shape, one

bioinspired shark scale is done using the “loft” tool

twice. Afterwards, this single model is replicated

along a flat surface with the “Pattern sketch driven”

command (Figure 1E).

2.3.2 Mask Acquisition

A grayscale mask is required to transfer the designed

pattern to the unit cell that works as the base for the

stent. Matlab R2022a

®

(Mathworks, Inc.) was used to

convert the STL file with shark skin pattern into a

grayscale mask. The STL is imported by “stlread”

tool, plotted with “patch” tool, transformed into an

image in grayscale with “rgbtogray” command and

“rescale” function is used to obtain the final mask

with better resolution. Finally, the image is trimmed

and saved to use in the next step (Figure 1F).

2.3.3 Surface Texturing

Once the unit cell is designed in CAD, the STL file is

imported to 3D Coat V4.9.65

®

(Pilgway). This

software offers a wide range of tools for digital

sculpting over the STL by “displacement mapping”,

a method that apply height maps to displace the points

or voxels of the mesh.

Regarding that, the shark skin mask is imported as

image in 3D Coat. Displacement’s height is directly

proportional to intensity in gray scale. The mask is

projected from the front view and it is used as

template over the surface micropatterned with the

chosen brush, determined by shape (in this case shark

scale), height and radius. To sculpt the surface, “live

clay” tool is used, which allows to add more density

of triangles where it is required on the surface to

achieve micrometer and well-defined range of the

micropatterning.

2.3.4 Manufacturing Process

Technology used to manufacture the stent prototype

is two-photon polymerisation (2PP), NanoOne

(UpNano GmbH, Vienna, Austria). It is a lithography

process capable of generating 3D structures with

nanometer feature sizes. The model was prepared in

Think3D (UpNano GmbH, Vienna, Austria) and

printed with UpPhoto (2-photon resin, UpNano)

which is biocompatible and non-cytotoxic (Materials

– UpNano – High-Resolution 3D Printing, n.d.), in

printing mode “vat” with a laser power of 250 mW at

a writing speed of 750 mm/s. To save time infill mode

“coarse” is selected and structuring was done in one

step with Fluar 5x/0.25 objective (Carl Zeiss

Microscopy, New York, United States).

After printing, the sample was rinsed in isopropyl

alcohol and air dried. A scanning electron microscopy

(SEM) (Zeiss EVO MA10, Oberkochen, Germany)

was used for imaging, and previously, the sample was

gold coated with a Quorom Q150R ES sputter coater

(Quorum Technologies Ltd, Laughton, United

Kingdom). Manufacturing and imaging process

followed in this study is similar to (Franco-Martínez

et al., 2022).

3 RESULTS

3.1 Micropatterning Unit Cell

Figure 2, shows the micropatterned unit cell

demonstrating the possibility of patterning 3D object

with curved surfaces. Due to the performance of 3D

Coat, the dimensions of the textures in CAD (Figure

2A) and 3D Coat (Figure 2B) varied a few microns

because of the size and place of the mesh triangles, as

it is commented in section 2.3.3. It is assumed that

this deviation will not affect the superhydrophobicity

state, since the fabrication creates the same or more

due to its accuracy. Additionally, the imprecisions

could enhance hemocompatibility thanks to produce

a non-uniform area, as shown in (Koh et al., 2010)

when the high aspect ratio textures are deformed and

bent complicating the adhesion of platelets.

Figure 2: (A) CAD microtextures with dimensions. (B) 3D

Coat microtextures with dimensions.

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

146

3.2 Reverse-Engineered

Reconstruction of Microtextured

Stent

From the textured unit cell, the coronary stent is

reconstructed. First, the cell is replicated “𝑁𝑦” times

radially to form the ring, which is then cloned “𝑁𝑥”

times linearly to assemble the patient-specific

textured coronary stent, whose length and outer

radius are equal to the artery dimensions (Figure 3).

However, in the second model, the connector is

replicated only “ 𝑁𝑥-1” times due to its design

(section 2.1).

This simplicity in the reconstruction is a

consequence of the macroscopic and microscopic

view explored in the computational design of

coronary stents.

Figure 3: Reconstruction of textured coronary stents.

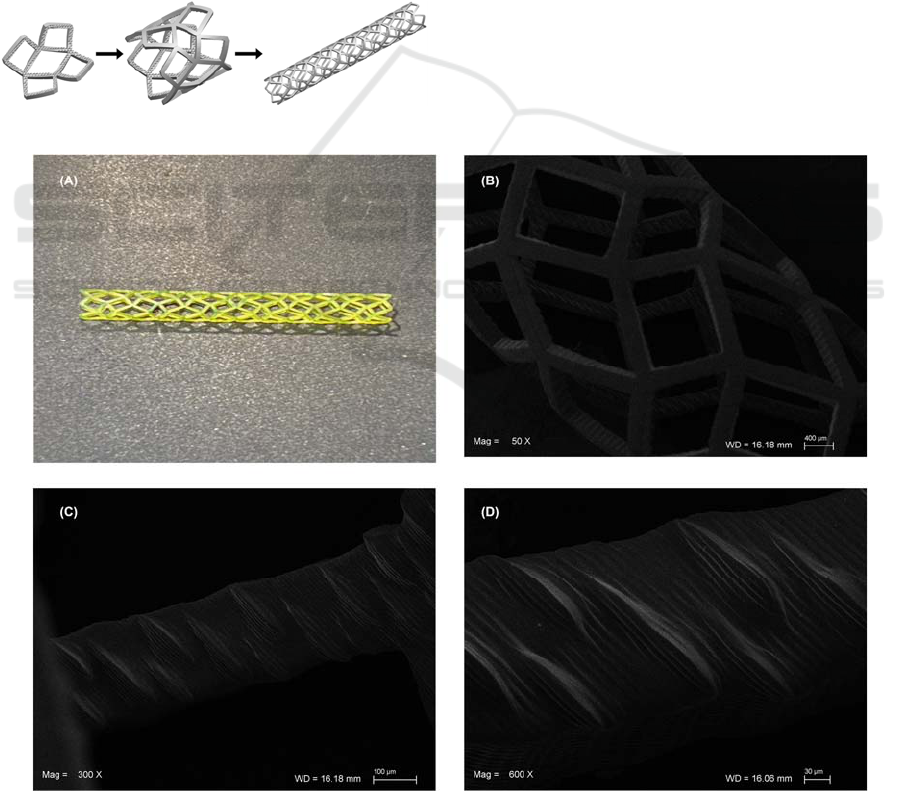

3.3 Microtextured Stent Manufacturing

3D manufacturing process is used to fabricate the

microtextured first design strategy stent prototype

(Figure ). The second design (Figure 1B) has not been

manufactured yet.

The microtextured stent prototype can be

observed in Figure . It is shown the inner surface

microtextured with remarkable shark’s scales, despite

of the sides riblets cannot be seen in most of them

(Figure D). Indeed, the stent was printed in “vat”

mode with infill “coarse” which is very fast and the

printing time was 20 minutes approximately. It is

feasible to reach higher accuracy with more precise

objective and longer printing time.

This prototype demonstrates that 3D objects with

complex and controlled surface topography can be

manufactured. In literature, most of microstructures

are made on a flat surface, as done in (Koh et al.,

2010), (Celik et al., 2021) or (Jung & Bhushan, 2009).

Hoshian et al. developed a manufacturing process

to design flexible tubes with microstructures on inner

surface. However, the structures where completely

random in shapes and position, in contrast to the 2PP

Figure 4: Microtextured Stent. (A) Real prototype. (B) SEM image outer surface with 50x magnification. SEM images inner

microtextured surface (C) 300x and (D) 600x magnification.

Design and Manufacturing of Microtextured Patient-Specific Coronary Stent

147

printing process that allows controlled and complex

structures to be made.

Regarding the material employed, despite its

biocompatibility, it may not be appropriate to use as

a stent due to its mechanical properties. In this case,

authors believe that it is feasible to use it as a

template, manufacturing the final stent in another

material, for example by applying the process

developed in (Hoshian et al., 2017). The material,

interaction with blood and implantation have to be

investigated in following studies.

4 CONCLUSIONS

In this study, a patient-specific microtextured stent

was designed and manufactured to minimize

restenosis and thrombi formation without the use of

anticoagulant medicines, whose design process is

characterized by its low computational and time cost,

due to the exposed three-dimensional object

modelling and texturing strategies.

Based on the design strategies described above,

considering their macroscopic (development) and

microscopic (unit cell and connector) view, it is

possible to computationally model any type of

coronary stent. Furthermore, the parameterization

favors the customization of these biodevices, since

the equation approach is a function of the length and

mean radius of the artery. Shark scales is well-known

because its drag reduction and superhydrophobicity

in air conditions. Additionally, it is oleophobic under

water conditions. Therefore, the authors chose it as

bioinspired microtexture for the inner surface and

believe that this topography is interesting because its

oleophobic behaviour. If the microstructures reach

oleophobicity under blood conditions, the adsorption

of proteins will not be possible and, consequently,

platelets adhesion will be reduced.

Finally, the authors demonstrated that it is

possible to design complex micropatterns on 3D

objects through this study of the stent. Even this novel

method could be applied to texture other implants

with different patterns, such as tracheal stents, grafts

or dental implants to achieve better biocompatibility

and avoid problems after surgery. However, it should

be noted that the study in its current form is mainly

the design process. Indeed, according to the European

Medical Devices Regulation 2017/745, customized

implants cannot reach patients without prescription

and involvement in the design procedure of

physicians and surgeons, therefore, this research

brings an engineering point of view. Consequently,

before the presented designs can be considered

successful solutions, collaboration with healthcare

personnel would be essential to improve the work by

taking into account the problems that may arise in the

pre-, intra- and postoperative phases; and by

performing systematic in vitro and in vivo

evaluations.

ACKNOWLEDGEMENTS

This research study has been funded by the European

Union’s Horizon 2020 Research and Innovation

Programme under grant agreement No. 953134

(INKplant project: Ink-based hybrid multi-material

fabrication of next generation implants).

"Optimized Hydrodynamic Flow Behaviour by

Selective Surface Structured of Ceramic 3D Printed

Rotodynamic Blood Pumps - OPTIFLOW-3D"

funded by the Austrian Research Promotion Agency

(FFG), Nr. 891239.

REFERENCES

Canfield, J., & Totary-Jain, H. (2018). 40 Years of

Percutaneous Coronary Intervention: History and

Future Directions. Journal of Personalized Medicine,

8(4), Article 4. https://doi.org/10.3390/jpm8040033

Celik, N., Sahin, F., Ruzi, M., Yay, M., Unal, E., & Onses,

M. S. (2021). Blood repellent superhydrophobic

surfaces constructed from nanoparticle-free and

biocompatible materials. Colloids and Surfaces B:

Biointerfaces, 205, 111864. https://doi.org/10.1016/

j.colsurfb.2021.111864

CVD Statistics. (n.d.). Retrieved 29 December 2022, from

https://ehnheart.org/cvd-statistics.html

Franco-Martínez, F., Grasl, C., Kornfellner, E., Vostatek,

M., Cendrero, A. M., Moscato, F., & Lantada, A. D.

(2022). Hybrid design and prototyping of metamaterials

and metasurfaces. Virtual and Physical Prototyping,

17(4), 1031–1046. https://doi.org/10.1080/17452759.

2022.2101009

Ho, M.-Y., Chen, C.-C., Wang, C.-Y., Chang, S.-H., Hsieh,

M.-J., Lee, C.-H., Wu, V. C.-C., & Hsieh, I.-C. (2016).

The Development of Coronary Artery Stents: From

Bare-Metal to Bio-Resorbable Types. Metals, 6(7),

Article 7. https://doi.org/10.3390/met6070168

Hoshian, S., Kankuri, E., Ras, R. H. A., Franssila, S., &

Jokinen, V. (2017). Water and Blood Repellent Flexible

Tubes. Scientific Reports, 7(1), 16019. https://doi.org/

10.1038/s41598-017-16369-3

Jung, Y. C., & Bhushan, B. (2009). Wetting Behavior of

Water and Oil Droplets in Three-Phase Interfaces for

Hydrophobicity/philicity and Oleophobicity/philicity.

Langmuir, 25(24), 14165–14173. https://doi.org/10.

1021/la901906h

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

148

Koh, L. B., Rodriguez, I., & Venkatraman, S. S. (2010). The

effect of topography of polymer surfaces on platelet

adhesion. Biomaterials, 31(7), 1533–1545. https://doi.

org/10.1016/j.biomaterials.2009.11.022

Materials – UpNano – high-resolution 3D printing. (n.d.).

Retrieved 31 October 2022, from https://www.

upnano.at/materials/

Movafaghi, S., Wang, W., Bark, D. L., Dasi, L. P., Popat,

K. C., & Kota, A. K. (2019). Hemocompatibility of

super-repellent surfaces: Current and future. Materials

Horizons, 6(8), 1596–1610. https://doi.org/10.1039/

C9MH00051H

Pan, C., Han, Y., & Lu, J. (2021). Structural Design of

Vascular Stents: A Review. Micromachines, 12(7),

770. https://doi.org/10.3390/mi12070770

Phantom Coronary Artery Models | NIH 3D Print

Exchange. (n.d.). Retrieved 11 April 2022, from

https://3dprint.nih.gov/discover/3dpx-012589

Polanec, B., Kramberger, J., & Glodez, S. (2020). A review

of production technologies and materials for

manufacturing of cardiovascular stents. Advances in

Production Engineering & Management, 15(4), 390–

402. https://doi.org/10.14743/apem2020.4.373

Schillinger, M., Sabeti, S., Dick, P., Amighi, J., Mlekusch,

W., Schlager, O., Loewe, C., Cejna, M., Lammer, J., &

Minar, E. (2007). Sustained Benefit at 2 Years of

Primary Femoropopliteal Stenting Compared With

Balloon Angioplasty With Optional Stenting.

Circulation, 115(21), 2745–2749. https://doi.org/10.

1161/CIRCULATIONAHA.107.688341

Tomberli, B., Mattesini, A., Baldereschi, G. I., & Di Mario,

C. (2018). Breve historia de los stents coronarios.

Revista Española de Cardiología, 71(5), 312–319.

https://doi.org/10.1016/j.recesp.2017.11.016

Wang, Q., Fang, G., Zhao, Y.-H., & Zhou, J. (2018).

Improvement of Mechanical Performance of

Bioresorbable Magnesium Alloy Coronary Artery

Stents through Stent Pattern Redesign. Applied

Sciences, 8(12), 2461. https://doi.org/10.3390/

app8122461.

Design and Manufacturing of Microtextured Patient-Specific Coronary Stent

149