Model-Driven Optimisation of Monitoring System Configurations for

Batch Production

Andreas Margraf

1 a

, Henning Cui

2 b

, Simon Heimbach

3

, J

¨

org H

¨

ahner

2

, Steffen Geinitz

1

and Stephan Rudolph

3

1

Fraunhofer IGCV, Am Technologiezentrum 2, 86159 Augsburg, Germany

2

Institute for Computer Science, University of Augsburg, Am Technologiezentrum 8, 86159 Augsburg, Germany

3

Institute of Aircraft Design, University of Stuttgart, Pfaffenwaldring 31, 70569 Stuttgart, Germany

Keywords:

Engineering Automation, Graph-Based Design Language, Machine Vision, Algorithm Selection.

Abstract:

The increasing need to monitor asset health and the deployment of IoT devices have driven the adoption

of non-desctructive testing methods in the industry sector. In fact, they constitute a key to production effi-

ciency. However, engineers still struggle to meet requirements sufficiently due to the complexity and cross-

dependency of system parameters. In addition, the design and configuration of industrial monitoring systems

remains dependent on recurring issues: data collection, algorithm selection, model configuration and objective

function modelling. In this paper, we shine a light on impact factors of machine vision and signal processing in

industrial monitoring, from sensor configuration to model development. Since system design requires a deep

understanding of the physical characteristics, we apply graph-based design languages to improve the decision

and configuration process. Our model and architecture design method are adapted for processing image and

signal data in highly sensitive installations to increase transparency, shorten time-to-production and enable de-

fect monitoring in environments with varying conditions. We explore the potential of model selection, pipeline

generation and data quality assessment and discuss their impact on representative manufacturing processes.

1 INTRODUCTION

The growing use of automation, non-desctructive sys-

tems (NDT) and optical sensors raises the need for

highly accurate yet efficient machine vision solutions.

While the algorithmic perspective of monitoring sys-

tems has been addressed by a highly dynamic com-

munity around the field of Artificial Intelligence (AI),

only little research has been conducted to bridge the

gap between system design and algorithm configu-

ration. This paper proposes a model-driven frame-

work for selecting architectural synthesis of machine

vision systems according to technical requirements

for a given monitoring task. For the realization of

this framework, a graph-based design language is uti-

lized, a tool, that allows for the automation of large

parts of an engineering design process. Modeled after

human languages, they use vocabulary and rules to

create a design language grammar. Each valid com-

bination of words then forms a variant of the prod-

a

https://orcid.org/0000-0002-2144-0262

b

https://orcid.org/0000-0001-5483-5079

uct. The execution of the abstract rules of the design

grammar and the domain-specific model is performed

by translations of the model using a design compiler

(Alber and Rudolph, 2004). Beyond that, we discuss

methods to select the most promising and efficient al-

gorithms besides the popular Deep Neural Networks

(DNN).

The spread of large systems with interactive be-

havior renders them more difficult to manage, while at

the same time they exhibit partly unexpected emerg-

ing behavior. A computing paradigm denoted Or-

ganic Computing (OC) is set out to equip systems

with so-called self-x properties, e.g. self-healing, self-

configuring and self-adapting (M

¨

uller-Schloer and

Tomforde, 2017). The vision of OC is highly focussed

on the idea to incorporate nature-inspired algorithms

to allow for a self-organization in dynamically chang-

ing requirements (Schmeck et al., 2010). This study is

intended to incorporate OC principles into the process

of monitoring system design and configuration.

While engineering design usually builds on infor-

mal textual representation, system variants are typi-

cally created by domain experts without predefined

176

Margraf, A., Cui, H., Heimbach, S., Hähner, J., Geinitz, S. and Rudolph, S.

Model-Driven Optimisation of Monitoring System Configurations for Batch Production.

DOI: 10.5220/0011688900003402

In Proceedings of the 11th International Conference on Model-Based Software and Systems Engineering (MODELSWARD 2023), pages 176-183

ISBN: 978-989-758-633-0; ISSN: 2184-4348

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

design decisions. A design variant is considered valid

as long as it is consistent with the requirements. Due

to the physical complexity, alternative design variants

are never explored. In addition, the process chain is

confronted with gaps and discontinuities, which pre-

vents an efficient exploration of the solution space.

The approach proposed in this study intends to bridge

that gap by providing a formal model-based transfor-

mation chain that generates an executable represen-

tation of the system according to predefined require-

ments. Although the potential of machine learning for

real-world applications remains undisputed, the setup

stage of industrial monitoring sensors requires great

human effort due to extensive configuration and adap-

tation. In the context of the challenge imposed on a

monitoring system, we pledge to explore the follow-

ing research questions (RQ):

RQ1: How can graph-based design languages re-

duce the factor of uncertainty in monitoring sys-

tem development?

RQ2: Which are the limiting factors that impede al-

gorithm development in an application environ-

ment?

RQ3: How can the gap between a lab-based and

real-world environment be narrowed?

These questions were previously discussed as part

of Automated Design of Processing Pipelines (ADPP)

(Stein et al., 2018) which has been proposed for im-

age segmentation, interpretation and signal filtering,

cf. (Margraf et al., 2017b; Hammami et al., 2018).

While ADPP optimizes the combinations of opera-

tors, this study will mainly discuss the development

of monitoring systems designed to acquire data.

The remainder of this work is structured as fol-

lows:

Sec. 1 starts by introducing graph-based design

concepts in monitoring system development, before

giving an overview on related work in Sec. 2. Sec.

3 describes the model-based approach for system de-

sign and configuration before testing it on related real-

world use cases in Sec. 4. In Sec. 4.2, we critically

reflect on our model and discuss the results for indus-

trial applications. We conclude on our findings in Sec.

5 and give a short outlook on future work.

2 RELATED WORK

The following section gives an overview on related

fields of research and previous work that inspired this

paper:

The application of grammars inspired by formal

languages proved useful for the development of de-

scription languages for engineering design objects as

shown by Alber et al. (Alber and Rudolph, 2004).

Furthermore, Walter et al. proposed a process chain

that automatically generates state machines from re-

quirements for system designs to provide an exe-

cutable system model (Walter et al., 2019). Neumaier

et al. used graph-based languages to generate the pipe

structure for landing gear design (Neumaier et al.,

2022).

State-of-the-art monitoring systems are equipped

with machine learning algorithms which have been

developed over several decades for signal process-

ing, image segmentation, natural language processing

and classification (Schmidhuber, 2015). Several sci-

entific publications between 2010 and 2015 marked

a turning-point in deep learning research: transfer

learning significantly improved model accuracy, as

shown in related studies (Lin and Jung, 2017; Tan

et al., 2018), while data augmentation helped to en-

large training data as presented by Mertes et al. for

defects in fibre textiles (Mertes et al., 2022).

To the best of our knowledge, graph-based design

languages have not been applied before for generating

monitoring system designs as proposed in this study.

While heuristic-driven approximation allows to bet-

ter generalize under uncertainty, our approach offers

interpretable solution paths and detailed documenta-

tion but rules out unexpected behaviour. The depth

of the solution space can be adapted to the engineer-

ing domain. However, complex applications require

an elaborated analysis and a far-ranging technical un-

derstanding modeling the physical constraints accord-

ingly.

The aforementioned publications cover the most

relevant topics of the field of research but serve as a

summary to the reader and therefore cannot guarantee

completeness.

3 GRAPH-BASED COMPONENT

AND ALGORITHM SELECTION

In this paper, we propose a novel, innovative

framework for developing monitoring solutions us-

ing graph-based design languages. Our concept is

deemed to improve efficiency of signal and image

segmentation in the context of industrial quality mon-

itoring. We take a bottom-up approach to the selection

of sensors, components and filter algorithms, which is

referred to as ‘Monitoring Architecture and Algorithm

Selection (M-AAS)’.

Model-Driven Optimisation of Monitoring System Configurations for Batch Production

177

A B C

(a) Graph G

A

L:

B

(b) Pattern graph L

X

R:

(c) Replacement graph R

X C

(d) Modified graph H

Figure 1: An example graph G, a replacement rule and its

modified graph after the rule has been applied.

3.1 Graph Rewriting and Model

Transformation

Let G = (V,E) be a connected (un)directed graph with

vertex set V and edge set E. The solution of any opti-

mization problem on G corresponds to some subset of

vertices V

′

⊆ V or subset of edges E

′

⊆ E. A graph

rewriting system consists of a set M of rewrite rules

p : L → R, with L being the pattern graph and R be-

ing the replacement graph. A graph rewrite rule p is

applied to the host graph G by searching for an oc-

currence of the pattern graph L and by replacing the

subgraph by an instance of the replacement graph R.

The search for the occurrence of L in G, known as

isomorphism, is solved using a pattern matching al-

gorithm. Graph H represents the modified graph as

a result of the application of a graph rewrite rule p,

formally known as: L

p

−→ R. As can be seen in Fig.

1, given host graph G and using rewrite rule p returns

graph H. Rewrite rules can be further regulated in

the case of labelled graphs, such as in string-regulated

graph grammars.

Each node in a graph is set to represent a re-

quirement, component, function or a solution princi-

ple. In our framework, the design language is based

on the Unified Modeling Language (UML). The key

components of a graph-based design language are the

vocabulary, the set of rules and the production sys-

tem. While the vocabulary is modeled in a UML

class diagram, the rules are represented as Model-to-

Model (M2M) or Model-to-Text (M2T) transforma-

tions. An activity diagram defines the production sys-

tem workflow. The result graph H, which we refer

to as design graph, is generated during compilation

when the design language is applied. It is then vi-

sualized in an UML instance diagram. For further

use, the design graph can be mapped into domain-

specific languages by software plug-ins for e.g. trans-

lation to CAD models. M-AAS allows the generation

of variants based on models and rule sets combined,

which is why mere model translations, e.g. through a

QVT (Query/View/Transformation) approach, would

not be sufficient. The M-AAS approach is performed

over three stages:

(1) Assign specific values or value ranges to each in-

put node (problem understanding)

(2) Search for a valid system composition and algo-

rithms with respect to rules (formal dependencies,

constraints)

(3) Configure and optimize the suggested algorithms

The parameters for stage (1) have to be requested

from domain experts or users. This first step is con-

sidered decisive; it is usually the origin of miscon-

ceptions and faulty system designs when carried out

without guidelines. Therefore, this part of the M-ASS

approach is developed with regard to the guidelines

by VDI/VDE

1

no. 2632 for machine vision design

(VDI/VDE, 2015) and ISO 8758 (ISO, 1998).

In stage (2), we apply the aforementioned graph

transformation using the rule set. All rules are mod-

eled as part of activity diagrams and contain context-

specific constraints and formal dependencies as ex-

plained in Sec. 3.3. Stage (3) covers the fine-tuning

of algorithm configurations, depending on the output

reflected in the design graph. Details of algorithm

tuning are not part of this study. At first, the system

requirements have to be documented by specific met-

rics and definitions. In light of the aforementioned

workflow, the following section offers an overview

of methods to meet its challenges and explains the

details of M-AAS. From the model perspective, each

edge E is derived from an object instance; the ob-

jects are created as soon as the collection of input

parameters, derived from the requirements collection,

has been applied. All objects are created according

to the class diagram as shown in Fig. 2 and 4. As

a result, the framework provides a use-case specific

system architecture with components and processing

units as well as suitable segmentation and classifica-

tion models. Any unforeseen changes can be fed into

the framework upon request and optimization can be

performed repeatedly.

3.2 Requirements Analysis

At the start of the monitoring system design process,

the inspection task needs to be converted to a set of

requirements. Solving the trade-off between target

performance and hardware is heavily dependent on a

precise understanding of the inspection task. The in-

spection task depends on the following criteria: task

1

German Association of Engineers

MODELSWARD 2023 - 11th International Conference on Model-Based Software and Systems Engineering

178

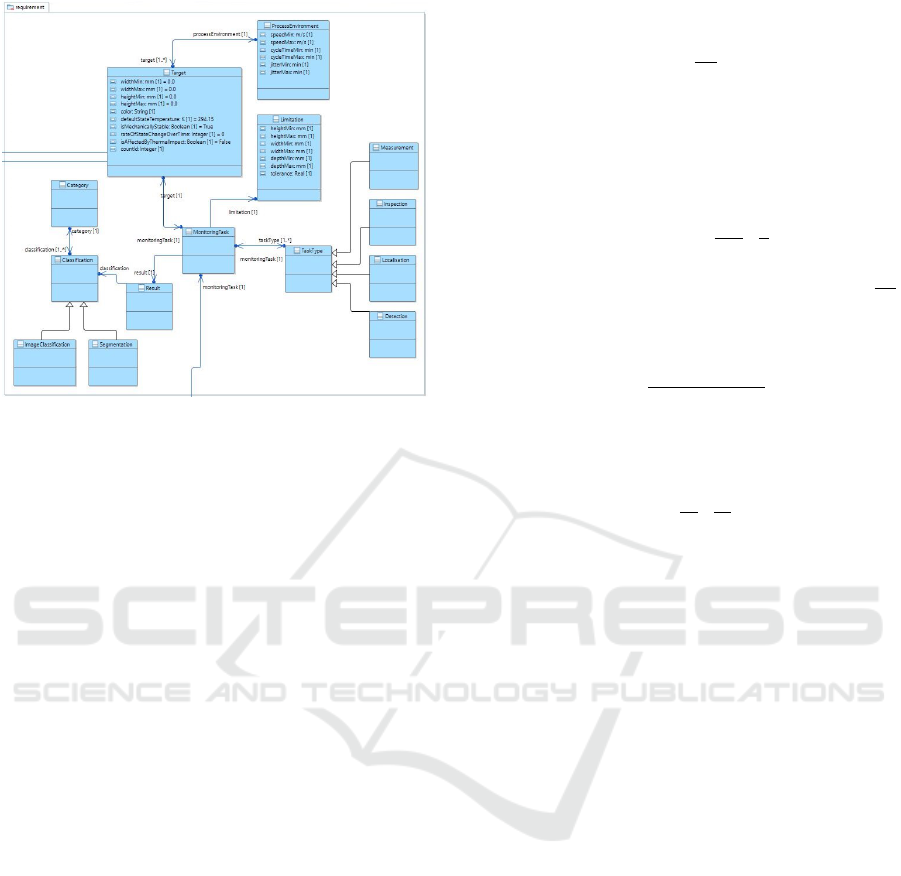

Figure 2: Model view of a typical industrial inspection task;

this model represents a high-level perspective on the prob-

lem domain, but reveals dependencies between requirement

values and possible system components and algorithms.

category, difficulty, complexity and context-invariant

representation. For image processing, task categories

can be divided into five major types of processing: a)

image classification, b) object detection, c) semantic

segmentation, d) instance segmentation, e) panoptic

segmentation. For sources offering time series or sig-

nal flow data, classification and segmentation tasks

comprise the following categories: a) signal classi-

fication, b) instance detection, c) outlier or anomaly

detection, d) change point detection.

For the application assessment, we collect the fol-

lowing parameter range [min,max]:

• the scan area width l

scan

and height h

scan

• the space dimension width l

Space

, height h

Space

and depth d

Space

• cycle time CT

• production speed v

p

• inspection object width l

ob j

and height h

ob j

The graph rewriting and model transformation can be

successfully executed if the requirement data is valid.

3.3 System Design Rules Derived from

Physical Laws

For the camera system, we define the parameters as

follows:

According to the Nyquist-Shannon sampling the-

orem, at least twice the sampling rate B is required to

sufficiently approximate the original signal f

s

(Shan-

non, 1948):

f

s

>

1

2B

For the system design, we define the nyquist factor

nyq = 10 for measurement and nyq = 3 for inspection

tasks. Additionally, the sensor resolution equals the

object space resolution ξ and depends on tolerance t

and interpolation i as follows, cf. (Smith, 2000):

ξ

ob ject space

=

t

nyq

·

1

i

For i = 1 this can be shortened to: ξ

ob ject space

=

t

nyq

The sensor pixel size (s

p

) depends on object width

W

ob j

and object space resolution ξ as follows:

s

p

=

max(l

ob j

,h

ob j

)

ξ

ob ject space

The sensor frequency f

s

depends on production speed

v

p

, resolution r

c

and sensor pixel size s

p

and is defined

as follows:

f

s

=

v

p

r

c

·

1

s

p

The minimum bandwidth W

min

depends on bit size

(i.e. number of bits) b and s

p

in the following manner:

W

min

= s

p

· f

s

· b

Moreover, the specifications of optical systems are de-

termined on the basis of the parameters image size

y

′

(by default 1/3

′′

), (real) target size (and width) y,

working distance a and focal length f

′

o

. The character-

istics for the optics component are defined as follows:

f

′

o

= a/(y/y

′

+ 1)

y = y

′

· (a/ f

′

o

− 1)

a = f

′

· (y/y

′

+ 1)

y

′

= y · f

′

/(a − f

′

o

)

Parameter f

′

o

constitutes a minimum requirement that

applies to specific optics. Furthermore, the con-

straints for y and vector of space dimensions a are

defined as follows:

y ≥ max(l

ob j

,h

ob j

)

a = min[w,h,l] ∧ a ≤ (l

space

,h

space

,d

space

)

The real-time frame T F is defined as the difference

between the cycle time CT and jitter J:

T F = CT − J

All formulas listed here represent the core part of the

rule set that defines the model transformation of the

monitoring system design.

Model-Driven Optimisation of Monitoring System Configurations for Batch Production

179

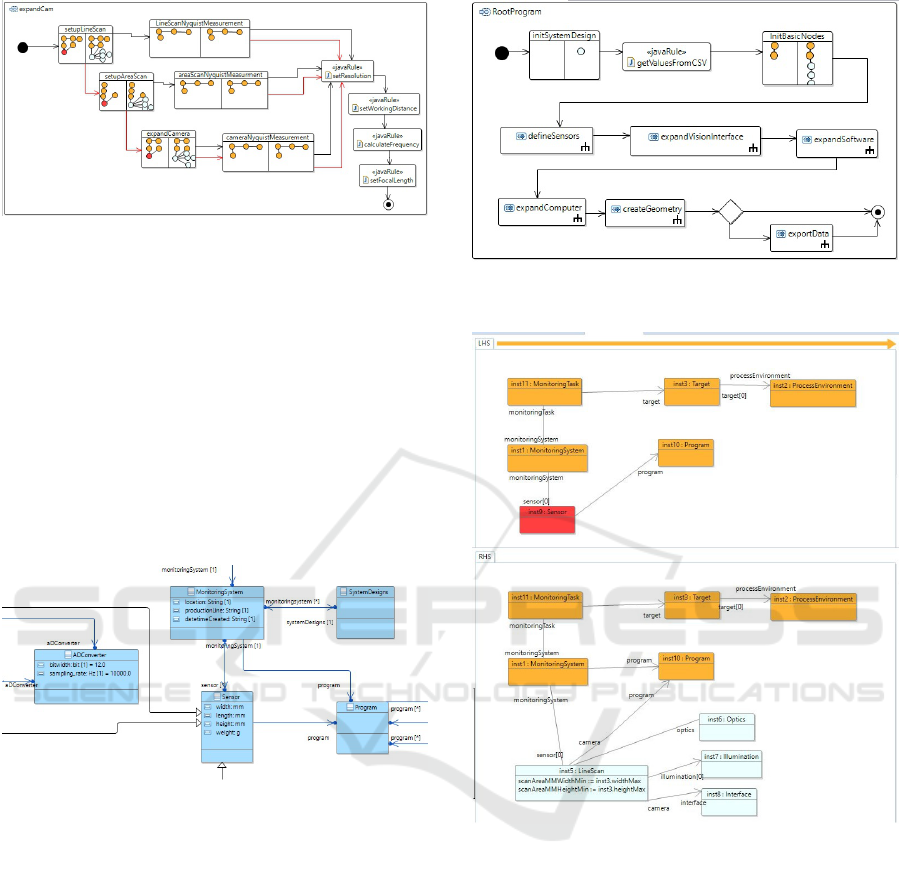

Figure 3: Rule set for camera and optics.

3.4 Component and Algorithm

Modelling

As can be seen in the model in Fig. 4, a machine vi-

sion system consists of the following parts: sensor, il-

lumination, communication interface, computer, pro-

cessor and a program for data processing.

Since stage 2 suggests a high level representation

of the system, there is still room for optimization in

each node. At this stage, only nodes that contain sen-

sor types or periphery compatible to the system re-

quirements remain in the result graph.

Figure 4: Model view of the superordinate architecture

model of a monitoring system.

For applications that require a camera-based sys-

tem, the sensor class is replaced by a camera object

(LineScan or AreaScan) and included in the graph as

a node. The model also considers analogue signals,

i.e. vibration and weight which requires accelerom-

eters or piezoelectric sensors. A sample transforma-

tion rule for the camera component is given in Fig. 3

(expandCamera): if the requirements suggest optical

monitoring, a camera node is instantiated. Accord-

ing to the model, the camera node contains parame-

ters that determine its state and functionality. This in-

cludes sensor frequency f

s

, which is calculated based

on cycle time, scan range and resolution s

p

. The

rule set also determines the details of the optics node

which contains parameters f

′

o

, y and a. The physical

basis for all of these parameters is elaborated in Sec.

3.3.

Figure 5: Root activity diagram that defines the order of rule

transformation on the graph.

Figure 6: Graph rewrite rule defining the replacement of

a sensor node with a line scan camera and related compo-

nents.

In addition, the model allows to equip the com-

puter with an FPGA chip. The graph is then expanded

with logic for signal processing which is later ex-

ported to VHDL code for the synthetisation of the bit-

stream. The expansion of the graph includes - among

other things - the number and types of digital inter-

faces to the sensors (AD converters) and the encoder-

s/decoders for the host communication. This commu-

nication can be based on a USB interface and contains

the live feed from the filtered signals as well as new

parameters for the filters from the host. Subsequently,

the filter pipeline is synthesized to a bitstream in a

specific FPGA model. The filter pipeline is set to lo-

calize anomalies in the incoming signal. Alongside

MODELSWARD 2023 - 11th International Conference on Model-Based Software and Systems Engineering

180

Figure 7: Illustration of the design graph showing one vari-

ant of a monitoring system for a specific set of requirements.

Each node represents a node instantiation, starting with the

monitoring system and ending at the program node.

the FPGA configuration, the model allows the use of

machine learning models.

It depends, of course, on the features of the input

data (bit size, frame size, structure) and process speci-

fications (frequency, bandwidth, realtime conditions).

Finally, the model suggests an interface for data stor-

age. At this point, we only provide the raw interface,

but will leave it up to future research activities to add

details on its specification.

Fig. 5 illustrates the activity diagram, modeling

the order of conditions and transformation rules ap-

plied on the graph. The activity nodes initSystemDe-

sign, getValuesFromCSV and InitBasicNodes are con-

cerned with the initialization of basic system nodes.

The stage denoted defineSensors decides on the type

of sensor to use whereas expandVisionInterface is

concerned with details on the machine vision com-

ponent. The nodes expandSoftware and expandCom-

puter finally add the related software and computing

unit. For further usage, the results are exported in a

routine called exportData.

Each sensor is connected to a program, a node

that is always required to process incoming data and

contains a data processing pipeline. The pipeline it-

self incorporates an algorithm represented by either

a machine learning model or a set of f ilter opera-

tors. The transformation ruleset expandSoftware con-

siders the parameters H

o

, f

s

,b,W to determine possi-

ble pipepline variants. A sample pipeline may look

as follows: (sensor) → (program) → (pipeline) →

(acquisition) → ( f ilter) → (SV M).

4 EVALUATION

4.1 Experimental Setup

In this section, the use of the presented model trans-

formation and graph rewriting method in industrial

applications will be discussed in more detail. For

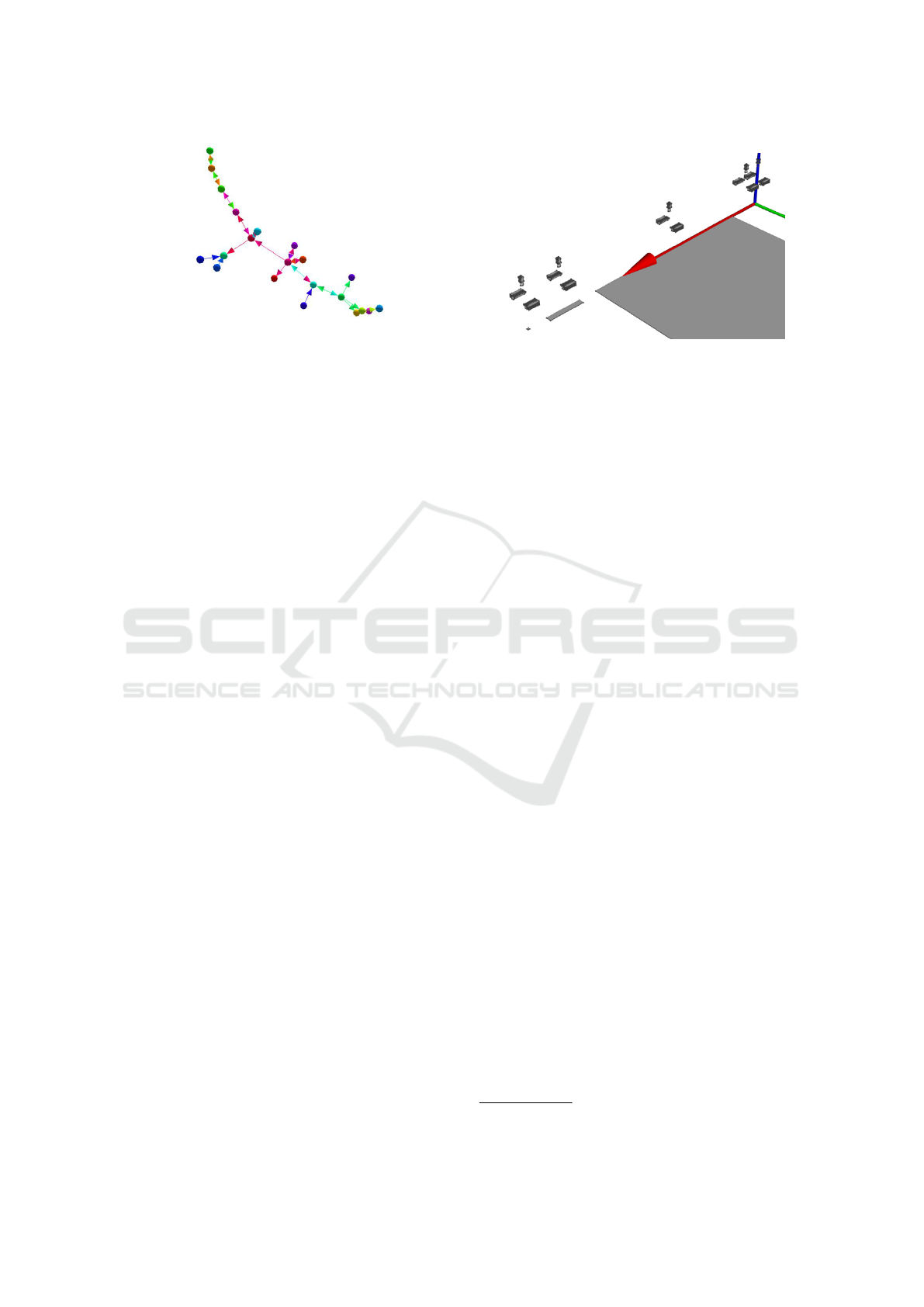

Figure 8: CAD view based on open CASCADE that shows

the most promising configurations for each application

which are lined up for demonstration; each setup consists of

a camera sensor, optics, focus lighting and the target area.

this purpose, four representative application exam-

ples from industrial environments dealing with qual-

ity monitoring in production are demonstrated. The

industrial monitoring tasks mentioned include:

• Anomaly Detection in carbon fibre production

(CF) (Geinitz et al., 2016; Margraf et al., 2017b)

• Roving monitoring for fibre placement layups

2

(FP) (Margraf et al., 2017a)

• Monitoring of resin impregnation in the pultru-

sion process (PR) (Strauß and Wilhelm, 2020)

• Production of wetlaid nonwoven fabric (WL)

(Sauer et al., 2019)

All monitoring tasks can be potentially monitored

using optical sensors. In consequence, we expect the

following graph transformation rules to generate sys-

tem configurations with variants of camera sensors

and related software architectures.

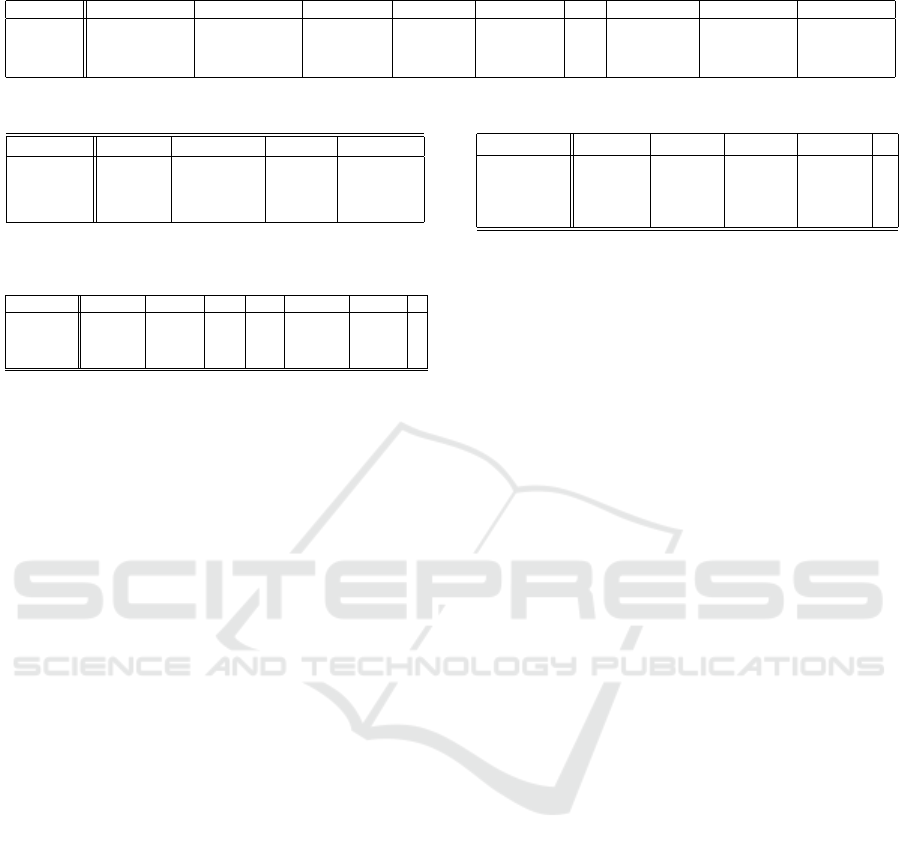

Tables 1 and 2 contain all parameters relevant to

the related processes. For once, the values were ex-

tracted from the previously mentioned publications

which applies to CT,v

p

,l

ob j

,h

ob j

, or implicitly de-

ducted as for l

space

,h

scan

and the task context (cf. Tab.

2). Parameters l

space

and h

scan

are based on realistic

assumptions.

Furthermore, we apply the design language as

presented in Fig. 5 which includes the rule set ex-

pandCamera as illustrated in Fig. 3. The vocabu-

lary and transformation rules for the monitoring sys-

tem are modelled in the Design Compiler 43 (DC43)

(Schmitt, 2017) environment. The compilation en-

gine then generates the design graph.

4.2 Results and Discussion

In this section, the results of the model transformation

are critically reflected and evaluated in the context

2

Usually, 8 rovings exhibit a width of 1/4

′′

plus spacing.

Model-Driven Optimisation of Monitoring System Configurations for Batch Production

181

Table 1: Technical requirements of selected production processes for optical monitoring systems.

Application l

scan

h

scan

l

space

h

space

d

space

CT v

p

l

ob j

h

ob j

CF [30,1000] (mm) [0,∞] (mm) [50,50] (mm) [50,50] (mm) [50,50] (mm) [0,∞] [0.1,1] (m/s) [5,3000] (µ) [5,∞] (µ)

FP [0.635,200] (mm) [0, ∞] (mm) [0,300] (mm) [0,230] (mm) [0,150] (mm) [0,∞] [0.1,1] (m/s) [0.1,0.635] (cm) [0.1,0.635] (cm)

PR [78.76,86.6] (mm) [49.23,57.8] (mm) [0,∞] (mm) [0,∞] (mm) [0,1500] (mm) [0,∞] [0.3,5] (m/min) [5,86.6] [5,57.8] (mm)

WL [614,614] (mm) [0,∞] (mm) [0,1000] (mm) [0,∞] (mm) [0,720] (mm) [0,∞] [*,30] (m/min) [0.15,30] (mm) [0.15,30] (mm)

Table 2: Task context requirements.

Application Inspection Measurement Detection Localisation

CF - x x x

FP x - - x

PR - x x -

WL x - x -

Table 3: Values resulting from model transformation for

camera sensor configuration.

Application ξ[px] l[px] l[mm] h[px] h[mm] f

s

[1/T ] b

CF 1.65 · 10

−3

1.82 · 10

6

3000 1 1.65 · 10

−3

1.21 · 10

6

3

FP 6.60 4.55 30 1 30 151.50 3

WR 1.65 35.15 58 1 870 504.99 3

WL 3.30 · 10

−3

9090 30 1 30 1.52 · 10

5

3

of the application examples. Furthermore, the proce-

dure is discussed with regard to the research questions

mentioned in section 1.

The values for camera variants are listed in Tab. 3

and the optics solution space is given in Tab. 4. As

can be seen in Tab. 3, tiny objects increase the res-

olution and sensor size requirements substantially as

it is the case for CF and WL. In contrast, FP and PR

can be monitored with smaller sensors at a far lower

resolution. Likewise, the frequency values peak at

1.2 · 10

6

Hz for CF. While the frequency for WL is

still comparatively high, PR and FP are satisfied with

a frequency well below 1000 Hz. As Tab. 4 suggests,

low f

′

values correlate with high resolution require-

ments (cf. CF and WL). It should also be mentioned,

that the range for FP and PR between f

′

min

and f

′

max

is

comparatively large while it is strikingly small for CF

and WL which handle macroscopic objects. Also, the

maximum target size y

max

for CF largely exceeds the

values of all other sample applications. All param-

eters mentioned in this section result from applying

design rules and grammar and were stored as param-

eters in the nodes of the design graph (cf. Fig. 7).

The values can be regarded as accurate for the system

design concept, since they are based on real specifica-

tions and physical laws.

In reference to RQ1 we proposed a model which

is instantiated by collecting all relevant requirement

parameters. The nature of the transparent and human-

readable model and rule set allows to trace each deci-

sion made on design variants.

The limiting factors for algorithm development

mentioned in RQ2 result from the multi-dimensional

search space and uncertainties contained in the data.

Nevertheless, the M-AAS approach includes all rele-

vant dependencies between the system components

Table 4: Resulting specification for the optics configuration.

Application f

′

min

[mm] f

′

max

[mm] y

min

[mm] y

max

[mm] a

CF 3.3 · 10

−6

0.0165 1 5000 -

FP 0.57 113.80 1 200 -

PR 0.15 72.91 1 500 -

WL 6.6 · 10

−4

0.41 1 614 -

and the algorithms, although some details cannot be

fully considered.

RQ3 can be answered as follows: the proposed

approach ensures that details of the specification are

collected at the earliest possible stage, i.e. before sys-

tem development begins. The approach is set to auto-

mate large parts of monitoring system design.

The use of graph-based models, transformation

and user knowledge helps to efficiently identify the

solution space. Secondly, we provide an analysis of

the transferability of our approach and our detection

performance when only a single sample in the sup-

port set is targeted. This provides a lower bound of

our detection performance in essence. Thereby, the

adoption of each component to new, unknown situ-

ations can be performed upon request. This is even

the case without compromising on accuracy or run-

time. For reasons of simplicity, this study is limited

to the lab-based character of our experimental setup:

we have not explicitly taken into account the cost of

single components or the full-scale variants. For prac-

tical use, a connection to product databases will have

to be established. Since products and prices change

regularly, the authors decided to focus on merely tech-

nical parameters.

More than one relation is defined based on expert

input as to increase the compatibility of small datasets

by a quantitative comparison of results based on the

algorithm. Therefore, context-sensitive heuristics are

selected for different kinds of applications.

5 CONCLUSIONS AND FUTURE

WORK

This paper presents a top-down approach for model-

driven design of industrial monitoring systems and

data processing pipelines. Graph-based design lan-

guages and model transformation rules allow to map

the workflow from inspection task definition, sensor

design to algorithm selection and data flow configu-

ration. The framework proposed in this conceptual

MODELSWARD 2023 - 11th International Conference on Model-Based Software and Systems Engineering

182

study aims to automate a substantial part of monitor-

ing system development. The approach suggests im-

provements in design efficiency of complex monitor-

ing systems and processing algorithms. Furthermore,

it is expandable in terms of additional degrees of free-

dom.

Future work will focus on detailed, specific mon-

itoring tasks in industrial environment with long tail

detection and classification problems. We assume that

a more systematic decomposition of system design

tasks will lead to more compact designs. We encour-

age the research community to continue the ground-

work presented in this study by extending the models

and rule set to allow for more detailed design deci-

sions.

ACKNOWLEDGEMENT

The authors would like to thank the German Federal

Ministry for Economic Affairs and Climate Action

(BMWK) for public funding of the research project

AirCarbon III within Lufo-IV and the German Fed-

eral Ministry of Education and Research (BMBF) for

supporting the project SaMoA within VIP+.

REFERENCES

Alber, R. and Rudolph, S. (2004). On a grammar-based

design language that supports automated design gen-

eration and creativity. In Knowledge Intensive Design

Technology, pages 19–35. Springer US.

Geinitz, S., Margraf, A., Wedel, A., Witthus, S., and Drech-

sler, K. (2016). Detection of Filament Misalignment

in Carbon Fiber Production Using a Stereovision Line

Scan Camera System, volume 158-USB of DGZfP-

Proceedings BB. M

¨

unchen.

Hammami, M., Bechikh, S., Hung, C.-C., and Said, L. B.

(2018). A multi-objective hybrid filter-wrapper evo-

lutionary approach for feature construction on high-

dimensional data. In 2018 IEEE Congress on Evo-

lutionary Computation (CEC). IEEE. GP for multi-

objective feature contruction and selection.

ISO (1998). Geometrical product specification (gps) - sur-

face imperfections - terms, definitions and parameters.

Standard ISO 8785:1998, ISO.

Lin, Y.-P. and Jung, T.-P. (2017). Improving EEG-

based emotion classification using conditional transfer

learning. Frontiers in Human Neuroscience, 11.

Margraf, A., Geinitz, S., Wedel, A., and Engstler, L.

(2017a). Detection of surface defects on carbon fiber

rovings using line sensors and image processing algo-

rithms. SAMPE 2017.

Margraf, A., Stein, A., Engstler, L., Geinitz, S., and H

¨

ahner,

J., editors (2017b). An Evolutionary Learning Ap-

proach to Self-configuring Image Pipelines in the

Context of Carbon Fiber Fault Detection: 2017 16th

IEEE International Conference on Machine Learning

and Applications (ICMLA).

Mertes, S., Margraf, A., Geinitz, S., and Andr

´

e, E. (2022).

Alternative data augmentation for industrial monitor-

ing using adversarial learning.

M

¨

uller-Schloer, C. and Tomforde, S. (2017). Organic Com-

puting: Technical Systems for Survival in the Real

World. Autonomic Systems. Birkh

¨

auser, Cham, 1st

edition.

Neumaier, M., Kranemann, S., Kazmeier, B., and Rudolph,

S. (2022). Automated piping in an airbus a320 land-

ing gear bay using graph-based design languages.

Aerospace, 9(3):140.

Sauer, M., Feil, J., Manis, F., Betz, T., and Drechsler,

K. (2019). Thermoplastic multi-material nonwovens

from recycled carbon fibres using wet-laying technol-

ogy. In 22nd Symposium on Composites, volume 809

of Key Engineering Materials, pages 210–216. Trans

Tech Publications Ltd.

Schmeck, H., M

¨

uller-Schloer, C., C¸ akar, E., Mnif, M., and

Richter, U. (2010). Adaptivity and self-organization

in organic computing systems. ACM Transactions on

Autonomous and Adaptive Systems, 5(3):1–32.

Schmidhuber, J. (2015). Deep learning in neural networks:

An overview. Neural Networks, 61:85–117.

Schmitt, J. (2017). Total engineering automation.

https://www.iils.de/downloads/IILS-WhitePaper-

TotalEngineeringAutomation.pdf, accessed 10-08-

2022.

Shannon, C. E. (1948). A mathematical theory of communi-

cation. Bell System Technical Journal, 27(3):379–423.

Smith, W. (2000). Modern Optical Engineering: The De-

sign of Optical Systems. Optical and electro-optical

engineering series. McGraw Hill.

Stein, A., Margraf, A., Moroskow, J., Geinitz, S., and

H

¨

ahner, J. (2018). Toward an Organic Computing Ap-

proach to Automated Design of Processing Pipelines.

ARCS Workshop 2018; 31th International Conference

on Architecture of Computing Systems. VDE.

Strauß, S. and Wilhelm, F. (2020). Development of a flex-

ible injection and impregnation chamber for pultru-

sion of high reactive resins. Procedia Manufacturing,

47:956–961.

Tan, C., Sun, F., Kong, T., Zhang, W., Yang, C., and Liu,

C. (2018). A survey on deep transfer learning. In Ar-

tificial Neural Networks and Machine Learning ICAN

2018, pages 270–279. Springer International Publish-

ing.

VDI/VDE (2015). Machine vision - guideline for the prepa-

ration of a requirement specification and a system

specification. Standard VDI/VDE 2632 Part 2:2015-

10, VDI/VDE/VDMA, Berlin, DE.

Walter, B., Martin, J., Schmidt, J., Dettki, H., and Rudolph,

S. (2019). Executable state machines derived from

structured textual requirements - connecting require-

ments and formal system design. In Proceedings of the

7th International Conference on Model-Driven Engi-

neering and Software Development. SCITEPRESS -

Science and Technology Publications.

Model-Driven Optimisation of Monitoring System Configurations for Batch Production

183