Generation and Characterization of Fork Gratings in Fused Silica

Sebastian Buettner, Erik Thieme and Steffen Weissmantel

Laserinstitute Hochschule Mittweida, Technikumplatz 17, Mittweida, Germany

Keywords: Fork Grating, Orbital Angular Momentum, Fluorine Laser, Fused Silica, Calcium Fluorine Mask,

Micro Structuring, Micro Machining, Direct Laser Fabrication.

Abstract: Fluorine laser micro structuring enables the generation of fork gratings in fused silica. These micro-optical

elements can be used to influence the orbital angular momentum of light. This property of light has been

researched for more than 30 years and is becoming increasingly interesting for various applications. One of

them is optical data communication, where this can be used to increase the transmission capacity of optical

fibers. Now we have been able to demonstrate a simple fabrication method based on the fluorine laser micro

structuring technique, which allows us to generate different types of gratings. The results of our investigations

as well as those of the geometrical and optical characterization are presented.

1 INTRODUCTION

Electromagnetic (EM) fields are well understood

since Maxwell. The wavelength, polarization,

amplitude and phase are the common properties to

describe these fields. Each of mentioned can be

influenced and modulated by optical elements or

devices according to the requirements of the technical

application. In particular, the optical data

communication is based on the (de-)modulation of

these properties. This allows a simultaneous

transmission of optical signals. In the field of optical

data communication different, so called, multiplexing

methods were developed to increase the data rate. The

multiplexing methods, which, based on the

wavelength or polarization, cannot be developed

further due to the limited capacity of optical channels.

These limitations are caused by nonlinear effects, due

to the high intensities within the fibers (Richardson,

2010). One solution for this problem could be using

the orbital angular momentum (OAM) of EM fields

for multiplexing purposes (Xie et al., 2018 and

Bozinivic et al., 2013). However, the OAM is an

interesting property which also can be used for other

technical applications like optical tweezers. This

allows the rotation of microscopic particles by laser

light (Yao et al., 2011). Moreover, quantum optical

methods allow the entanglement of OAM states of

photons. This enables the development of new

techniques in the field of quantum optics (Mair et al.,

2001, Fickler et al. 2012 and Fickler et al., 2018). In

the last years several methods for micro-optics

fabrication were developed too, which allows the

miniaturisation and integration of micro-optics. First

and foremost, photolithography is a process for

creating highly precise microstructures. But the

process is expensive and time-consuming. Our

investigations show that we can fabricate irregular

micro-structures such as fork gratings in a much

easier way. For this we developed a fluorine laser

micro structuring method, which allows us to

generate individual grating geometries within a few

milliseconds. Moreover, we could show that these

gratings already can be used for OAM manipulation.

Accordingly, our process is verry suitable for an

efficient and flexible integration of these kinds of

optical elements and potentially for the development

of new communication hardware.

2 FUNDAMENTALS

In 1992 Les Allen and colleagues (Allen et al., 1992)

could show that electromagnetic fields include

angular momentum.

𝐽

⃗

=𝜖

𝑟

⃗

×(𝐸

⃗

×𝐵

⃗

)𝑑𝑟

(1)

Moreover, it is shown that the total angular

momentum is composed by the spin angular

momentum 𝑠⃗ and the orbital angular momentum 𝑙

⃗

.

The spin angular momentum (SAM) is associated

40

Buettner, S., Thieme, E. and Weissmantel, S.

Generation and Characterization of Fork Gratings in Fused Silica.

DOI: 10.5220/0011685500003408

In Proceedings of the 11th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2023), pages 40-45

ISBN: 978-989-758-632-3; ISSN: 2184-4364

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

with a circular polarization, whereas the orbital

angular momentum is resulting from a spatial

distribution.

𝐽

⃗

=

𝜖

2𝑖𝜔

𝐸

∗

(𝑟

⃗

×∇)

,,

𝐸

𝑑

𝑟

⃗

+

𝜖

2𝑖𝜔

𝐸

∗

×𝐸 𝑑

𝑟

⃗

(2)

More precisely, the orbital angular momentum

results from a helical phase shift, which, for example,

can be observed in Gaussian-Laguerre laser modes.

However, such a phase can also be induced by a phase

element that modulates an even EM field with an

amplitude 𝑢

(

𝑟,𝜑,𝑧

)

.

𝑢

(

𝑟,𝜑,𝑧

)

=𝑢

(

𝑟,𝑧

)

∙𝑒

∙𝑒

(3)

The expression 𝑒

describes an azimuthal

dependency of the phase, where 𝜑 is the azimuthal

angel and 𝑙 the topological charge (TC) (Allen et al.

2009 and 2011). There are several methods to induce

or influence the OAM of an EM field. As mentioned,

the Gaussian-Laguerre laser modes have an intrinsic

OAM which can be changed e.g., by a cylindrical

lens. Furthermore, it is possible to convert SAM to

OAM by anisotropic materials (Marrucci et al., 2006)

and q-plates (Karimi et al., 2009).

Back to the phase modulation, OAM can be

induced by optical elements like spiral phase plates

(SPP) or fork gratings (FG). These elements changing

the phase of an EM wave with an azimuthal

dependency. The phase shift results from an

azimuthal change of the optical thickness within a

transparent material. Due to the fabrication process

SPPs resemble a spiral staircase and can be generated

by changing the optical thickness of a substrate step

by step. In the case of SPPs, the TC defines the

number of 2π phase jumps within the structure, which

also represents the gear number of a helical

modulated wave front. The sign of 𝑙 gives the sense

of rotation of the phase, which is also called

handedness. Depending on the transition direction of

the optical elements, the handedness of the modulated

EM field is ether the same or inverted to the one of

the structures. Other than SPPs, FGs are a

superimposition of a helical phase and a grating

phase. Therefore, the helical phase is hidden within

the grating structure and can be recognized by the

ending grating bars and grooves within the structure.

The higher the TC, the more grating bars and grooves

ending within the structure.

FGs work slightly different relating to the OAM

modulation. In general, optical gratings bend the light

in one or more diffraction orders. Therefore, FGs

modulate and bend the light simultaneous and in a

different way for each diffraction order. The higher

the diffraction order, the higher is the OAM of these

order. Diffraction orders with an opposite sign also

show a different handedness, which is a result of the

law of conservation of momentum. For the generation

and examination of FGs, in addition to understanding

the function of the optical elements, their calculation

is necessary. The calculation of those gratings was

done using the numerical calculation software

Matlab

®

. Moreover, we basically follow the solution

of Galvez (Galvez E., 2016) to calculate the FG

layouts. The source code for calculation is given in

Table 1. In Figure 1 a) the calculated continuous

phase distribution of an FG with a TC of 1 is shown.

The developed fabrication process requires the

generation of a projection masks. For this, the phase

distribution must be converted into a binary, which is

done by a rounding operation (see Figure 1 b)). From

this, we can extract the grating geometry for the mask

generation.

Table 1: MATLAB

®

-Source for calculation of FGs.

N=500; l=1; n=10;

x=linspace(-N/2,N/2,N);

[X,Y]=meshgrid(x,x);

[phi,R]=cart2pol(X,Y);

bl=linspace(0,n*2*pi,N).*ones(N,N)

phase=round(mod(phi*l+bl,2*pi)/(2*pi));

Figure 1: Calculated phase distribution of a blazed fork

grating a) and its binary representation b).

Moreover, the knowledge of the micro structuring

depth is necessary for the FG generation. For a 2π

phase shift, the depth depends on the design

wavelength 𝜆 and the refractive indices of the

substrate 𝑛

and the continuum 𝑛

. It can be

calculated using equation 4.

ℎ=

𝜆

𝑛

−𝑛

(4)

For our investigations we used the fused silica

corning 7980. The refractive index of the material

a)

b

)

Generation and Characterization of Fork Gratings in Fused Silica

41

( 𝑛

= 1.4607 ) was calculated by the Sellmeier

equation for a wavelength of 𝜆= 532 𝑛𝑚. This leads

to a depth of ℎ = 1.1547 µ𝑚. It should be noted that,

unlike blaze gratings, binary gratings are ineffective

at a phase shift of 2𝜋. Therefore, the optimum phase

shift for binary FGs is at 𝜋, which corresponds to a

structure depth of ℎ = 0.577µ𝑚.

3 EXPERIMENTAL SETUP

The fluorine laser is very suitable for processing

fused silica and other wide band gap materials, due to

the short wavelength of 157 nm (7.9 eV). Moreover,

the used mask projection technique allows the

fabrication of different optical elements. The laser

machine and the appropriate processes are explained

detailed in earlier publications (Pfeifer M. et al. 2013,

2014, 2017 and Büttner S. et al. 2019, 2020).

Moreover, it is shown that this technology is very

flexible. By using different masks and micro

structuring methods a whole variety of micro-optical

elements can be fabricated. Recapped, there are three

options for processing material using the mask

projection technique: The movement of a mask within

the laser beam and static work piece, the movement

of the work piece and a static mask and an all-static

setup. Due to the laser source (Lambda Physics

LPF220i), the material is removed pulse by pulse.

The fabrication process depends on the target

microstructure, as well as the mask geometry, which

must be adapted too.

The process we developed consists of three steps,

the calculation of the grating geometry, the

generation of the mask by fluorine laser micro

structuring and the generation of the gratings. As

mask material we use calcium fluoride (CaF

2

) which

is transparent for the wavelength of the fluorine laser.

The treatment of the polished CaF

2

substrate surface

increases the roughness. Due to this, the transmitted

radiation is scattered in this area and the energy

density is reduced in the corresponding areas within

the image of the mask. As result, the mask geometry

is transferred into the workpiece. Based on the

calculation, the grating patterns were converted into a

machine program, which allows the fabrication of the

masks itself by fluorine laser micro structuring.

The generated pattern can be scaled up to the

required grating size. This should be done in

consideration of the feature size and the optical

resolution of the imaging system of the laser machine.

The up and down scaling is useful for adjusting the

optical properties of the grating. To show the

possibilities of this technique we calculated and

generated five different masks in an CaF

2

substrate

(see Figure 2). This technique currently allows the

generation of binary structures only, but contrary to

using tantalum masks, the layout of the masks in CaF

2

can be individual without compromising of the

mechanical stability of the mask.

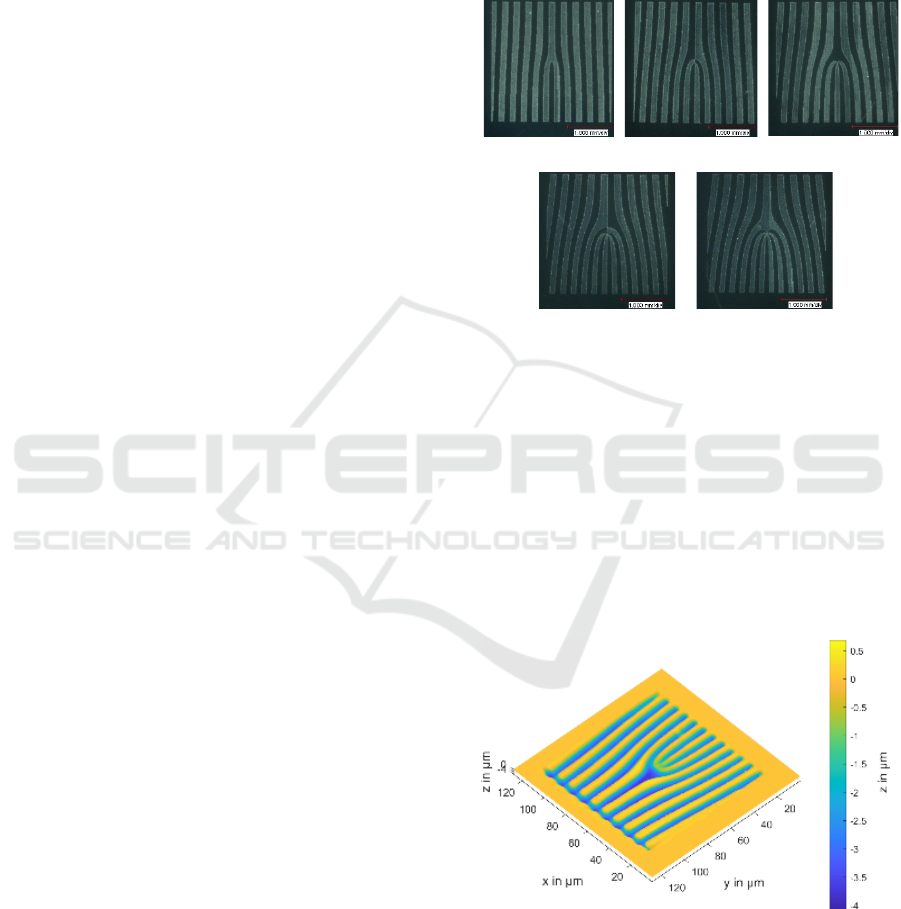

Figure 2: Calcium fluoride masks for the fabrication for

fork gratings with a TC of 𝑙 = 1,2,3,4,5 {a), b), c), d), e)}.

4 RESULTS

As mentioned above, we used a static mask design for

grating generation. In addition to the CaF

2

grating

masks, a 100 x 100 µm² square tantalum mask was

used to expose only the corresponding patterned areas

of the grating masks to laser radiation. A Slight

misalignment of the tantalum and the grating mask

leads to structuring errors, as can be seen in Figure 3.

Figure 3: Confocal image of an FG in fused silica Corning

7980.

By using a larger tantalum mask the area

surrounding the grating can be lowered such as the

grating is exposed. Contrary to expectations, the

analysis of the produced structures shows that the

a)

b

)

c)

d)

e

)

PHOTOPTICS 2023 - 11th International Conference on Photonics, Optics and Laser Technology

42

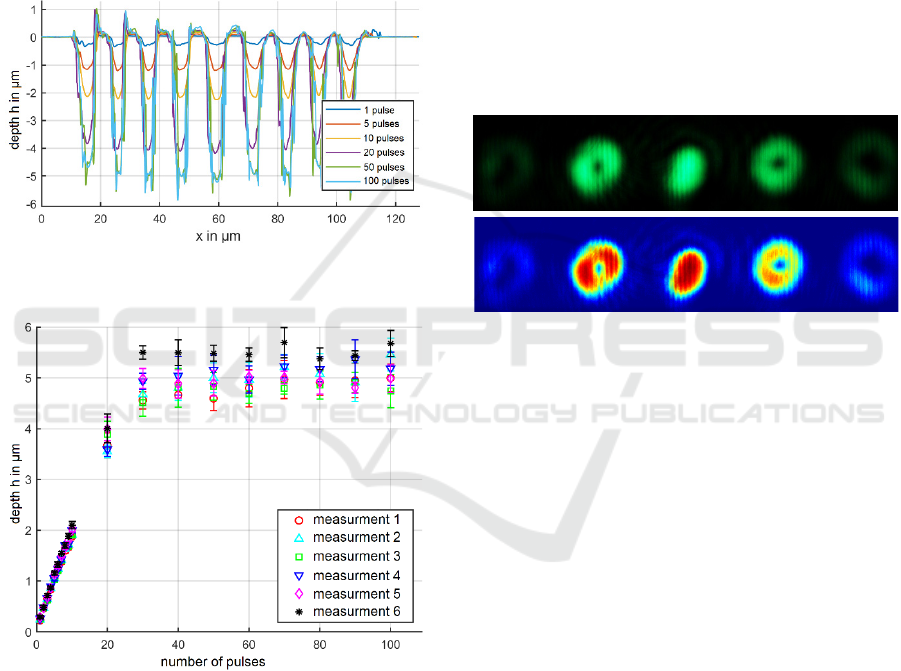

lattice is not binary at all (see Figure 4). The shape of

the grating profile section becomes more sinusoidal

with increasing number of laser pulses. The grating

bars were also influenced by the laser radiation.

Therefore, the function of the CaF

2

masks differs

from that of the tantalum masks. As can be seen in

Figure 5, up to 20 pulses, the depth of the

microstructure depends linearly on the number of

laser pulses. A further increase of the number of

pulses does not increase the depth of the grooves.

Therefore, the total depth of the micro structuring is

limited.

Figure 4: Profile section of the FGs fabricated with different

numbers of laser pulses.

Figure 5: Micro structuring depth depending on the number

of laser pulses for different locations within one FG.

For each grating type, this linear dependence was

observed up to 20 laser pulses. The maximum depth,

on the other hand, depends on the laser pulse fluence

and the corresponding ablation depth per pulse. In

general, the laser power, the efficiency of the imaging

system and the optical parameters of the mask

material are the main limiting factors. According to

this, a maximum structure depth of 5 µm was reached

on average. The period of the grating was set to

20 µm, which results in a feature size of around

10 µm. Therefore, the aspect ratio is limited to a

maximum of 2:1. Moreover, the increase of the

number of pulses, the grating bars getting higher than

the initial surface by the ablation process. This can be

explained by the redeposition of material in the areas

not having been exposed to radiation. It is currently

unclear what the fine structure and optical properties

of the redeposited material are, but the influence of

the geometry deviations on the function should be

significantly stronger. Furthermore, we observed the

diffraction image of the gratings, using a microscope

and an appropriate laser source for the backside

illumination of the optical elements. One diffraction

image is shown in Figure 6 a). To see differences in

the intensity more clearly, we calculated a colored

representation b) of the image.

Figure 6: Microscopic diffraction image a) and colored

representation b) of the diffraction image of an FG {𝑙=1,

ℎ =0.540 µ𝑚}.

The FG work as expected. Due to the shape of the

grating the intensity is mainly diffracted to the 0

th

and

the ± 1

st

diffraction orders. The 0

th

order does not

show any OAM modulation contrary to the higher

orders. The modulated diffraction orders show the

typical circular shaped intensity distribution of beams

with OAM. Moreover, the radius of the distributions

increases with the number of the diffraction order due

to the increase of the OAM. As can be seen, the radius

of 2

nd

diffraction orders is larger than the one of the

1

st

. The ± 2

nd

diffraction orders are also visible, but

the intensity is significantly lower as can be seen.

Moreover, the comparison of the + 1

st

and - 1

st

diffraction orders show a slight difference in the

intensity distribution. This can be explained by the

slightly asymmetric shaped slopes of the grating bars

(see Fig 7). Furthermore, the grating grooves are not

even, which resulted from a misalignment of the

workpiece related to the imaging plane of the optical

system. This can be easily corrected but it may also

be used to generate defined grating slopes.

Finally, controlling the slope angel opens the

opportunity to fabricate blazed gratings using this

technique and motivates further investigations.

a)

b

)

Generation and Characterization of Fork Gratings in Fused Silica

43

Figure 7: Profile sections of the FGs { 𝑙=1}

fabricated with different numbers of laser pulses.

5 CONCLUSIONS AND

OUTLOOK

For the fabrication of FG’s, a new method was

developed. The process is based on the fluorine laser

micro structuring and uses the mask projection

technique. The first step is the calculation of the

grating pattern and generation of a machine program

thereof. Following, the grating layout is transferred

into a VUV grade CaF

2

substrate using fluorine laser

micro structuring. The VUV grade CaF

2

is

transparent for 157 nm radiation, but in the laser

treated areas the roughness and therefore the

scattering of the radiation is increased. Due to this,

the substrate can be used as amplitude mask itself and

an individual geometry can be transferred into a fused

silica substrate. This was done using different

numbers of laser pulses. We could show that the

structure depth depends linear on the number of

pulses until 20 laser pulses. For more than 20 pulses

the depth of the structures does not increase further.

Moreover, the structure depth is limited and a

maximum aspect ratio of 2:1 can be reached. This

represents a limit in feature size range regarding to

the target modulation depth. Furthermore, it could be

shown that the FG work as expected. The diffraction

image shows diffraction orders up to the ± 2

nd

order.

The asymmetric distribution of intensity is a result

from the asymmetric slopes of the grating bars. The

reason for this is a slightly misalignment between

image plain and surface of the work piece, which

easily can be corrected. But potentially this could also

be used to generate blazed FG. In general, we could

show that the generation of FG’s work well and the

optical function satisfy our expectations. To improve

this, the generation of blazed FG is the next goal of

our investigations. An easy and flexible fabrication

method for blazed FG’s could push forward the OAM

multiplexing method due to new possibilities in

production of OAM multiplexing hardware.

REFERENCES

Richardson, D. J. (2010). Filling the Light Pipe. In: Science,

330 (6002), pp. 327-328.

Xie, Z.; Gao, S.; Lei, T.; Feng, S.; Zhang, Y.; Li, F.; Zhang,

J.; Li, Z.; Yuan, X. (2018). Integrated (de)multiplexer

for orbital angular momentum fiber communication. In:

Photonics Research, 6(7), pp. 743-749.

Bozinivic, N.; Yue, Y.; Ren, Y.; Tur, M.; Kristensen, P.;

Huang, H.; Willner, A.E.; Ramachandran, S. (2013).

Terrabit-Scale Orbital Angular Momentum Mode

Division Multiplexing in Fibers. In: Science,

340(6140), pp. 1545-1548.

Yao, A.M.; Padgett, M.J. (2011). Orbital Angular

Momentum: origins, behaviour and applications. In:

Advances in Optics and Photonics, 3, pp. 161-204.

Mair A.; Vaziri, A.; Weihs, G.; Zeilinger, A. (2001).

Entanglement of the orbital angular momentum states

of photons. In: Nature, 412, pp. 313-316.

Fickler, R.; Lapkiewicz, R.; Plick, W. N.; Krenn, M.;

Schaeff, C.; Ramelow, S.; Zeilinger, A.

(2012). Quantum Entanglement of High Angular

Momenta. Science, 338(6107), 640–643. doi:10.1126/

science.1227193

Fickler, Robert; Krenn, Mario; Zeilinger, Anton

(2018). Mit Lichtschrauben ans Quantenlimit. Physik

in unserer Zeit, 49(1), –. doi:10.1002/piuz.201801494

Allen, L.; Beijersbergen, M.W.; Spreeuw, R.J.C.;

Woerdman, J.P. (1992). Orbital angular momentum of

light and the transformation of Laguerre-Gaussian laser

modes. In: Physical Review A, 45(11), pp. 8185-8189.

Allen, L.; Padget, M. (2011). The Orbital angular

momentum of light. In Twisted Photons, WILEY-VCH

Verlag GmbH, pp. 1-12, Weinheim.

Marrucci, L.; Manzo, C.; Paparo, D. (2006). Optical Spin-

to-Orbital Angular Momentum Conversion in

Inhomogeneous Anisotropic Media. Physical Review

Letters, 96(16), 163905 doi:10.1103/PhysRevLett.

96.163905

Karimi, Ebrahim; Piccirillo, Bruno; Nagali, Eleonora;

Marrucci, Lorenzo; Santamato, Enrico

(2009). Efficient generation and sorting of orbital

angular momentum eigenmodes of light by thermally

tuned q-plates. Applied Physics Letters, 94(23),

231124–. doi:10.1063/1.3154549

Pfeifer, M.; Weissmantel, S.; Reisse, G. 2013. Direct laser

fabrication of blaze gratings in fused silica. In: Applied

Physics A, 112(1), pp. 61-64.

Pfeifer, M.; Jahn, F.; Kratsch, A.; Steiger, B.; Weissmantel,

S. 2014. F2-Laser Microfabrication of Diffractive

Optical Elements. In: Proceedings of 2nd International

Conference on Photonics, Optics and Laser

Technology, pp. 91-96.

Pfeifer, M.; Büttner, S.; Zhang, R.; Serbay, M.;

Weißmantel, S. (2017). F2-Lasermikrostrukturierung

von Mikro-Fresnel-Linsen, In: Scientific Reports,

10. Mittweidaer Lasertagung, (2), pp. 127-130.

Büttner, S.; Pfeifer, M.; Weissmantel, S. (2019).

Manufacturing of Cylindrical Micro Lenses and Micro

PHOTOPTICS 2023 - 11th International Conference on Photonics, Optics and Laser Technology

44

Lens Arrays in Fused Silica and Borosilicate Glass

using F2-Laser Microstructuring. In: Proceedings of 7th

International Conference on Photonics, Optics and

Laser Technology, pp. 66-72.

Büttner, S.; Pfeifer, M.; Weissmantel, S. (2020).

Fabrication of Micro Spiral Phase Plates in Fused Silica

using F2-Laser Microstructuring. In: Proceedings of 8th

International Conference on Photonics, Optics and

Laser Technology, pp. 114-121.

Galvez, E.: Computer Program FORKED DIFFRACTION

PATTERN, Version 1.0 (2016), WWW Document:

(http://departments.colgate.edu/physics/gpl.htm).

Generation and Characterization of Fork Gratings in Fused Silica

45